Making method of ultrathin antibiotic hydrogel film

A hydrogel and thin film technology, applied in medical science, metal material coating technology, bandages, etc., can solve difficult problems such as nanoscale film thickness control, and achieve good biocompatibility, operability, and stability Strong, precisely controlled thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of component A

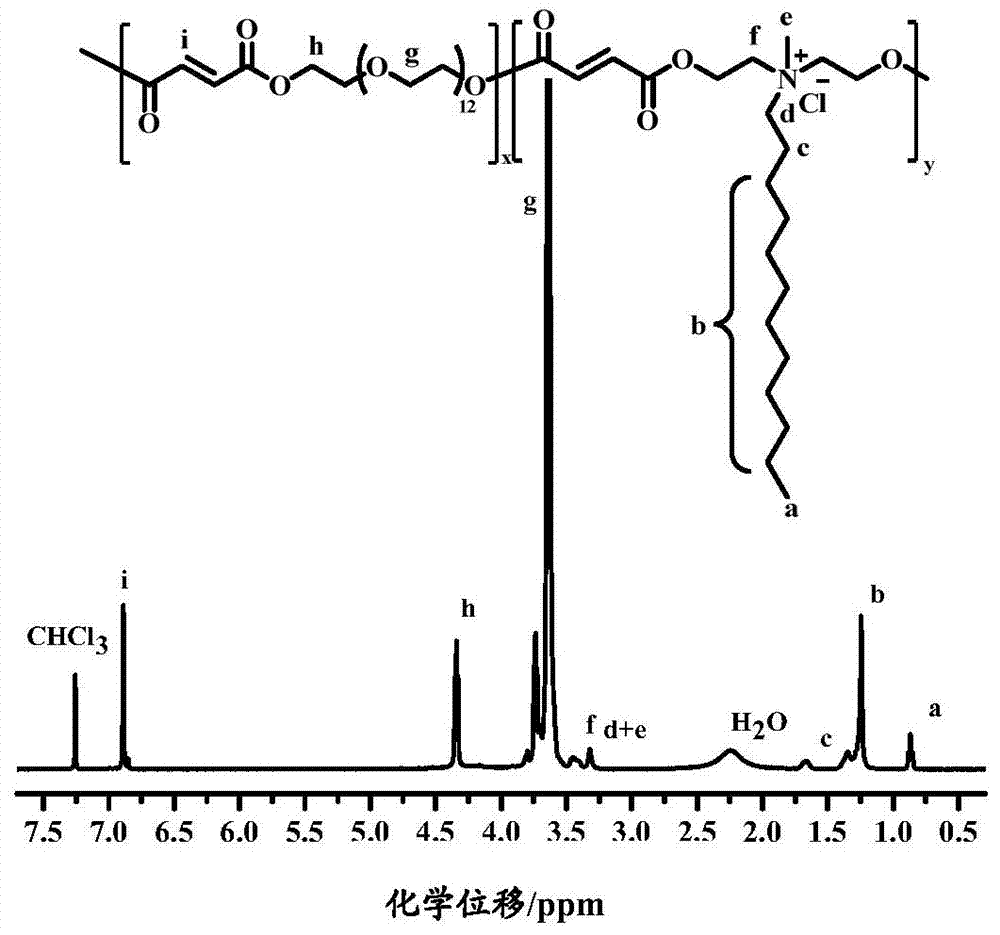

[0044] Add 12mmol PEG-400 and 6mmol dodecylbishydroxyethylmethylammonium chloride into a 250mL three-necked flask, and dissolve with 70mL dichloromethane. Add 20mmol fumaryl chloride and 36mmol triethylamine dropwise, and react at room temperature for 24 hours. The obtained product is precipitated in cold ether, washed and dried to prepare polyethylene glycol-fumaryl chloride-dodecylbishydroxyethylmethyl ammonium chloride. Such as figure 1 It can be seen from the shown nuclear magnetic spectrum that polyethylene glycol-fumaryl chloride-dodecylbishydroxyethylmethyl ammonium chloride has been prepared by the above method.

[0045] (2) Preparation of Copolymer Solution I

[0046] Prepare 50mM Na with pH=7.4 2 HPO 4 / NaH 2 PO 4 Buffer solution, dissolve 250mg of polyethylene glycol-fumaryl chloride-dodecylbishydroxyethylmethylammonium chloride in 25ml of buffer solution to obtain a copolymer solution I with a concentration of 1%.

[...

Embodiment 2

[0057] The embodiment is the same as that of Example 1, except that in step (5), the substrate is repeated 10 cycles in the copolymer solution I and the copolymer solution II.

Embodiment 3

[0059] The embodiment is the same as that of Example 1, except that in step (5), the substrate is repeated 20 cycles in the copolymer solution I and the copolymer solution II.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com