OLED device transparent cathode and manufacturing method thereof

A technology of a transparent cathode and a manufacturing method, applied in the field of OLED display, can solve problems such as poor process matching, film damage, etc., achieve good surface coverage, reduce unevenness, and meet brightness requirements and current driving capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The purpose of the present invention is to design a transparent conductive cathode film that can significantly improve the transparency and conductivity of the OLED transparent cathode layer in view of the problem that the existing OLED transparent cathode layer has poor compatibility with light transmittance and conductivity.

[0036] The embodiments of the present invention will be preferably described below in conjunction with the embodiments.

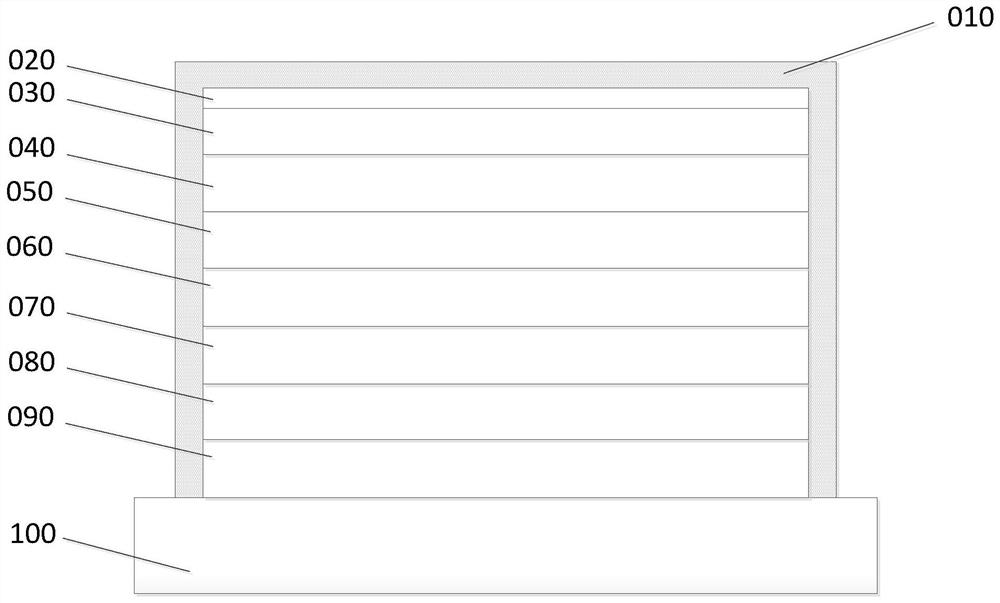

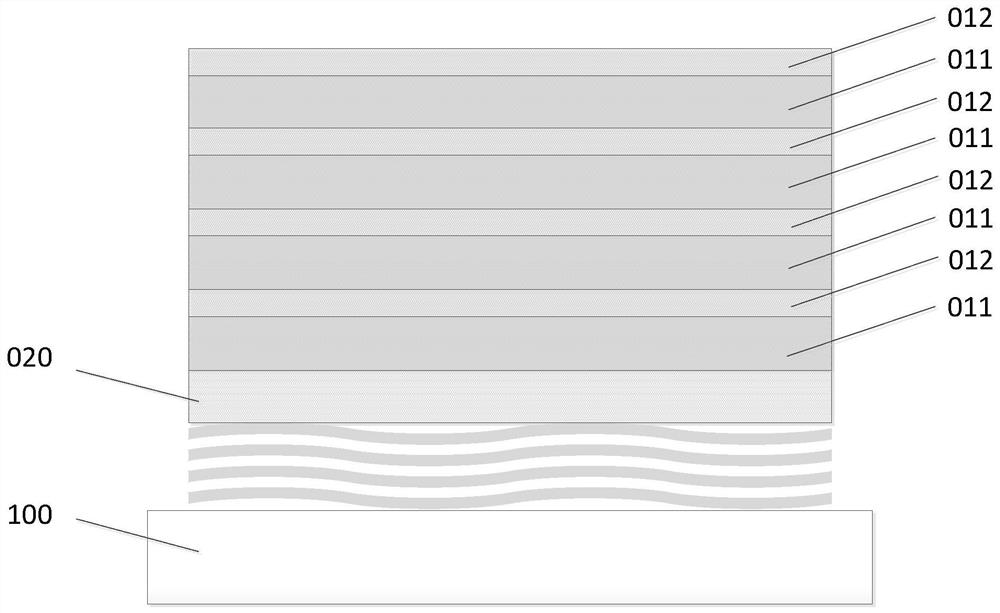

[0037] Such as Figure 1-Figure 2 Shown, the fabrication method of OLED device transparent cathode comprises:

[0038] The manufacturing process of the transparent cathode film layer as the transparent cathode layer is as follows: a transparent and conductive cathode film is directly deposited on the surface of the OLED device by atomic layer deposition;

[0039] When the atomic layer deposition method is prepared, diethyl zinc is used as the zinc source material, trimethylaluminum is used as the aluminum source material, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com