Hot-press tooth-aligning clamp for toothed shaft part and gear

A technology for parts and gears, which is applied in the field of toothed shaft parts and gear hot-pressing clamps, can solve the problems of insufficient clamping force, inaccurate positioning, and complicated operation, so as to achieve convenient processing, improve general performance, and ensure accurate The effect of degree and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

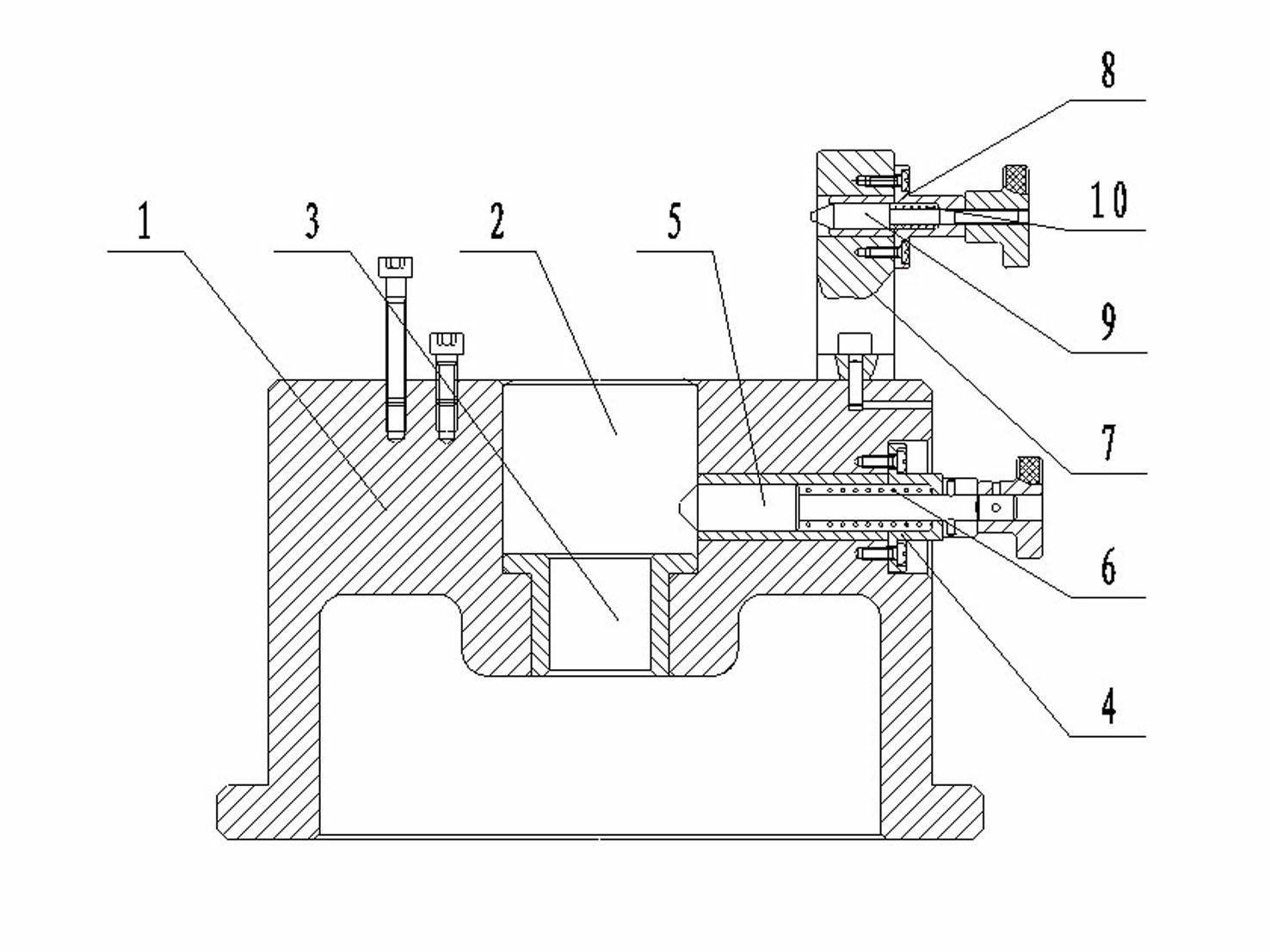

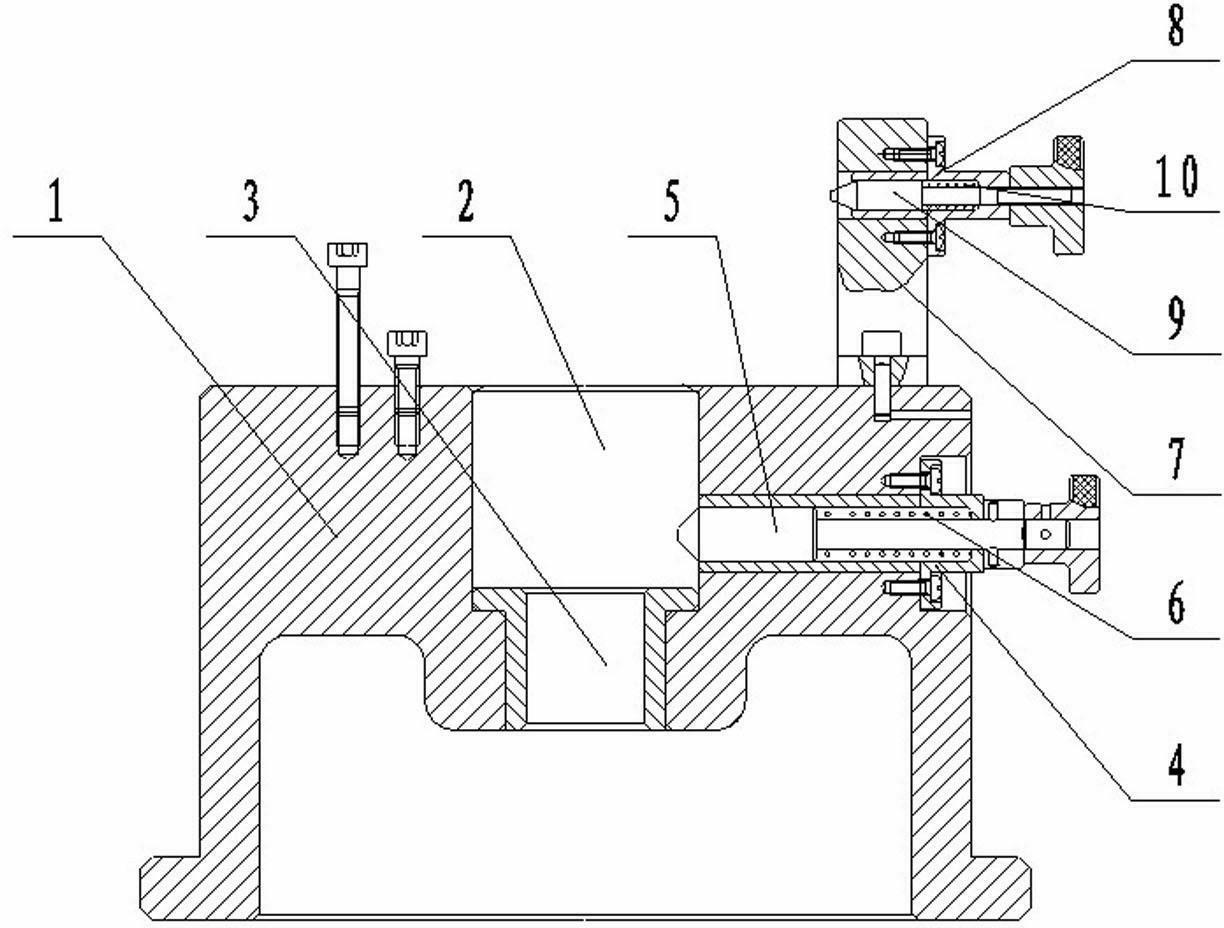

[0009] Toothed shaft parts and gear hot-pressed gear alignment fixture, including base 1, the center of the upper end of base 1 is provided with counterbore 2 downwards, the bottom of counterbore 2 is covered with positioning sleeve 3, and the side wall of base 1 is pierced with a guide sleeve fixed to it Ⅰ4, guide sleeve Ⅰ4 is pierced with stepped positioning pin Ⅰ5, the side of positioning pin I 5 with a larger diameter matches the inner wall of guide sleeve I4, and the side of positioning pin I 5 with a smaller diameter is covered with a spring placed in guide sleeve I4 I6; the upper end of the base 1 is fixed with a support plate 7, and the side wall of the support plate 7 is pierced with a guide sleeve Ⅱ8 fixed to it. The guide sleeve Ⅱ8 is located directly above the guide sleeve Ⅰ4, and the center line of the guide sleeve Ⅱ8 and the guide sleeve Ⅰ4 is in the upper and lower directions. The tolerance is less than or equal to 0.02mm. The guide sleeve Ⅱ8 is worn with a stepp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com