Flexible quick-changing locating device

A positioning device and a flexible technology, applied in the field of rapid replacement devices, can solve the problems of increasing the labor intensity of operators, affecting the production capacity of the production line, and long time for line change and adjustment, so as to reduce the storage space of tooling, practical positioning methods, and shorten the replacement time. The effect of line time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

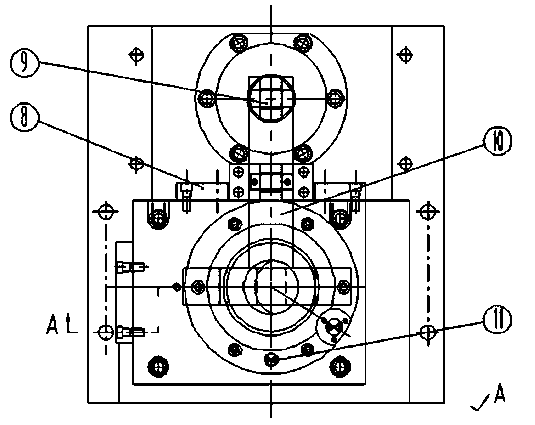

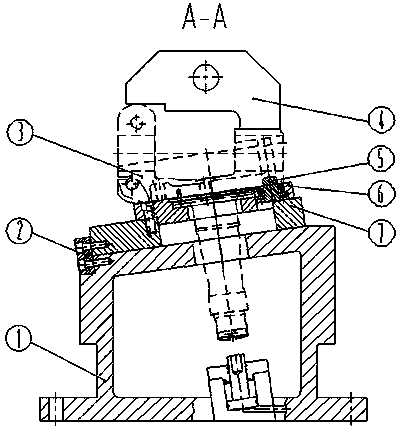

[0010] Such as figure 1 , figure 2 As shown, the bottom surface of the fixture body 1 is processed with a keyway, which is connected to the machine tool workbench through a key, and the fixture body 1 is fixed to the machine tool workbench with bolts. The fixture body 1 is equipped with a side positioning plate 2 and a front positioning plate 8 to realize the positioning of the angle plate 7 on the fixture body 1. The side positioning plate 2 and the front positioning plate 8 are respectively connected to the fixture body 1 and the angle plate 7 by bolts. The angle plate 7 is connected with the fixture body 1 through bolts, and is used for adjusting the positioning angle of the fixture. The positioning disk 6 realizes the positioning on the angle plate 7 through the first positioning pin 11 and the notch of the angle plate 7, and is fixed on the angle plate 7 by bolts. The workpiece 3 is positioned on the positioning disc 6 through the second positioning pin 5 and the notch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com