III-nitride enhanced HEMT based on composite barrier layer structure and manufacturing method of III-nitride enhanced HEMT

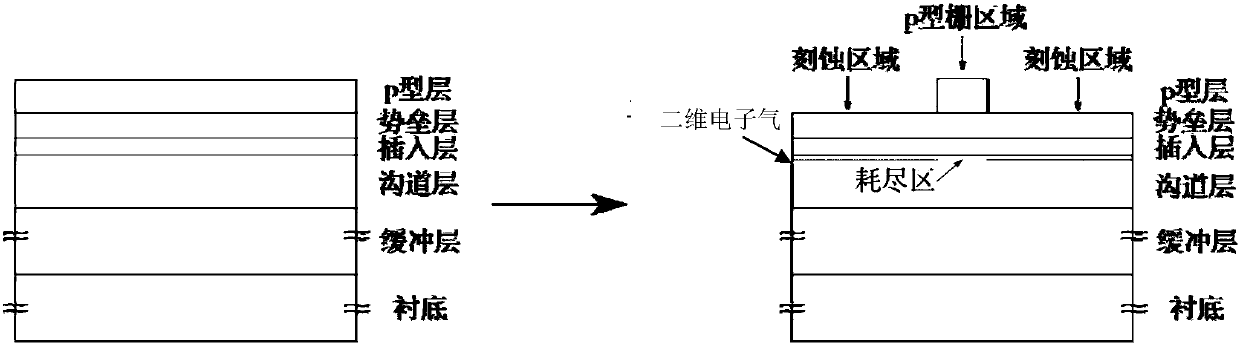

A technology of compound potential barrier and fabrication method, applied in III-nitride enhanced HEMT and fabrication thereof, field effect transistor device field, can solve the problem of inability to meet device reliability requirements, lower gate threshold voltage swing, and forward gate The problems such as the increase of electrode leakage can achieve the effect of ensuring on-chip uniformity, improving gate threshold voltage swing, and suppressing forward gate leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

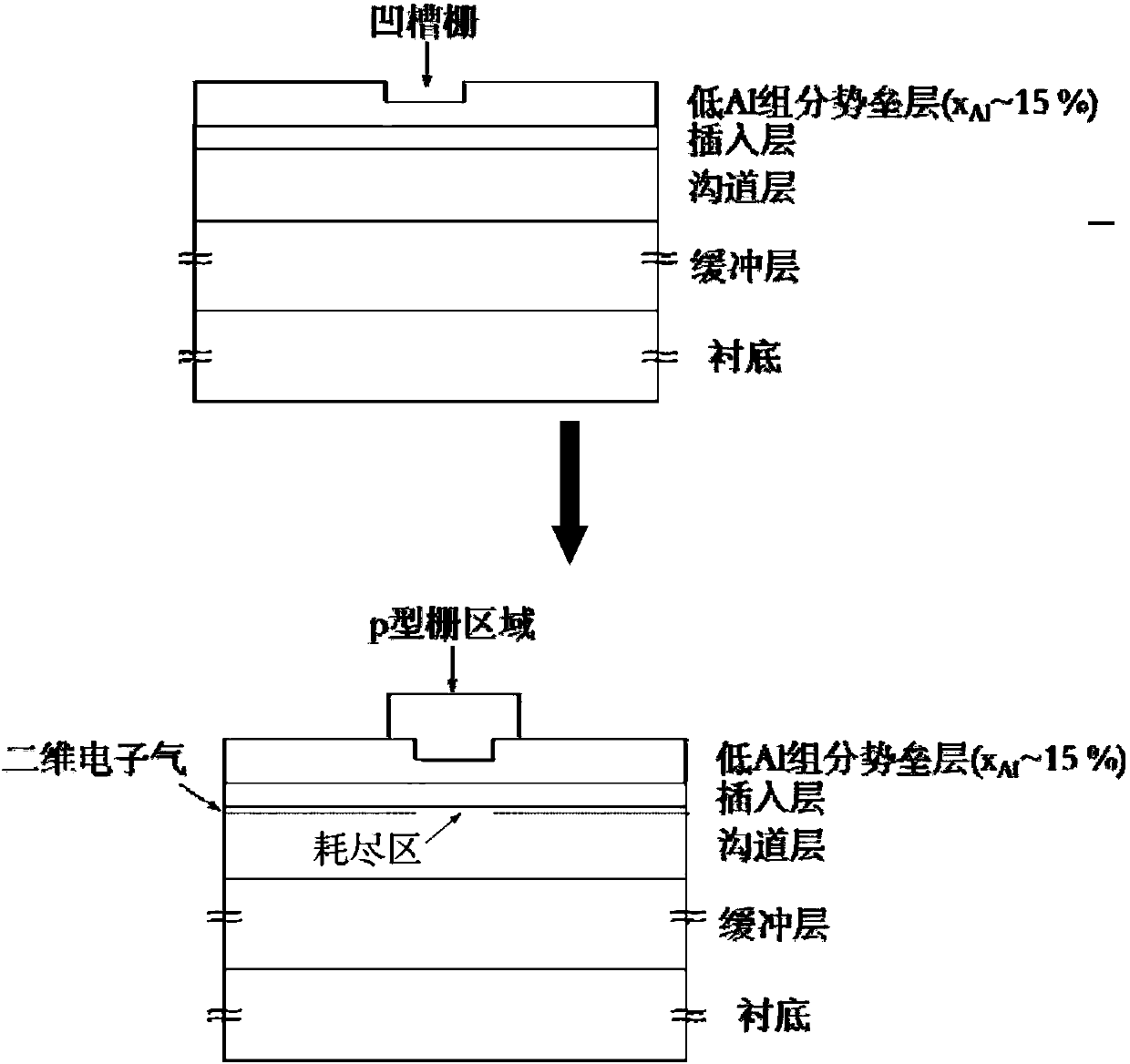

[0095] Embodiment 1 A kind of based on Al 0.15 Ga 0.85 N / Al 0.30 Ga 0.70 The fabrication method of the HEMT of the N double potential barrier layer comprises the following steps:

[0096] Step S1: MOCVD epitaxial growth of HEMT based on AlGaN double barrier layer heterojunction. The upper barrier layer is an AlGaN barrier layer with a low Al composition, the Al composition is 15%, and the thickness is 20-35nm; the lower barrier layer is a high Al composition AlGaN barrier layer, the Al composition is 30%, and the thickness is 20-35nm. 5-10nm. The AlN insertion layer is about 1nm; the GaN channel layer is 50-200nm. HEMT epitaxial structures such as Figure 4 shown. The buffer layer can be made of GaN or AlGaN with graded Al composition, or a combination of both; the substrate can be made of sapphire, silicon carbide, gallium nitride or aluminum nitride.

[0097] Step S2: Groove gate etching. The photoresist AZ5214 is used as a mask, and the groove gate is etched by ICP...

Embodiment 2

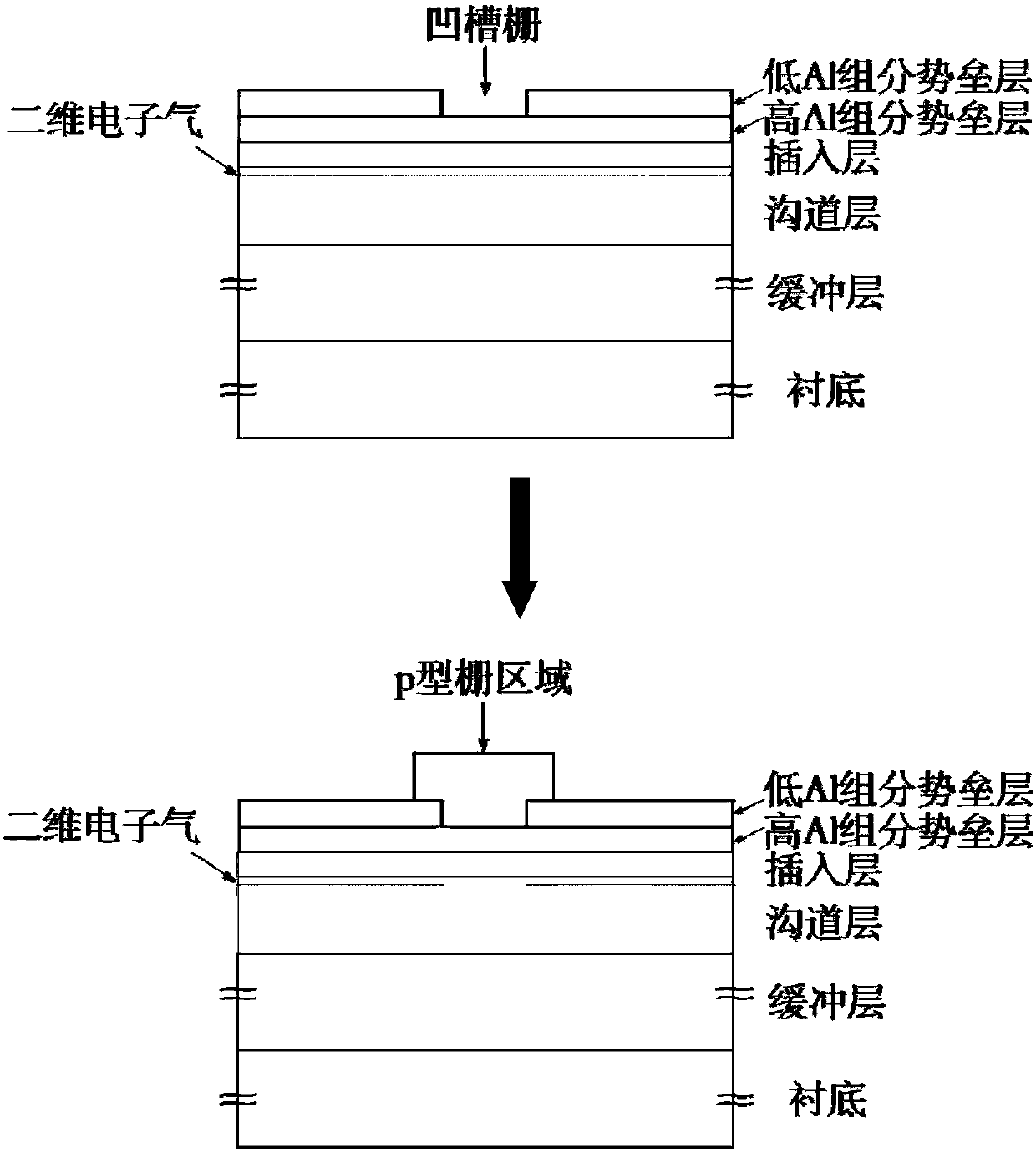

[0104] Embodiment 2 A kind of based on Al 0.15 Ga 0.85 N / AlN / Al 0.30 Ga 0.70 The manufacturing method of the HEMT of N multi-barrier layer comprises the following steps:

[0105] Step S1: MOCVD epitaxial growth of HEMT based on AlGaN multi-barrier layer heterojunction, that is, a sandwich-type AlGaN barrier layer structure containing AlN insertion layer: the upper barrier layer is an AlGaN barrier layer with a low Al composition, and the Al composition The lower barrier layer is an AlGaN barrier layer with a high Al composition, the Al composition is 30%, and the thickness is 5-10nm; between the two is a thin AlN layer with a thickness of about 1-30nm. 2nm, the role of this layer is to provide a wider process window for self-terminating etching, making the trench gate etching process more stable and reliable. In addition, the AlN insertion layer is about 1nm; the GaN channel layer is 50-200nm. HEMT epitaxial structures such as Figure 13 shown. Wherein, the buffer layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com