Full-automatic knitting machine

A fully automatic, needle machine technology, used in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of poor automation and high price, and achieve the effect of small commutation impact and stable and reliable machine operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

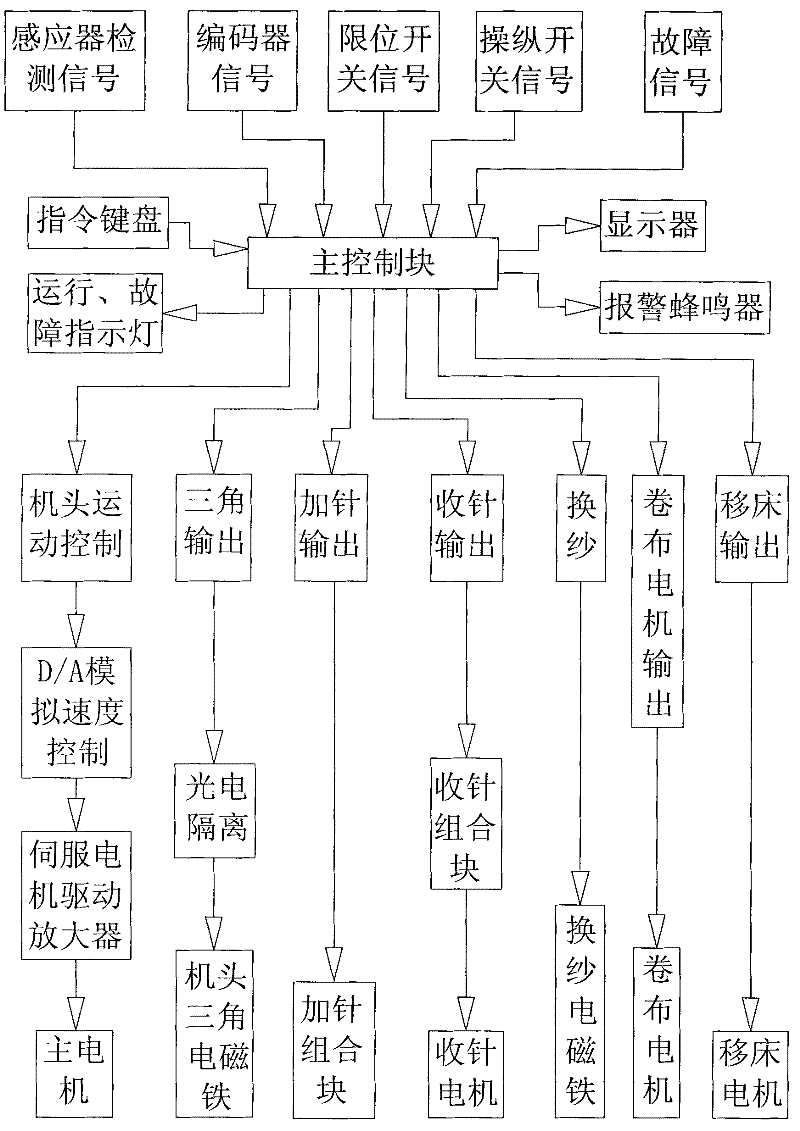

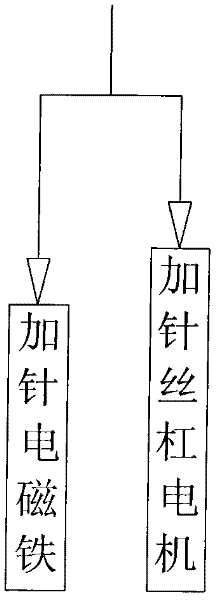

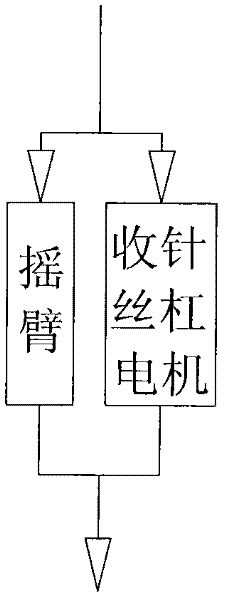

[0024] Such as Figure 1 to Figure 4 As shown, the embodiment of the present invention, the fully automatic retractable needle machine, includes a matching machine head, a main control processor and a man-machine interface part, and the machine head is equipped with a bed-moving motor, a main motor, and a triangular electromagnet of the machine head. , needle adding combination block, needle narrowing combination block, yarn changing electromagnet and cloth winding motor; the main control processor is externally connected with an output part and an input part; the main control processor has built-in driver software, and the driver software controls the output part and input part Separate operation with the man-machine interface part; the output part includes the bed moving output module, the head movement control module, the triangle output mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com