Manufacturing method of submerged pipeline steel pipe

A submarine pipeline and manufacturing method technology, applied in the field of metallurgy, can solve problems such as uneven wall thickness, high price of seamless pipes, unchecked patent documents, etc., achieve the effect of refining grains and improving product performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

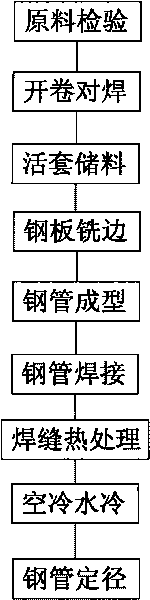

[0011] figure 1 Shown is the production process of the manufacturing method of the submarine pipeline steel pipe of the present invention:

[0012] 1. Raw material inspection. Inspection of hot-rolled steel coils to control the content of carbon, manganese and other alloying elements. The chemical composition weight percent of the hot-rolled steel coil is: C=0.04-0.08%; Si≤0.25%; Mn≤1.65%; P≤0.020%; S≤0.005%; Nb+V+Ti≤0.15%; Ce≤0.41%, the balance is Fe and unavoidable impurities.

[0013] Due to the work hardening phenomenon of ERW steel pipe during forming, the longitudinal yield strength increases, and the yield ratio increases. However, the Bauschinger effect occurs due to the need for flattening during the transverse tensile test of the steel pipe, resulting in a decrease in the transverse yield strength of the steel pipe. In order to avoid the increase of longitudinal strength exceeding the standard requirements and the transverse decrease exceeding the requirements, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com