Self-compensation type floating three-jaw power chuck for cylindrical grinding machine

A cylindrical grinding machine, self-compensation technology, applied to grinding machines, machine tools designed for grinding the rotating surface of workpieces, grinding workpiece supports, etc. Small scope and other problems, to achieve the effect of saving production change time, facilitating production change adjustment, and avoiding production change errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

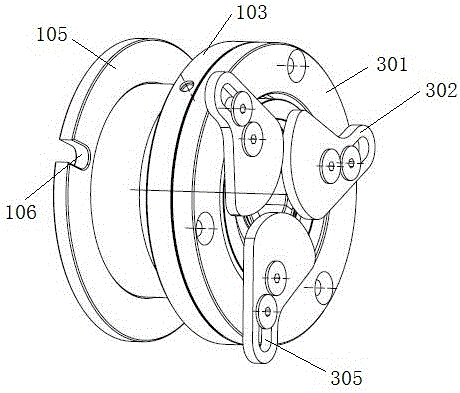

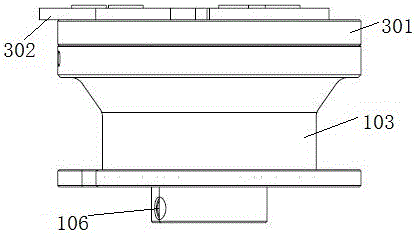

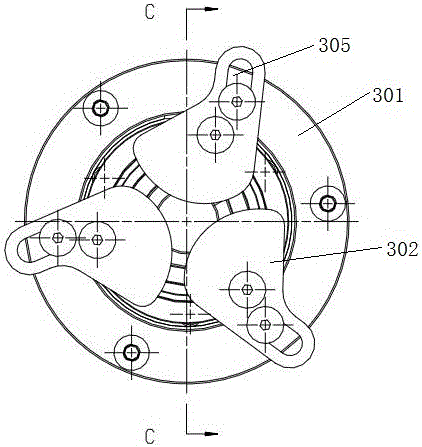

[0024] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

[0025] A self-compensating floating three-jaw power chuck for a cylindrical grinder, comprising:

[0026] The casing, the casing includes a central sleeve 102 axially provided with a central through hole 101 and an outer shell 103 sleeved outside the central sleeve 102, and an accommodation cavity is formed between the central sleeve 102 and the outer shell 103; the center The inner wall of the through hole 101 is provided with a threaded hole 104 for fixing the chuck on the tip. Set on the top of the grinding machine through the central through hole 101, the threaded hole 104 through the central through hole 101 is provided with a fixing bolt, the chuck is fixed on the top, and the axial relative position between the jaws of the chuc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com