Tea leaf tidying machine based on spatial swaying mechanism

A technology of tea stripping machine and swing mechanism, which is applied in the field of mechanical equipment, can solve the problems affecting the working efficiency and service life of tea stripping machine, the vibration noise of tea stripping machine, and the resonant open welding of the frame, so as to reduce the failure of the machine The effect of high efficiency, compact structure and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

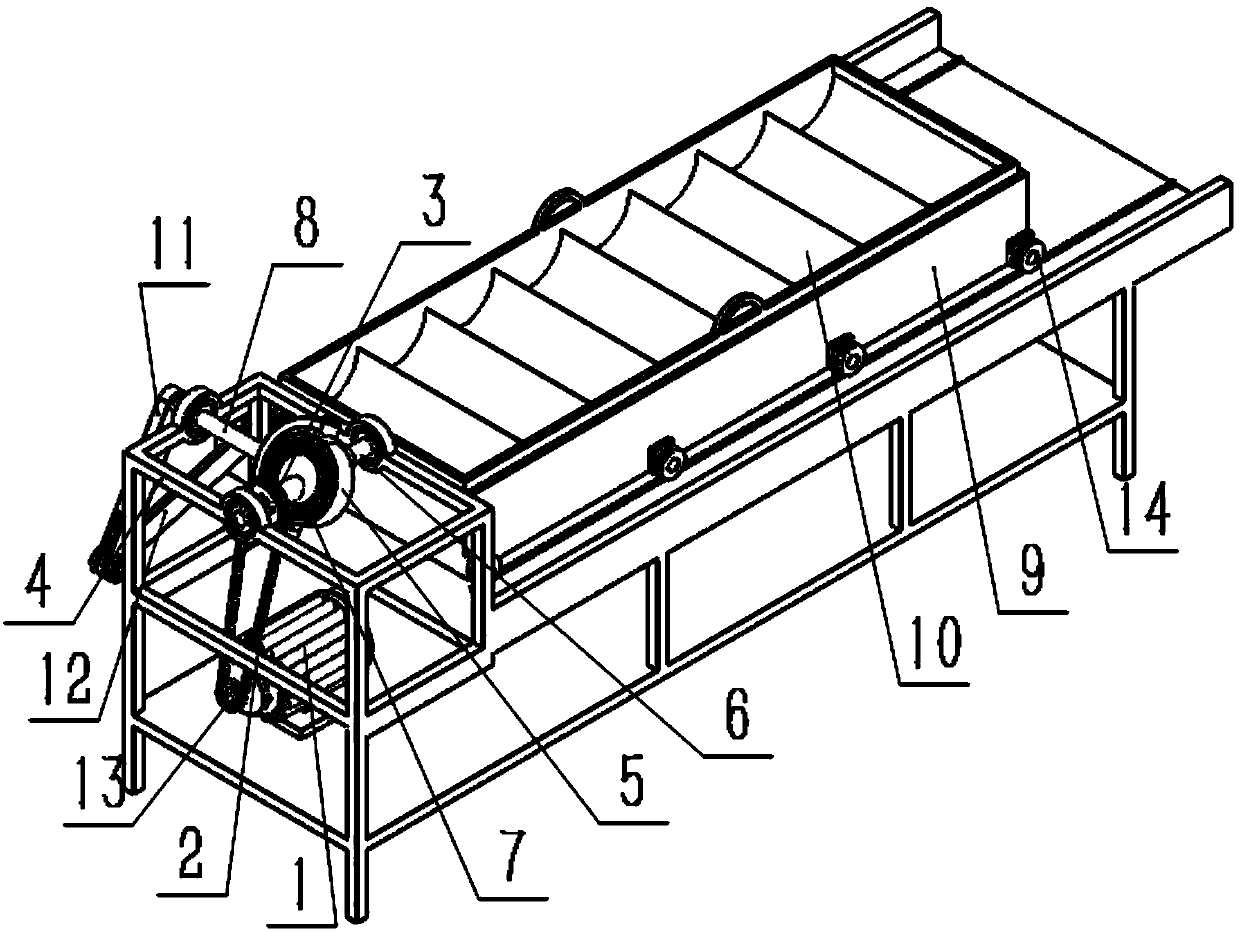

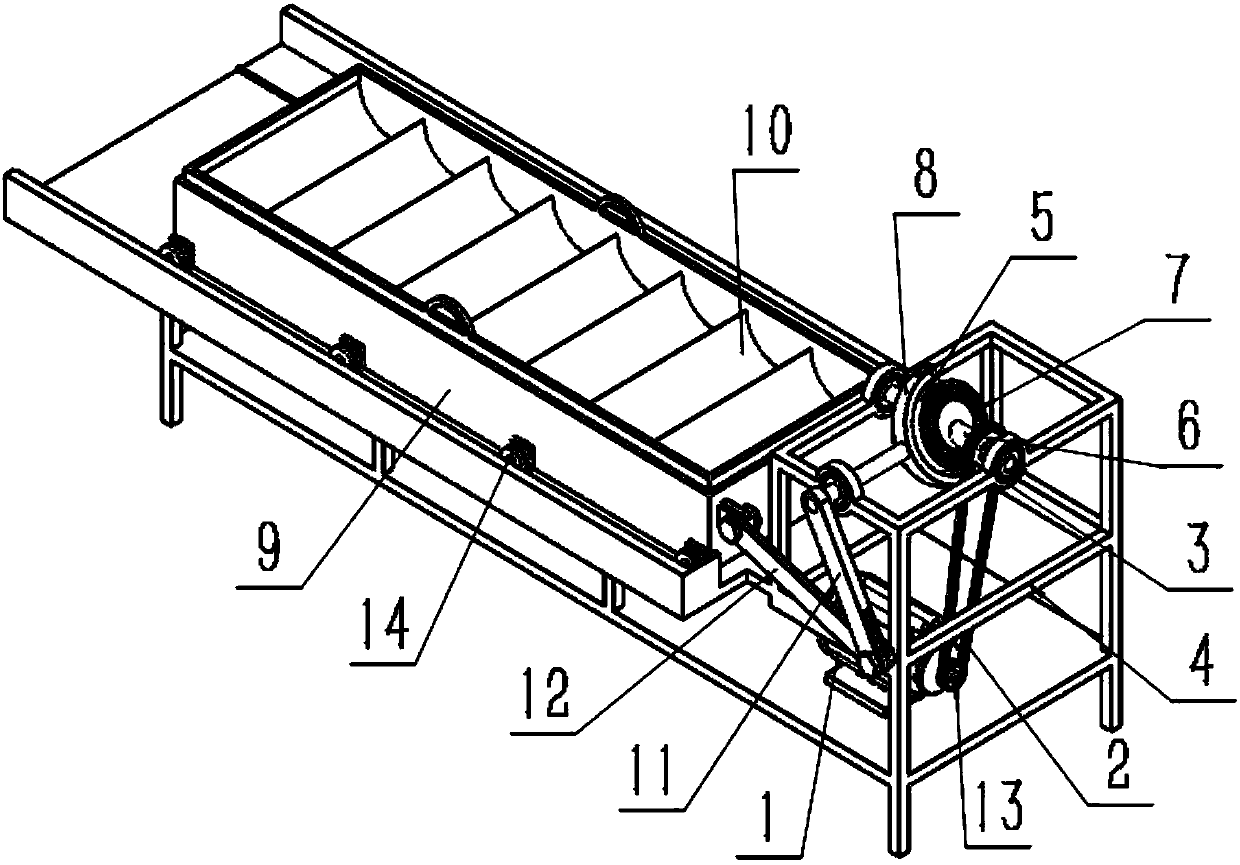

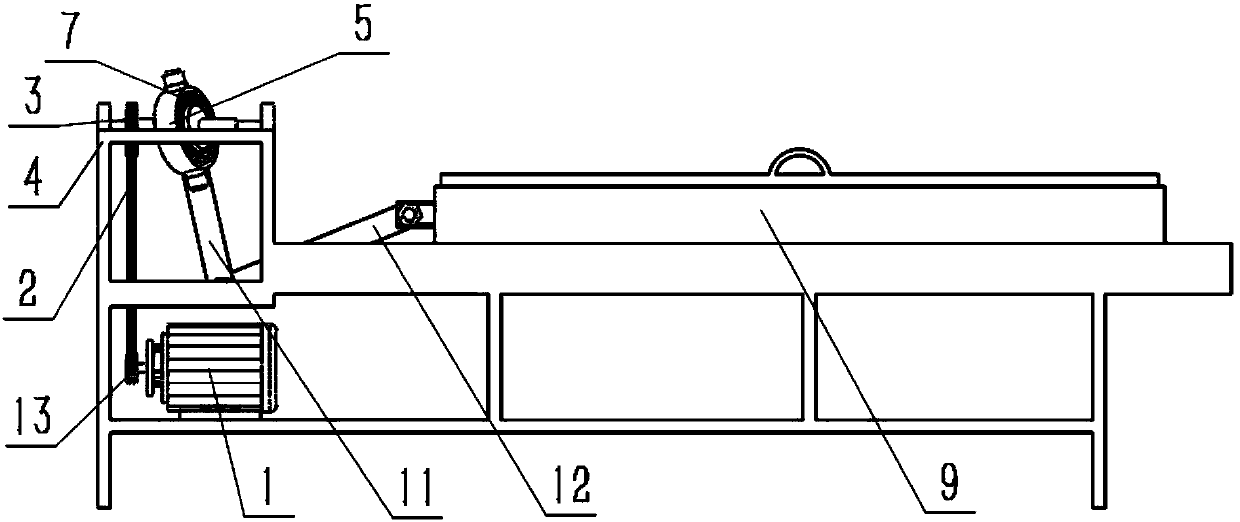

[0040] Below in conjunction with accompanying drawing, technical solution of the present invention is made more specific description:

[0041] like figure 1 , 2 , 3, 4, and 5: the present invention includes a frame 4, a space swing mechanism, a strip assembly and a drive mechanism;

[0042] The space swing mechanism includes a drive shaft 6 and a collar 5, the drive shaft 6 is provided with a collar journal 61, the axis of the drive shaft 6 intersects with the axis of the collar journal 61 and forms an included angle , the bushing ring 5 is installed on the bushing ring journal 61 through the bearing 7, the bushing ring 5 is connected with the driven rod 8, and the axes of the driven rod 8 and the driving shaft 6 intersect perpendicularly, The driving shaft 6 drives the driven rod 8 to reciprocate and rotate by itself through the bushing ring 5; the space swing mechanism also includes a connecting rod 12 arranged perpendicular to the driven rod 8 and a swing rod 11, one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com