Quick laser cladding device and cladding method of flat metal parts

A technology of metal parts and cladding, applied in the direction of metal material coating process, coating, etc., can solve the problems that are not conducive to improving cladding efficiency, high construction cost, high construction cost, etc., and achieve low equipment construction and operation costs, reduce The effect of system construction and operation cost and fast cladding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

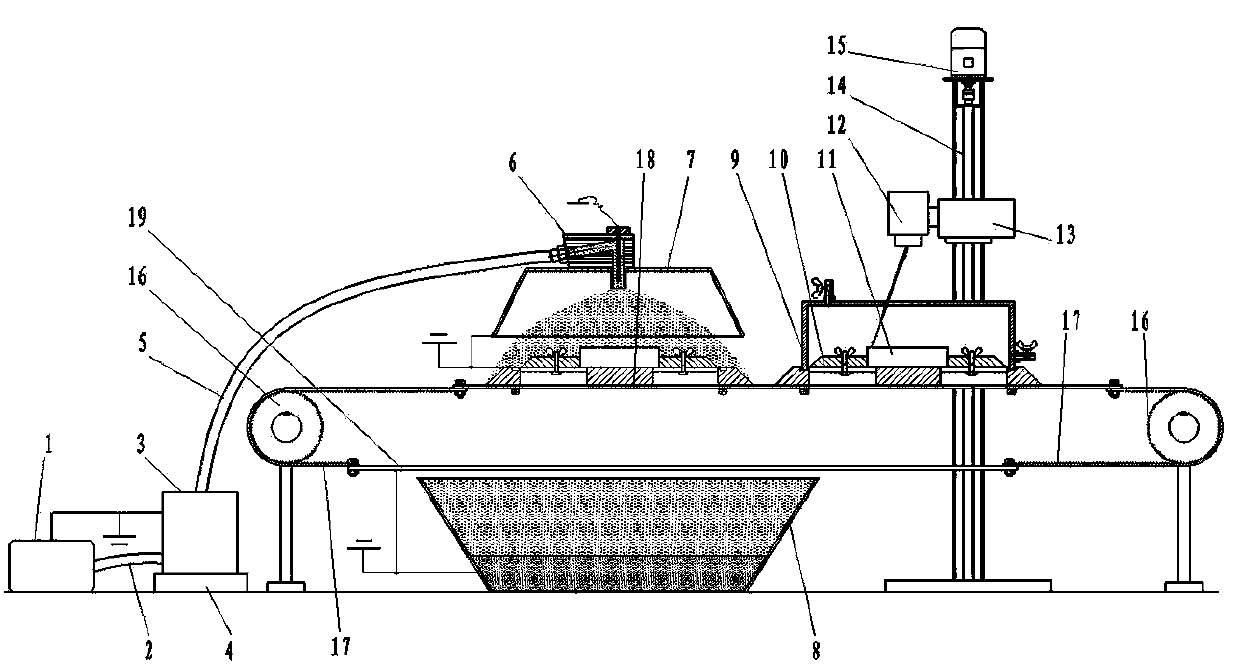

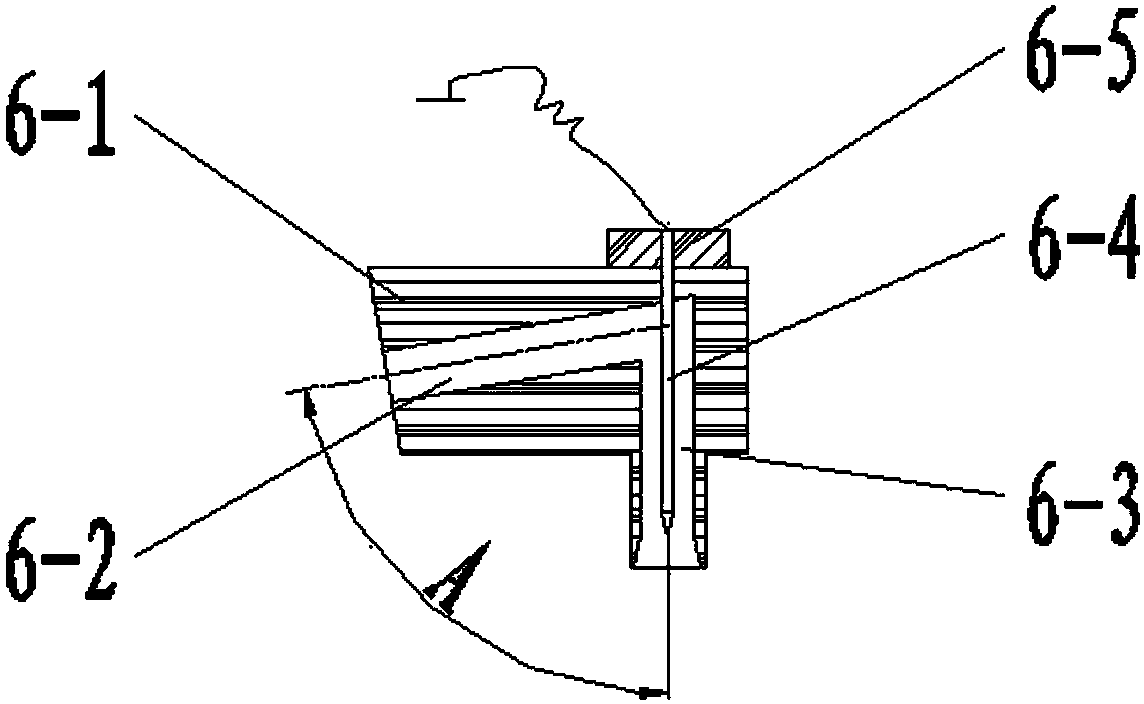

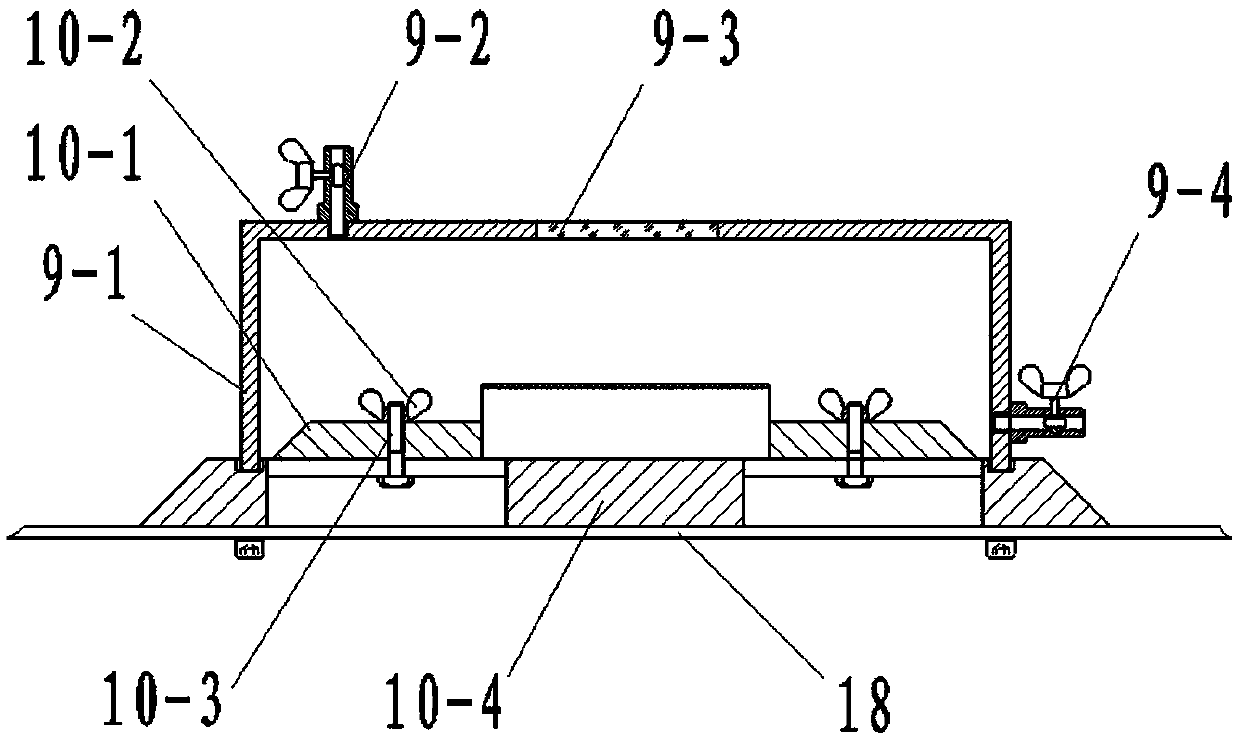

[0043] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a laser rapid cladding device for planar metal parts 11, consisting of five modules: an electrostatic powder spraying device, a laser galvanometer fast scanning device, a gas protection module, a part 11 transmission module and a part 11 fixing fixture, the electrostatic powder spraying device Including an air compressor 1, the air compressor 1 communicates with the powder tank 3 installed on the electronic balance 4 through the carrier gas pipe 2, and the other end of the powder tank 3 connects with the powder inlet channel of the electrostatic powder spraying head 6 through the powder feeding pipe 5 6-2 is connected, the rear end of the powder inlet flow channel 6-2 is connected with the powder outlet flow channel 6-3, the angle between the two is 30o ~ 60o, and there is a An ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com