Pure water electromagnetic ball valve

A pure hydroelectric and magnetic ball technology, used in fluid pressure actuation devices, servo motor components, mechanical equipment, etc., can solve problems such as application limitations, impurity jamming, increase processing difficulty and processing cost, and achieve easy standardization, hydraulic pressure, etc. Effects of force balancing, shortening of commutation and reset times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

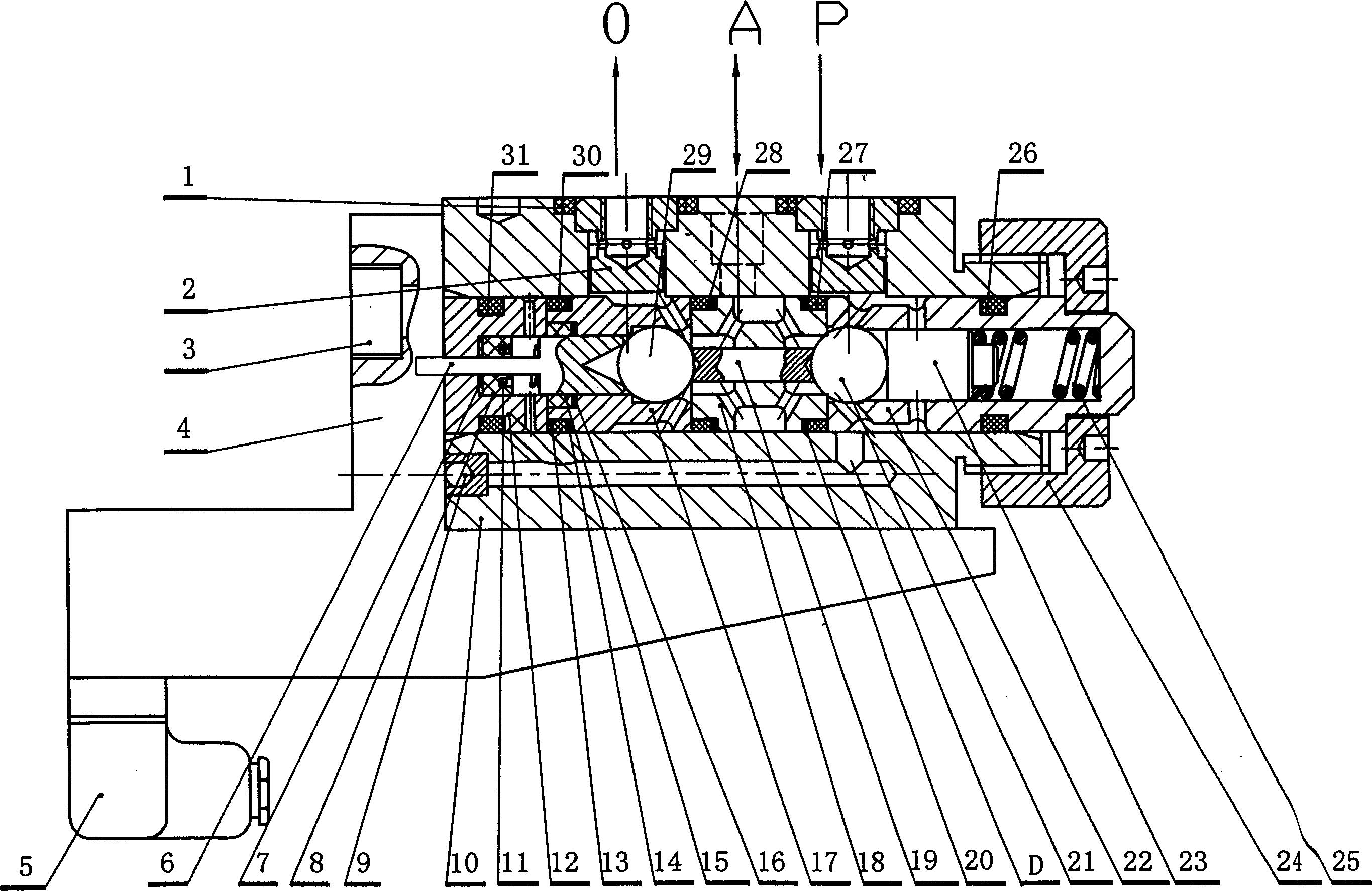

[0024] As shown in the accompanying drawings, the present invention includes:

[0025] In the valve body 10 holes, from right to left, there are spring valve sleeves 22 with two groups of holes in the radial direction, eight-hole valve sleeves 18 with two groups of holes in the radial direction, and six-hole valve sleeves with a group of holes in the radial direction. Sleeve 17, a two-hole valve sleeve 12 with a group of holes in the radial direction, a regulating valve sleeve cover 24 is arranged on the small cylindrical surface at the right end of the spring valve sleeve 22, and the valve sleeve cover 24 is pressed against 22 spring valve sleeves protruding from the valve body 10 On the shoulder, the force amplifying mechanism 4 equipped with the dry DC electromagnet 5 is pressed on the left end face of the push rod 6, and one end of the spring stopper 23 installed in the spring valve sleeve 22 is pushed against the return spring 25, and the other end of the spring stopper 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com