Special clamp for five-axis machining center of automobile steering knuckle structural part

A technology of five-axis machining centers and automobile steering knuckles, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of unsatisfactory processing quality, low processing efficiency, and complicated clamping, and achieve large market promotion The effect of high value, high processing and running precision, and uniform and stable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

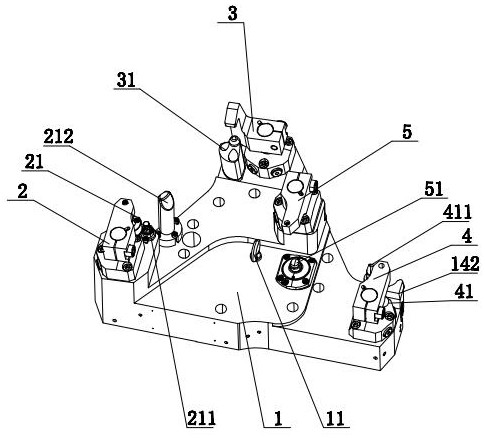

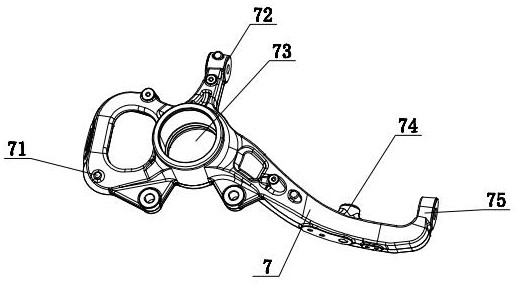

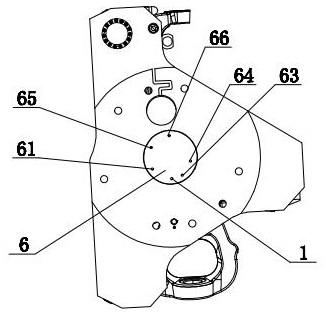

[0019] see Figure 1 to Figure 4 As shown, the technical solution adopted in this specific embodiment is: it includes a clamp body 1, a first telescopic fixed block 2, a second telescopic fixed block 3, a third telescopic fixed block 4, a fourth telescopic fixed block 5, an oil circuit control Disk 6, the fixture body 1 is in a triangular structure, the first telescopic fixing block 2 is fixed at the first corner of the fixture body 1 by fastening screws, and the second telescopic fixing block 2 is fixed at the second corner by fastening screws. The telescopic fixed block 3, the third telescopic fixed block 4 is fixed by fastening screws at the third corner, and the fourth telescopic fixed block 5 is arranged between the second telescopic fixed block 3 and the third telescopic fixed block 4. The fourth telescopic fixed block 5 is fixedly connected with the fixture body 1 through fastening screws, the bottom of the fixture body 1 is provided with an oil circuit control panel 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com