Ferrite, and transformer and method for driving it

A ferrite and transformer technology, applied in the field of driving the transformer, driving the transformer, can solve the problem that the magnetic core loss cannot be reduced, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

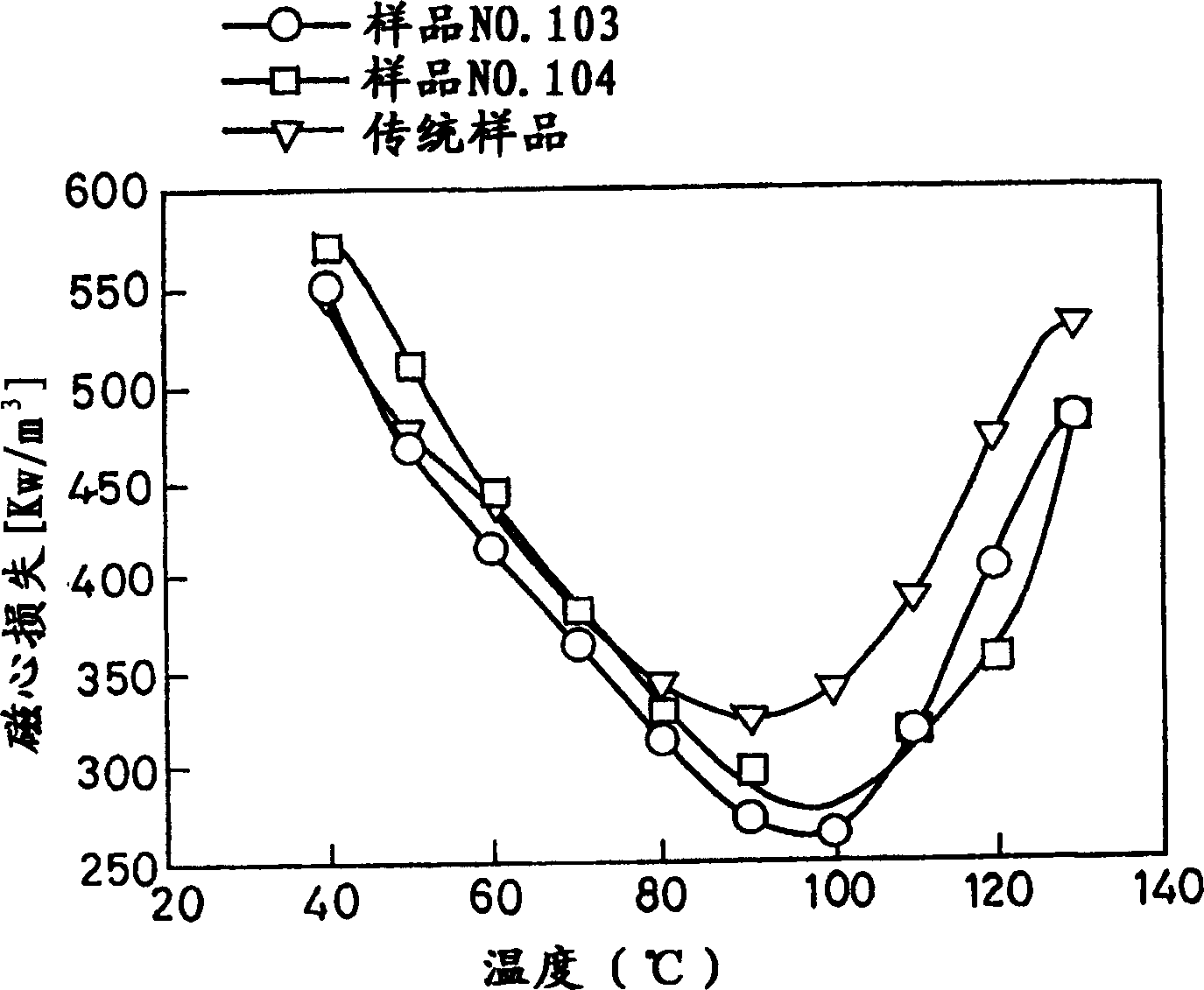

Embodiment 1

[0102] Weigh each base ingredient Fe at the predetermined content shown in Tables 1 and 2 2 o 3 , MnO and ZnO, wet mixed, and then calcined in air at 850°C for 2 hours. According to the amount of the basic component, a predetermined amount of the secondary component SiO is added to the resulting mixture 2 , CaCO 3 , Nb 2 o 5 and ZrO 2 , wet ball milling to obtain a ferrite powder. To this powder was added 0.8% by weight of PVA binder based on its solid content, and granulated. The obtained pellets were formed into a ring shape (outer diameter: 24 mm, inner diameter: 12 mm, thickness: 5.5 mm) under a pressure of 1 ton / cm2. Put the molded body in the N that controls the partial pressure of oxygen 2 -O 2 In the atmosphere of the mixed gas, firing was carried out at a firing temperature of 1300° C. for 5 hours. In this way, a toroidal core having an outer diameter of 20 mm, an inner diameter of 10 mm, and a thickness of 5 mm was obtained. The composition of the final fe...

Embodiment 2

[0144] In the same manner as in Example 1, ferrite core samples (ring cores) for transformers each having a composition shown in Table 3 were prepared. Also, in the same manner as in Example 1, Bs in these samples was measured.

[0145] The resulting data are in Table 3.

[0146] table 3

[0147] Sample Basic component (mol%) Subcomponent (ppm) Bs(120℃)

[0148] No. Fe 2 o 3 ZnO MnO SiO 2 CaCO 3 Nb 2 o 5 ZrO 2 (mT)

[0149] 201 54.2 6.0 39.8 100 800 300 250 428

[0150] 202 54.4 5.0 40.6 100 800 300 250 438

[0151] 203 54.5 4.5 41.0 100 800 300 250 438

[0152] In the samples of the present invention, Bs decreases linearly as the ambient temperature increases from 100°C to 110°C to 120°C. From the data in Table 3, it can be seen that the Bs in these samples is not lower than 410 mT in the range of 100-120°C. The core losses in these samples were low at temperatures of 100-110°C.

Embodiment 3

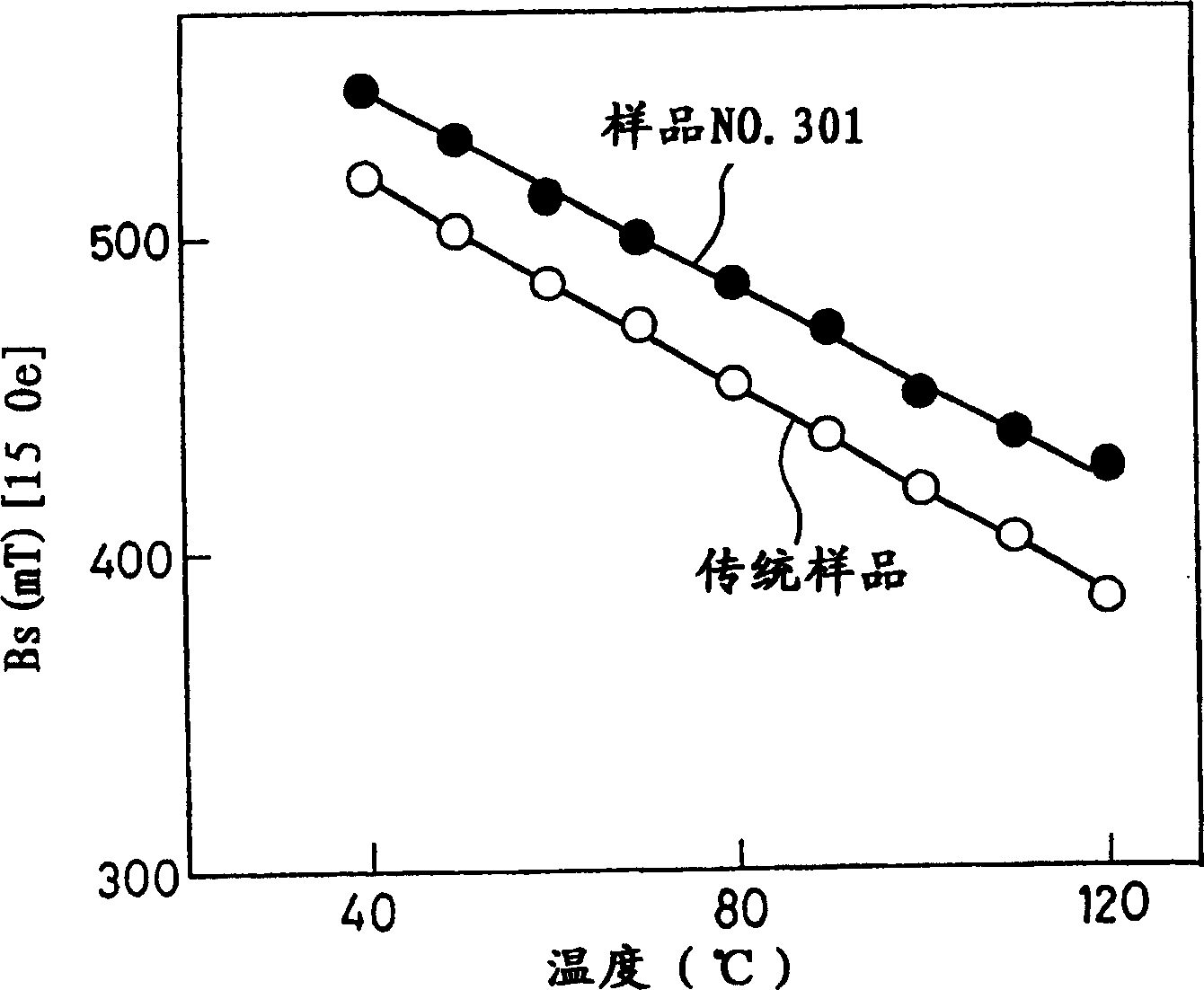

[0154]In the same manner as in Example 1, ferrite core samples (ring cores) for transformers each having a composition shown in Tables 4 and 5 were prepared. Also, in the same manner as in Example 1, Bs in those samples was measured. However, in this example, the samples were tested at an ambient temperature between 20°C and 120°C. Tables 4 and 5 show the data of Bs and the temperature dependence coefficient of Bs, dBs / dT (T=20~120°C). figure 2 Represent in sample No.301 (sample of the present invention, same as sample No.103 in embodiment 1) and in conventional sample (sample No.309, sample No. 106 same), the graph of the temperature-dependent change of Bs.

[0155] Table 4

[0156] Sample Basic component (mol%) Subcomponent (ppm) Bs(120℃) dBs / dT

[0157] No. Fe 2 o 3 ZnO MnO SiO 2 CaCO 3 Nb 2 o 5 ZrO 2 (mT) (T=20 to 120℃)

[0158] 301 54.0 8.0 38.0 100 800 300 250 428 -1.55

[0159] 302 54.1 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com