Switched reluctance motor with bipolar excitation 8/6 structure sectional rotor

A segmented rotor, bipolar technology, applied in the shape/pattern/structure of the magnetic circuit, the shape/pattern/structure of the winding conductor, the rotating parts of the magnetic circuit, etc. Resistor motor research reports, can not work properly and other problems, to achieve the effect of simple structure, cost saving, broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

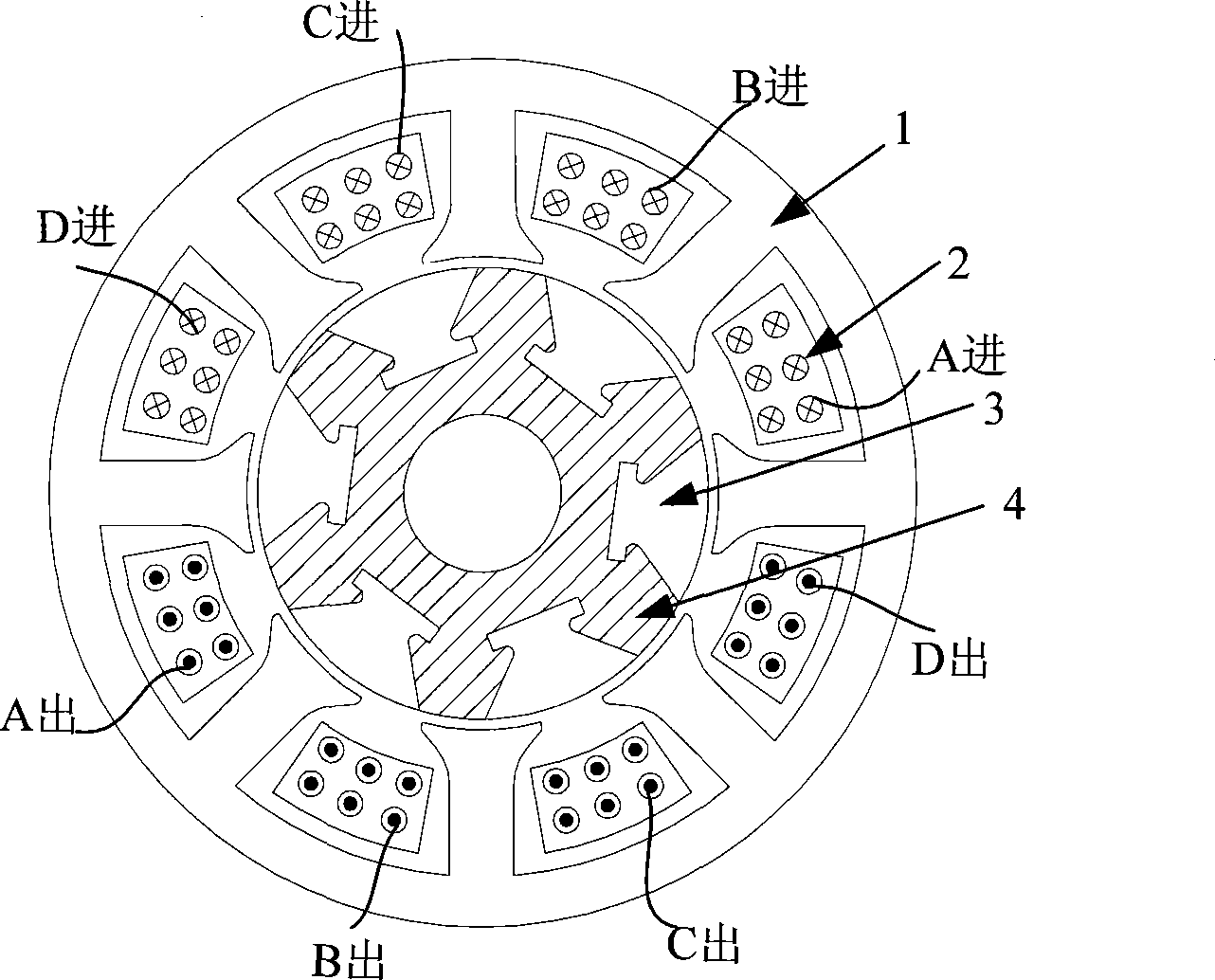

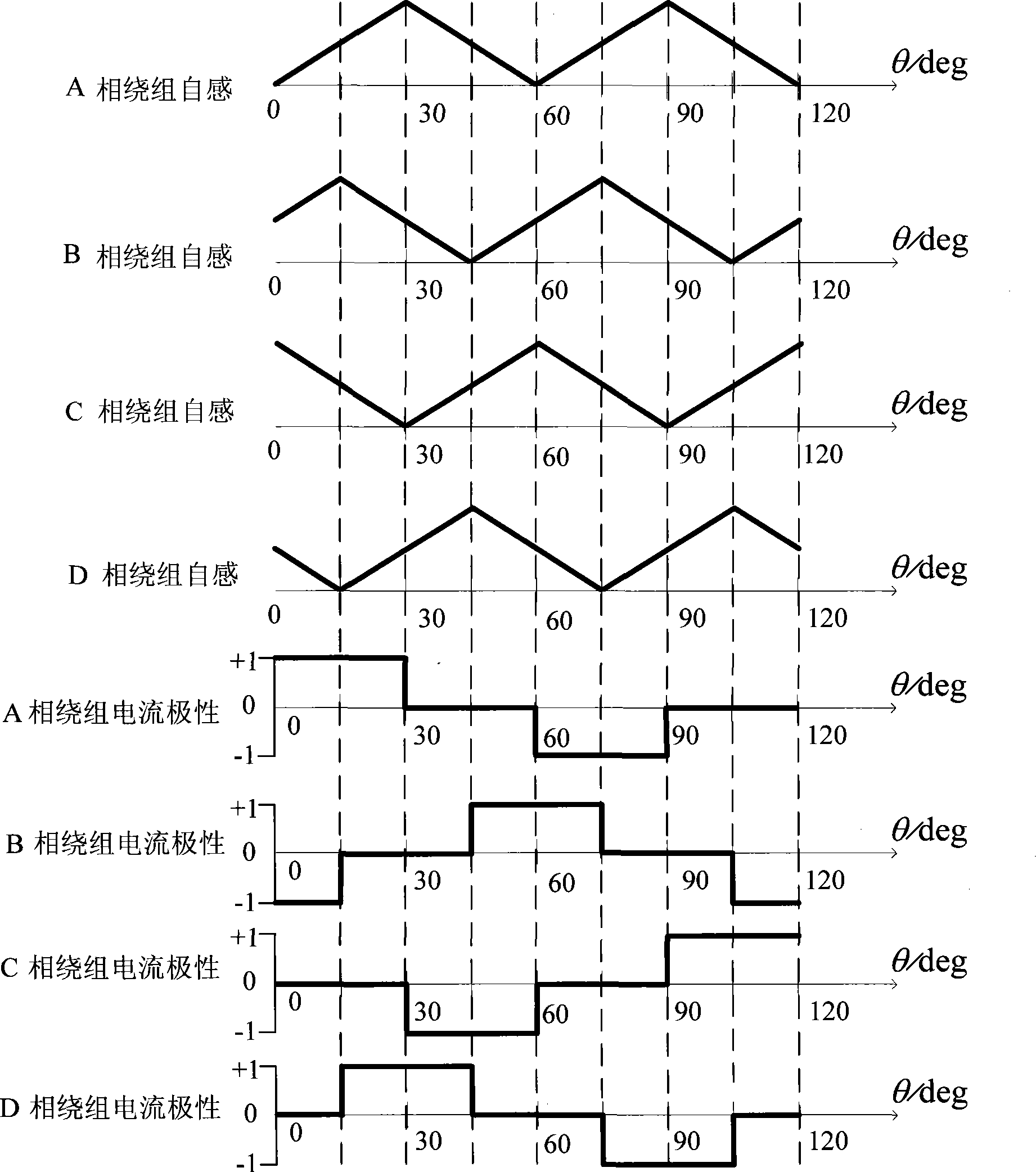

[0012] figure 1 Shown is a cross-sectional schematic diagram of a segmented rotor switched reluctance motor with bipolar excitation 8 / 6 structure of the present invention, including a radial stator 1, a stator winding 2, a segmented rotor core block 3 and a non-magnetic rotor sleeve 4, wherein : Six segmented rotor core blocks 3 are embedded in the non-magnetic rotor sleeve 4 to form a cylindrical rotor, the radial stator 1 has an eight-tooth and eight-slot structure, and the stator winding 2 in the two opposite slots is one Wire packs, each wire pack is a phase winding, a total of four phase windings, that is, A, B, C, D four-phase windings.

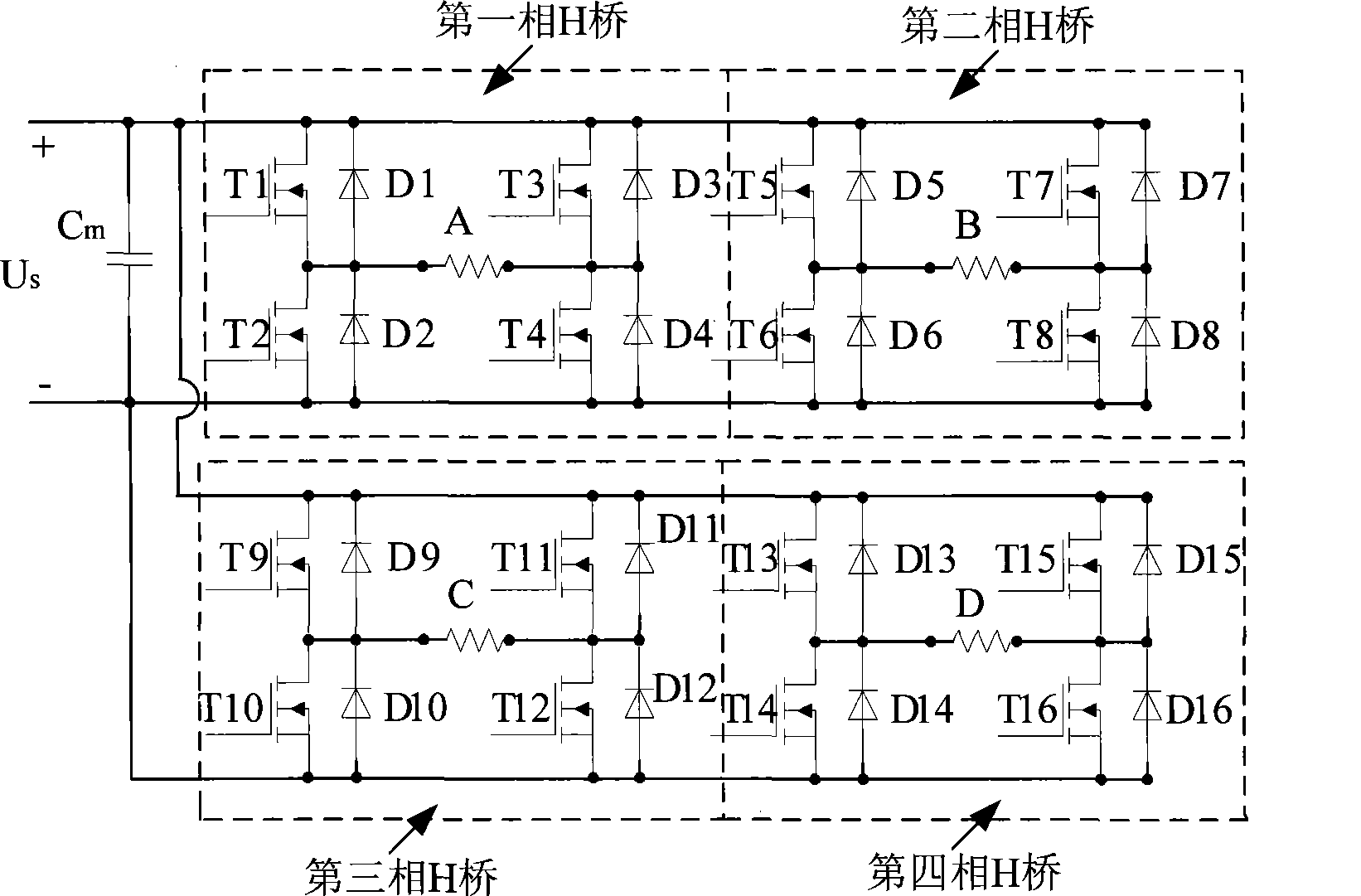

[0013] The power converter of the stator winding adopts a four-phase H-bridge topology circuit structure, such as figure 2 As shown, the DC excitation power supply U s The positive and negative terminals are connected in parallel with a capacitor C m , each phase of the H-bridge circuit is composed of two identical bridge arms, each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com