Patents

Literature

35results about How to "Good surface coverage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

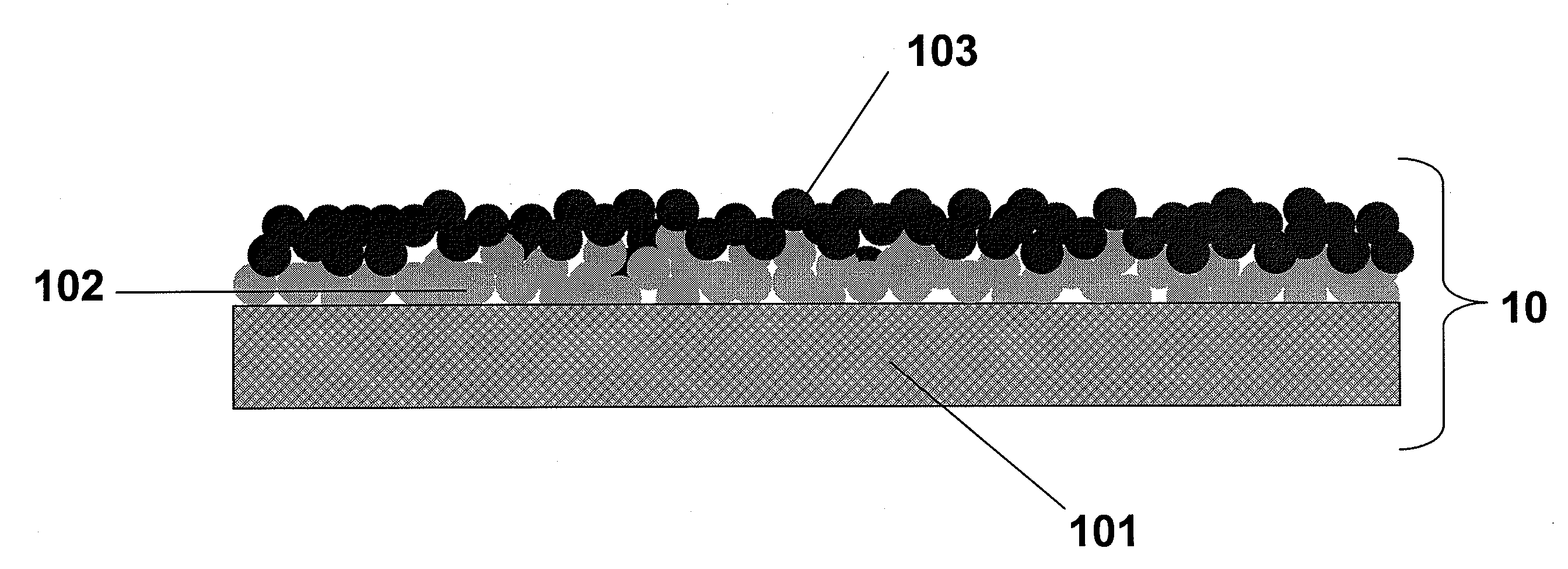

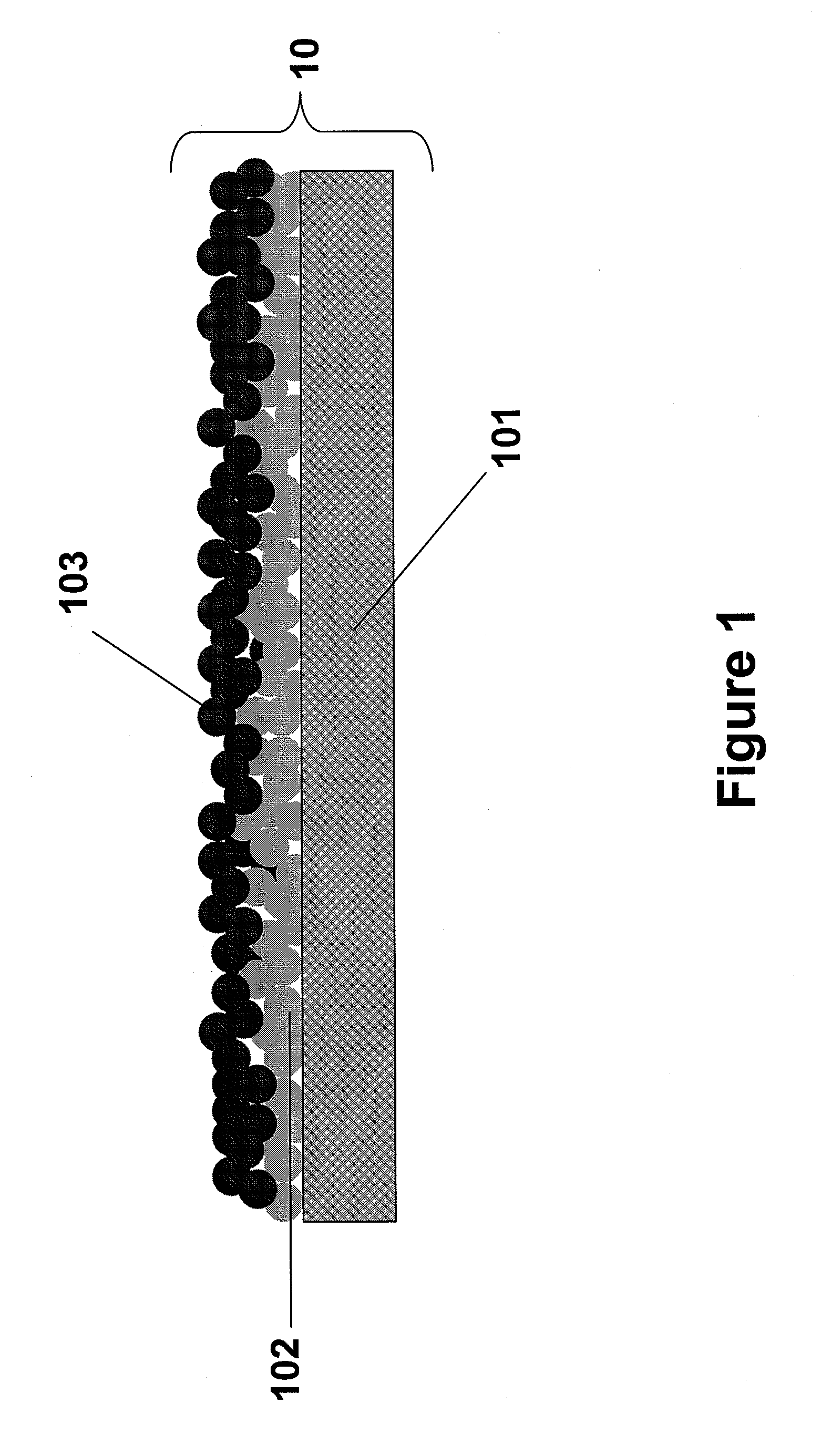

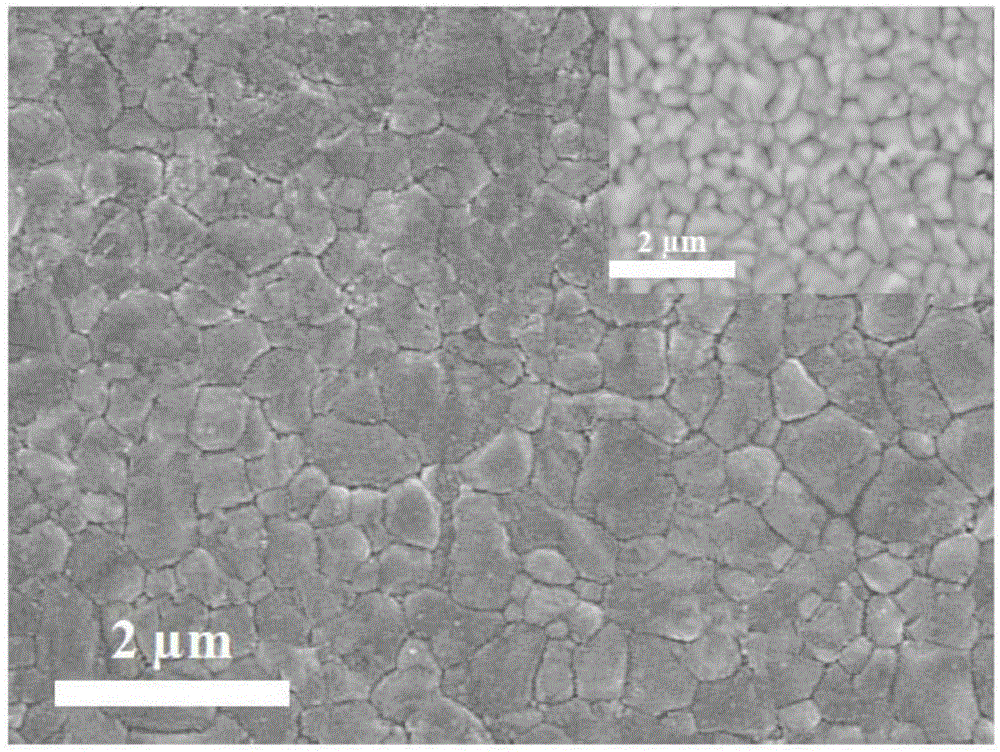

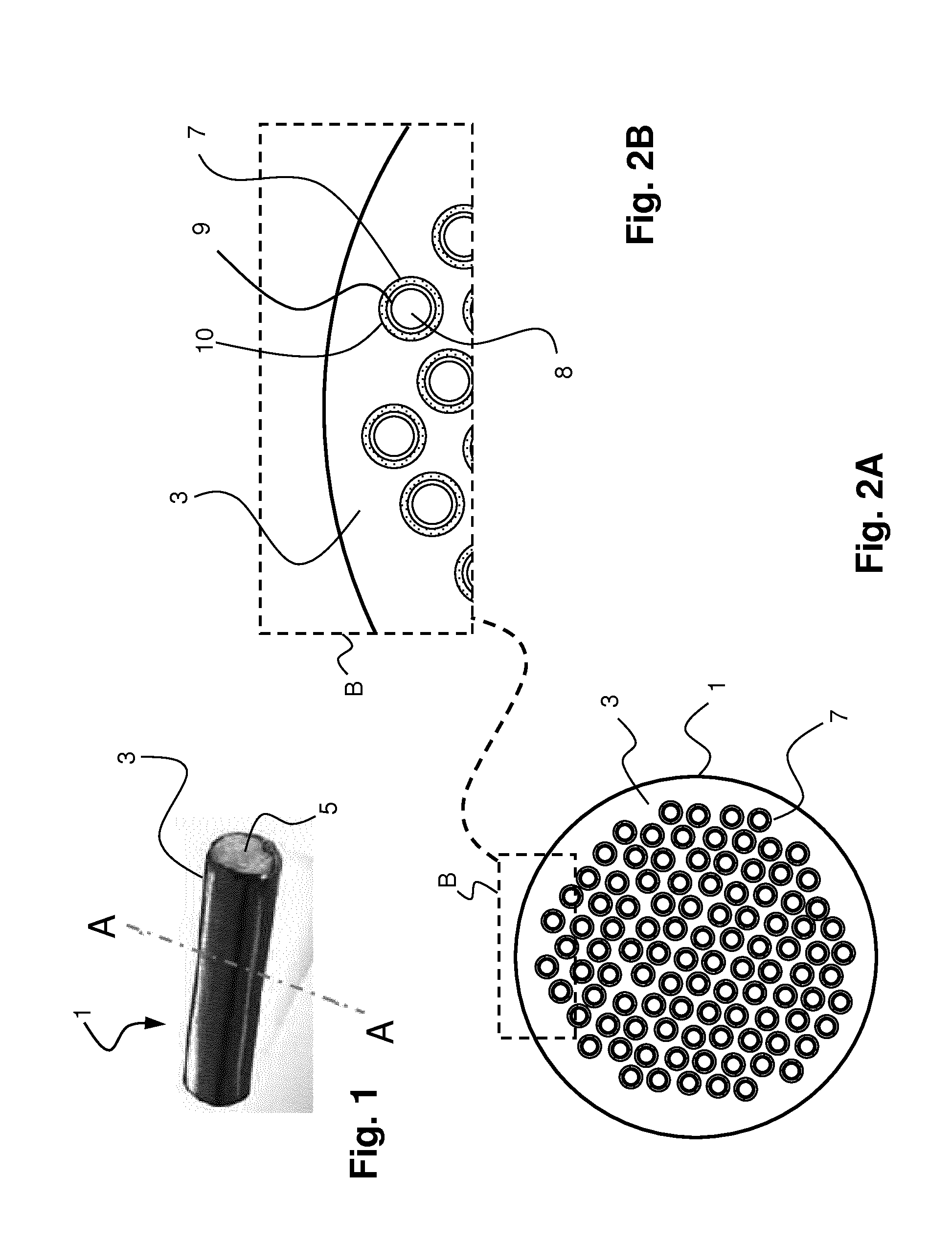

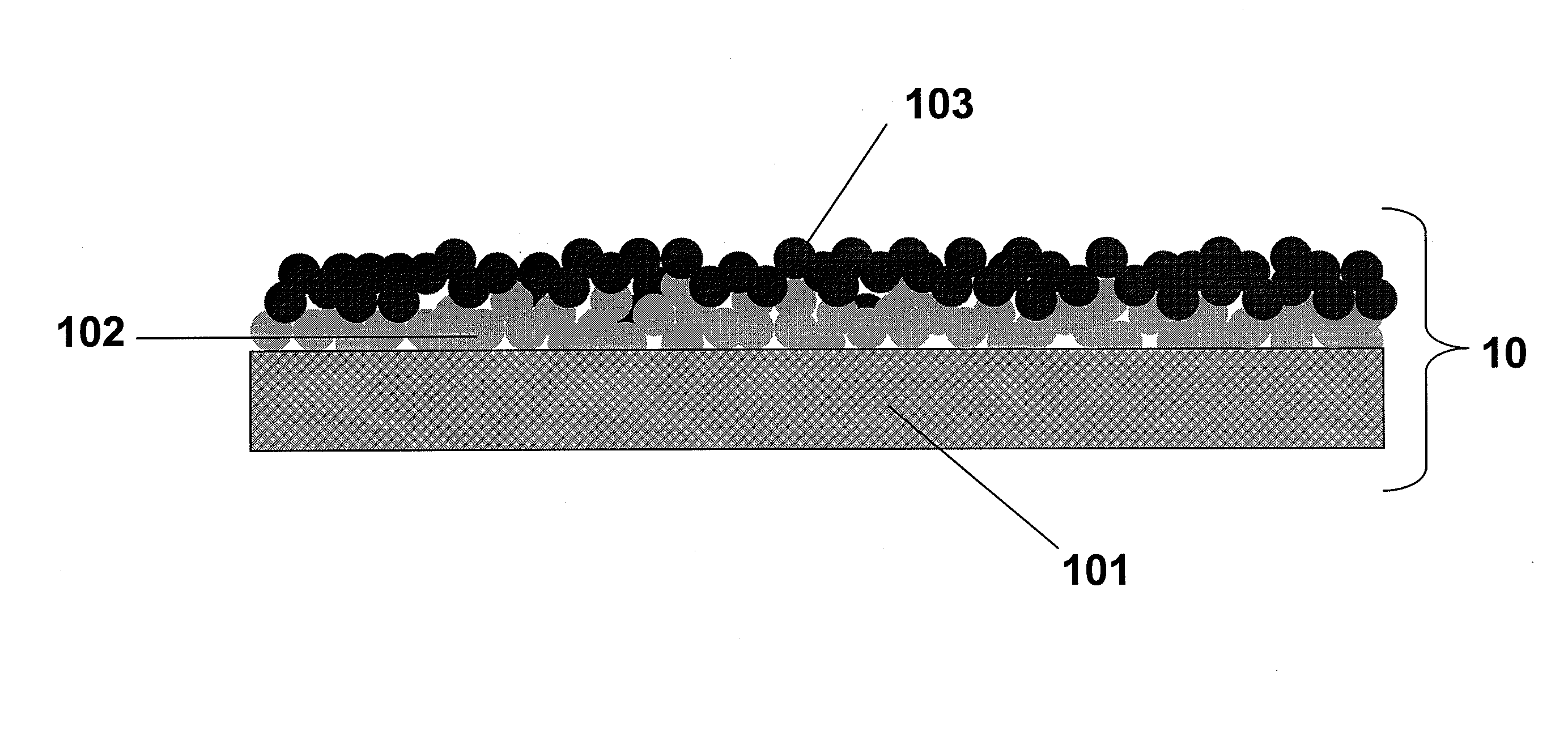

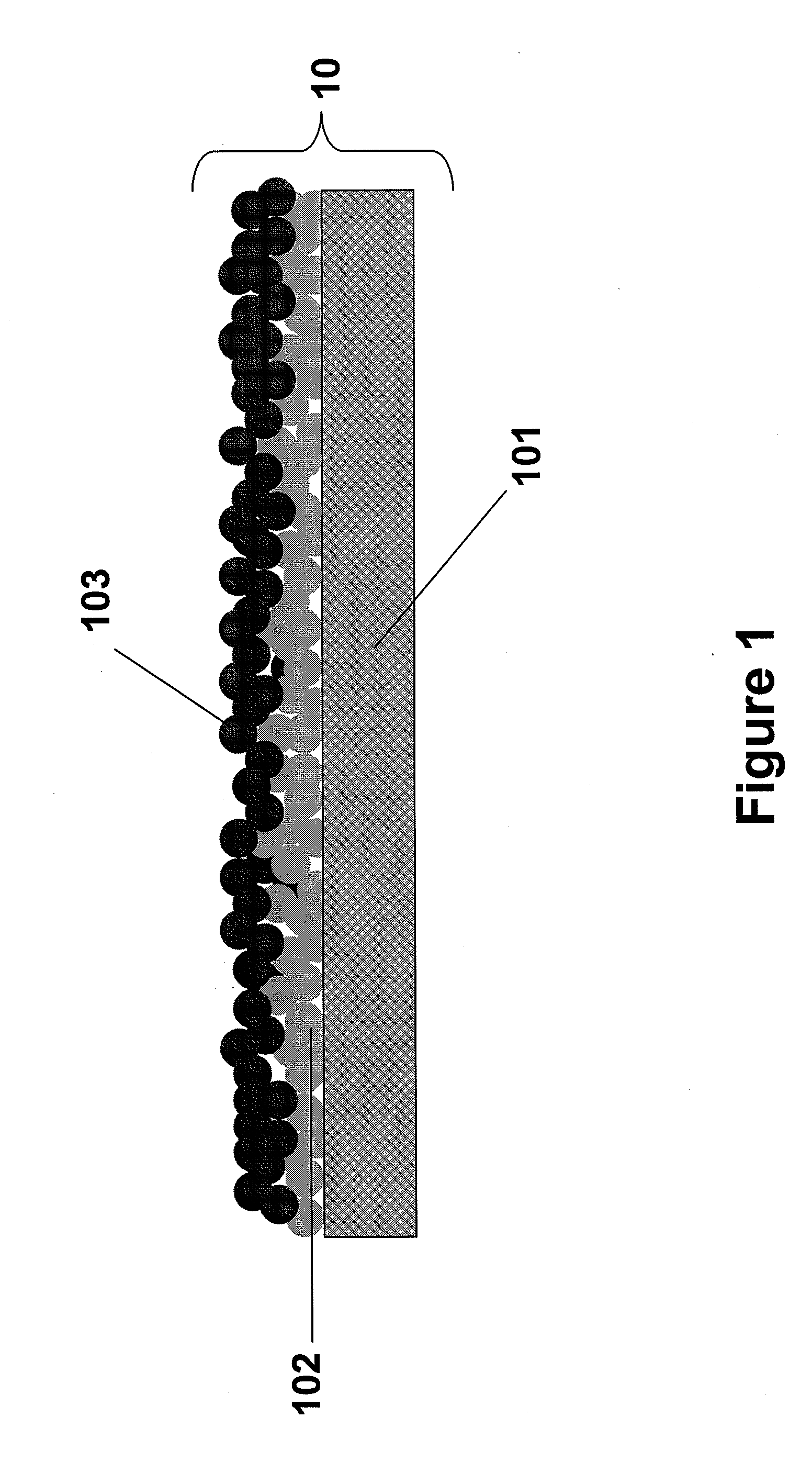

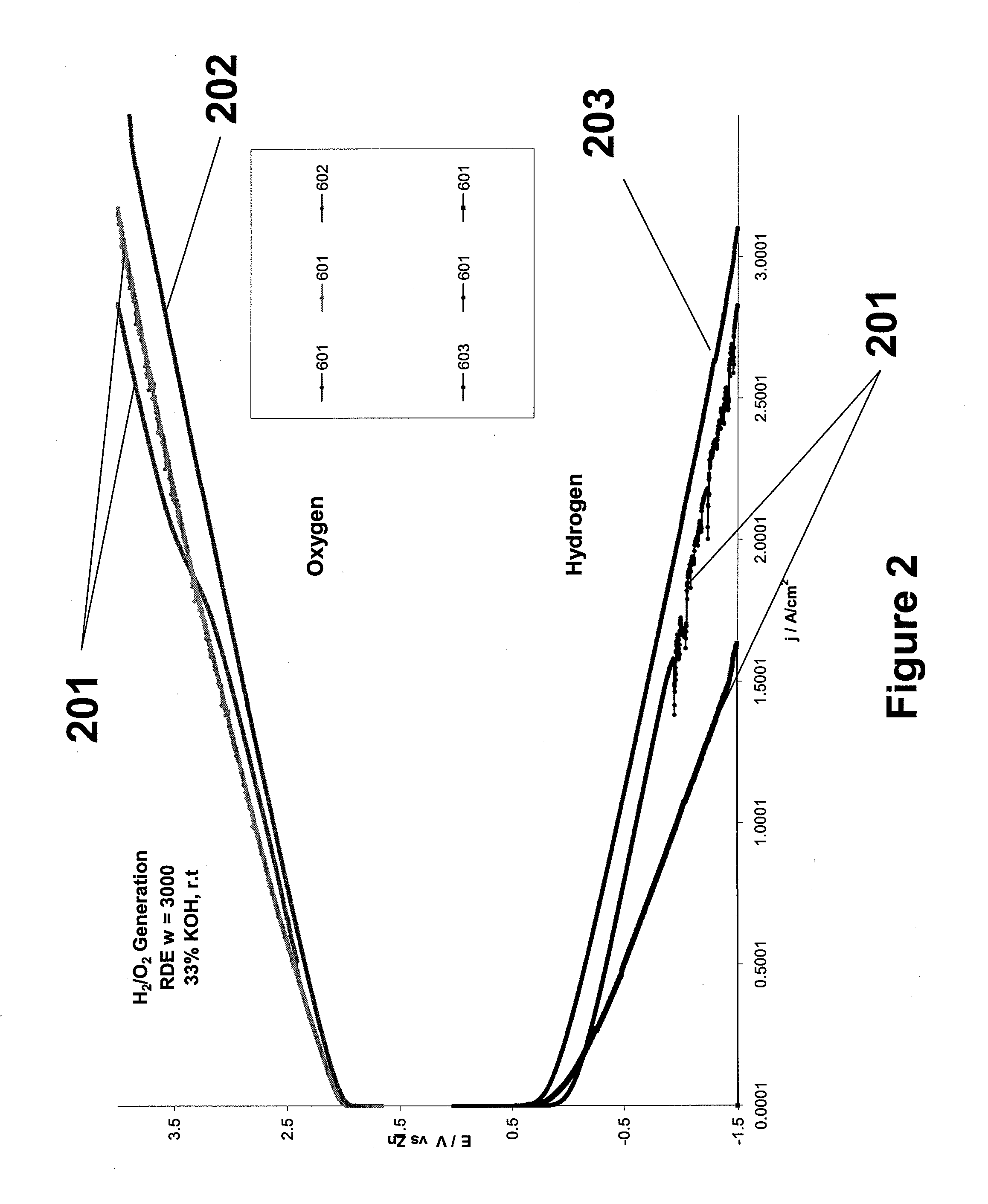

Nanoparticle coated electrode and method of manufacture

InactiveUS20090092887A1Increase surface areaFirmly connectedMachining electrodesMultiple component coatingsElectrolysisFuel cells

An electrode comprising a primary and secondary metal nanoparticle coating on a metallic substrate is prepared by dispersing nanoparticles in a solvent and layering them onto the substrate, followed by heating. The enhanced surface area of the electrode due to the catalytic nanoparticles is dramatically enhanced, allowing for increased reaction efficiency. The electrode can be used in one of many different applications; for example, as an electrode in an electrolysis device to generate hydrogen and oxygen, or a fuel cell.

Owner:BRICOLEUR PARTNERS LP

Method for Producing Wood Fibre Pellets

ActiveUS20090229771A1High strengthImprove compatibilityNon-fibrous pulp additionPaper/cardboardCelluloseOligomer

A process for producing pellets or granules comprising fibres of a lignocellulousic material, for use as a feedstock in plastics manufacture, conveying in a dry or wet air stream and applying to the fibres a liquid formulation comprising one or more polymers, monomers, or oligomers, forming the fibres into a solid product, and breaking down the solid product to produce said pellets or granules. Typically the conduit conveys the fibres in a plant for manufacture of fibre board.

Owner:NEW ZEALAND FOREST RES INST

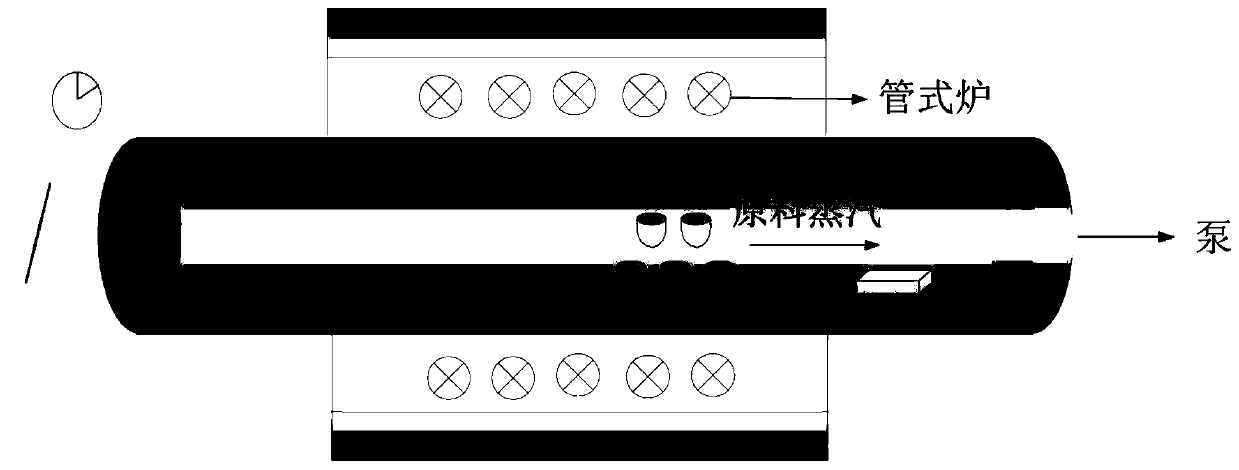

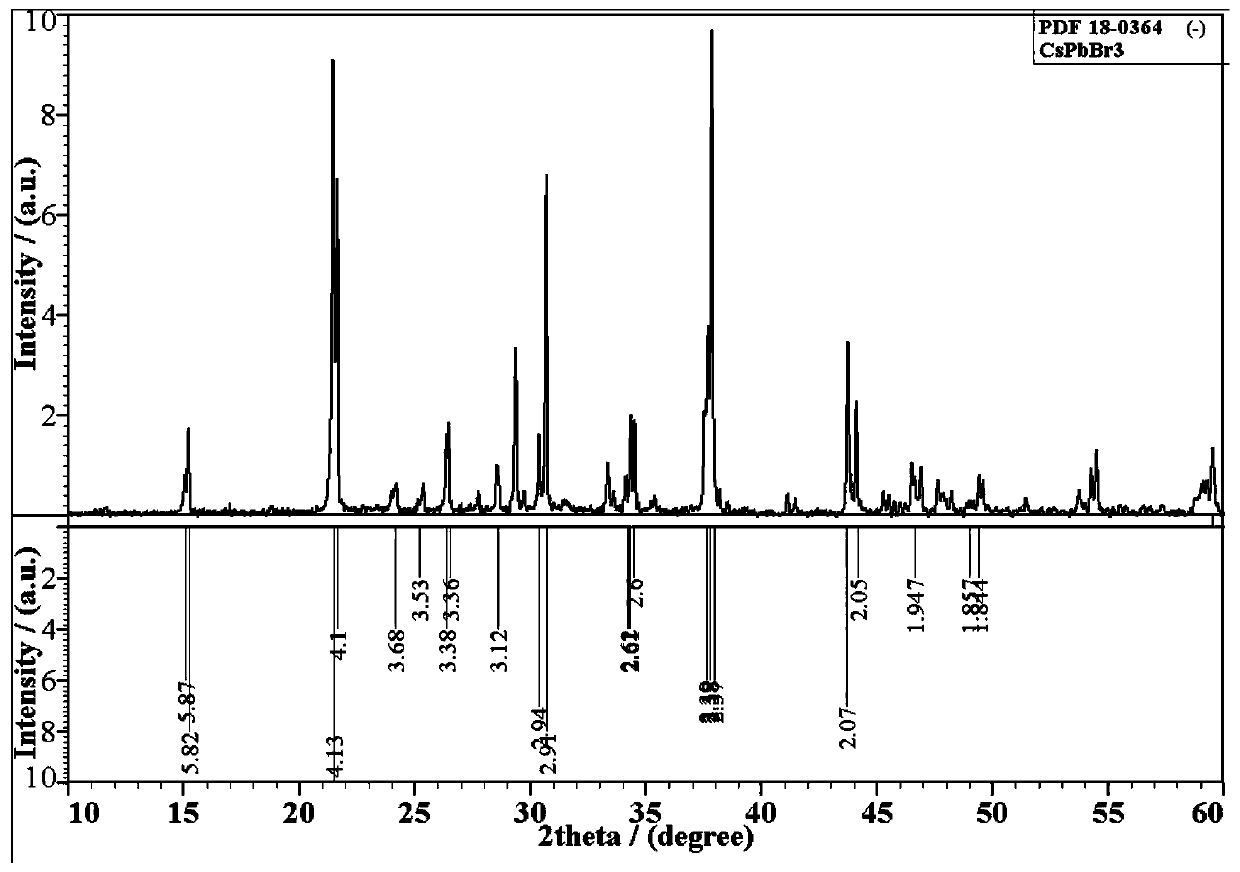

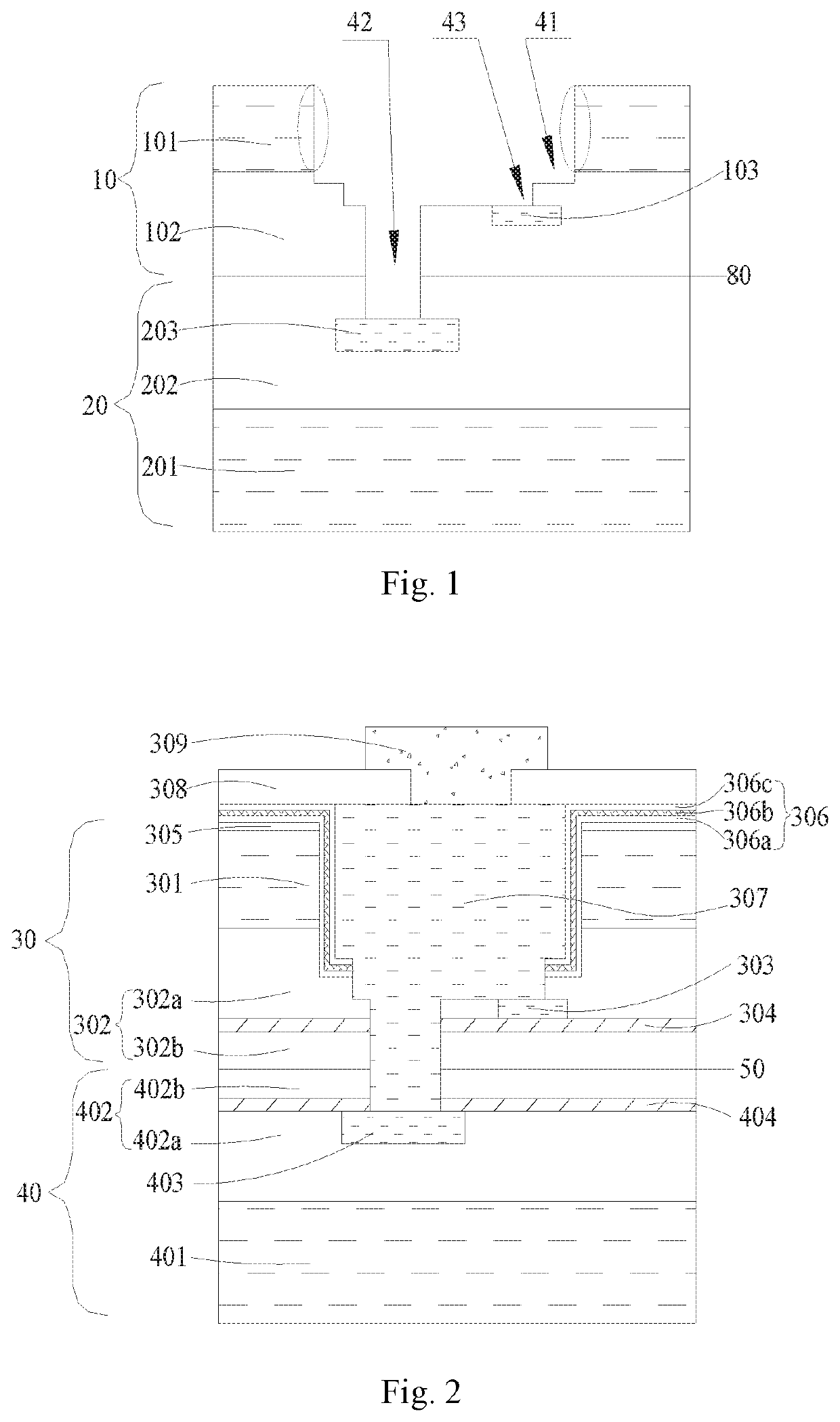

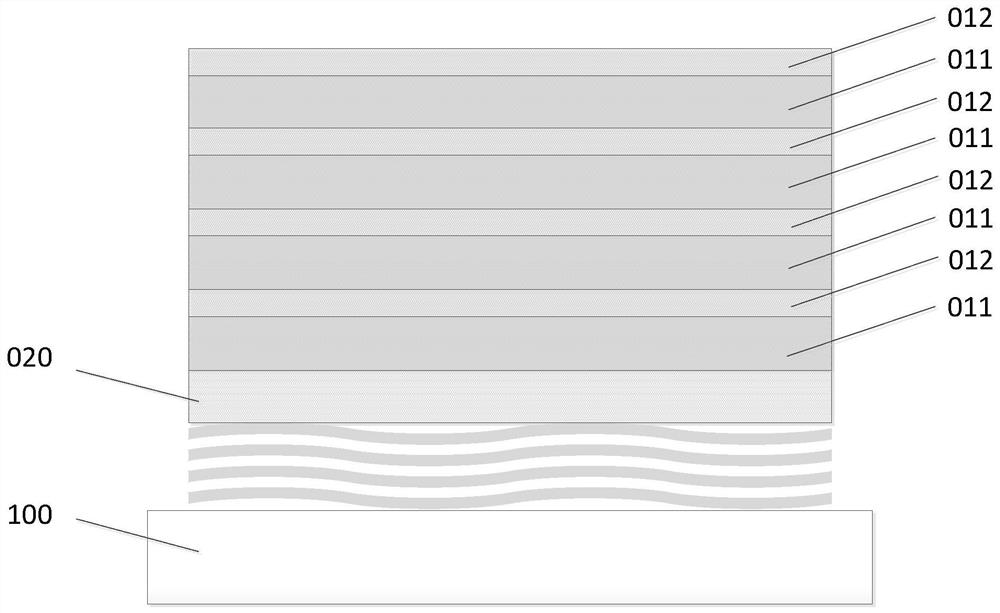

Preparation method of large-size mono-crystal perovskite film

ActiveCN105957970ASmall sizeHighly crystallineSolid-state devicesSemiconductor/solid-state device manufacturingGas phaseEvaporation

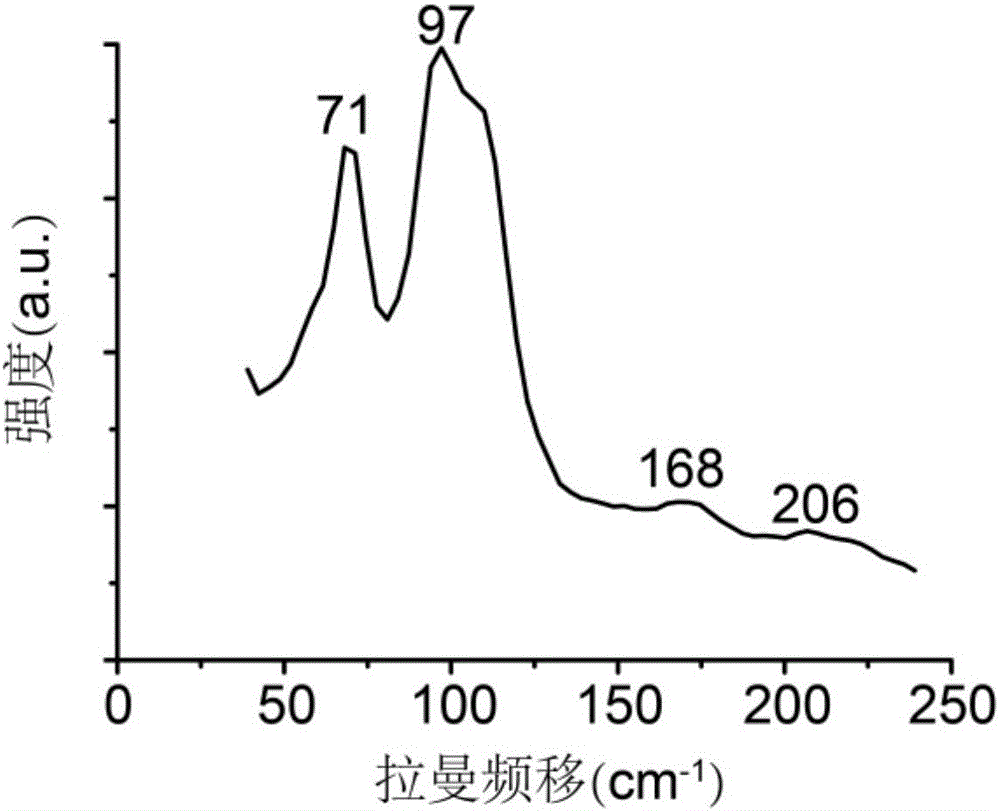

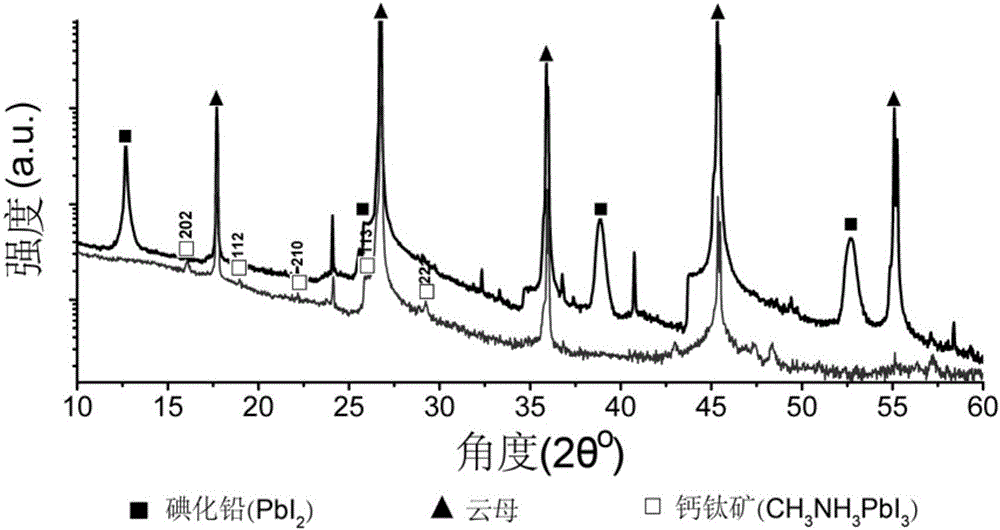

The invention relates to a preparation method of a large-size mono-crystal film, particularly relates to a preparation method of a large-size mono-crystal perovskite film and aims to solve a problem of low electrical performance caused by small mono-crystal size and poor crystallization quality of a perovskite film prepared through the technology in the prior art. According to the method, an organic predecessor and an inorganic predecessor are utilized, heating evaporation is realized to carry out gas phase reaction, and the large-size mono-crystal perovskite film is prepared on a substrate. Through the method, the large-size mono-crystal perovskite film with large size and high crystallization quality can be prepared, precise control on physical properties such as size, thickness and components of the film can be realized, and the large-size mono-crystal perovskite film prepared through the method can be applied to flexible solar energy cells, laser devices and LED devices.

Owner:海南睿德医疗器械有限公司

Silane-modified biopolymeric, biooligomeric, oxidic or siliceous filler, process for its production and its use

InactiveUS6893495B2Good surface coverageImprove dynamic performanceSilicaPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPolymer scienceSilanes

Silane-modified biopolymeric, biooligomeric, oxidic or siliceous filler obtainable by reacting at least one biopolymeric, biooligomeric, oxidic or siliceous filler in a compressed gas with at least one silane. The silane-modified biopolymeric, biooligomeric, oxidic or siliceous fillers are used in rubber compounds.

Owner:EVONIK DEGUSSA GMBH

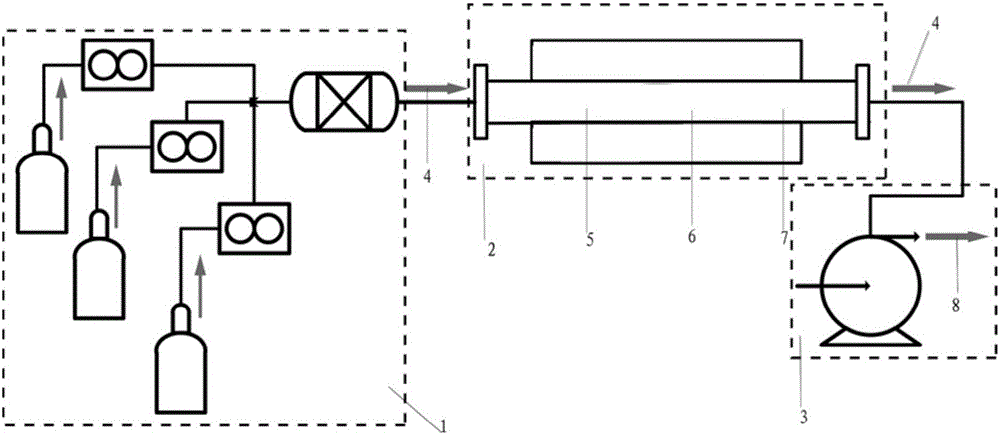

Method for using chemical vapor deposition method to prepare perovskite film solar cell

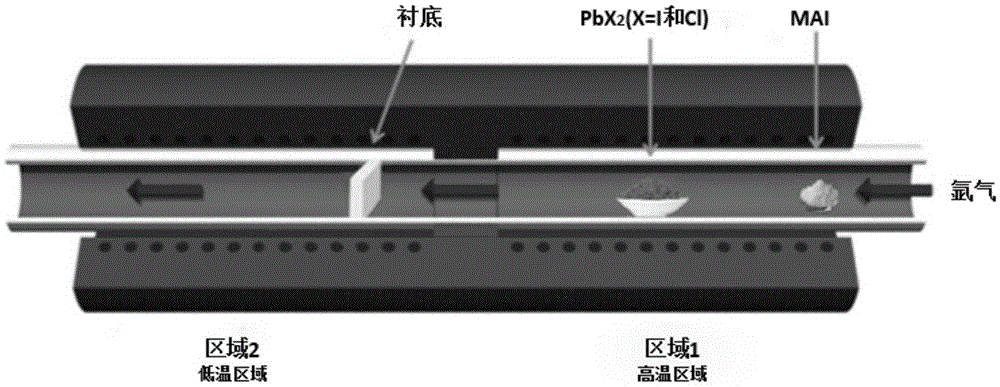

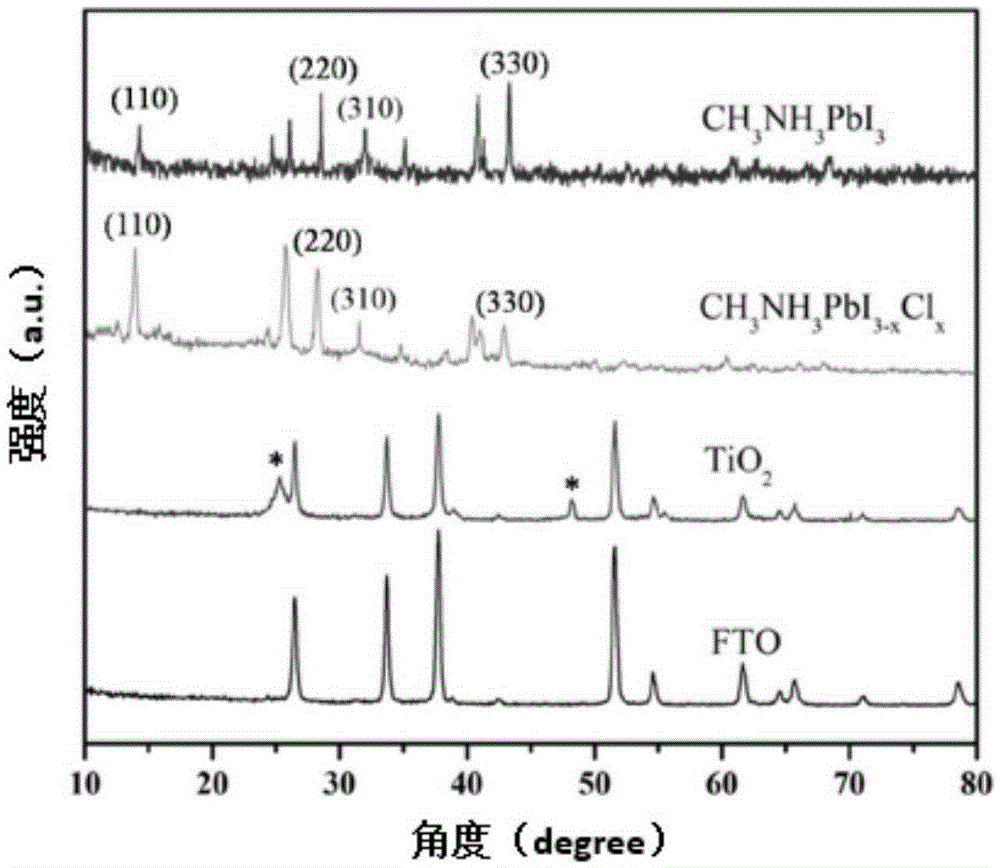

InactiveCN105355794AGood surface coverageLarge grainSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellGas phase

The invention discloses a method for using a chemical vapor deposition method to prepare a perovskite film solar cell. The method comprises the following steps of: (1) pre-processing a substrate; (2) coating a TiO2 compact layer on the surface of the substrate after the pre-processing; (3) using a one-step method to prepare a perovskite material layer; (4) carrying out spin coating on the perovskite material layer so as to prepare a Spiro-OMeTAD solar cell cavity transmission layer; and (5) drying a device prepared by the steps (1)-(4), completing cathode metal electrode deposition, and obtaining the perovskite film solar cell. According to the invention, a simple gas phase transmission method is utilized, the simple one-step chemical vapor deposition (CVD) method is developed, the halide perovskite solar cell is prepared without depending on high vacuum equipment, and the energy conversion efficiency exceeds 11%.

Owner:PKU HKUST SHENZHEN HONGKONG INSTITUTION

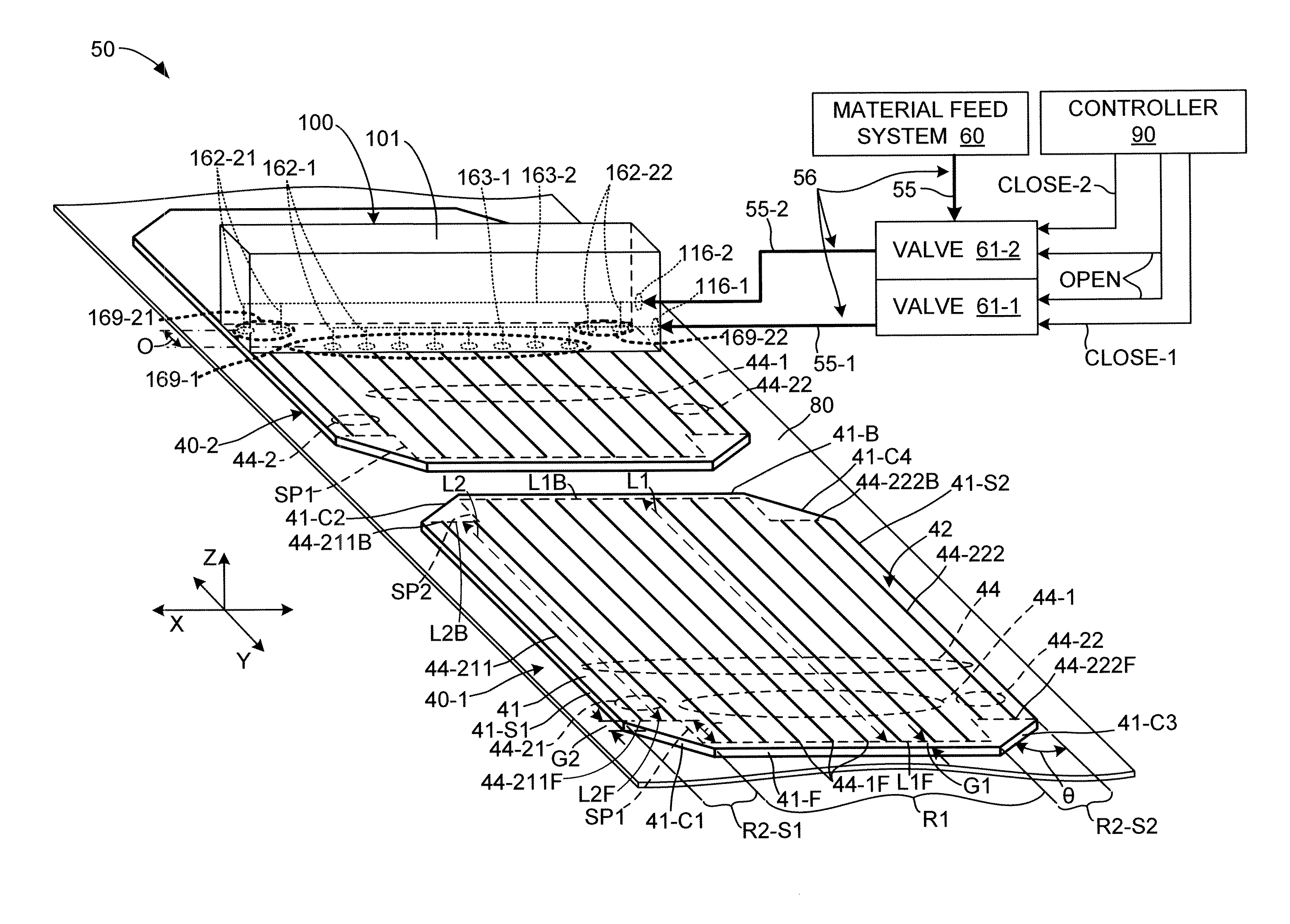

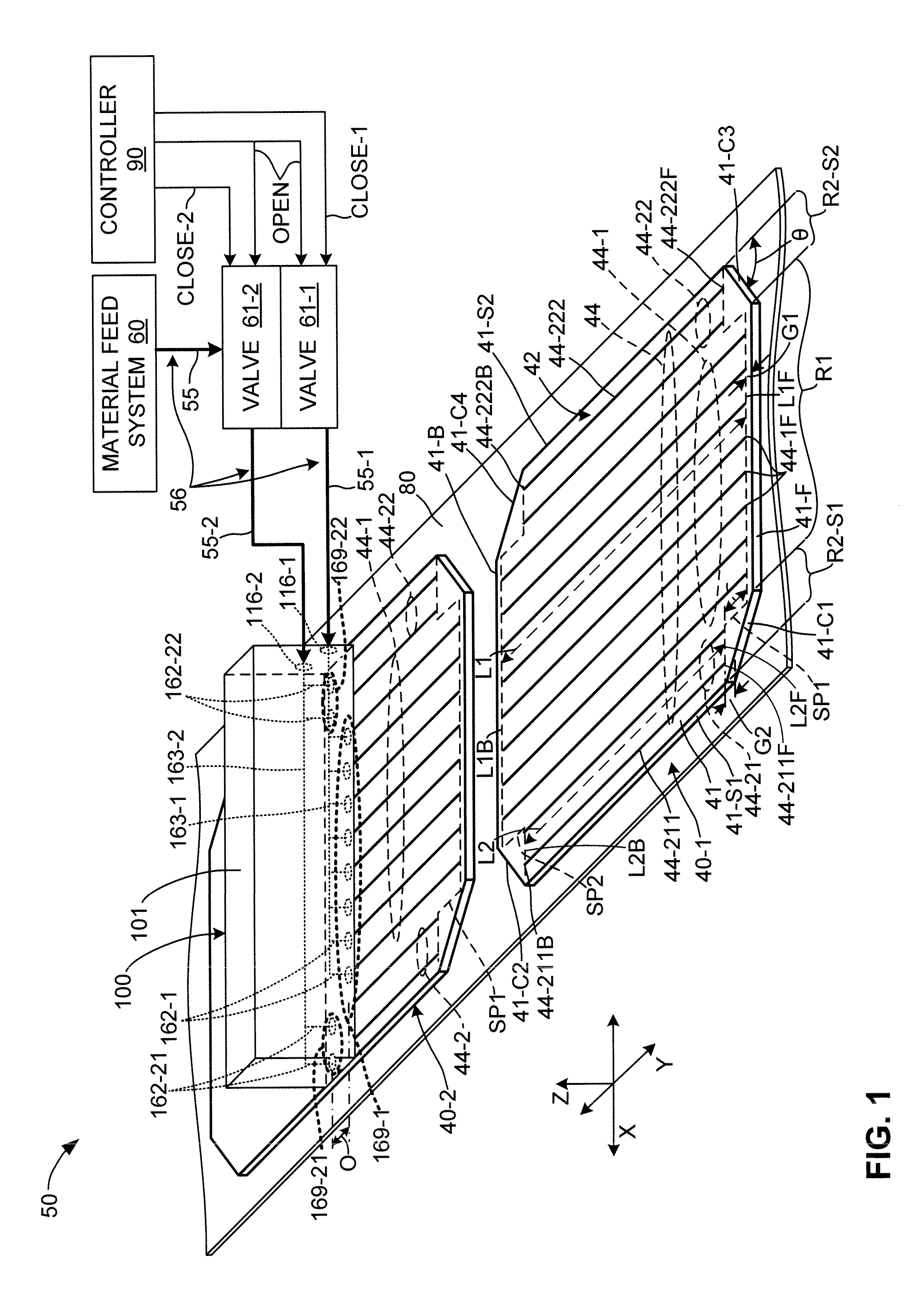

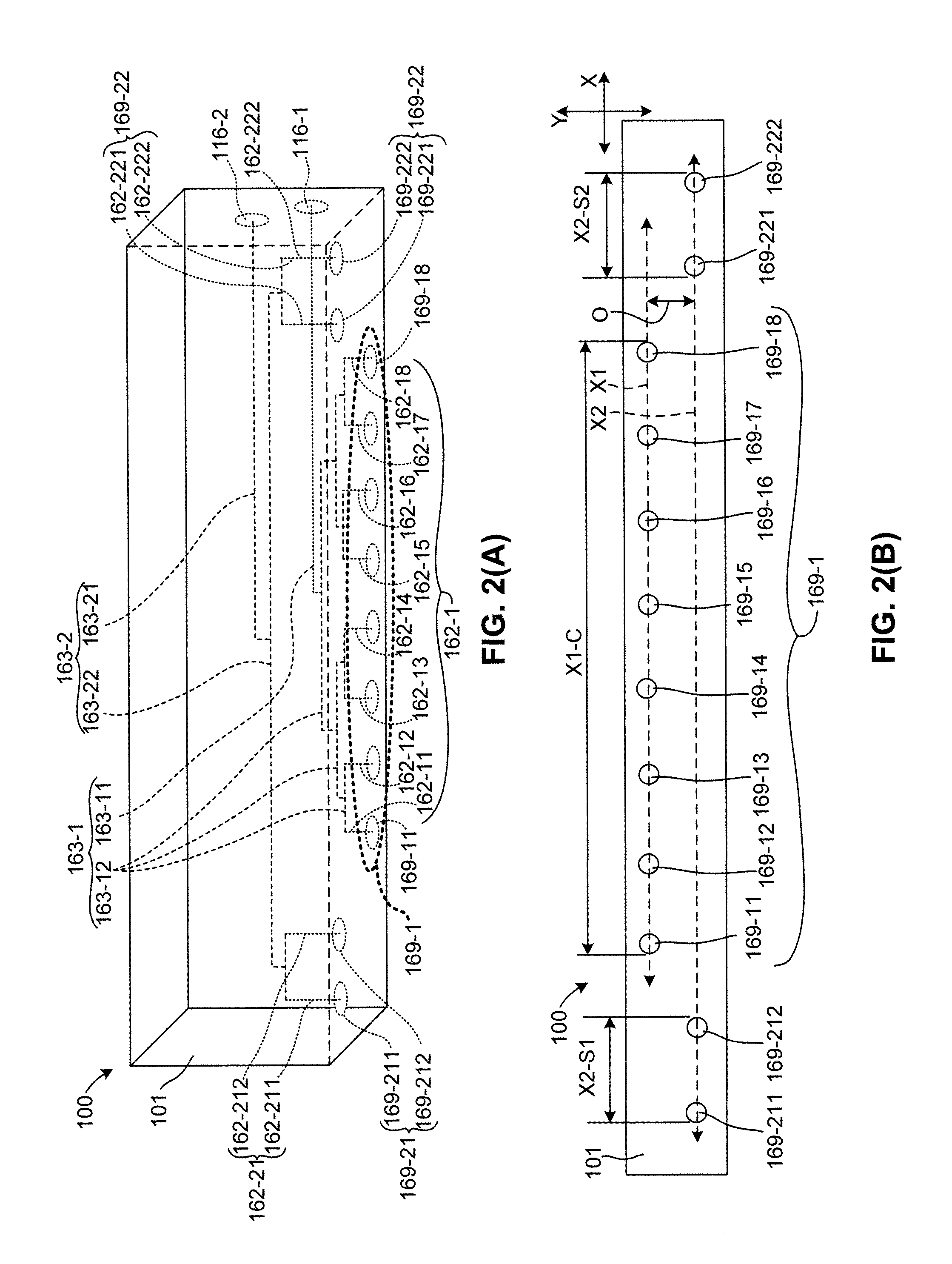

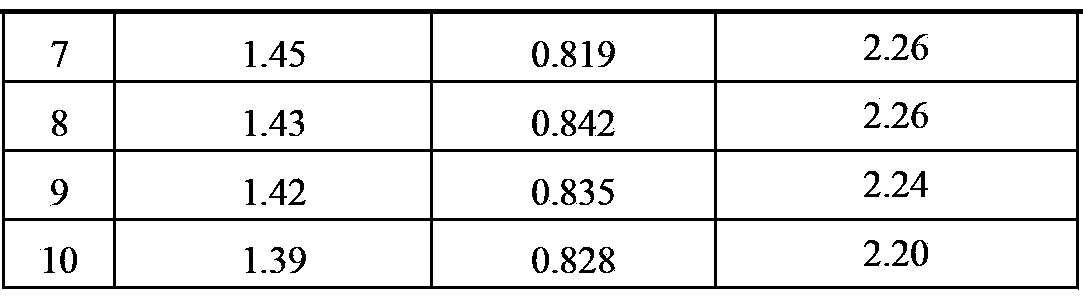

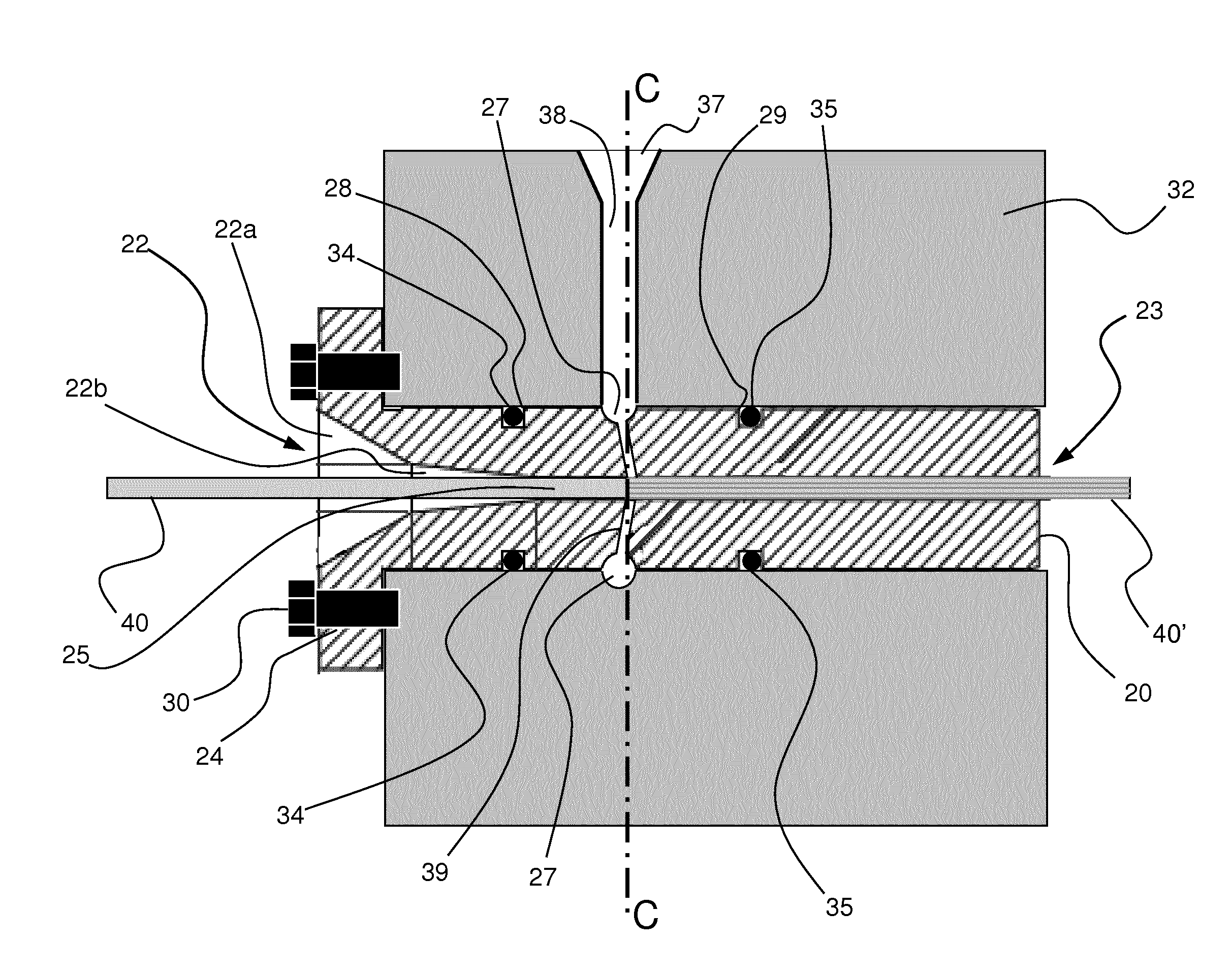

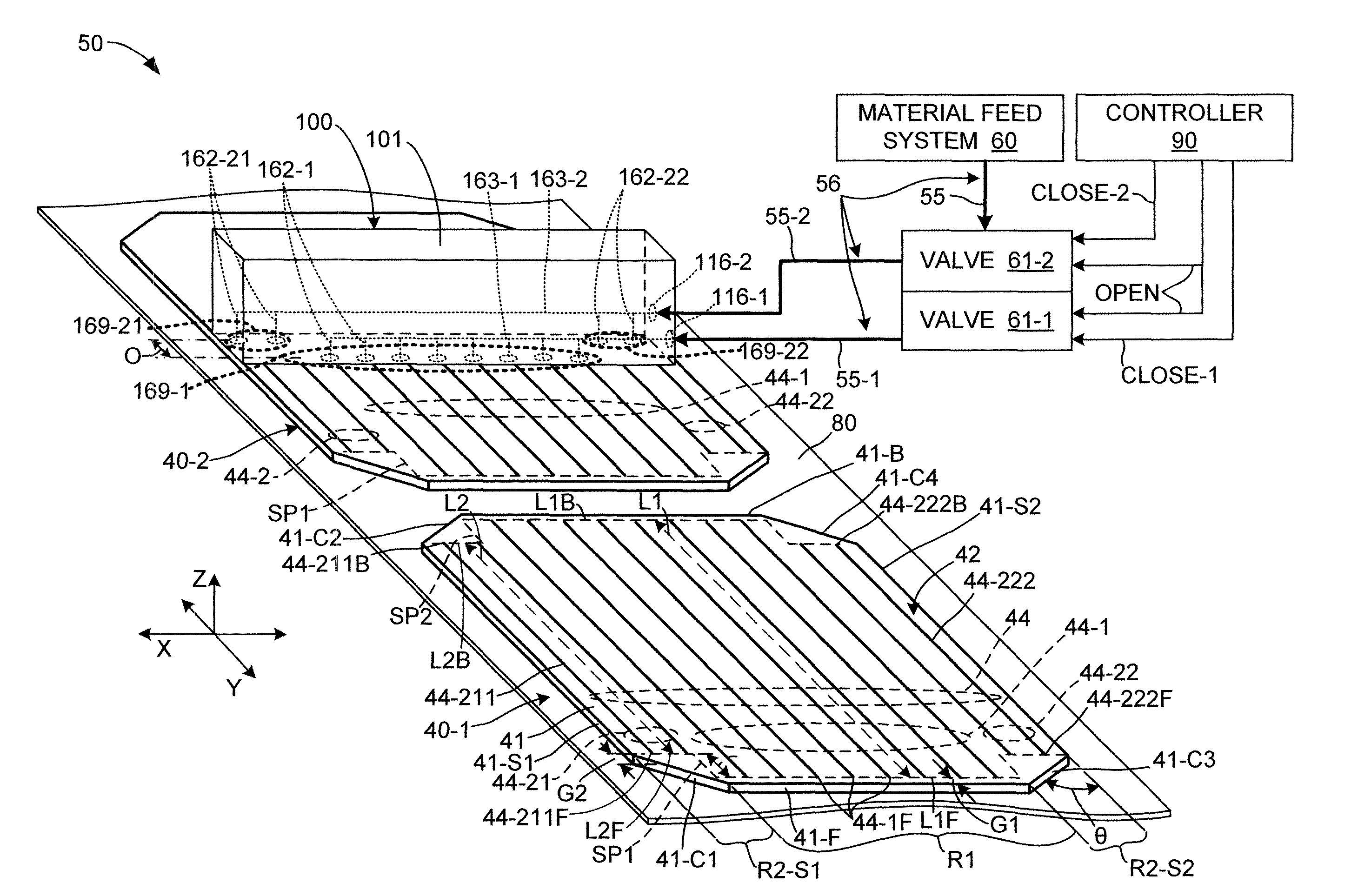

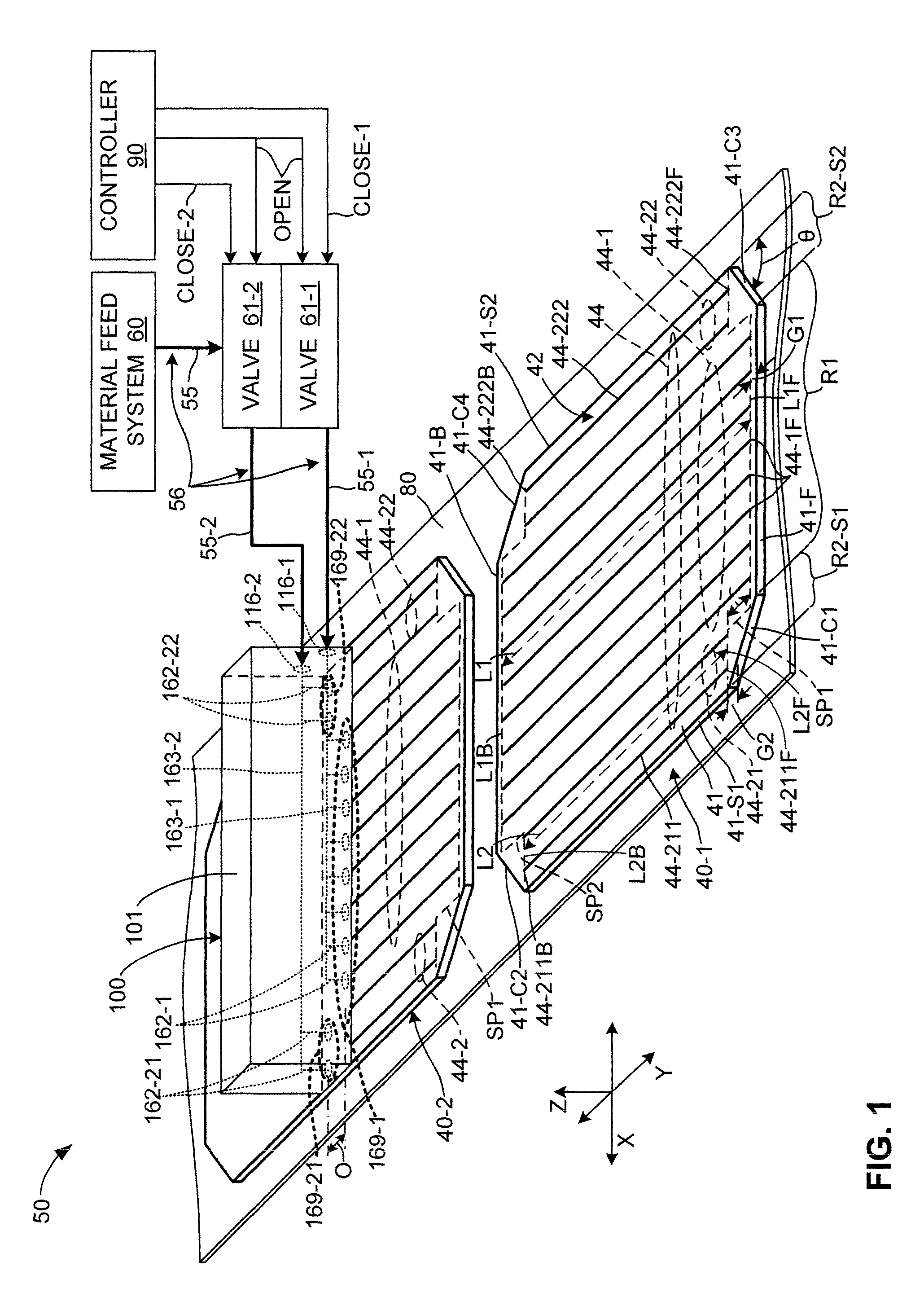

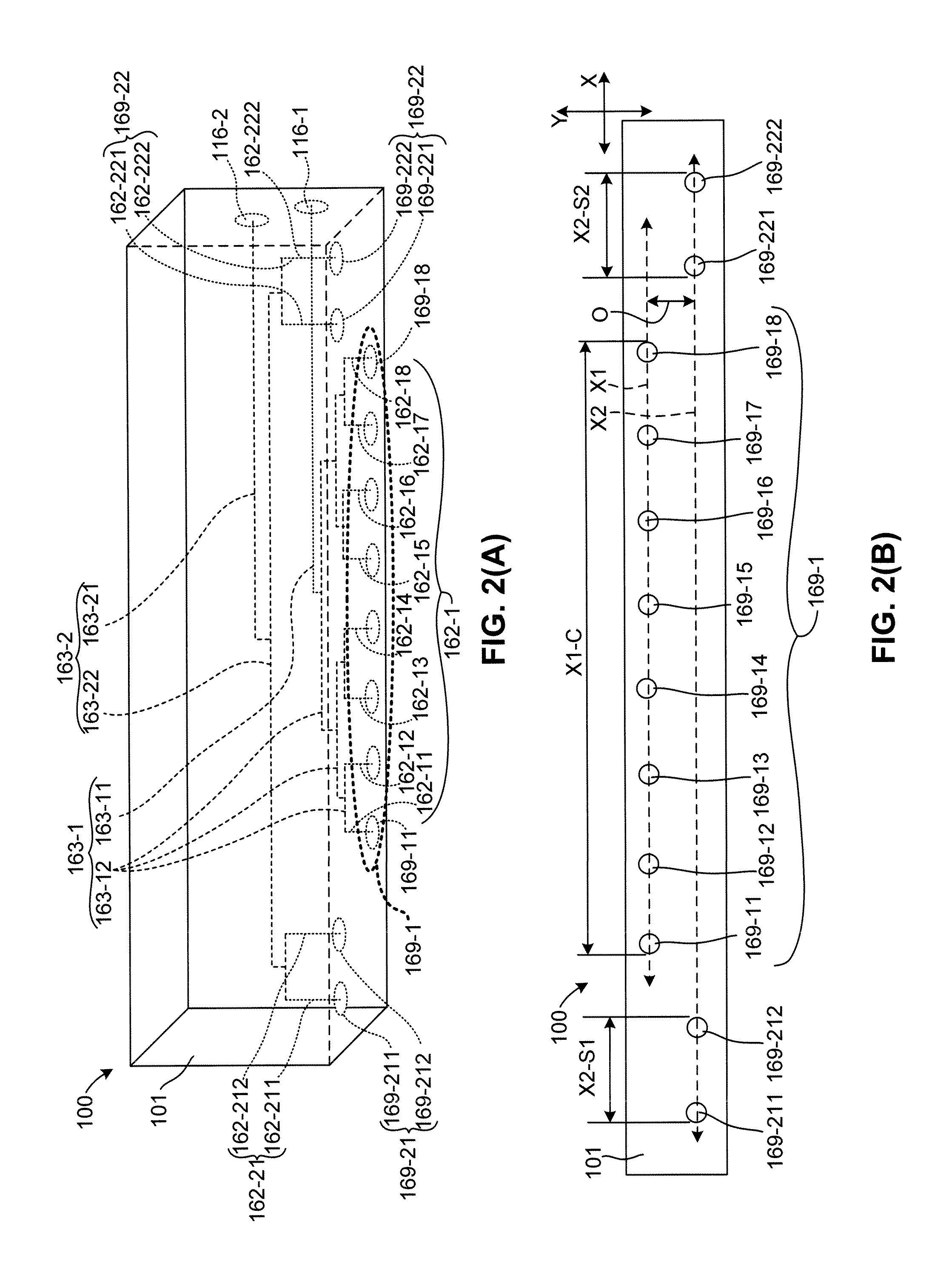

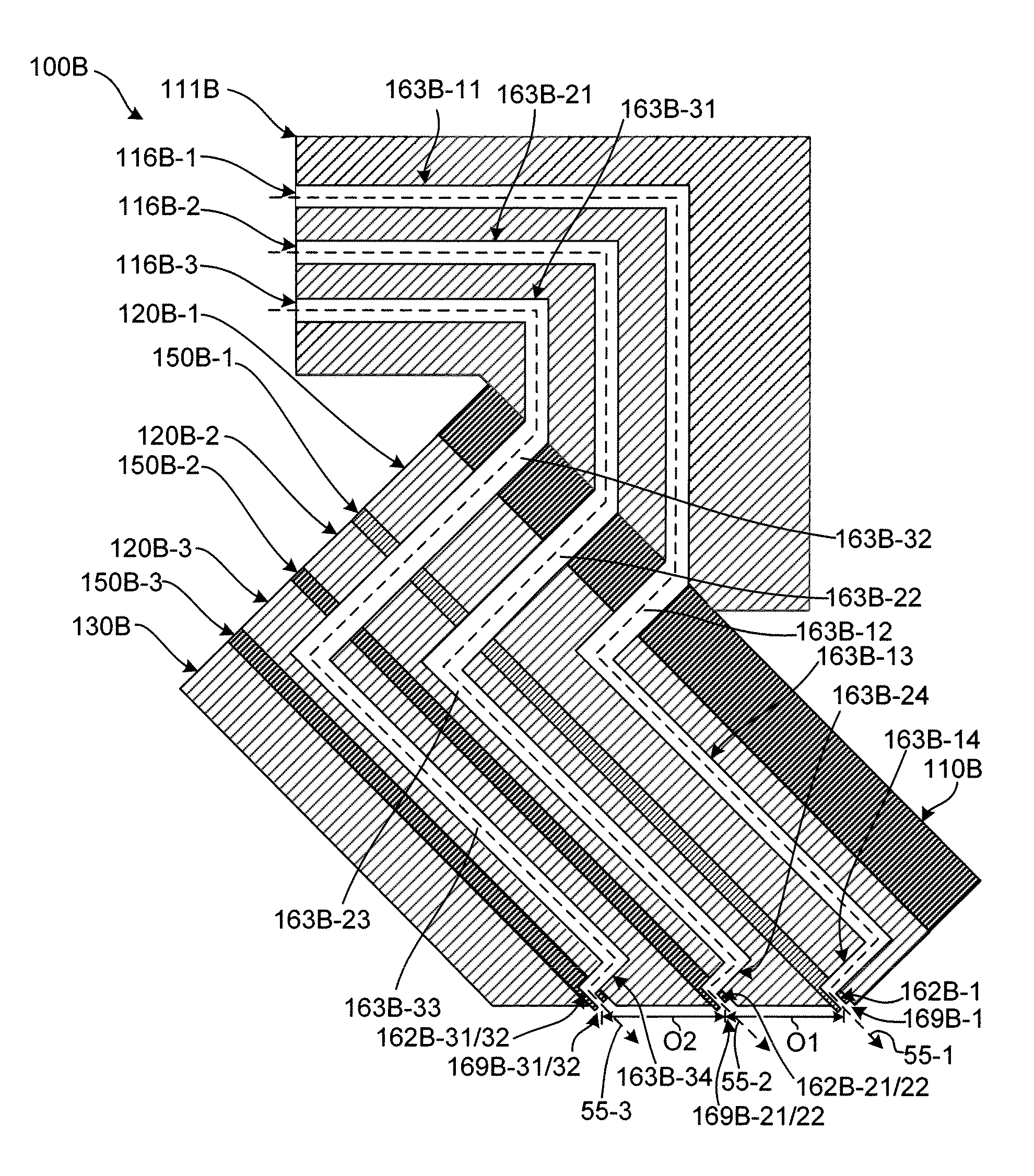

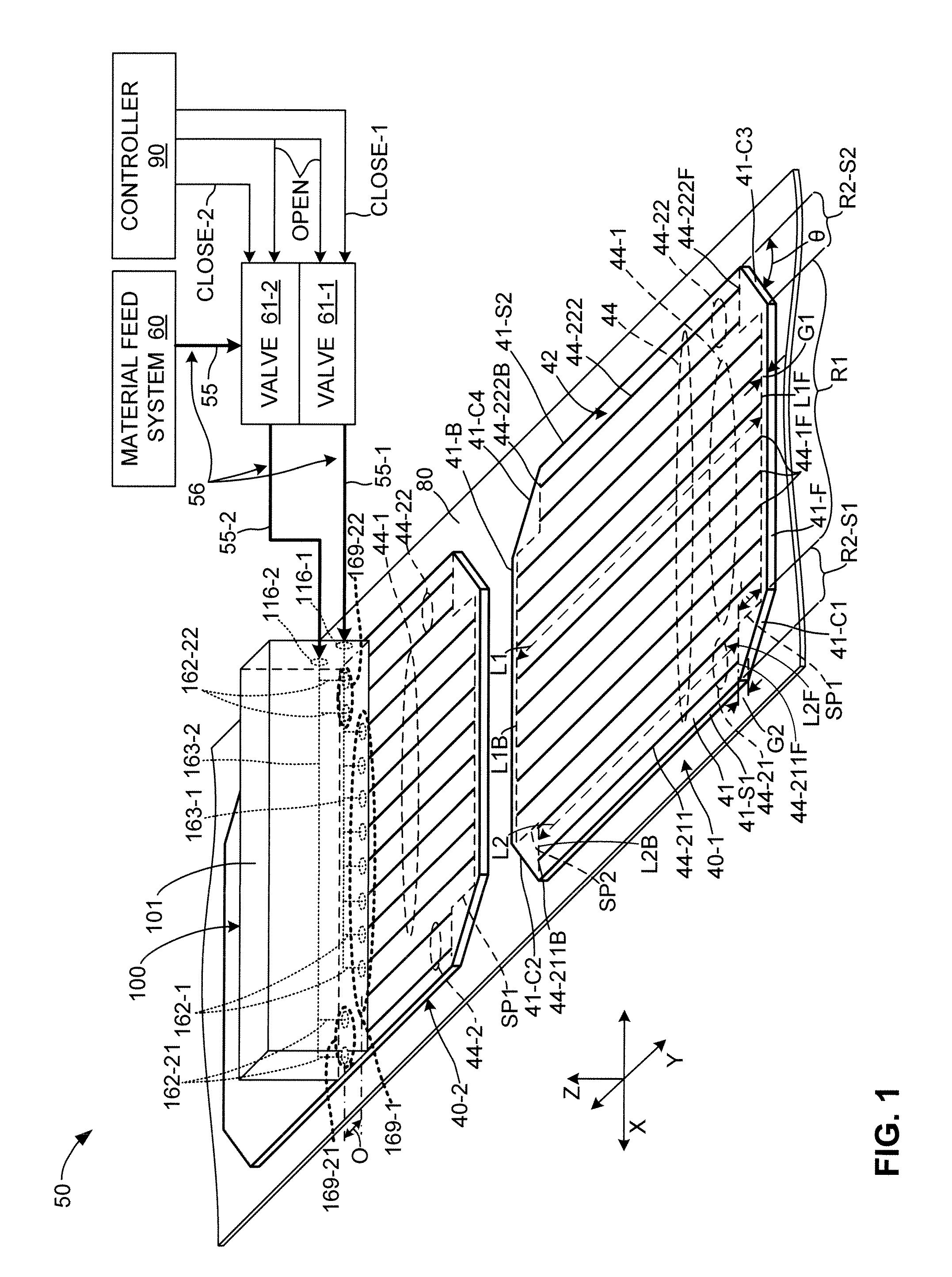

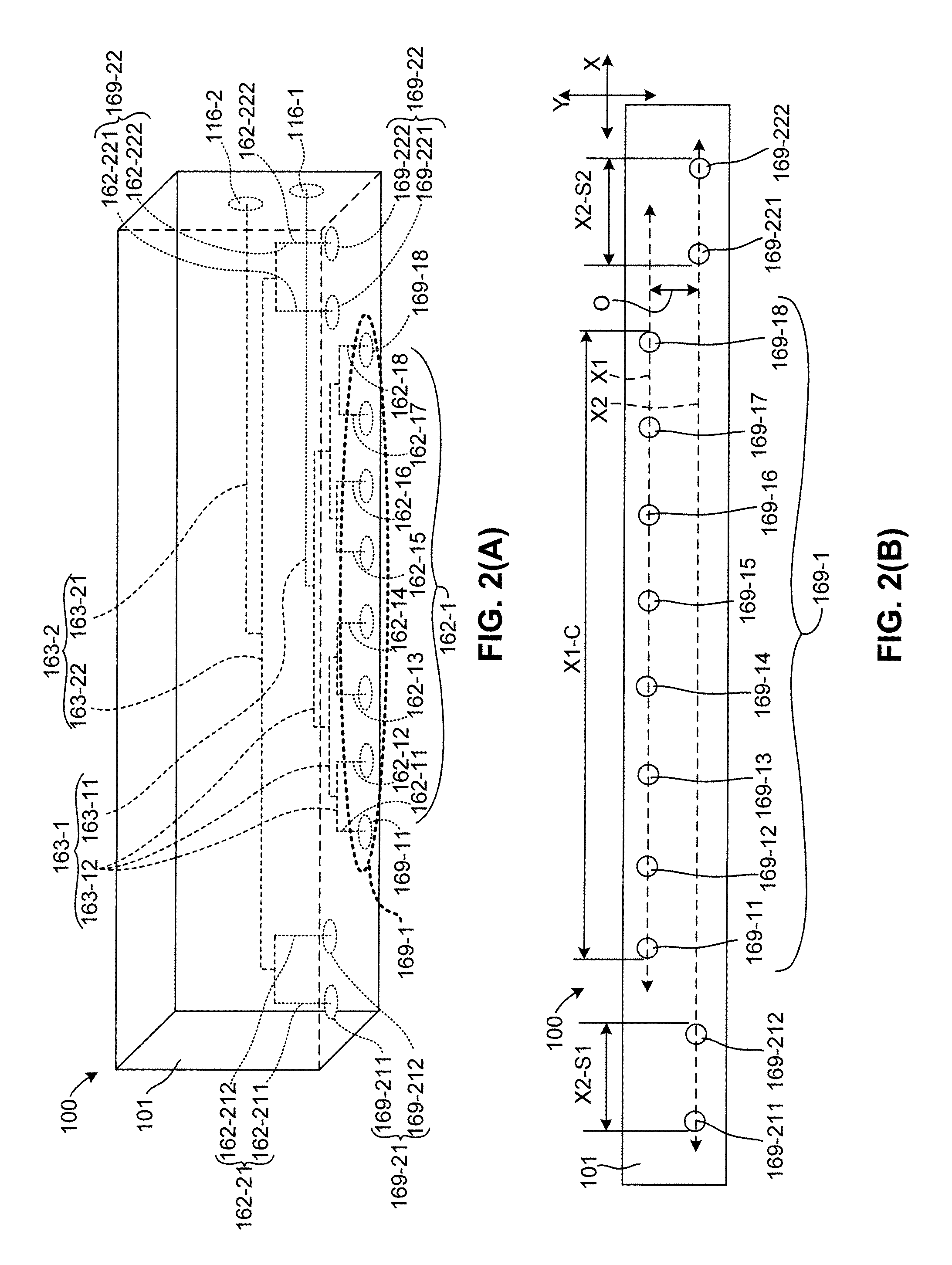

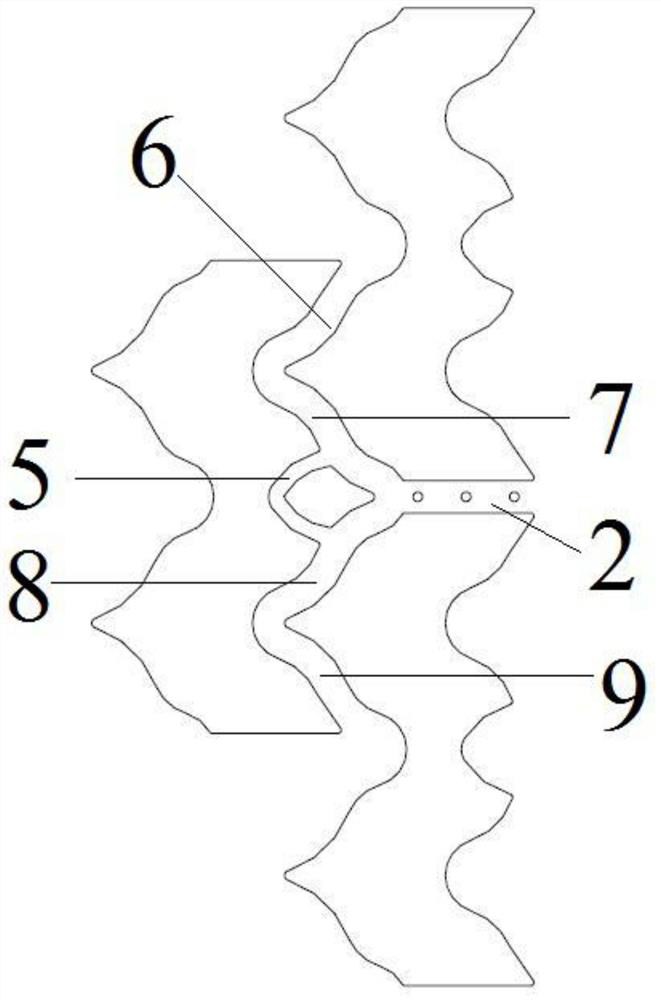

Micro-Extrusion Printhead With Offset Orifices For Generating Gridlines On Non-Square Substrates

ActiveUS20130206062A1Offset distance is facilitatedLow costLiquid surface applicatorsLiquid spraying apparatusStart signalSolar cell

A solar cell extrusion printing system that uses a micro-extrusion printhead to print longer central gridlines and one or more pairs of shorter “side” gridlines such that end points of the gridline sets form step patterns on an octagonal (pseudo-square) substrate. The printhead includes a set of central nozzles that receive ink from a first valve by way of a first flow channel to print the longer central gridlines, and additional sets of side nozzles that receive ink from additional valves by way of additional flow channels to print the shorter “side” gridlines. The central nozzles have outlet orifices that offset in the process direction from side outlet orifices of the side nozzles. A start signal is simultaneously sent to the valves such that ink is substantially simultaneously extruded through both the central and side orifices, whereby the extruded ink produces gridline endpoints having the desired step pattern.

Owner:PALO ALTO RES CENT INC

Silane-modified biopolymeric, biooligomeric, oxidic or siliceous filler, process for its production and its use

InactiveUS7208038B2Good surface coverageImprove dynamic performanceSilicaPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPolymer scienceBiopolymer

Owner:EVONIK DEGUSSA GMBH

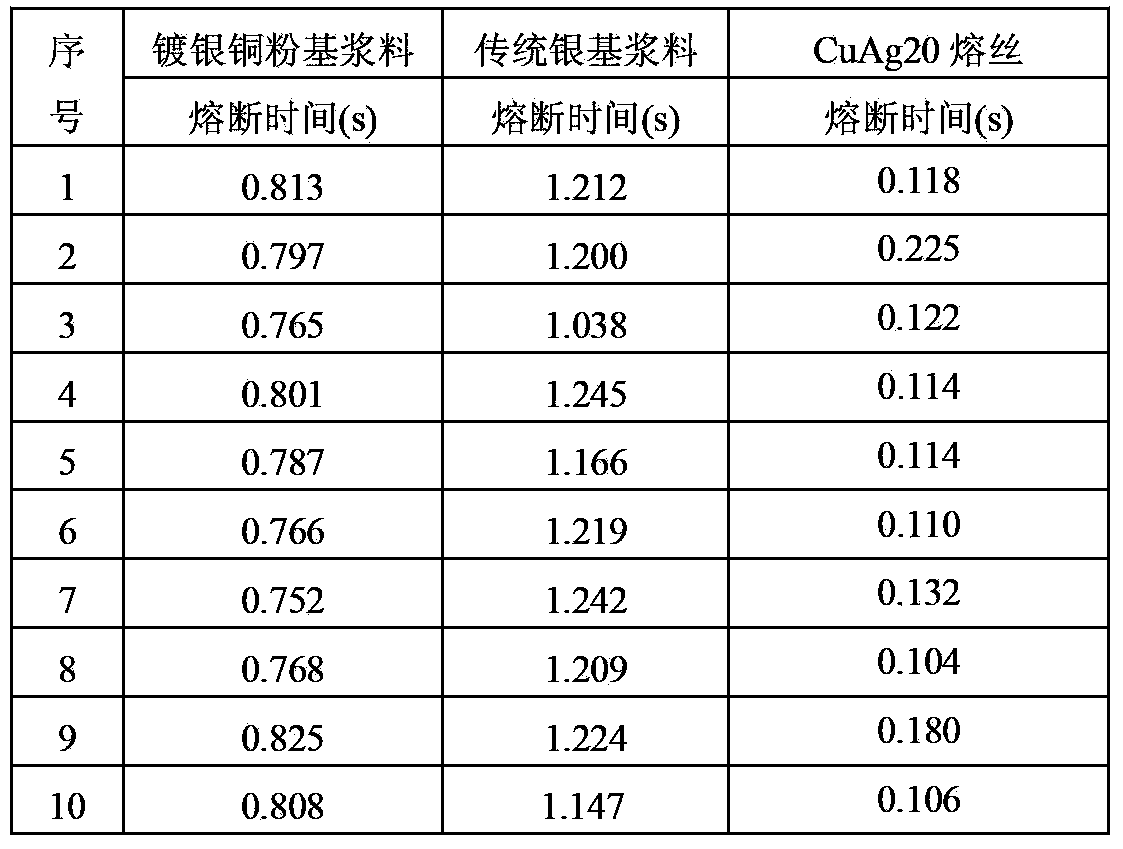

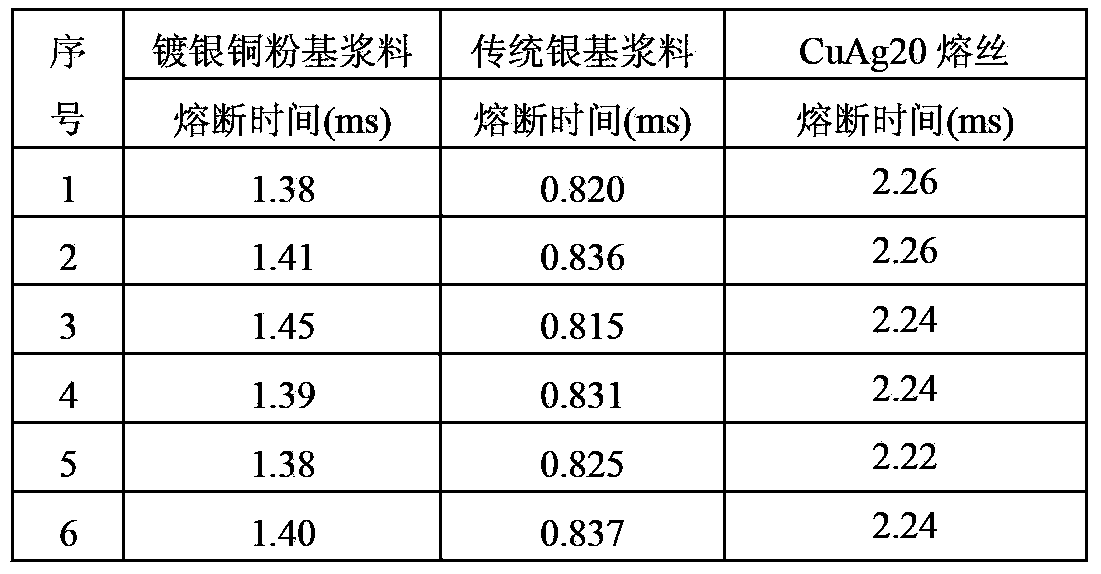

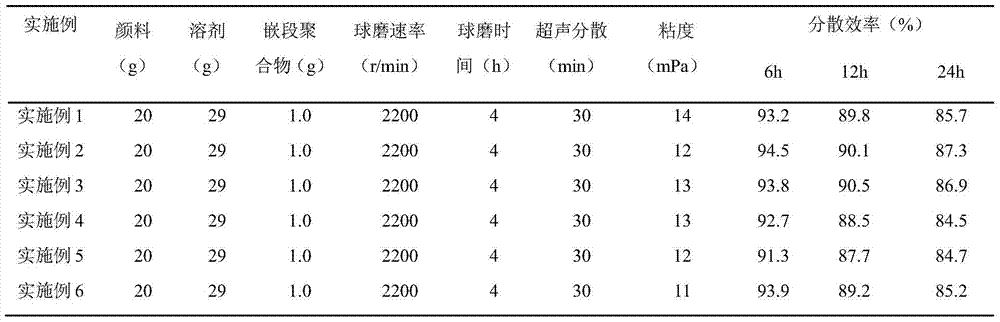

Electronic paste for fuse link of surface-mount fuse and preparation method thereof

ActiveCN103413591AImprove anti-pulse abilityPrevent oxidationNon-conductive material with dispersed conductive materialEmergency protective devicesWater bathsSilver paste

The invention relates to electronic paste and a preparation method of the electronic paste. The electronic paste comprises, by weight, 30-70% of silver-plated copper powder or silver-plated nickel powder, 0-40% of nano-silver powder, 3-15% of organic solvent, 5-12% of macromolecule resin and 2-10% of inorganic additive. The preparation method of the electronic paste comprises the steps of (1) weighing the macromolecule resin and the organic solvent in proportion, placing the macromolecule resin and the organic solvent into a container, placing the container into a thermostatic water bath, evenly mixing the macromolecule resin and the organic solvent to obtain an organic carrier, and (2) weighing the silver-plated copper powder or the silver-plated nickel powder, the nano-silver powder and the inorganic additives in proportion, adding the silver-plated copper powder or the silver-plated nickel powder, the nano-silver powder and the inorganic additives to the organic carrier obtained in the step (1), carrying out grinding and rolling to meet the requirement of the fineness to achieve even distribution of the solid-phase powder in the organic carrier. The preparation method of the electronic paste is simple, high in production efficiency and low in cost. When the obtained electronic paste is used for printing a fuse link structure of a surface-mount fuse, and compared with traditional silver paste, the pulse resistant capacity is greatly improved.

Owner:NANJING SART SCI & TECH DEV

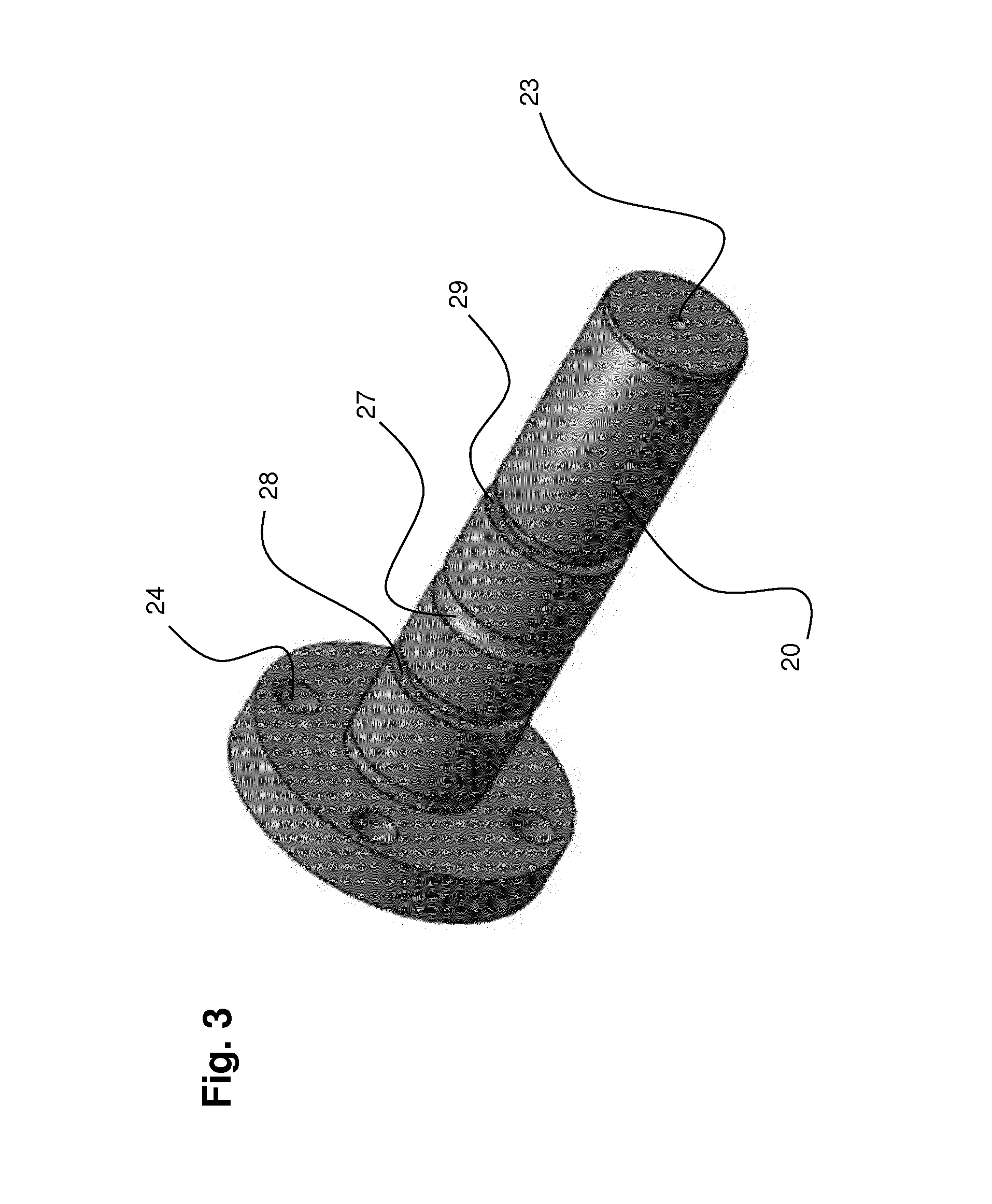

Method and device for manufacturing of a fibre-reinforced polymer composition

ActiveUS20150246463A1Efficient impregnationReduce the amount requiredLiquid surface applicatorsCoatingsPolymer scienceViscosity

The present invention is directed to a method of manufacturing a fibre-reinforced polymer composition comprising the steps of providing at least one multifilament strand comprising a plurality of continuous fibre filaments (5), applying an impregnating agent (10) to said strand to form an impregnated continuous multifilament strand, and embedding the impregnated continuous multifilament strand in a thermoplastic polymer material (3) for providing said fibre reinforced polymer composition, wherein said impregnating agent has a low viscosity at application temperature and is applied by jetting said impregnating agent onto the at least one continuous multifilament strand. The invention is further directed to a device (20) for use in such a method.

Owner:SAUDI BASIC IND CORP SA

Preparation method of lead-based halogen perovskite film for high-energy ray detection

ActiveCN110016646AQuality improvementHigh crystallinityFinal product manufactureVacuum evaporation coatingHigh energyGas phase

The invention discloses a preparation method of a lead-based halogen inorganic perovskite film for high-energy ray detection. According to the method, precursor raw materials are obtained through component regulation, the precursor raw materials are evenly mixed and then dispersed to serve as a plurality of evaporation sources, the proportions of all elements of the precursor raw materials in eachevaporation source keep unchanged, and thus vapor-phase transfer deposition preparation of the perovskite film is achieved through a homologous multi-branch co-evaporation method. An appropriate quantity of component raw materials are added in the deposition process of the vapor-phase transfer deposition method, and meanwhile the homologous multi-branch co-evaporation method is adopted, so that the inorganic perovskite thick film suitable for high-energy ray detection and other purposes can be prepared. Through the method, operation is simple, the prepared perovskite thick film has large thickness, large grains, good uniformity and good surface covering performance, and a semiconductor detector good in performance and excellent in stability can be manufactured.

Owner:HUAZHONG UNIV OF SCI & TECH

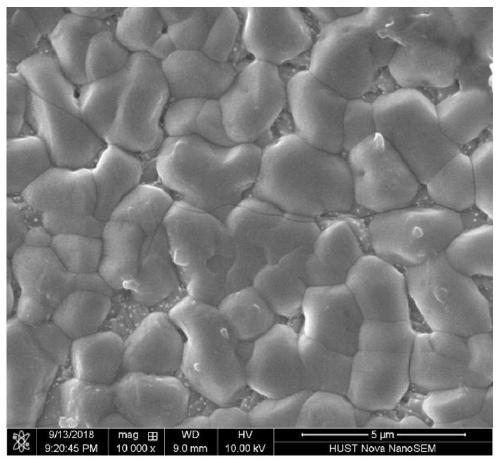

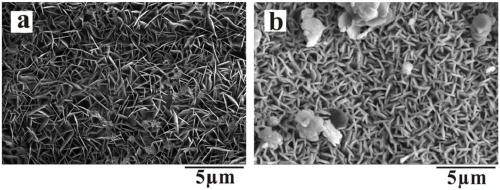

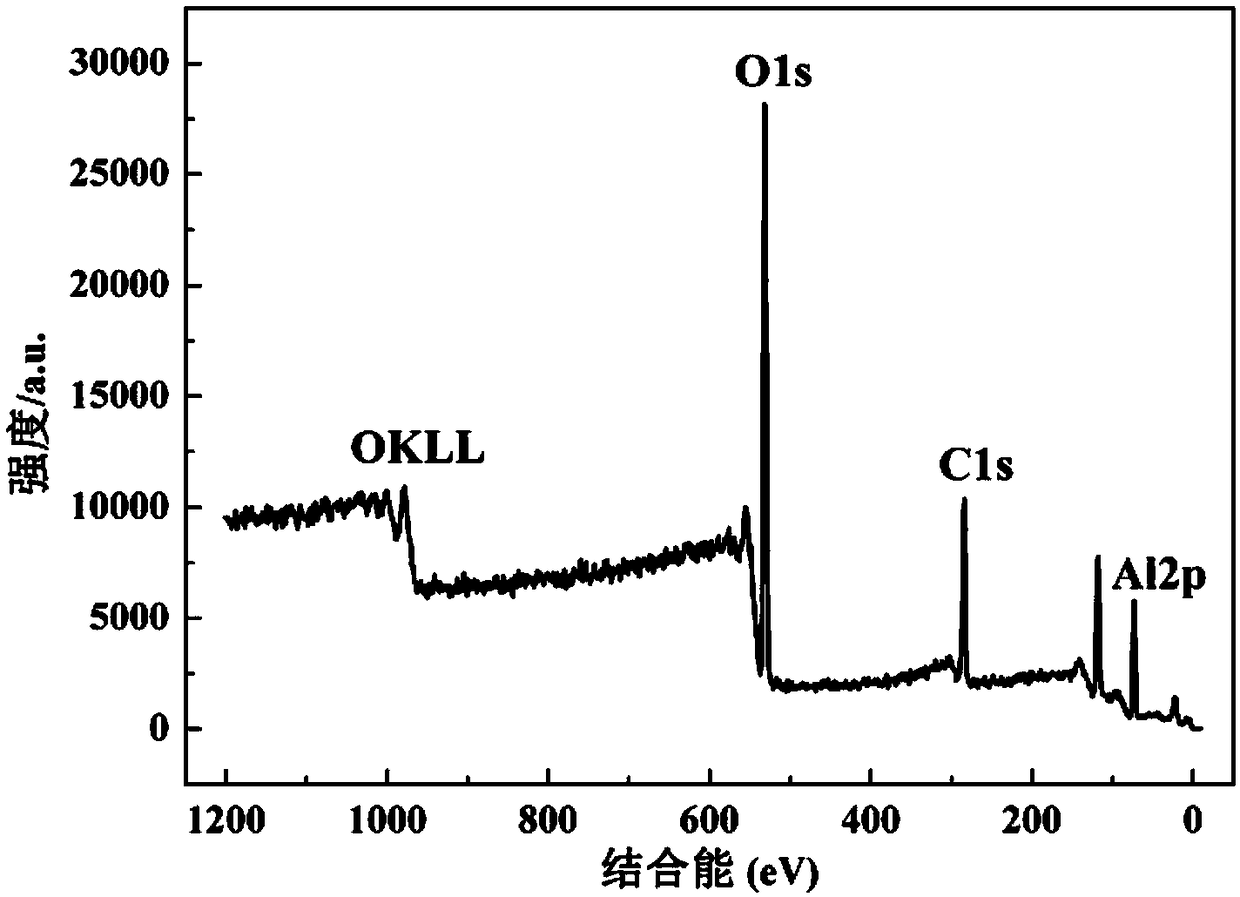

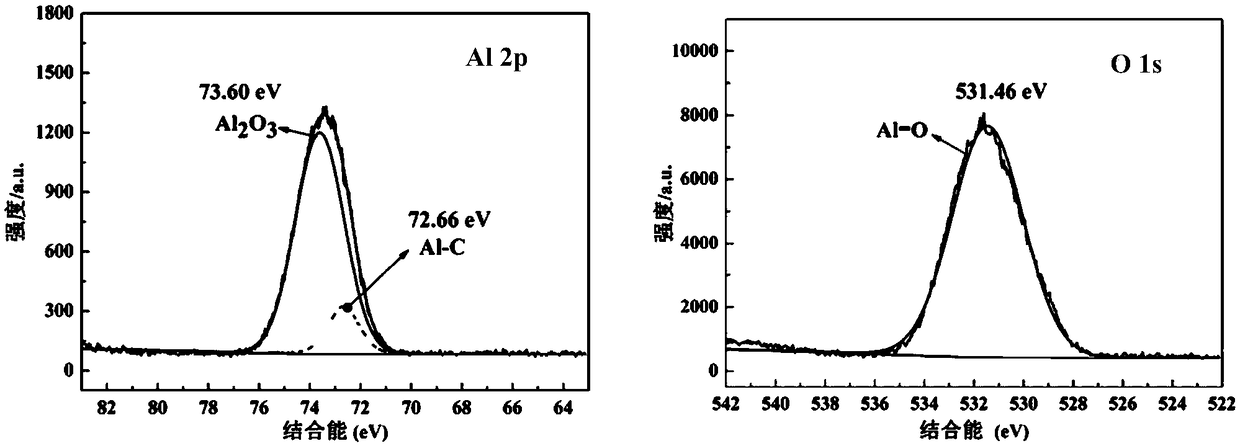

Preparation method of magnesium/magnesium alloy hydrotalcite-aluminum oxide composite coating

InactiveCN109023299AImprove bindingGood surface coverageLiquid/solution decomposition chemical coatingChemical vapor deposition coatingBiological activationAtomic layer deposition

The invention provides a preparation method of a magnesium / magnesium alloy hydrotalcite-aluminum oxide composite coating. The preparation method comprises the four steps including pretreatment of a magnesium alloy, preparation of a hydrotalcite coating, pretreatment of the hydrotalcite coating and atomic layer deposition of an aluminum oxide layer. The main chemical raw materials include aluminumnitrate, magnesium nitrate, sodium carbonate, sodium hydroxide, trimethyl aluminum and ultrapure water. The technical route is characterized in that a hydrothermal method is adopted to synthesize a carbonate hydrotalcite film on the surface of a magnesium / magnesium alloy matrix; and then the aluminum oxide coating is deposited on the surface of the hydrotalcite by using an atomic layer depositiontechnique after surface activation. The invention has the advantages that simple preparation and easy control are achieved, and the obtained composite coating has the compact structure, strong adhesion and good corrosion resistance; and the composite material prepared is suitable for the protection of magnesium alloy materials for engineering equipment.

Owner:SHANDONG UNIV OF SCI & TECH

Micro-extrusion printhead with offset orifices for generating gridlines on non-square substrates

ActiveUS8875653B2Good surface coverageMinor loss in cell electrical efficiencyConfectioneryCeramic shaping apparatusSolar cellVALVE PORT

A solar cell extrusion printing system that uses a micro-extrusion printhead to print longer central gridlines and one or more pairs of shorter “side” gridlines such that end points of the gridline sets form step patterns on an octagonal (pseudo-square) substrate. The printhead includes a set of central nozzles that receive ink from a first valve by way of a first flow channel to print the longer central gridlines, and additional sets of side nozzles that receive ink from additional valves by way of additional flow channels to print the shorter “side” gridlines. The central nozzles have outlet orifices that offset in the process direction from side outlet orifices of the side nozzles. A start signal is simultaneously sent to the valves such that ink is substantially simultaneously extruded through both the central and side orifices, whereby the extruded ink produces gridline endpoints having the desired step pattern.

Owner:XEROX CORP

Silane-modified biopolymeric, biooligomeric, oxidic or siliceous filler, process for its production and its use

InactiveUS20050223946A1Good surface coverageImprove dynamic performanceSilicaPigment treatment with organosilicon compoundsPolymer scienceBiopolymer

Silane-modified biopolymeric, biooligomeric, oxidic or siliceous filler obtainable by reacting at least one biopolymeric, biooligomeric, oxidic or siliceous filler in a compressed gas with at least one silane. The silane-modified biopolymeric, biooligomeric, oxidic or siliceous fillers are used in rubber compounds.

Owner:EVONIK DEGUSSA GMBH

Method For Generating Gridlines On Non-Square Substrates

InactiveUS20130206220A1High aspect-ratio gridlineEasy to operateSemiconductor/solid-state device manufacturingPhotovoltaic energy generationSolar cellSolar cell fabrication

A solar cell production method involves printing longer central gridlines and one or more pairs of shorter “side” gridlines such that end points of the two gridline sets form step patterns on octagonal (pseudo-square) substrates. A special printhead is used that includes a set of central nozzles which receive ink from a first valve by way of a first flow channel to print the longer central gridlines, and additional sets of side nozzles that receive ink from additional valves by way of additional flow channels to print the shorter “side” gridlines. The central nozzles have outlet orifices that offset in the process direction from side outlet orifices of the side nozzles. A start signal is simultaneously sent to the valves such that ink is substantially simultaneously extruded through both the central and side orifices, whereby the extruded ink produces gridline endpoints having the desired step pattern.

Owner:PALO ALTO RES CENT INC

Method for preparing high-entropy alloy composite coating on low-carbon steel surface

InactiveCN112376043AExpand the range of ingredient ratiosLow costTransportation and packagingMetal-working apparatusHigh entropy alloysAlloy composite

The invention discloses a method for preparing a high-entropy alloy composite coating on a low-carbon steel surface. The method comprises the following steps: pretreating the low-carbon steel surface,mixing Fe-Mn-Ni-Co-Cr high-entropy alloy according to atomic percent, and carrying out mechanical alloying to obtain high-entropy alloy powder; mixing the high-entropy alloy powder with graphite in amass ratio of 9: (1-1.2), and carrying out mechanical alloying to obtain graphene-coated high-entropy alloy powder to be cladded; evenly mixing the alloy powder to be cladded with a fluxing agent toobtain a mixture and then coating the mixture on the low-carbon steel surface, putting low-carbon steel into a high-frequency induction heating machine to be cladded, melting, cooling and condensing the powder to obtain the high-entropy alloy composite coating. According to the method disclosed by the invention, high-entropy alloy nanoparticles are prepared through the mechanical alloying method,and the graphene is obtained through mechanical stripping of the graphite, so that the high-entropy alloy nanoparticles are coated with the graphene, and the coating obtained through induction heatingcladding has excellent hardness, strength, corrosion resistance and high-temperature stability.

Owner:ZHONGBEI UNIV

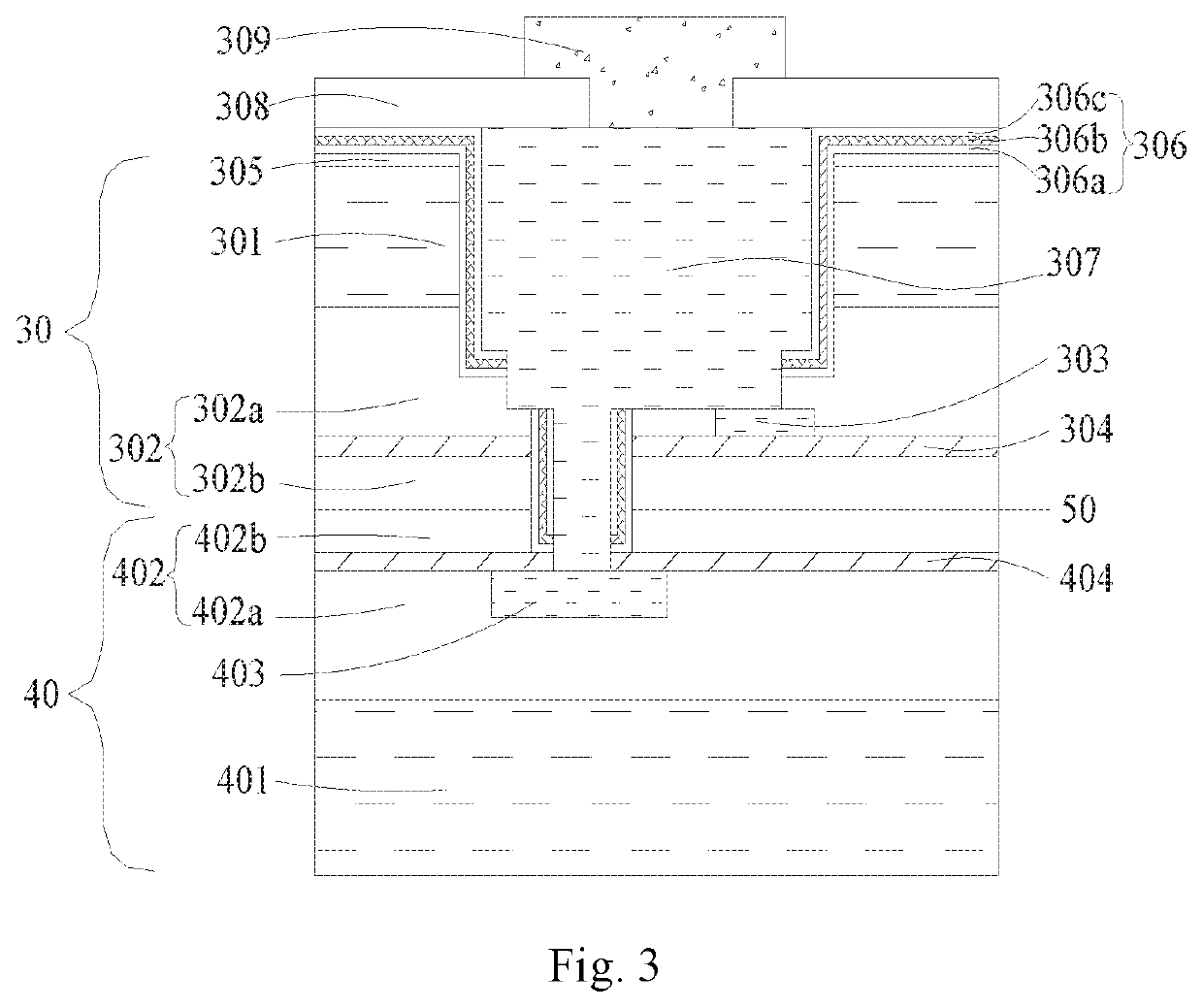

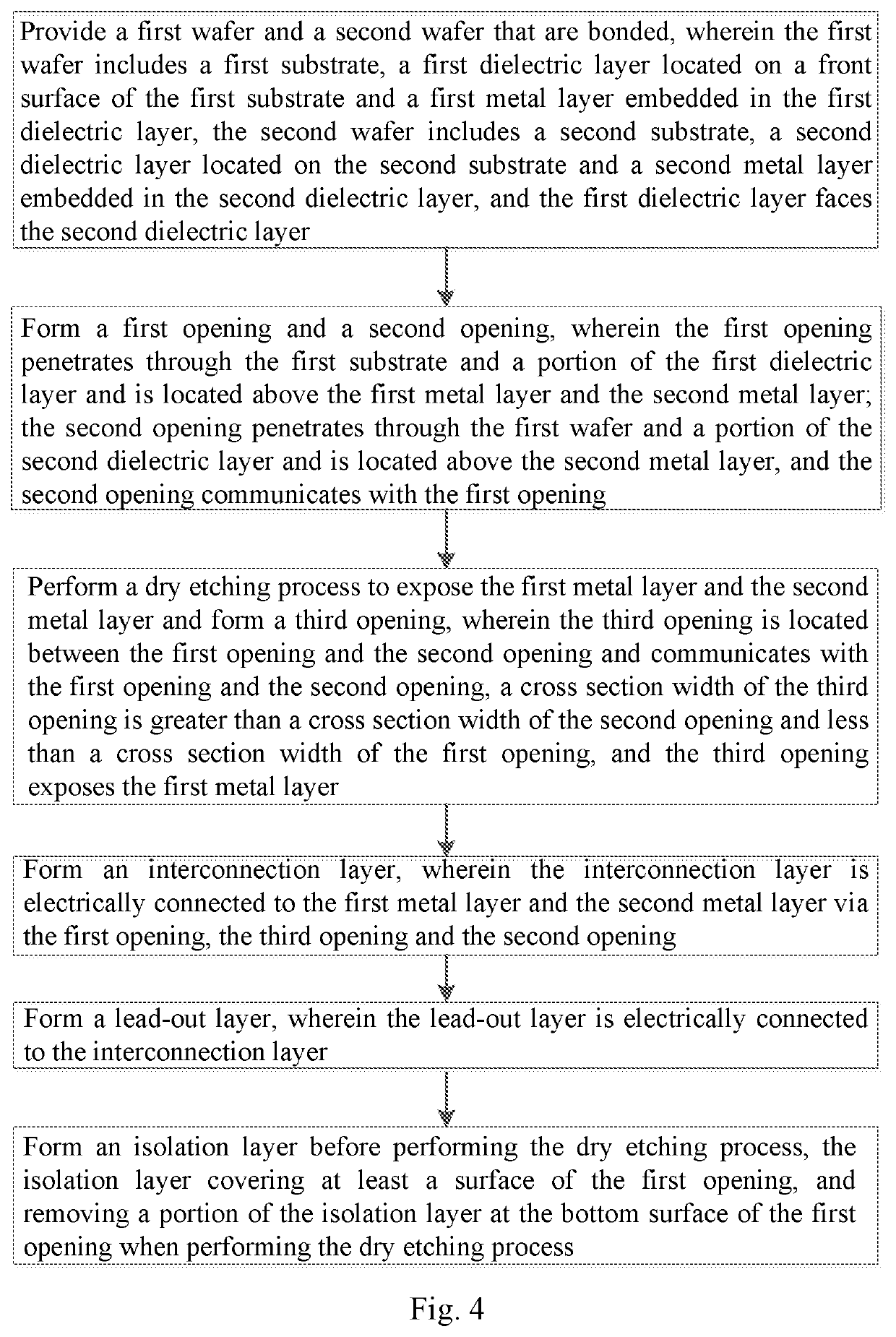

Semiconductor device and manufacturing method thereof

ActiveUS10943853B2Improve adhesionRelieve pressureSemiconductor/solid-state device detailsSolid-state devicesDevice materialPhysical chemistry

A semiconductor device and a manufacturing method thereof are disclosed. In the device, the isolation layer is used to prevent the first metal layer and the second metal layer which are over-etched and back-splashed from diffusing to a first substrate; and the isolation layer serves as a barrier layer to prevent an interconnection layer from diffusing into the first substrate. Further, the isolation layer includes a silicon nitride layer, which is advantageous for preventing the metal layers from back-splashing and diffusing to the sidewall of the first substrate. The isolation layer further includes a first silicon oxide layer and a second silicon oxide layer, wherein the second silicon oxide layer is used to protect the silicon nitride layer from being etched and consumed and the first silicon oxide layer is used to improve the adhesion between the silicon nitride layer and the first substrate.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

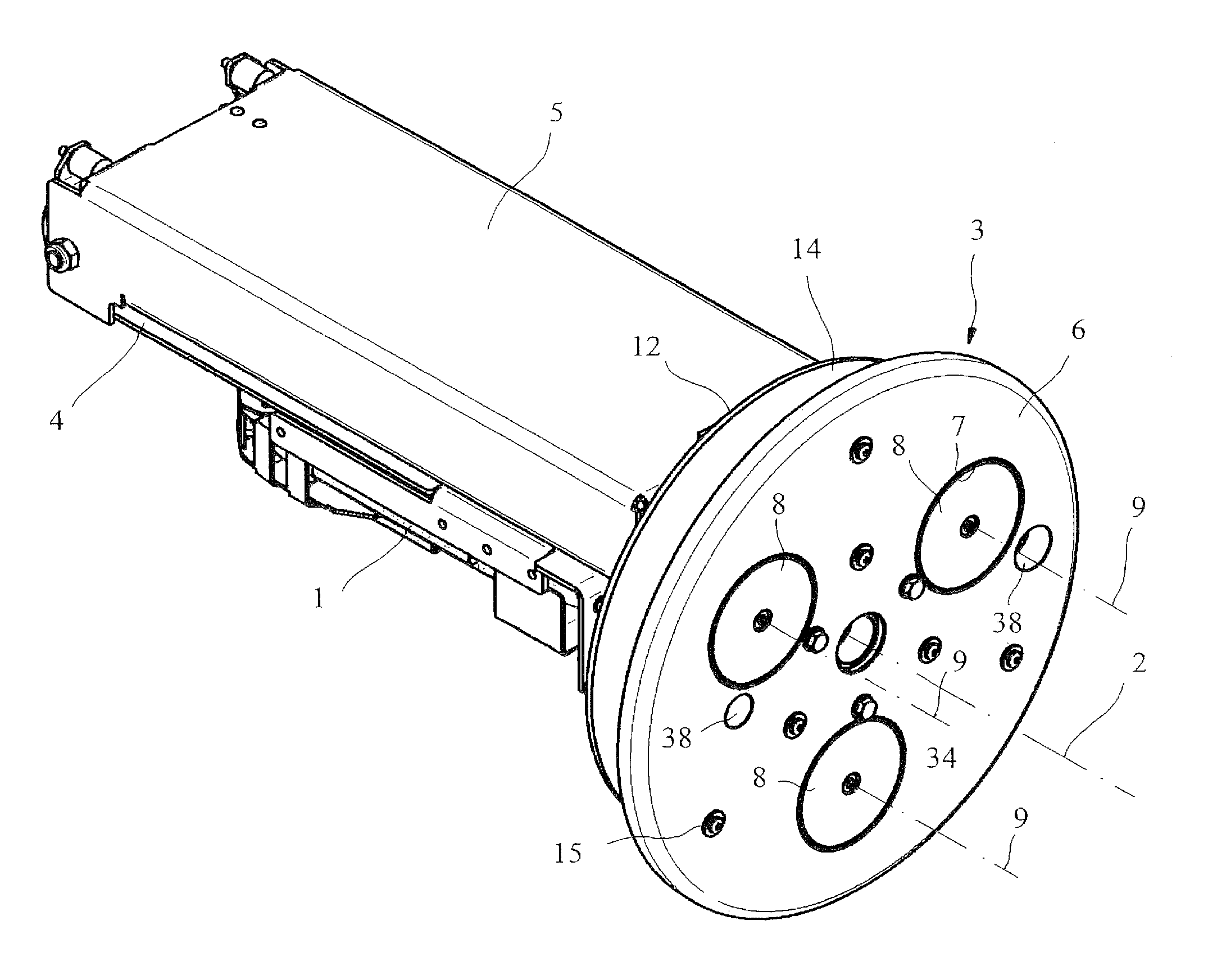

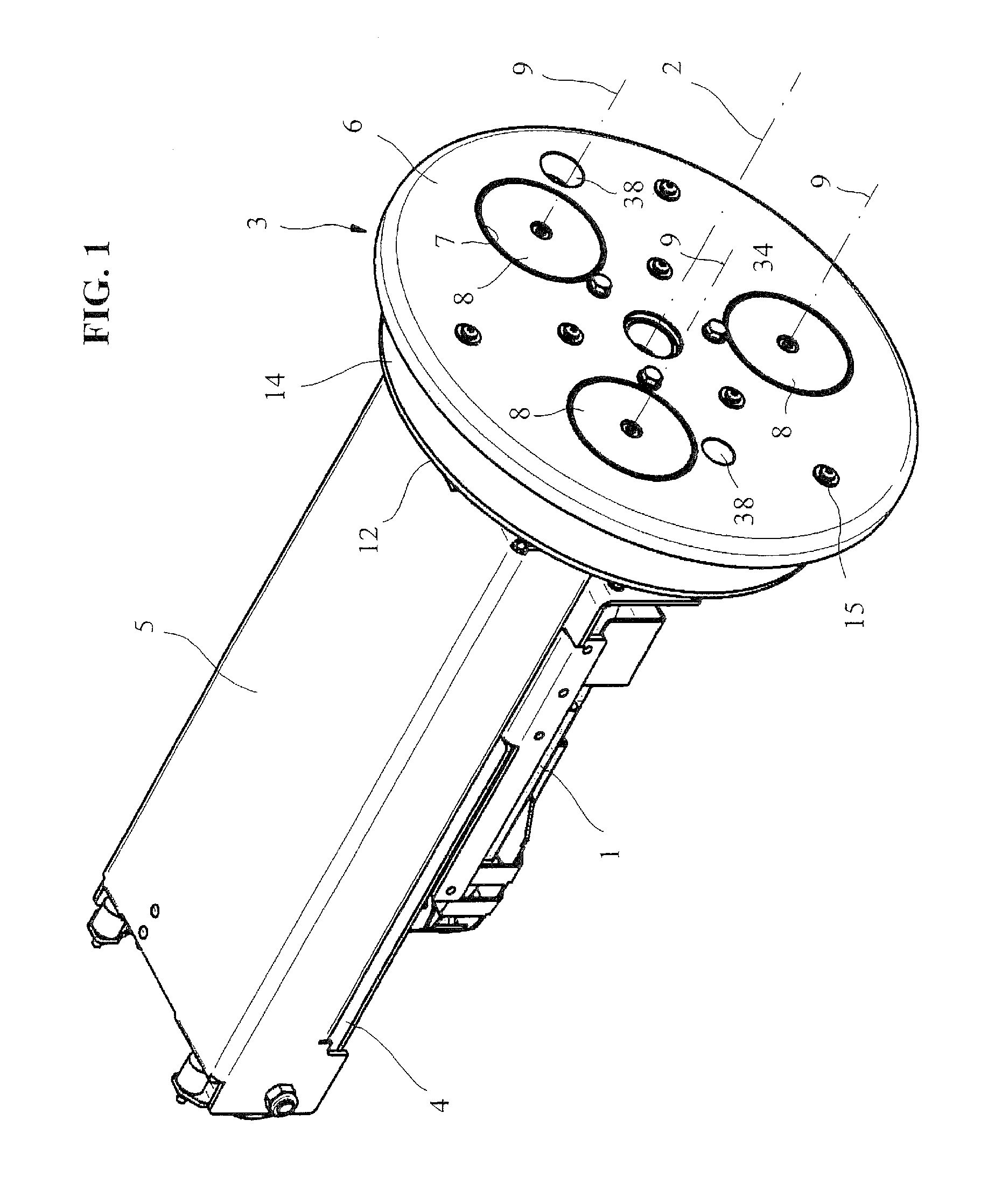

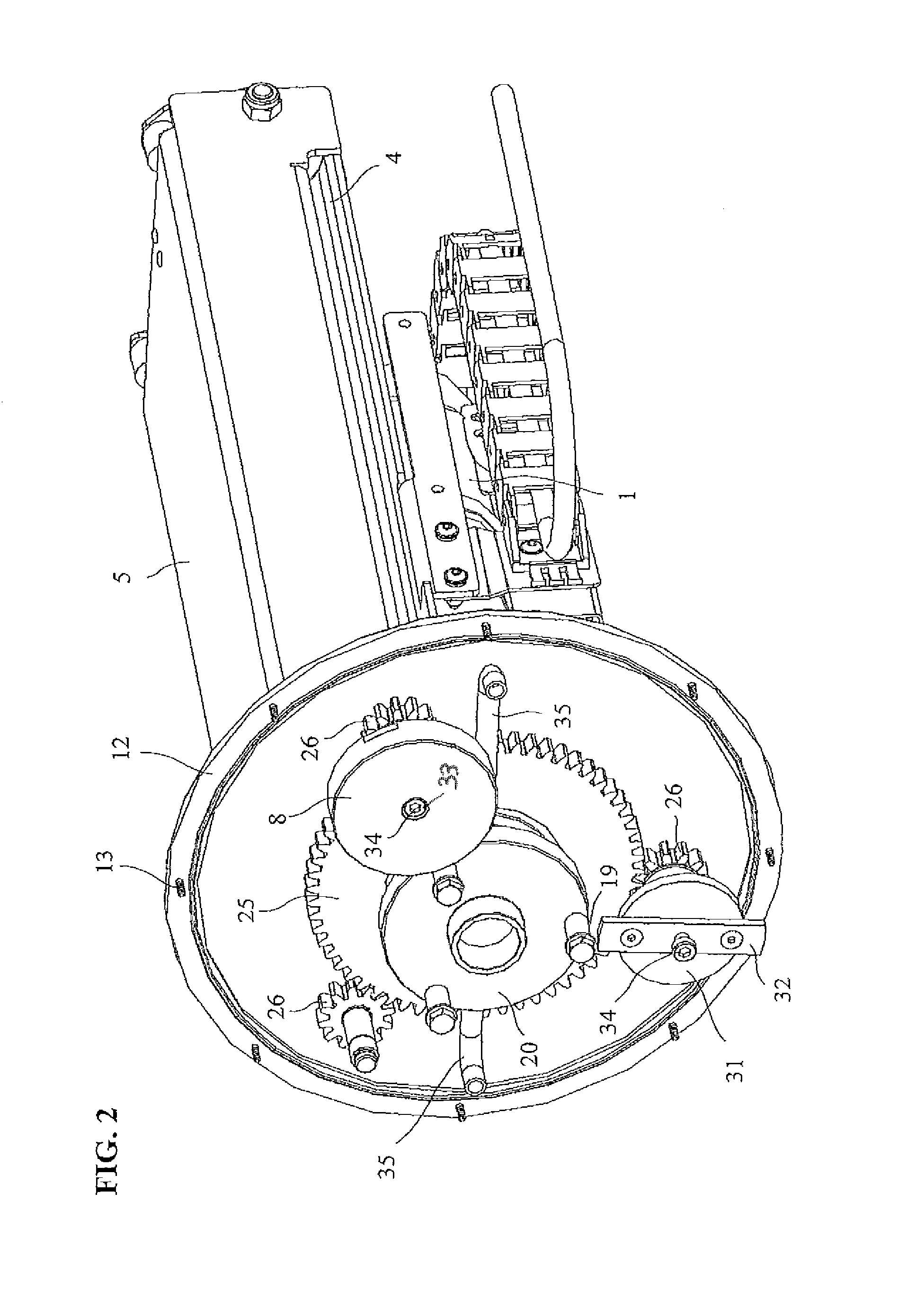

Device for cleaning vehicle wheels

InactiveUS8572791B2Good surface coverageEasy to cleanCarpet cleanersKitchenware cleanersGear wheelEngineering

Owner:WASHTEC HLDG

Method for producing wood fibre pellets

ActiveUS9511508B2High strengthImprove compatibilityPulping with organic solventsDomestic articlesCellulosePolymer science

Owner:NEW ZEALAND FOREST RES INST

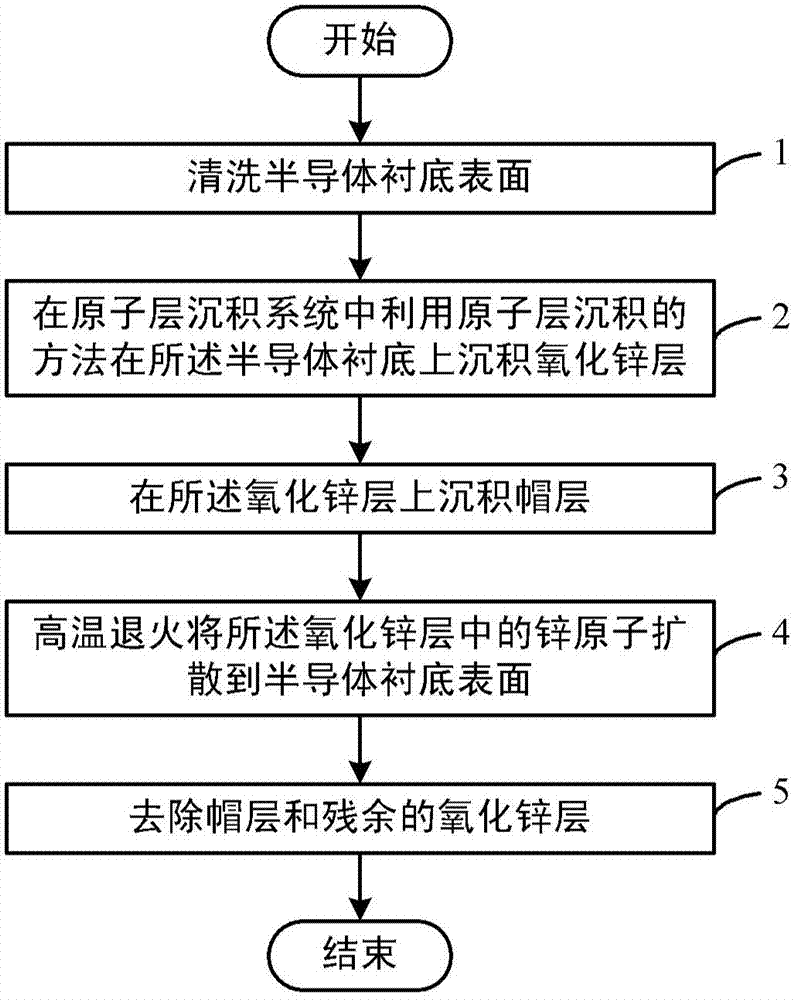

Method for manufacturing zinc-doped ultra shallow junction on surface of semiconductor substrate

InactiveCN104733285AGood uniformity of growth thicknessDiffusion controllableSemiconductor/solid-state device manufacturingAtomic layer depositionZinc atom

A method for preparing a zinc-doped ultra-shallow junction on a semiconductor substrate surface, which belongs to the technical field of semiconductor integration. In the method, a zinc-doped ultra-shallow junction is prepared on a semiconductor substrate surface in a diffusion manner from zinc in zinc oxide obtained by depositing an atomic layer. The method comprises: cleaning a semiconductor substrate surface (1); in an atomic layer deposition system, depositing a zinc oxide layer on a semiconductor substrate using an atomic layer deposition method (2); depositing a cap layer on the zinc oxide layer (3); diffusing zinc atoms in the zinc oxide layer to the semiconductor substrate surface by high-temperature annealing (4); and removing the cap layer and the zinc oxide layer (5). The method can be used for preparing ultra-shallow junctions of planar and non-planar semiconductor devices, and has the advantages of controllable junction depth and low damage to lattices of semiconductor substrates when used for doping of small-sized semiconductor devices.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

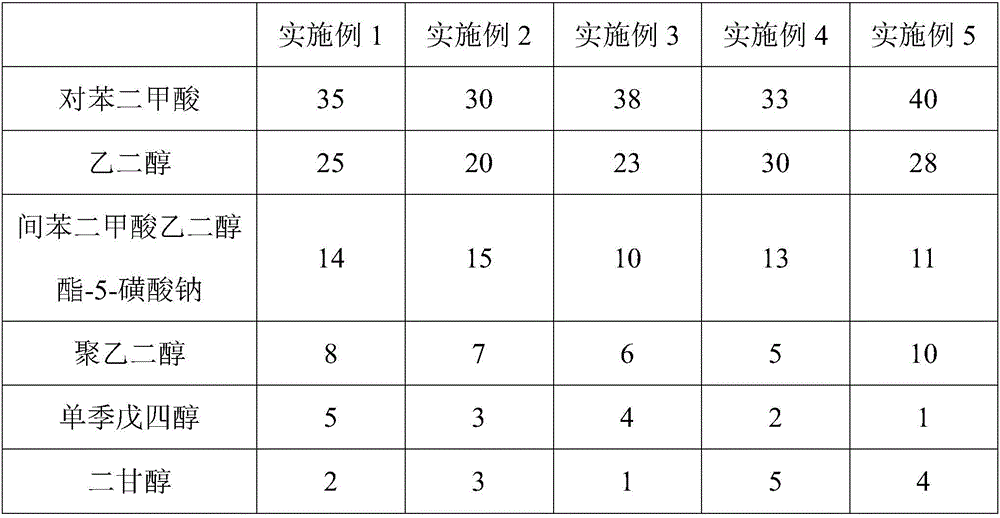

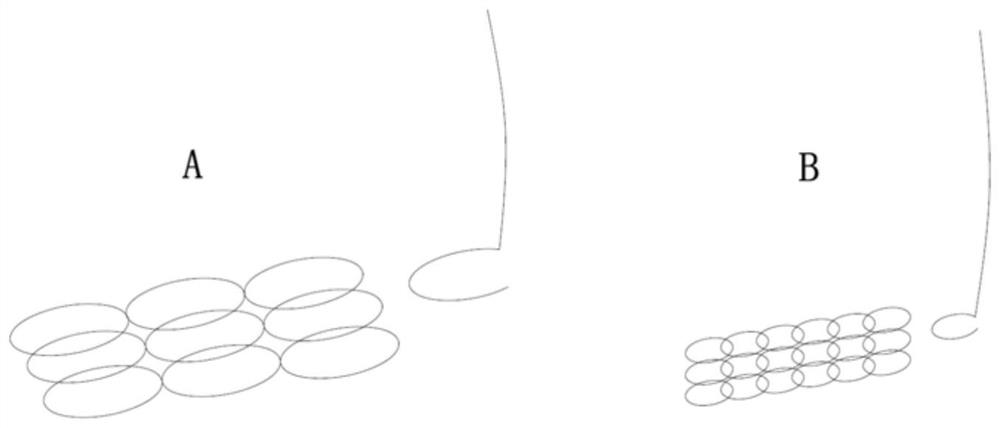

Preparation technology and preparation equipment for high-imitation cotton porous superfine profiled polyester fiber

ActiveCN102877143BWith moisture absorption and breathabilityAntistaticArtificial thread manufacturing machinesFilament/thread formingPolyesterAlcohol

The invention discloses a preparation technology and preparation equipment for high-imitation cotton porous superfine profiled polyester fiber. The technological flow is as follows: polyester chips are dried, the dried polyester chips are placed in an extrusion device, polyhydric alcohol is added in an online manner to carry out blending modification, and then melt is obtained; the melt is filtered and enters a spinning manifold, the filtered melt is subjected to section superfine processing and section profiled processing, the melt is extruded by a profiled spinning plate, and then melt trickle is obtained; circular blowing cooling solidification forming is then carried out, and then filaments are obtained; and then the filaments are wound and formed sequentially through oiling by an oil nozzle, pretangle and heat setting. The preparation equipment comprises a drying device, an extrusion device, a filter device, the spinning manifold, a circular blowing cooling solidifying device and a winding forming device, which are connected in sequence, wherein the extrusion device is connected with an online adding device. The preparation technology and the preparation equipment have the characteristics of moisture absorption, breathability, anti-static electricity, pilling resistance, softness and bulkiness, soft gloss, moisture wicking and discharging, soft touch sense, better surface coverage and bending resilience, and also can realize a high-imitation cotton effect.

Owner:ZHONGRUN SCI & TECH

Novel artificial tussah silk fibers

InactiveCN105778071AReduced comfortReduce manufacturing costElectroconductive/antistatic filament manufactureFilament/thread formingSulfonateAntistatic agent

The invention provides novel artificial tussah silk fibers and a manufacturing method of the novel artificial tussah silk fibers. The novel artificial tussah silk fibers are prepared by fusing and spinning modified polyester, wherein the modified polyester is prepared from the following components in parts by weight: terephthalic acid, ethylene glycol, ethyleneglycol m-phthalate-5-sodium sulfonate, polyethylene glycol, monopentaerythritol, diethylene glycol, an antistatic agent, an antioxidant and a stabilizer. The artificial tussah silk fibers are processed through a chemical and physical modification method, and one type of novel fiber materials capable of replacing natural tussah silk fibers can be developed; the characteristics of natural slight yellow color and luster, jewelry-like color and luster, and rough appearance and style of the artificial tussah silk fibers, the natural tussah silk fibers and fabrics are kept; the defects of common disadvantages of the artificial fibers and the natural tussah silk fibers are also overcome; comprehensive properties including humidity absorption and breathability, antistatic property, anti-pilling, softness and bulkiness, soft color and luster, stiffness and smoothness and uneasiness of deformation and the like are better than those of the natural tussah silk fibers.

Owner:ZHONGRUN SCI & TECH

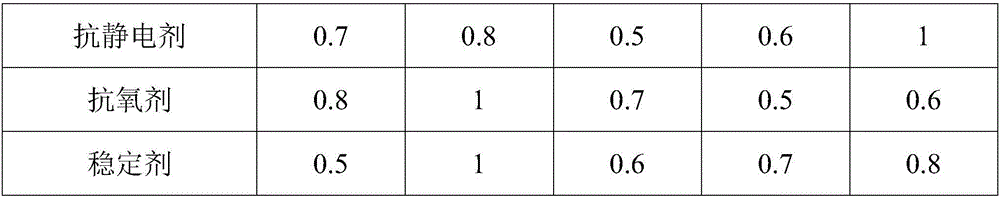

Silicon through hole structure-based metal filling method and silicon through hole structure

InactiveCN105679703AAvoid circuit breakingRealize vertical interconnectionSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSilicon chip

The invention relates to the technical field of three-dimensional integrated circuits, in particular to a silicon through hole structure-based metal filling method and a silicon through hole structure. The method comprises the following steps: after bonding a bearing substrate and a top silicon wafer, etching a silicon through hole on the top silicon wafer; sequentially depositing an insulating layer and a barrier layer in the silicon through hole; depositing a metal seed layer on the surface of the barrier layer in an atomic layer deposition manner; and depositing a metal conductor layer on the surface of the metal seed layer. The metal seed layer is added between the barrier layer and the metal conductor layer, so that circuit disconnection caused by a conductor fault can be avoided; and meanwhile, the condition that deposition of the metal seed layer has good surface coverage on any shape and form is achieved in the atomic layer deposition manner; the condition that the surface of the barrier layer can completely cover the metal seed layer is ensured; the circuit disconnection caused by the conductor fault is further avoided; and the process reliability of metal filling is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

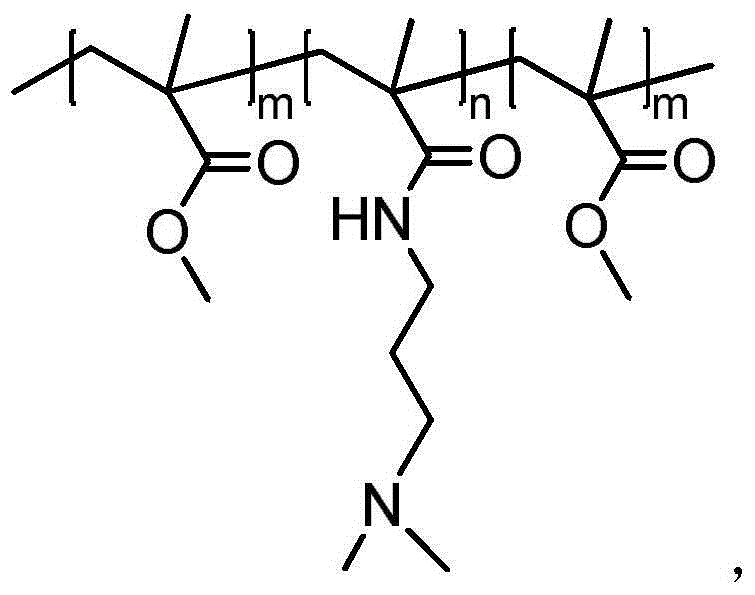

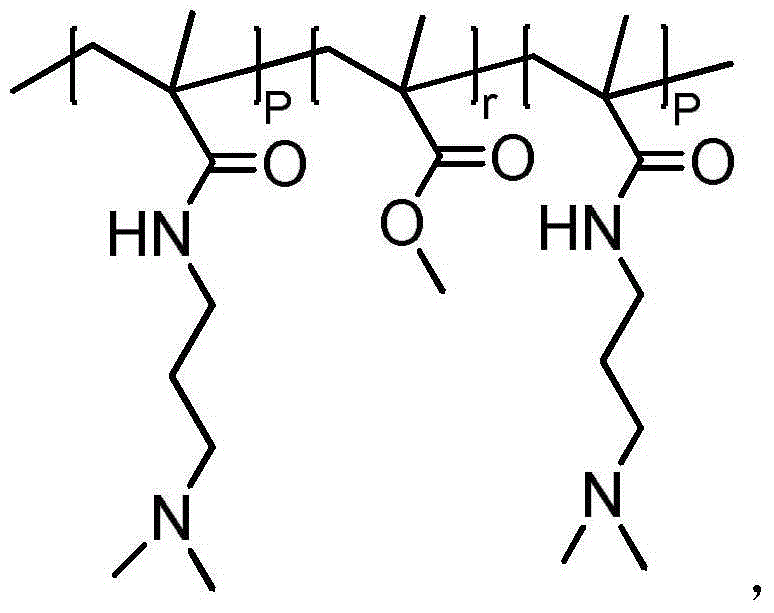

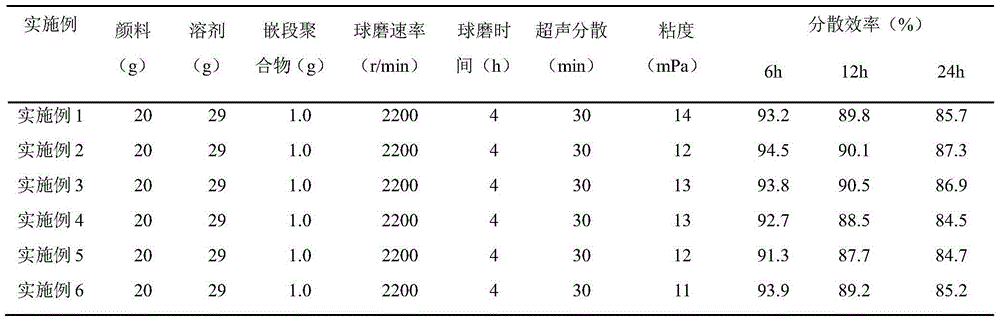

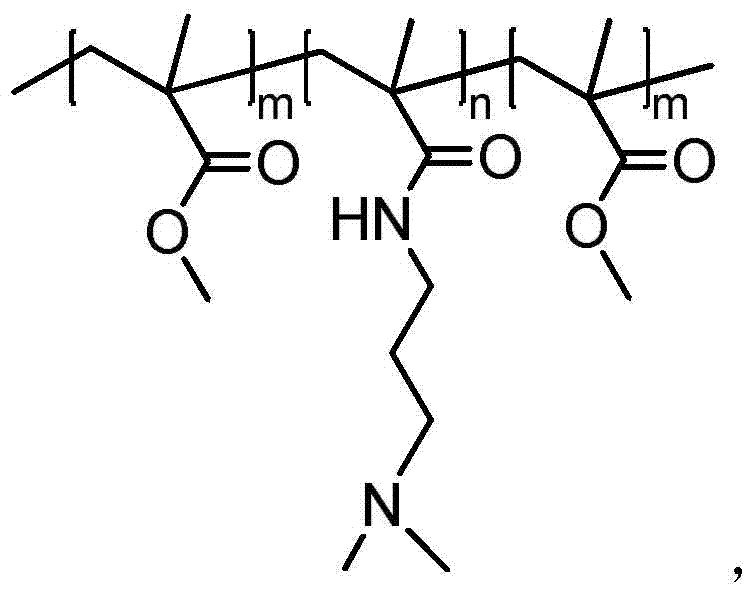

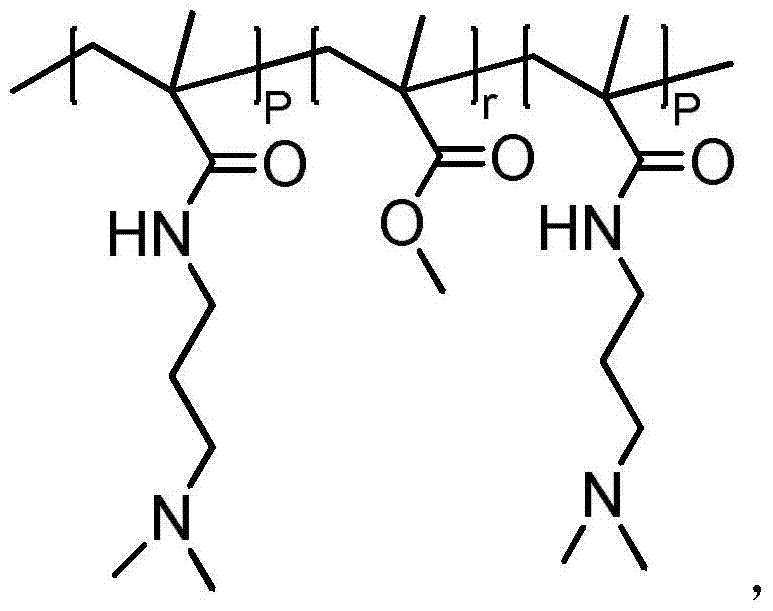

Acrylate segmented copolymer as well as synthesis method and application thereof

ActiveCN104592463AImprove dispersion stabilityProcess stabilityInksInorganic particleSynthesis methods

The invention belongs to the technical field of ceramic ink dispersing agents, and discloses an acrylate segmented copolymer as well as a synthesis method and an application thereof as a ceramic inkjet ink dispersing agent. The acrylate segmented copolymer is prepared by polymerizing methyl methacrylate and N-(3-dimethylamino propyl) methacrylamide. The synthesis method comprises the following steps: under an anaerobic condition, generating an RAFT reagent macromolecule by monomer N-(3-dimethylamino propyl) methacrylamide (or methyl methacrylate) under the action of an initiator and an RAFT reagent; and acting with the monomer methyl methacrylate (or N-(3-dimethylamino propyl) methacrylamide) and reacting under the induction of the initiator to generate the acrylate segmented copolymer. The acrylate segmented copolymer has good covering and encapsulation effect for the inorganic particle surfaces, is stable in dispersion system and is mainly applied to the dispersion of ceramic pigment particles for ceramic inkjet.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

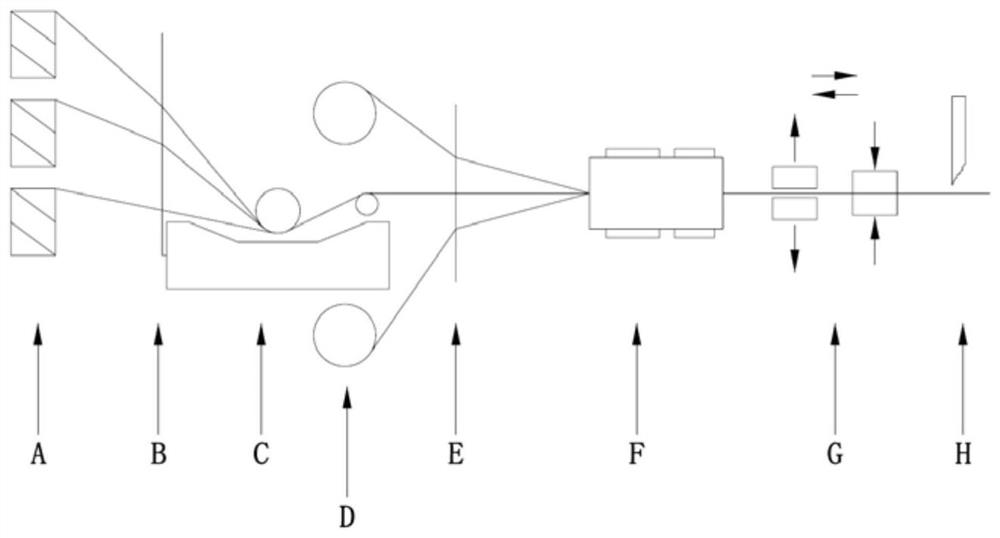

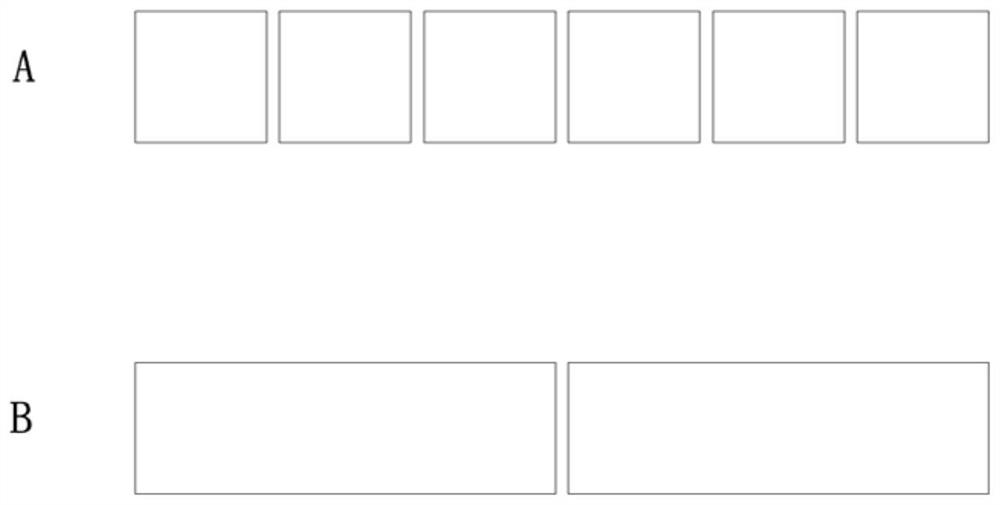

Continuous glass fiber stitchbonded felt production device and production method

The invention belongs to the technical field of non-woven reinforcing materials, and in particular relates to a production device and a production method of a continuous glass fiber stitched mat. The continuous glass fiber stitched mat production device includes a creel, a creel, a yarn dividing device, and a spinning head that are connected in sequence. A conveyor belt is installed under the spinning head, and a yarn pressing device is installed above one end of the conveyor belt. The conveyor belt, The transition plate, the sewing machine head, and the pulling roller are connected to the coiler in sequence, and the sewing machine head is connected to the stitching line pan head. The continuous glass fiber precursors are led out from the creel and enter the spinning machine head through the spinning device. The spinning machine head sprinkles the continuous glass fiber precursors on the conveyor belt to form a mat, and the conveyor belt conveys the felt tire through the yarn pressing device. The felt tire is thinned, and the thinned felt tire passes through the transition plate and enters the sewing machine head for sewing and forming, and then enters the coiler through the pulling roller for framing coiling. The invention has the advantages of large output, high production stability, stable quality and low production cost.

Owner:TAISHAN FIBERGLASS INC

Acrylic ester block copolymer and its synthesis method and application

The invention belongs to the technical field of ceramic ink dispersants, and discloses an acrylic ester block copolymer, a synthesis method thereof and its application as a ceramic ink-jet ink dispersant. The acrylate block polymer is prepared by polymerizing methyl methacrylate and N-(3-dimethylaminopropyl)methacrylamide. Its synthetic method comprises the following steps: under anaerobic conditions, monomer N-(3-dimethylaminopropyl) methacrylamide (or methyl methacrylate) generates RAFT reagent under the action of initiator and RAFT reagent The macromolecule reacts with the monomer methyl methacrylate (or N-(3-dimethylaminopropyl) methacrylamide) to generate the acrylate block polymer under the induction of the initiator. The acrylate block polymer has a good effect of covering and encapsulating the surface of inorganic particles, and has a stable dispersion system, and is mainly used in the dispersion of ceramic pigment particles for ceramic inkjet.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

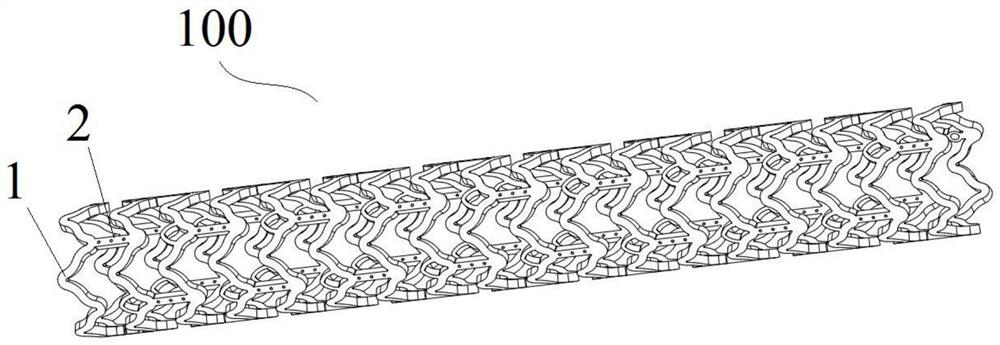

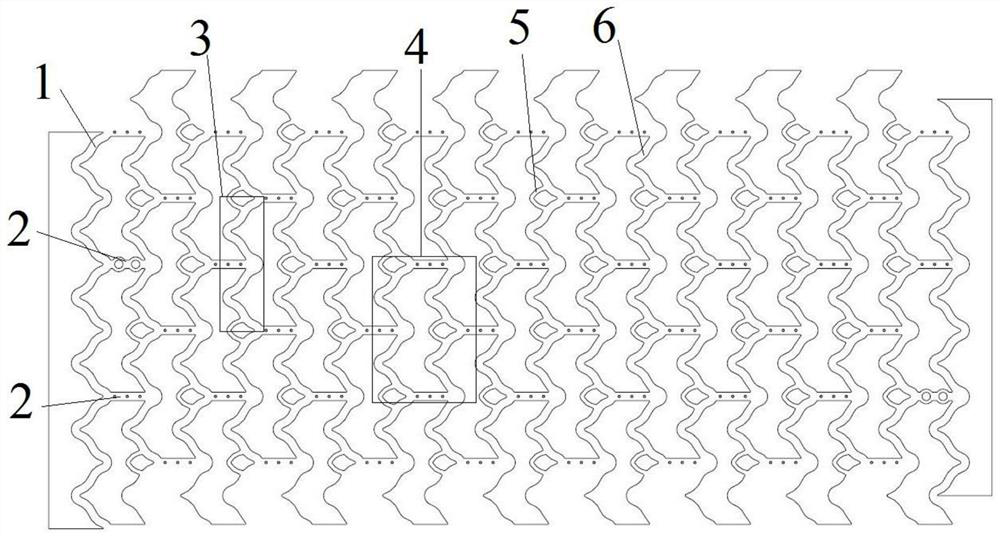

Degradable stent

The invention discloses a degradable stent which comprises a plurality of closed rings arranged at intervals in the axial direction. The closed ring can be radially contracted and contracted; every two adjacent closed rings are connected through a plurality of bridge rods which are evenly arranged in the circumferential direction, and a plurality of through holes are evenly formed in the bridge rods in the axial direction. The closed ring and the bridge rod are made of polylactic acid, polylactic acid-glycolic acid copolymer, zinc, magnesium, iron, zinc alloy, magnesium alloy or degradable polymer. The degradable stent disclosed by the invention is good in supporting performance.

Owner:南京友德邦医疗科技有限公司

Nanoparticle coated electrode and method of manufacture

InactiveUS20110300471A1Easy to evaporateGood surface coverageMachining electrodesMultiple component coatingsFuel cellsHydrogen

An electrode comprising a primary and secondary metal nanoparticle coating on a metallic substrate is prepared by dispersing nanoparticles in a solvent and layering them onto the substrate, followed by heating. The enhanced surface area of the electrode due to the catalytic nanoparticles is dramatically enhanced, allowing for increased reaction efficiency. The electrode can be used in one of many different applications; for example, as an electrode in an electrolysis device to generate hydrogen and oxygen, or a fuel cell.

Owner:QUANTUMSPHERE

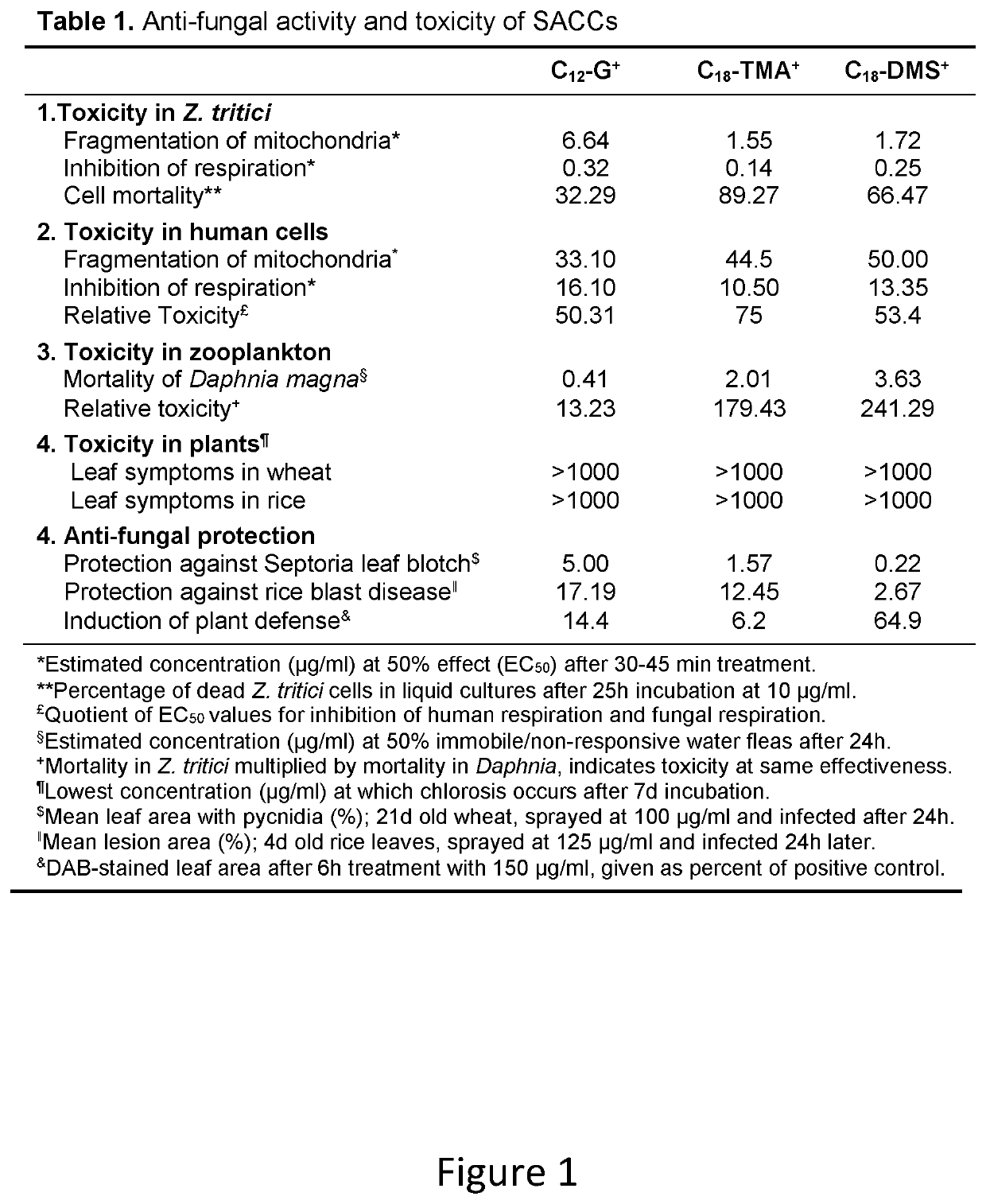

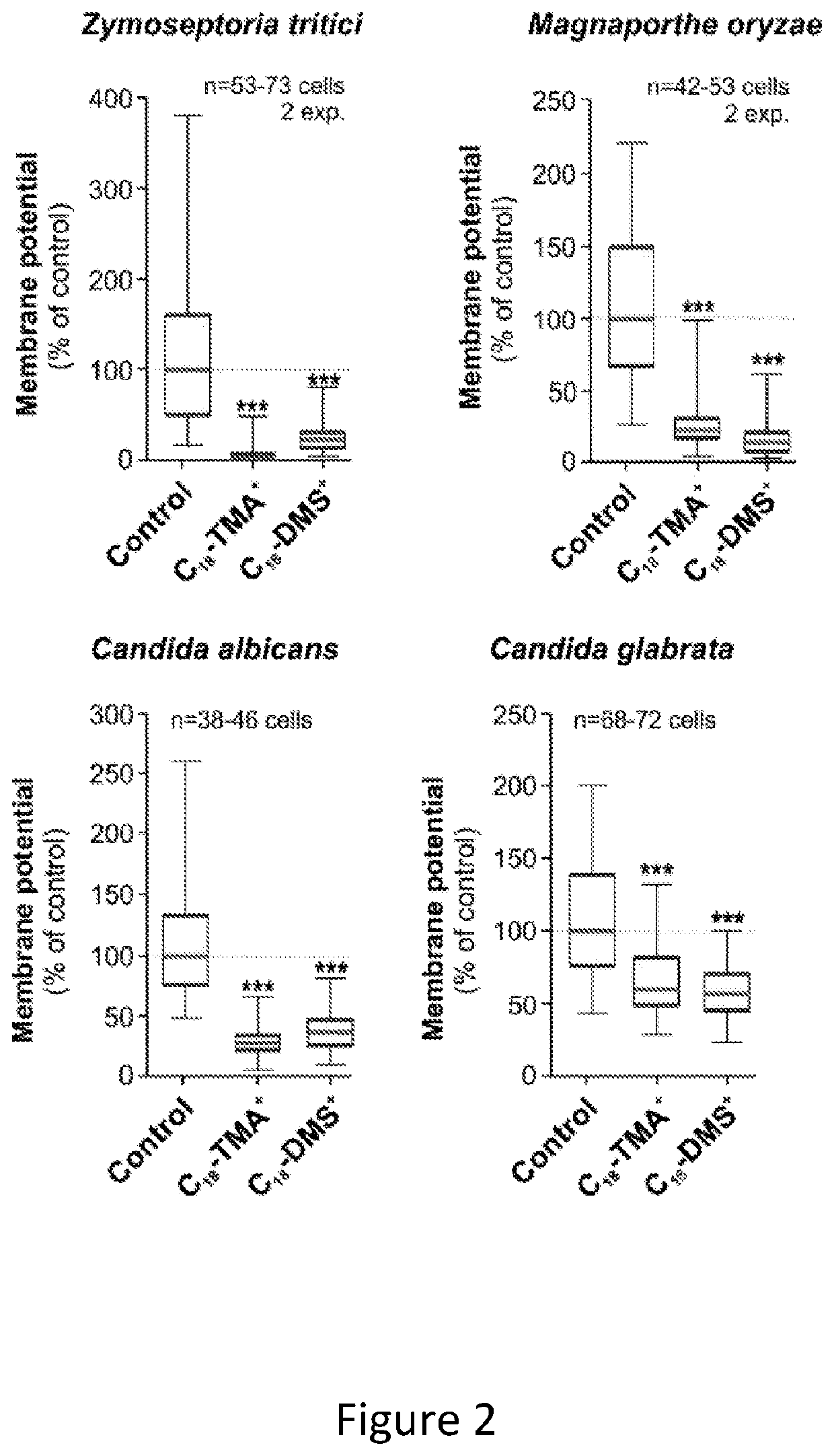

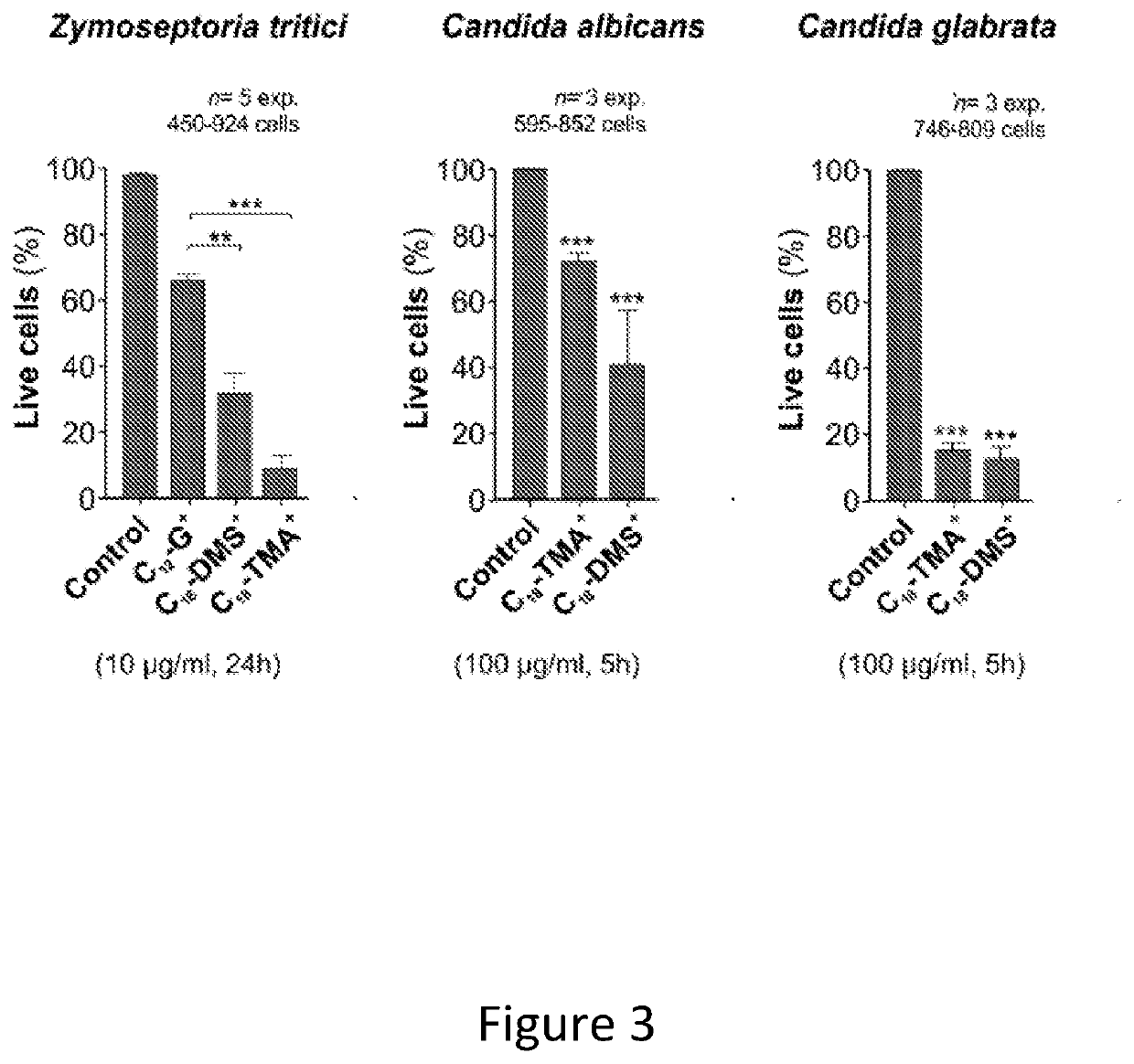

Antifungal Compositions

PendingUS20220174950A1Good curative effectGood surface coverageBiocideAntimycoticsAntifungalIsopropyl

The invention provides an antifungal composition comprising an antifungal compound of formula R—S+(R′)2 or R—N+(R′)3 wherein R is C17-C32 straight chain or branched alkyl; and each R′ is independently methyl, ethyl, propyl, isopropyl or butyl; and uses of said composition as antifungal agents.

Owner:UNIV OF EXETER

OLED device transparent cathode and manufacturing method thereof

InactiveCN112652726AImprove continuityGood surface coverageSolid-state devicesSemiconductor/solid-state device manufacturingSource materialThin membrane

The invention discloses an OLED device transparent cathode and a manufacturing method thereof. The manufacturing method comprises the following steps of directly depositing a transparent conductive cathode film on the surface of an OLED device by adopting an atomic layer deposition method, and during preparation of the atomic layer deposition method, using diethyl zinc as a zinc source material, trimethylaluminum as an aluminum source raw material, and hydrogen peroxide as an oxygen source raw material. The defect of poor process matching degree or thin film damage in the field of transparent cathode layers of OLEDs in the preparation method in the prior art is effectively avoided.

Owner:NANJING GUOZHAO OPTOELECTRONICS TECH CO LTD

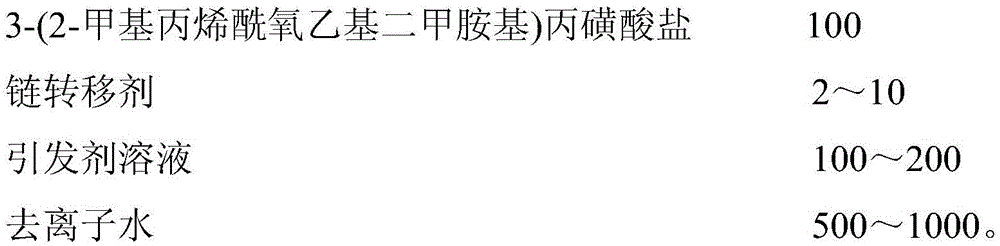

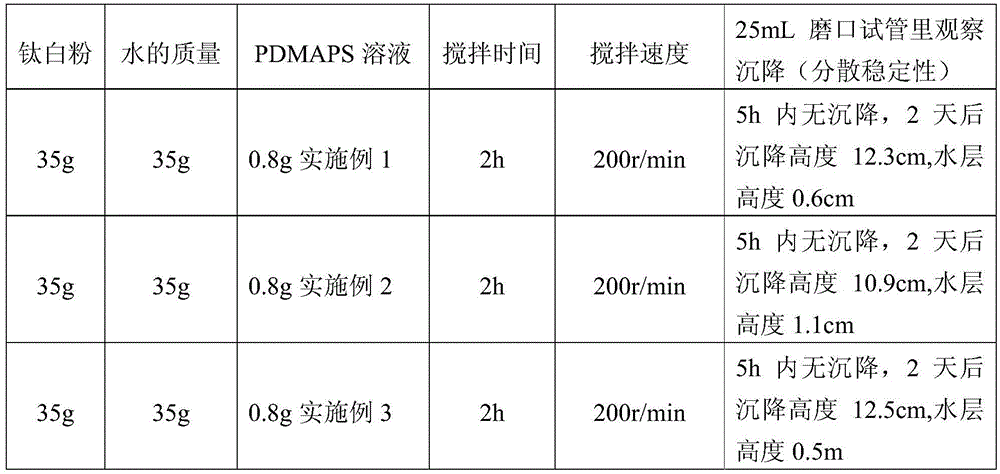

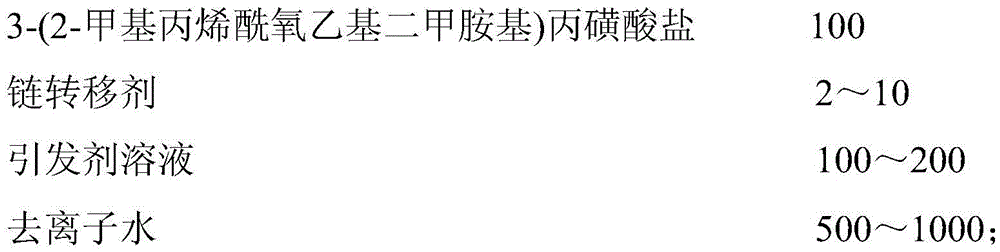

A new type of zwitterionic polyelectrolyte dispersant, method and application thereof

ActiveCN104211842BGood surface coverageGood encapsulation effectTransportation and packagingSulfonic acids salts preparationSlurryMicroparticle

The invention belongs to the technical field of dispersant preparation, and discloses a novel zwitterionic polyelectrolyte dispersant and its method and application. The dispersant is prepared by the following method: 100 parts by weight of 3-(2-methacryloyloxyethyl dimethylamino) propanesulfonate, 2-10 parts by weight of chain transfer agent are sequentially added to the reactor and 500-1000 parts by weight of deionized water, then stirred and dissolved to obtain a mixed solution; under the condition of 60-100 ° C, 100-200 parts by weight of initiator solution was added dropwise, and after 2-5 hours of reaction, heating was stopped and cooled to room temperature to obtain A colorless transparent liquid that is a zwitterionic polyelectrolyte dispersant solution. The dispersant has good surface coverage and encapsulation effects on the dispersed particles, and the dispersion system is stable; and it has good chemical and thermal stability, strong hydration ability and is not easily affected by the pH value of the solution. It can be applied to ceramic slurry dispersion, nanometer Powder dispersion, etc.

Owner:国科广化(南雄)新材料研究院有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com