Preparation method of n ion-doped cerium dioxide film

An ion doping, ceria technology, used in ion implantation plating, electrochemical generators, final product manufacturing, etc., can solve problems such as environmental pollution, achieve firm bonding, accurate and controllable thickness, and improve ionic conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a kind of N ion doped CeO 2 The preparation method of thin film, comprises the following steps:

[0024] (1) In Ar and N 2 In the mixed atmosphere of , the CeN film was obtained by magnetron sputtering with metal Ce as the target;

[0025] (2) Oxidize the CeN film prepared in the step (1) to obtain N 3- Doped CeO 2 film.

[0026] In the present invention, Ar and N 2 CeN thin films were obtained by magnetron sputtering in a mixed atmosphere with metallic Ce as the target. In the present invention, the gas flow rate of Ar is preferably 30-60 cm 3 / min, more preferably 40-50cm 3 / min; the N 2 The gas flow rate is preferably 5 ~ 10cm 3 / min, more preferably 6-8cm 3 / min.

[0027] In the present invention, the Ar and N are preferably 2 Pass in the vacuum chamber simultaneously or pass in the vacuum chamber respectively, the pressure of the vacuum chamber is preferably 9.5×10 -5 ~2.0×10 -4 Pa, more preferably 1.0×10 -4 ~1.5×10 -4 Pa; the...

Embodiment 1

[0039] Metal Ce is placed on the radio frequency cathode as a sputtering target, and the background pressure of the vacuum chamber reaches 9.5×10 -5 At Pa, feed Ar gas and N into the vacuum chamber at the same time 2 Gas, the gas flow rate is controlled at 30cm 3 / min and 5cm 3 / min, the sputtering pressure was controlled at 0.8Pa, the radio frequency power was 50W, and magnetron sputtering was carried out at 25°C for 2 hours to obtain a CeN thin film.

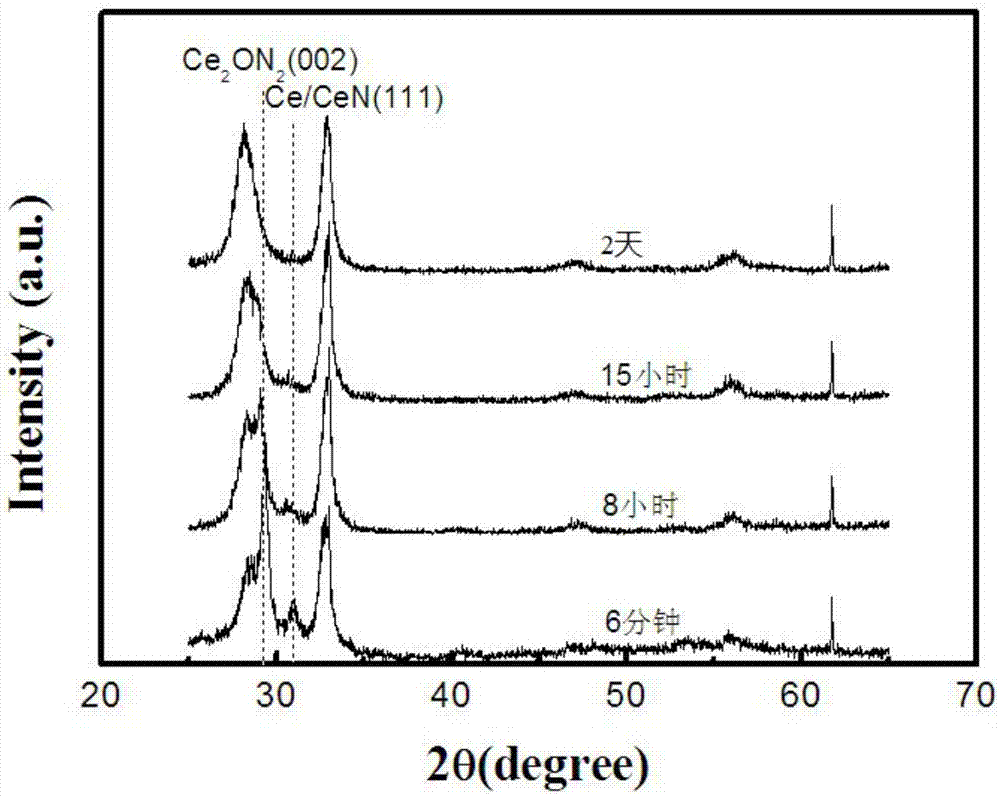

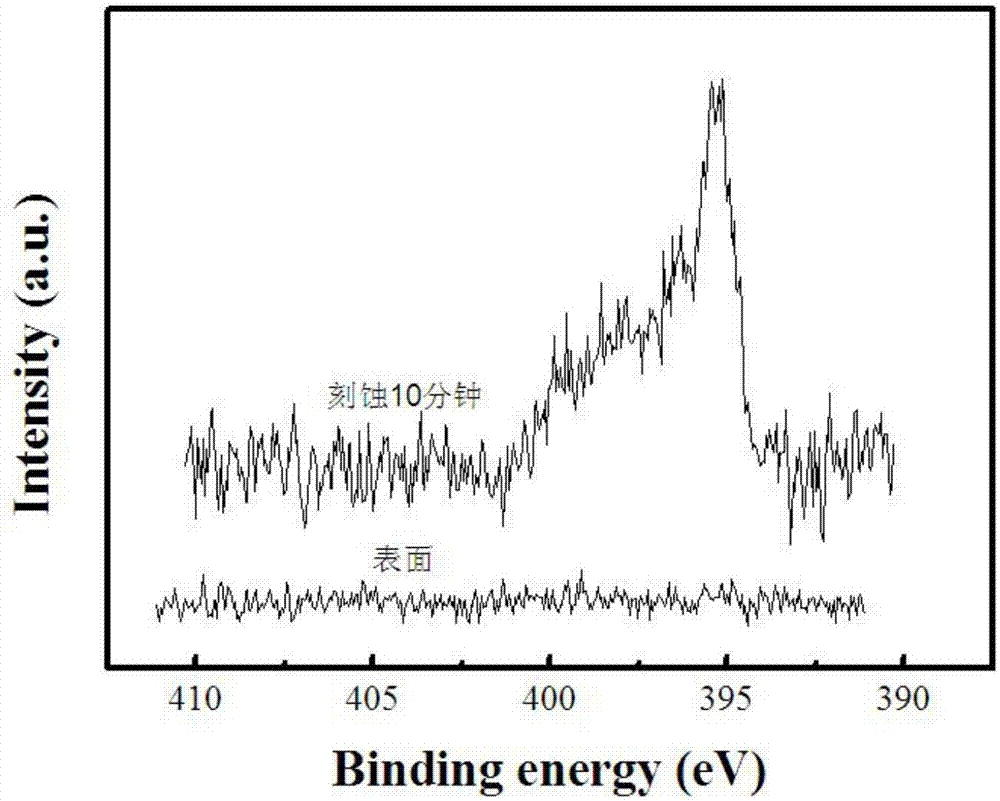

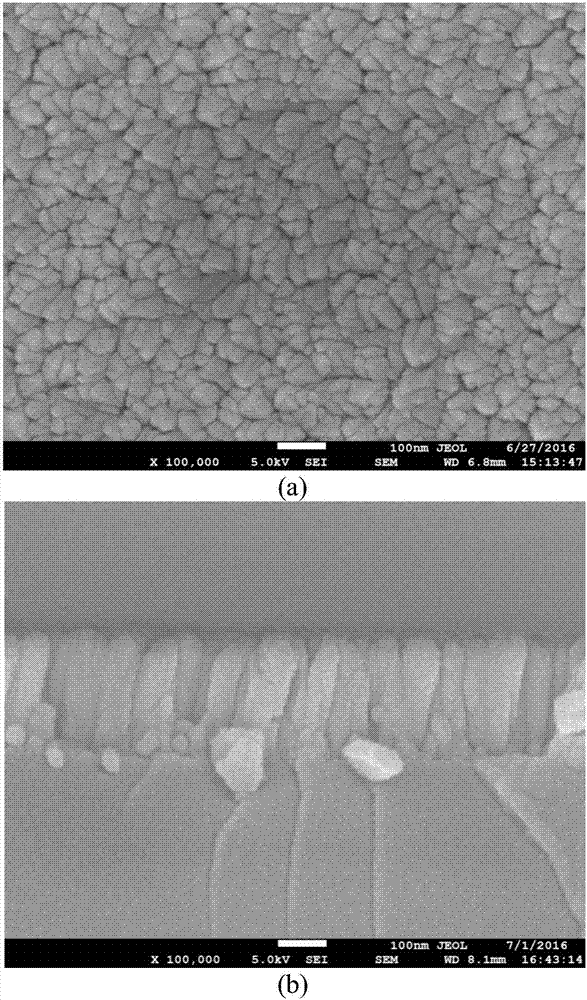

[0040] Take out the above-mentioned CeN film in the vacuum chamber and place it in the air for natural oxidation to obtain N 3- Doped CeO 2 Thin film, respectively measure the XRD pattern of the thin film sample when the oxidation time is 6 minutes, 8 hours, 15 hours and 2 days, the test results are as follows figure 1 shown. From figure 1 It can be seen from the figure that when the oxidation time is 6 minutes, the diffraction peak of the CeN phase can still be seen very clearly, indicating that the film sample has not ...

Embodiment 2

[0044] Metal Ce is placed on the radio frequency cathode as a sputtering target, and the background pressure of the vacuum chamber reaches 2.0×10 -4 At Pa, feed Ar gas and N into the vacuum chamber at the same time 2 Gas, the gas flow rate is controlled at 60cm 3 / min and 10cm 3 / min, the sputtering pressure was controlled at 2Pa, the radio frequency power was 200W, and magnetron sputtering was performed at 200°C for 4 hours to obtain a CeN thin film.

[0045] After taking out the CeN thin film in the vacuum chamber and placing it in the air for natural oxidation at room temperature for 20 days, the N 3- Doped CeO 2 film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com