Bucket-wheel speed reducer having buffering function

A technology of deceleration device and buffer force, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of low transmission efficiency, equipment overturning accident, large load, etc. Good effect with stiffness and self-lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

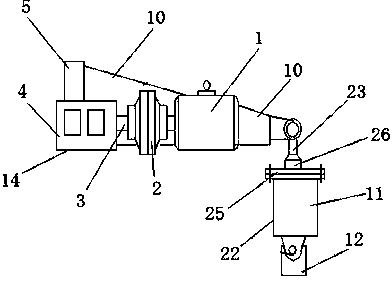

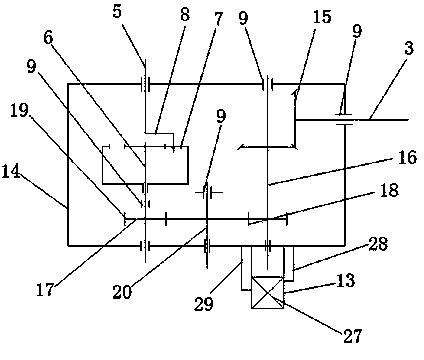

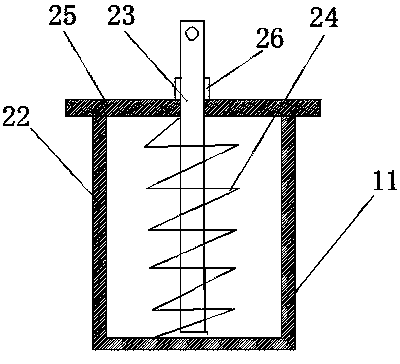

[0026] Do further description below in conjunction with accompanying drawing:

[0027] A bucket wheel reduction device with buffer force, comprising a motor 1, a coupler 2 connected to the motor 1, a transmission shaft 3 connected to the coupler 2, a reduction gear machine 4 connected to the transmission shaft 3, and a reduction gear The output shaft 5 that case 4 is connected, planetary transmission shaft one 6, the planetary gear 7 that is connected with planetary transmission shaft one 6, the planetary transmission shaft two 8 that is connected with planetary gear 7, transmission bearing seat 9. It uses welding or bolts to connect one end of the wedge-shaped or trapezoidal buffer plate 10 on the reduction gear machine 4, and the other end of the wedge-shaped or trapezoidal buffer plate 10 is connected with the buffer 11 through a pin; the lower end of the buffer 11 is connected with a A base 12; an oil feeder 13 is connected to the outside of the reduction gear machine 4; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com