A spliced air flotation vibration isolation platform and its installation method

A technology of vibration isolation platform and installation method, applied in machine/support, vibration suppression adjustment, spring/shock absorber, etc., can solve problems such as inability to meet actual needs, solve the problem of long optical path optical detection, overcome surface plane The effect of the bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

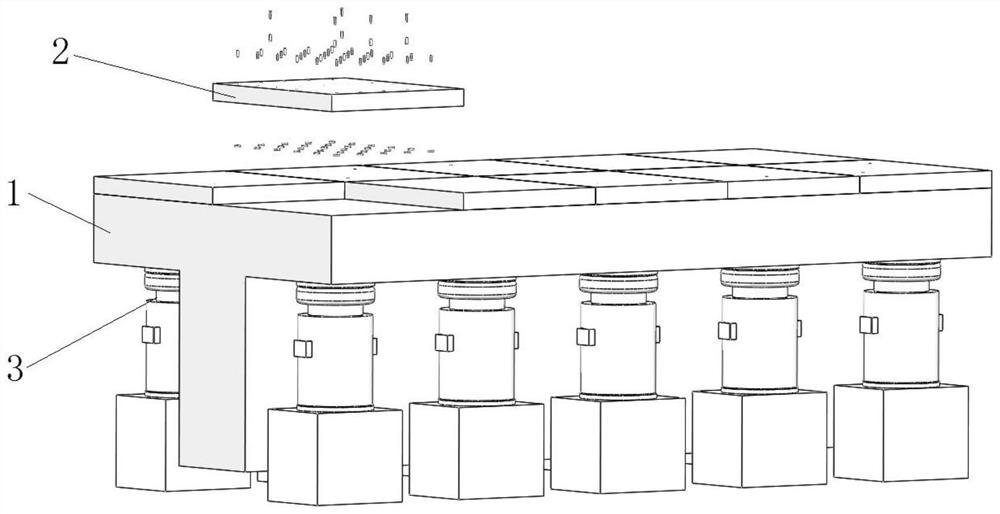

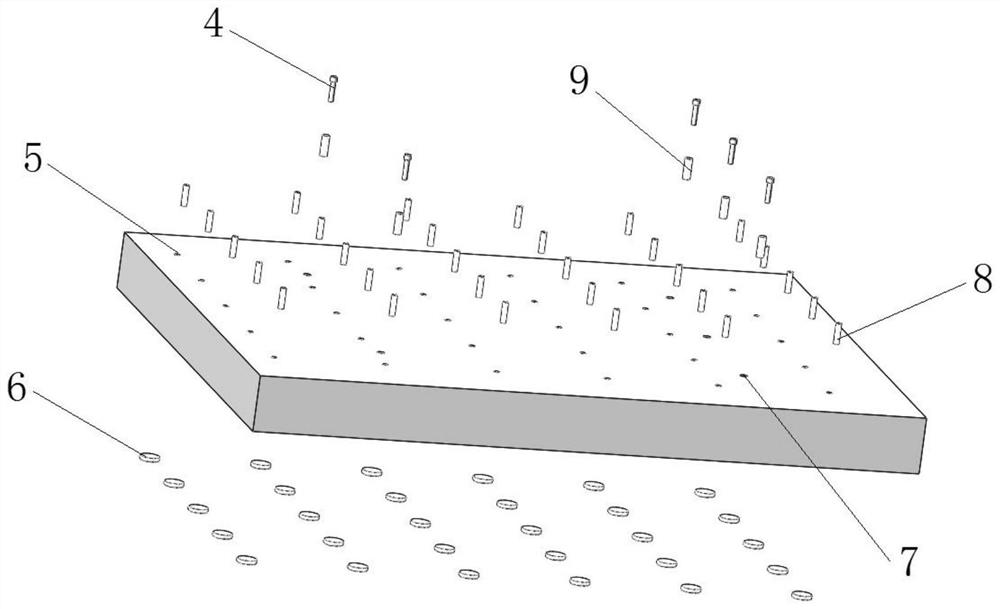

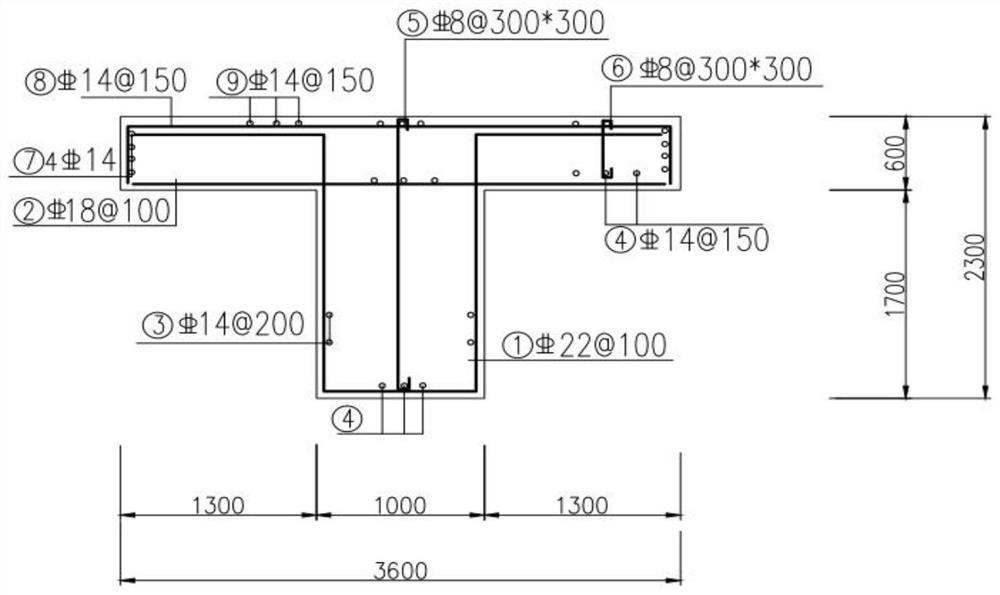

[0039] The spliced air bearing vibration isolation platform consists of a T-shaped platform body 1, a granite flat plate splicing unit 2, and an air spring 3. The cross-sectional dimensions of the T-shaped table body 1 are as follows: image 3 As shown, the length is 7m, the width is 3.6m, the height is 2.3m, and the height of the flange is 0.6m; the material of the T-shaped table body 1 is C40 concrete and HRB400 steel bar, and the specific reinforcement is detailed in image 3 . The vibration isolation platform table is composed of 10 granite slab splicing units 2. The vibration isolation platform table has a length of 1800mm, a width of 1400mm, and a thickness of 150mm. Figure 4 As shown: the distance between the glue injection holes is ≤300mm, there are 5 φ25 leveling holes on the board, 4 of which are also used as hoisting holes 7, and the glue injection holes are also used as mounting holes for inserts. The hole sealing area is inside the dotted line. The injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com