A double-station vacuum packaging mechanism for continuous operation

A vacuum packaging and double-station technology, applied in the field of machinery, can solve problems such as general packaging speed, and achieve the effect of improving mechanism efficiency, improving efficiency, and improving size and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

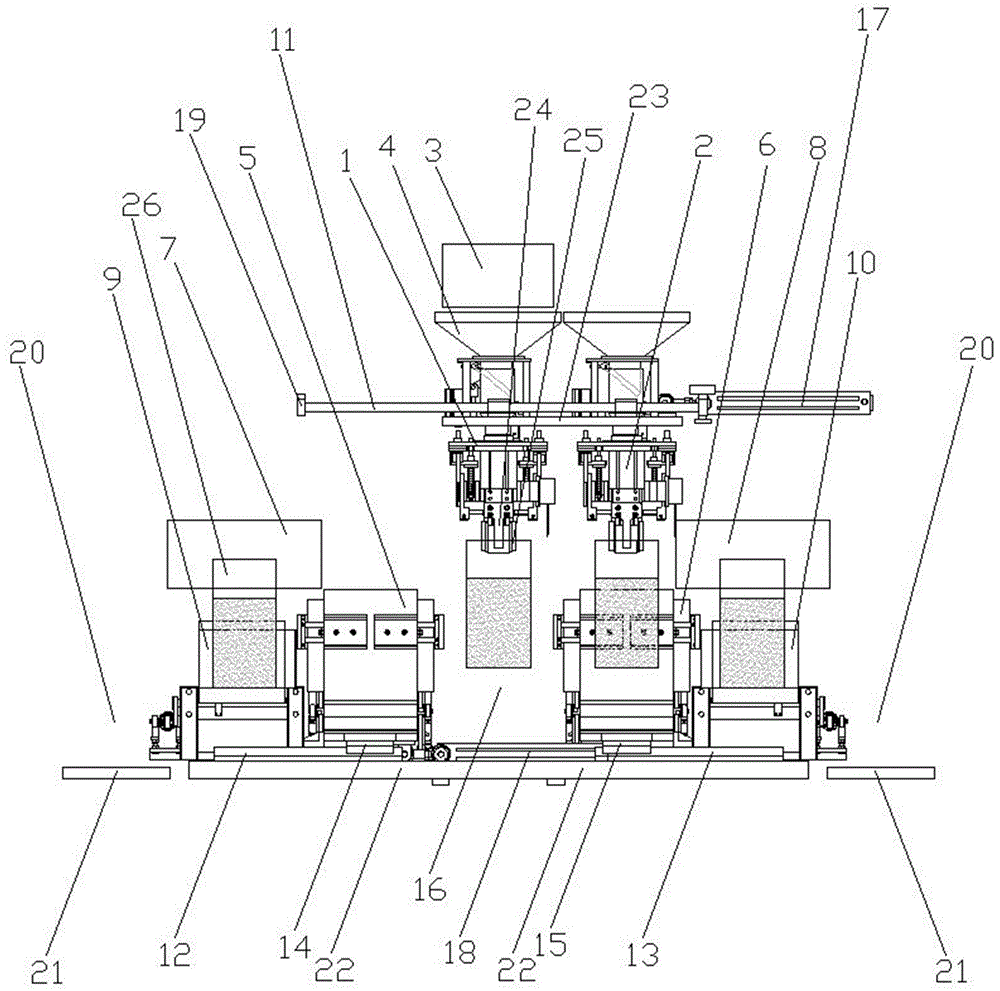

[0034] like figure 1 As shown, a double-station vacuum packaging mechanism for continuous operation is used for batch vacuum packaging of materials, which includes a frame, a filling assembly, a quantitative scale 3, the first and second shaping parts 5 and 6, the first and The second sealing components 7 and 8, the first and second discharge devices 9 and 10, the guide shaft 11, the guide rails 12 and 13, the packaging driving part, the filling driving part and the PLC industrial control.

[0035] The lower part of the frame is provided with an encapsulation driving part, the two sides are discharge positions 20, the upper part is provided with a filling driving part and a guide shaft 11 in the horizontal direction, a quantitative scale 3 is arranged above the middle part of the guide shaft 11, and the two ends of the guide shaft 11 are The first and second guide rails 12 and 13 are arranged below, and the first and second sliders 14 and 15 are correspondingly arranged on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com