Method for preparing titanium-stibium-tellurium (Ti-Sb-Te) phase change material and method for preparing phase change storage unit

A phase-change material and phase-change storage technology, applied in the field of microelectronics, can solve problems such as weak data retention, low crystallization temperature, and high power consumption of devices, and achieve low power consumption, good film compactness, and accurate and reliable thickness. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

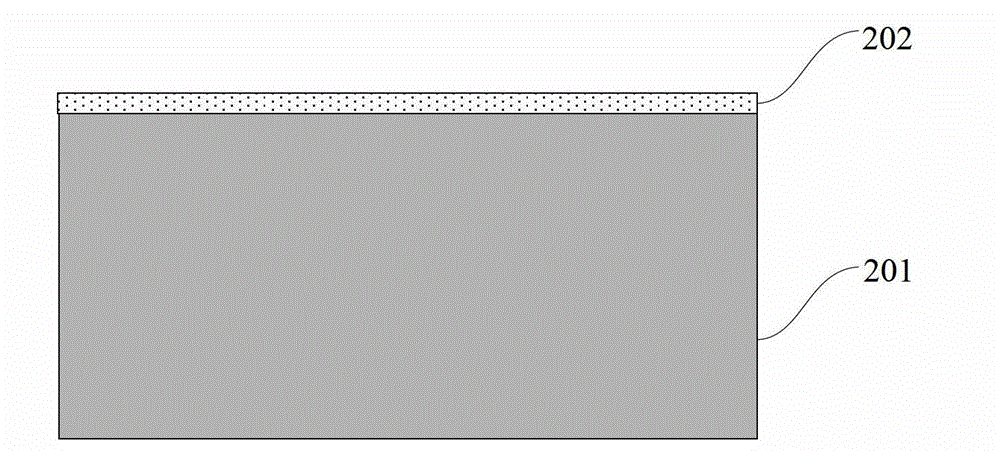

[0045] Such as Figure 1~Figure 3 As shown, this embodiment provides a method for preparing a titanium-antimony-tellurium phase change material by atomic layer deposition, comprising the following steps:

[0046] 1) Introduce Sb precursor SbCl on the substrate 3 Pulse to wash unabsorbed SbCl 3 , and then introduce Te precursor (R 3 Si) 2 Te pulse, cleaning unabsorbed (R 3 Si) 2 Te and reaction by-products;

[0047] 2) Introduce Ti precursor TiCl to the above substrate 4 Pulse to clean residual TiCl 4 , and then introduce Te precursor (R 3 Si) 2 Te pulse, cleaning residue (R 3 Si) 2 Te and reaction by-products;

[0048] 3) Introduce Sb precursor SbCl to the above substrate 3 Pulse, wash residual SbCl 3 , and then introduce the precursor of Sb (R 3 Si) 3 Sb pulse, cleaning unabsorbed (R 3 Si) 3 Sb and reaction by-products.

[0049] In this embodiment, one or more steps in steps 1), 2) and 3) can be repeated until a titanium-antimony-tellurium phase-change mater...

Embodiment 2

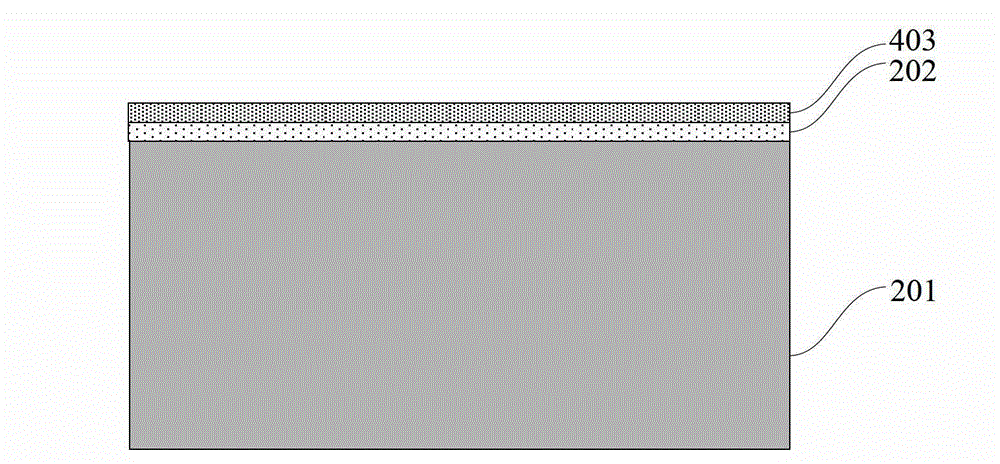

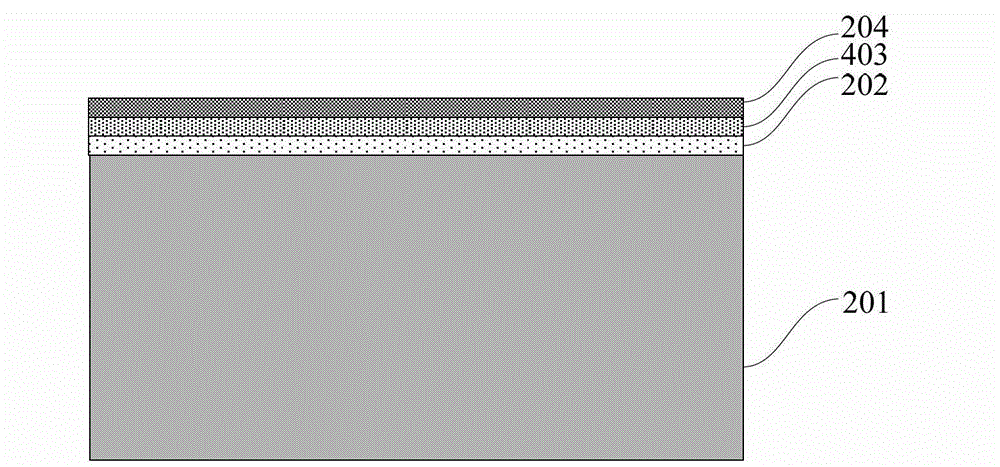

[0062] Such as Figure 4~Figure 9 As shown, the present embodiment provides a preparation method of a phase-change memory unit. The phase-change memory composed of the phase-change memory unit can be a variety of functional devices that use the principle of phase change to store data, such as using electric pulse programming Chalcogenide random access memory, or a storage disc programmed by laser pulses, or a memory programmed by electron beams, or a memory programmed by other energy particles, the preparation method of the phase change memory unit includes the following steps:

[0063] Such as Figure 4 As shown, step 1) is first performed, providing a semiconductor substrate 101 , and preparing the lower electrode 102 on the surface of the semiconductor substrate 101 . Specifically, the semiconductor substrate 101 is cleaned first, and then the lower electrode 102 is deposited on its surface, which can remove organic matter, metal ions, oxides and other impurities on the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com