Epitaxial growth method of yttrium iron garnet film

A yttrium iron garnet, epitaxial growth technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problem of no way to YIG thin film, can not accurately control the thickness of YIG thin film growth, etc., to achieve spin pump damping The effect of small factor, small coercivity and narrow ferromagnetic resonance linewidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be described in further detail below by examples in conjunction with the accompanying drawings, but the present invention is not limited to the examples given.

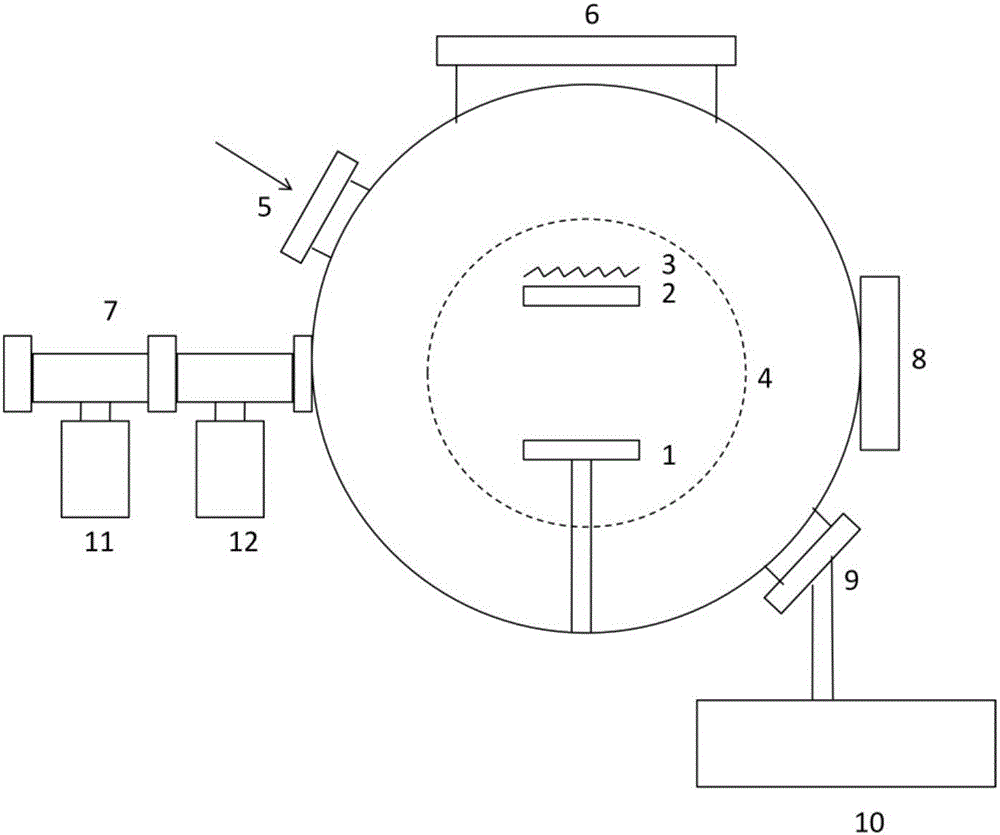

[0022] Explanation of reference signs: 1-target material, 2-sample holder, 3-heating wire, 4-observation window, 5-laser optical path, 6-pump group air inlet, 7-RHEED monitoring facility, 8-fluorescent screen and camera, 9 - protective gas vent, 10 - ozone generator, 11, 12 - small molecular pump.

[0023] Step 1: Pump the vacuum chamber containing the processed GdGaGa substrate to 8.6±1×10 -6 Pa, and heat the gadolinium gallium garnet substrate to a constant temperature of about 736°C. During the heating process, when it is heated to about 250°C, a 1.4×10 -3 A mixed gas of mbar ozone (20% by mass fraction) and oxygen (80% by mass fraction) was used as a shielding gas to avoid oxygen deficiency on the substrate during the heating process.

[0024] In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com