Expanding sleeve quick-change type general internal tooth inserting fixture

A quick-change, inserting internal gear technology, which is applied to gear teeth, gear cutting machines, manufacturing tools, etc., can solve the problems of inability to change and produce quickly, and cannot be used in common with different types of machine tools, so as to save time for production change and eliminate incompatibility , the effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail below in conjunction with accompanying drawing:

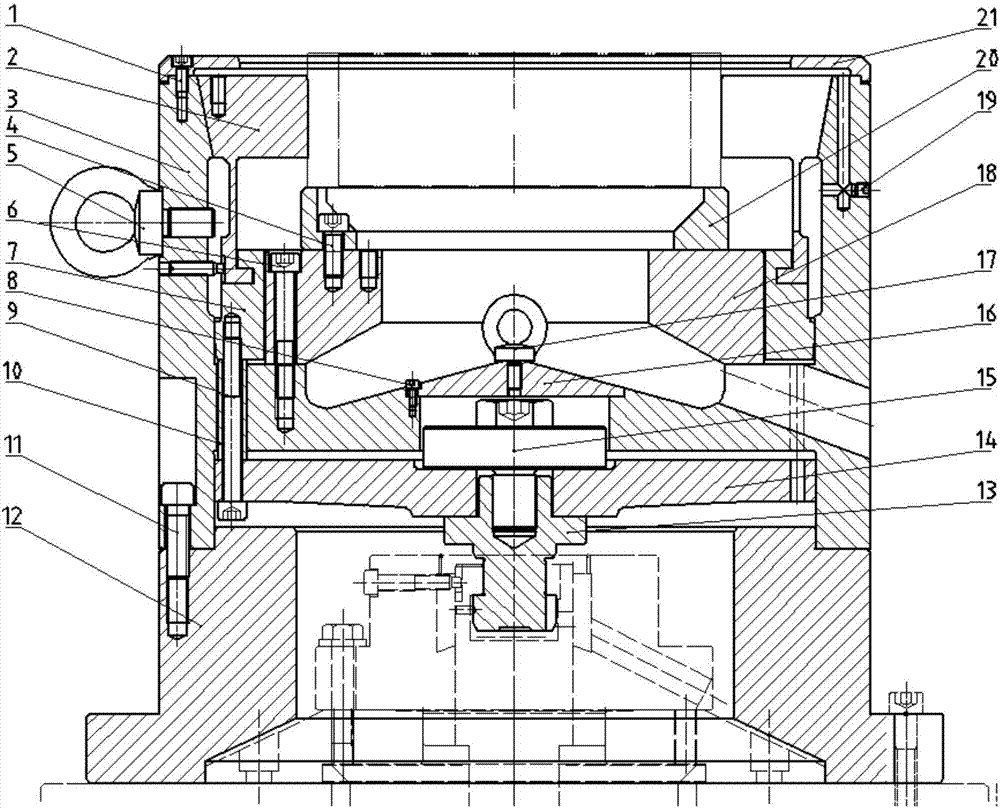

[0032] as follows figure 1 As shown, the present invention has designed a kind of new-style expanding sleeve quick-change type universal inserting internal gear fixture. The main functional parts of the clamp include expansion sleeve 2, clamp body 3, stretch sleeve 7, guide sleeve 10, adapter plate 12, transfer rod 13, pull plate 14, tension bolt 15, stop plate 16, support pad 18, fast Replace the flat pad 20 and cover plate 21. The adapter plate 12 is supported and fixed on the worktable; the inner hole at the lower end of the fixture body 3 is matched with the boss at the upper end of the adapter plate 12 and fixed; the inner cavity at the lower end of the fixture body 3 is provided with a pulling plate 14, and the inner hole on the outer edge of the pulling plate 14 The guide sleeve 10 passes through, and the upper end of the guide sleeve 10 passes through the clamp body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com