Aluminum substituted silicon doped apatite type lanthanum silicate solid electrolyte and preparation method thereof

A solid electrolyte, silicon doping technology, applied in the direction of circuits, fuel cells, electrical components, etc., can solve the problems of restricting development and achieve the effect of improving conductivity, increasing vacancy concentration, and multi-transmission space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

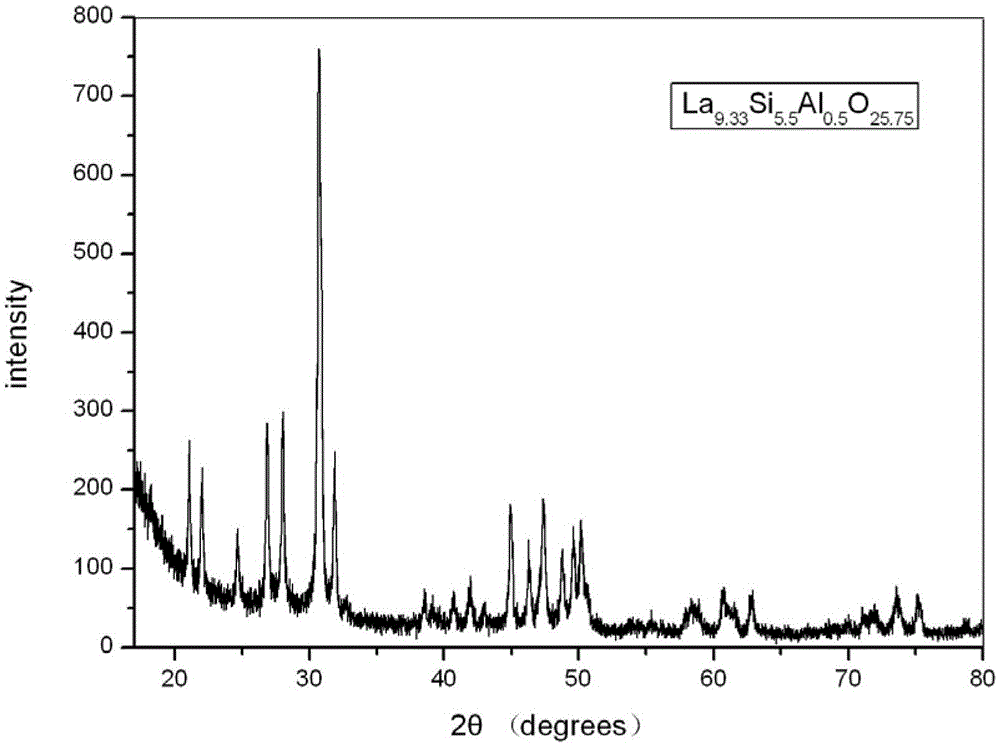

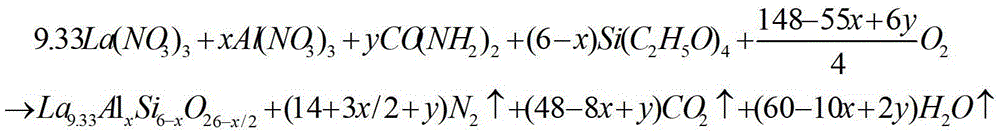

[0021] According to the molar ratio La:Si:Al=9.33:5.5:0.5, weigh La in turn 2 O 3 , Ethyl Orthosilicate and Al(NO 3 ) 3 , Use proper amount of absolute ethanol and HNO 3 Fully dissolve, then add urea and ethyl orthosilicate, heat and stir at 40°C to form a precursor solution, adjust the pH to 4 with ammonia water, and place it in a water bath device at 80°C. After 3 hours of heat preservation, a colorless and transparent precursor solution is obtained. glue. Put the precursor gel in a muffle furnace preheated to 600℃, the gel will quickly evaporate and burn when heated, accompanied by a light yellow burning flame, the whole burning process lasts about 5-7min, and white sponge-like foam powder is obtained body. The primary product is ground and calcined at 800°C for 12 hours to obtain high-purity La with good crystallization 9.33 Si 5.5 Al 0.5 O 25.75 Powder. The calcined powder obtained is further ground, pressed and molded at a pressure of 250 MPa, and sintered at 1400° C. fo...

Embodiment 2

[0023] According to the molar ratio La:Si:Al=9.33:5:1, weigh La in turn 2 O 3 , Ethyl Orthosilicate and Al(NO 3 ) 3 , Use proper amount of absolute ethanol and HNO 3 Fully dissolve, then add urea and ethyl orthosilicate, heat and stir at 40℃ to evenly form a precursor solution, adjust the pH to 5 with ammonia water, and place it in a water bath device at 80℃. After 3 hours of heat preservation, a colorless transparent precursor solution is obtained. glue. Put the precursor gel into a muffle furnace preheated to 550℃, the gel will quickly evaporate and burn when heated, accompanied by a light yellow burning flame, the whole burning process lasts about 5-7min, and white sponge-like foam powder is obtained body. The primary product is ground and calcined at 850°C for 10 hours to obtain high-purity La with good crystallization 9.33 Si 5 AlO 25.75 Powder. The calcined powder obtained is further ground, pressed and molded at a pressure of 250 MPa, and sintered at 1500° C. for 3 hour...

Embodiment 3

[0025] According to the molar ratio La:Si:Al=9.33:4:2, weigh La in turn 2 O 3 , Ethyl Orthosilicate and Al(NO 3 ) 3 , Use proper amount of absolute ethanol and HNO 3 Fully dissolve, then add urea and ethyl orthosilicate, heat and stir at 40°C and mix uniformly to form a precursor solution, adjust the pH to 6 with ammonia water, and place it in a water bath device at 80°C for 3h to obtain a colorless transparent gel. Put the gel in a muffle furnace preheated to 650°C, the gel quickly evaporates and burns when heated, accompanied by a light yellow burning flame, the entire burning process lasts about 5-7 minutes, and a white sponge-like foam powder is obtained. The primary product is ground and calcined at 900°C for 8 hours to obtain high-purity La with good crystallization 9.33 Si 4 Al 2 O 25 Powder. The calcined powder obtained is further ground, pressed and molded under a pressure of 250 MPa, and sintered at 1600° C. for 3 hours to obtain an apatite-type lanthanum silicate soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com