Patents

Literature

85results about How to "Meet brightness requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

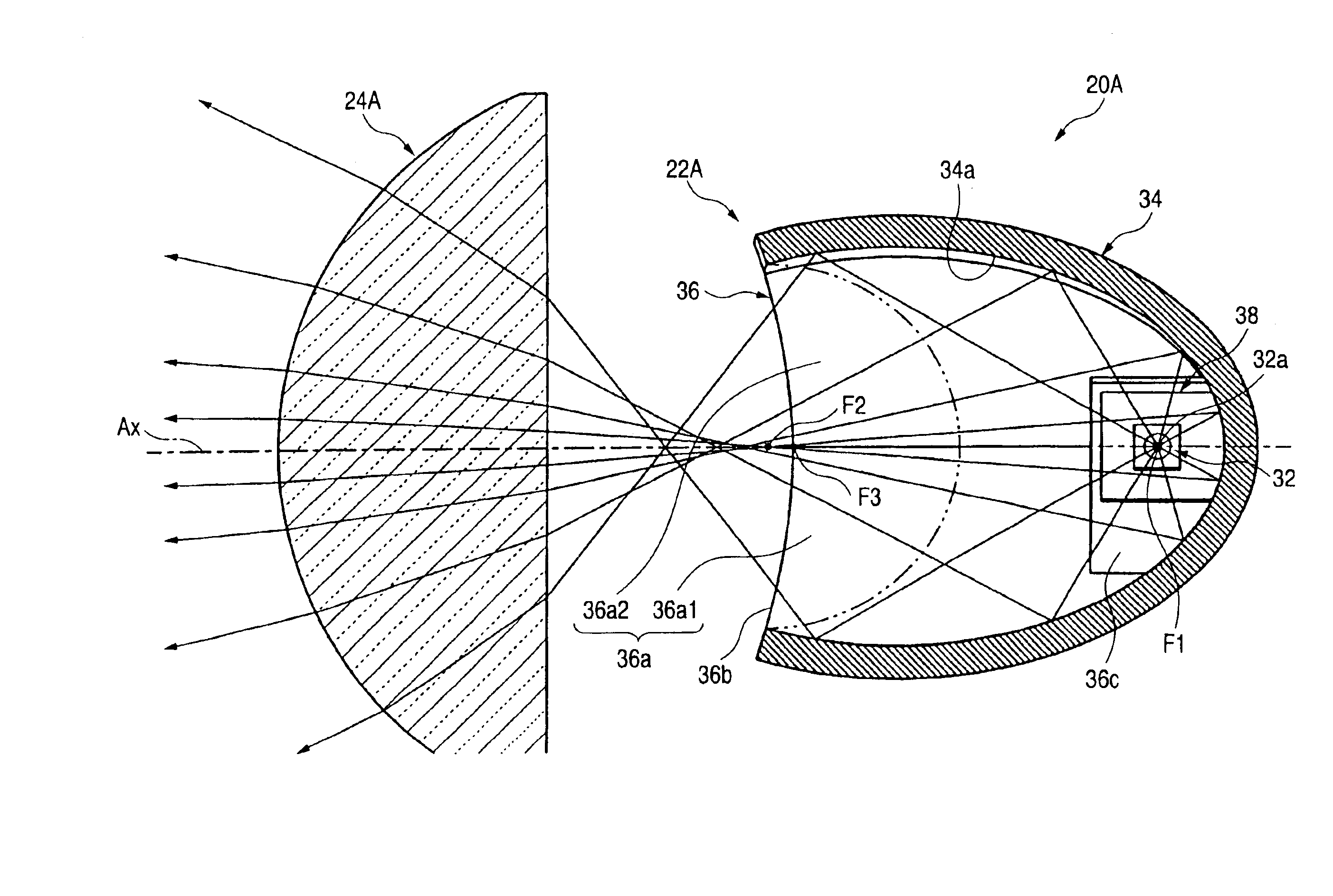

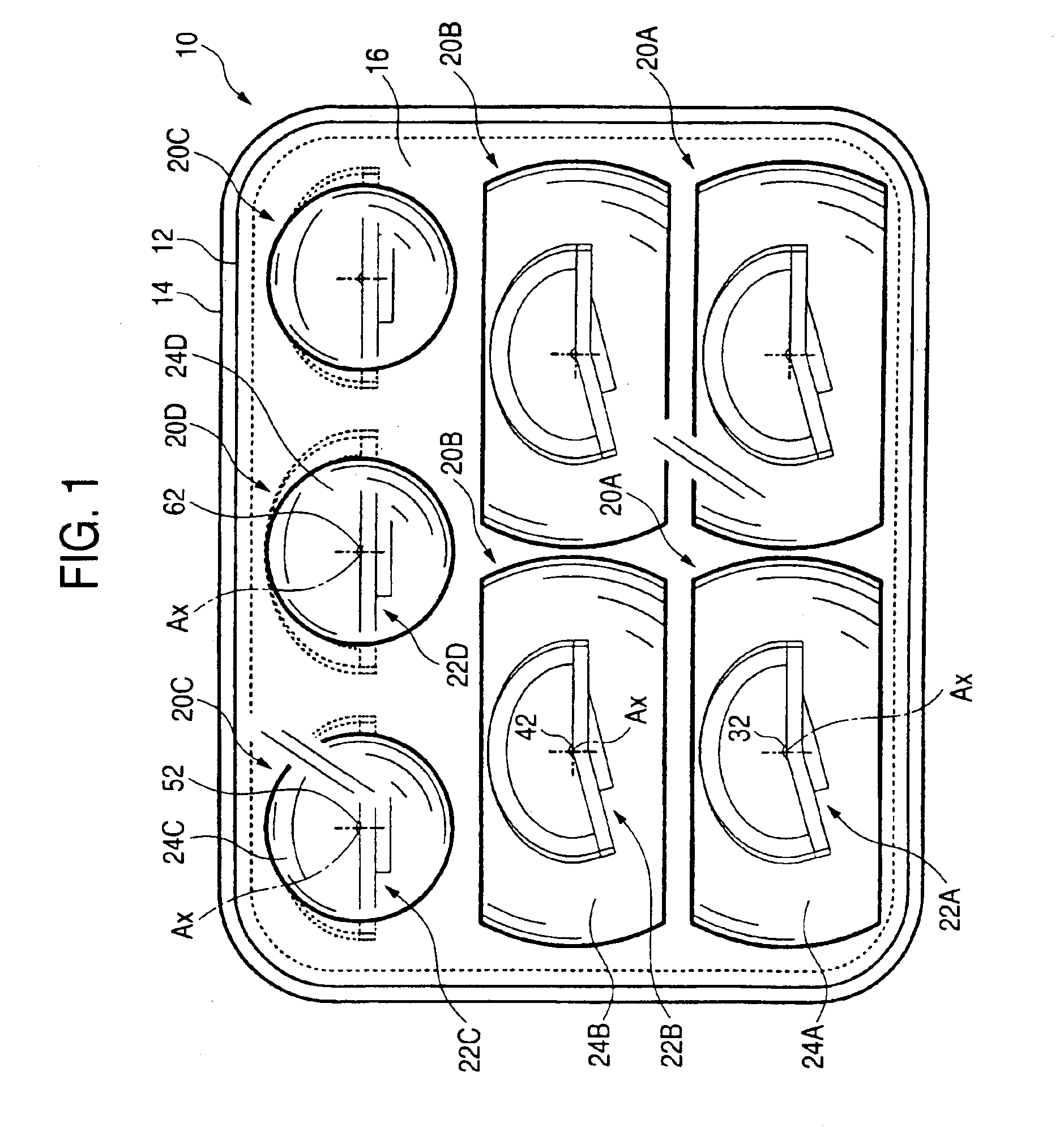

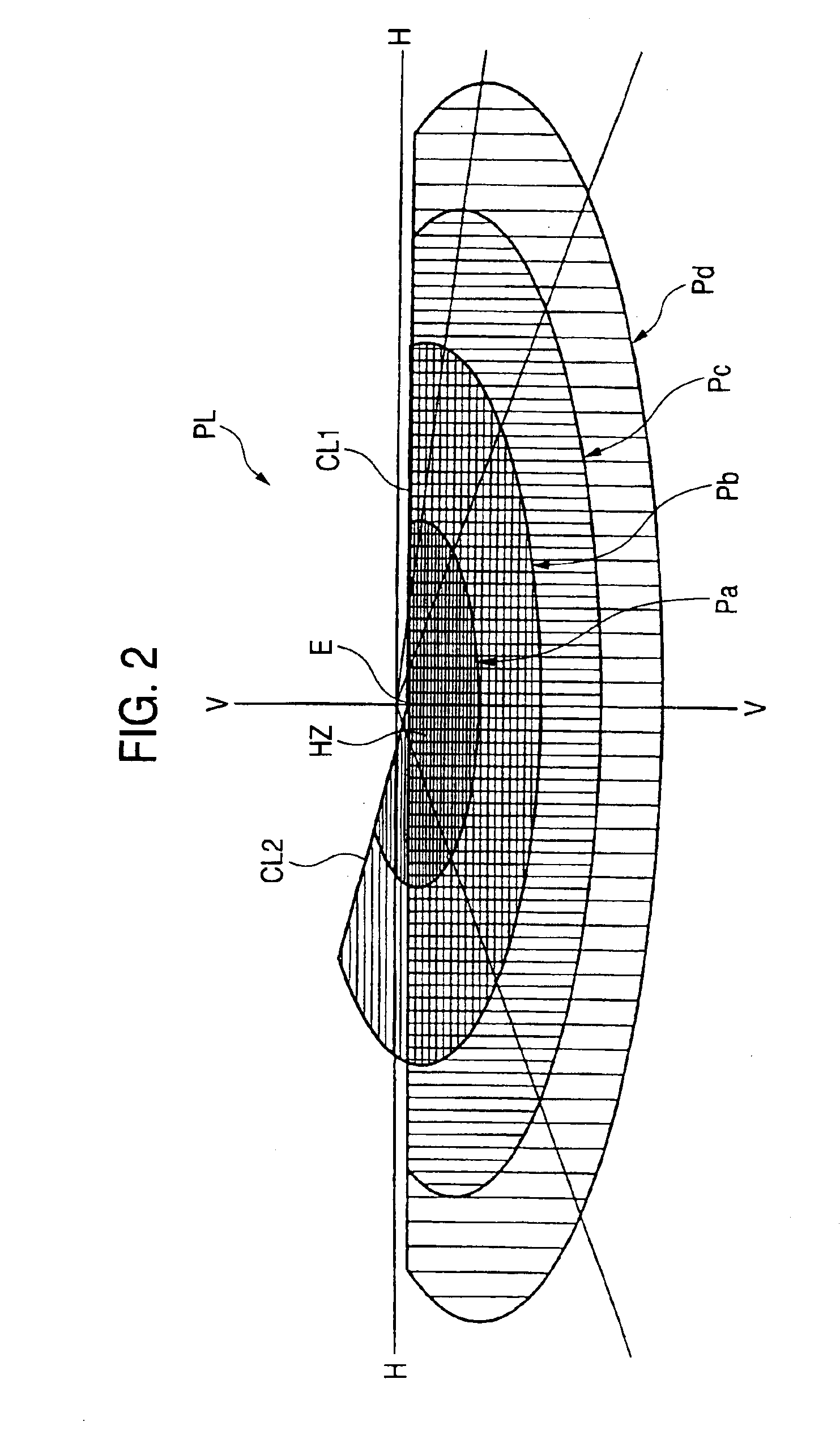

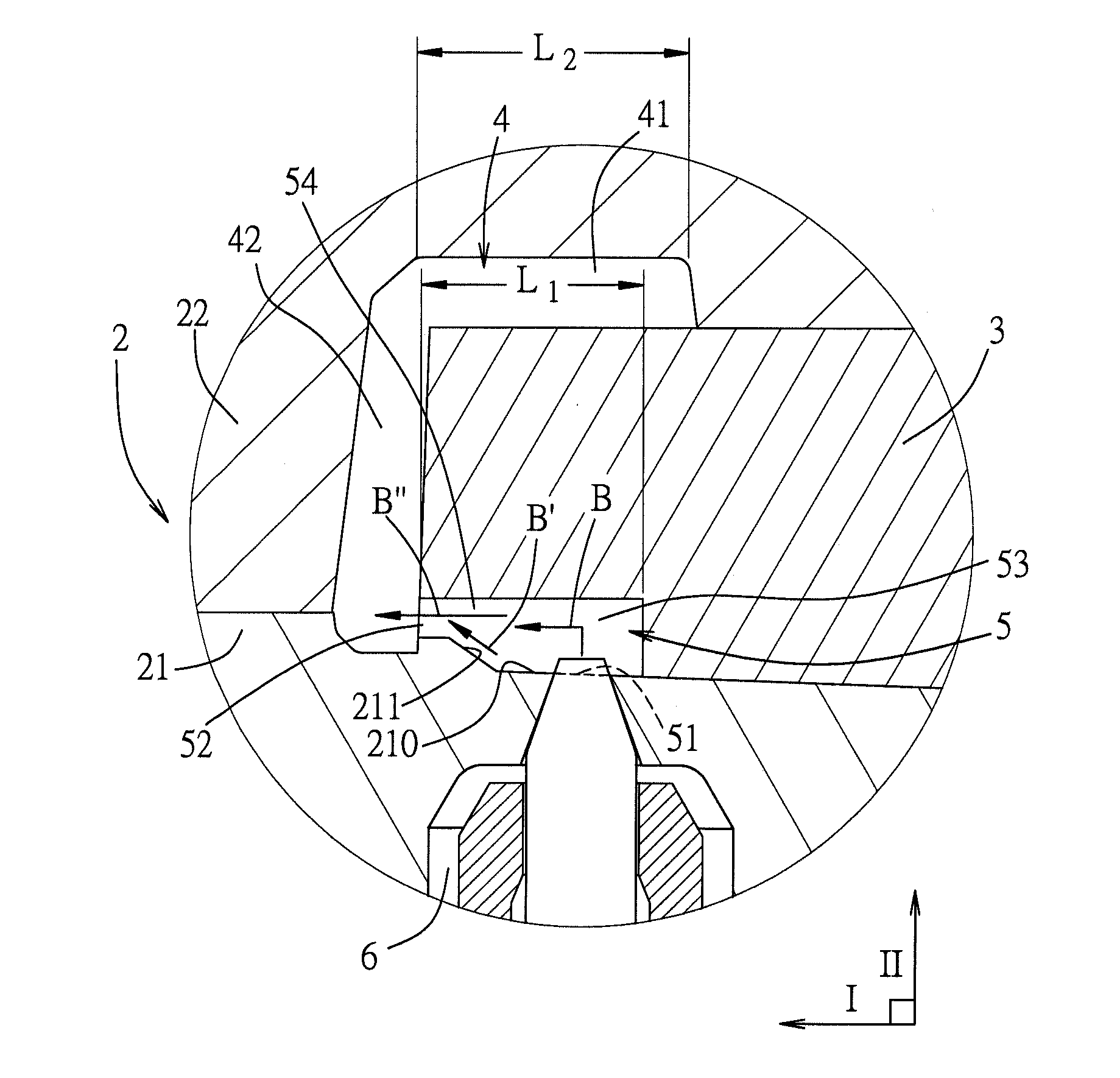

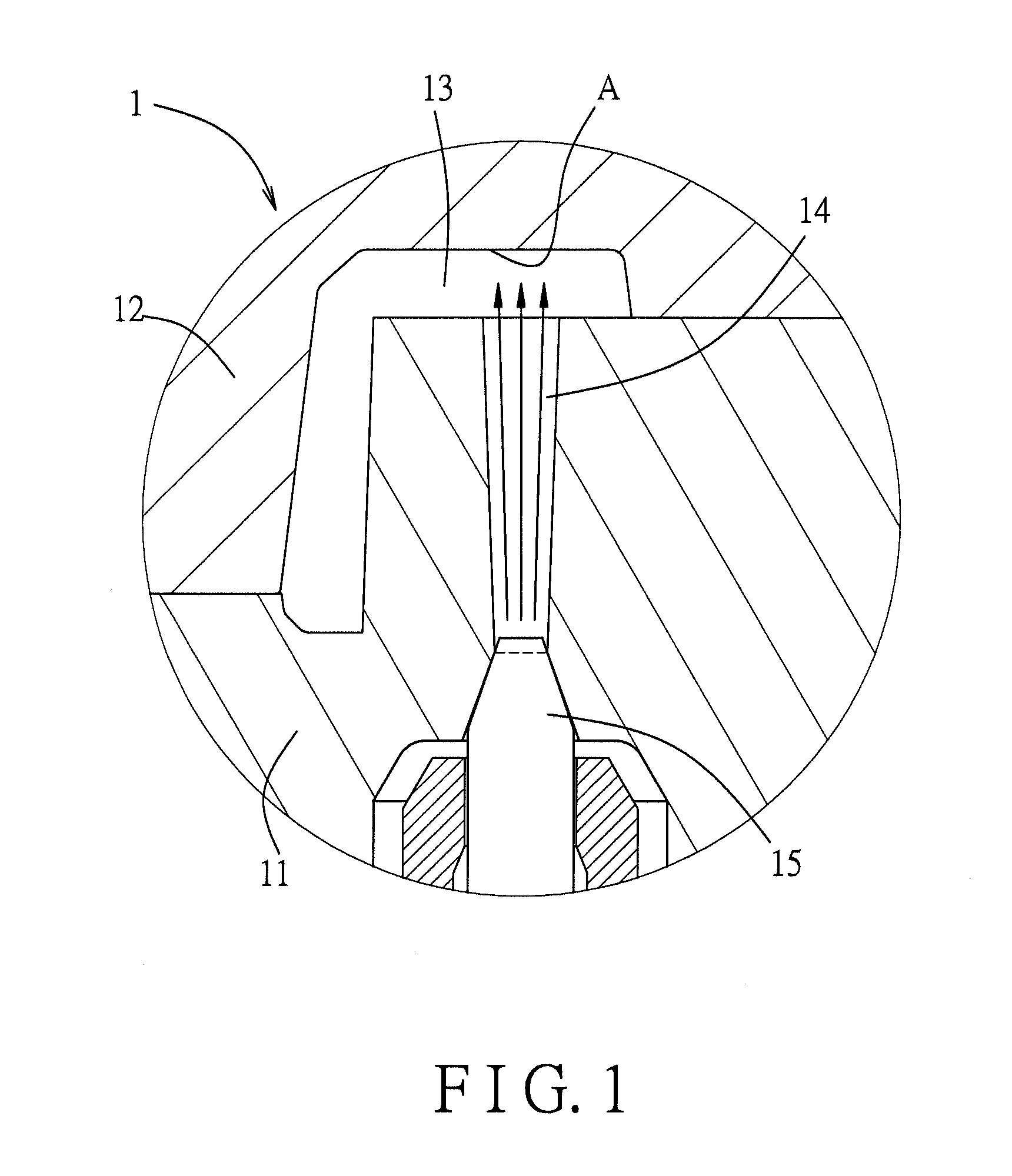

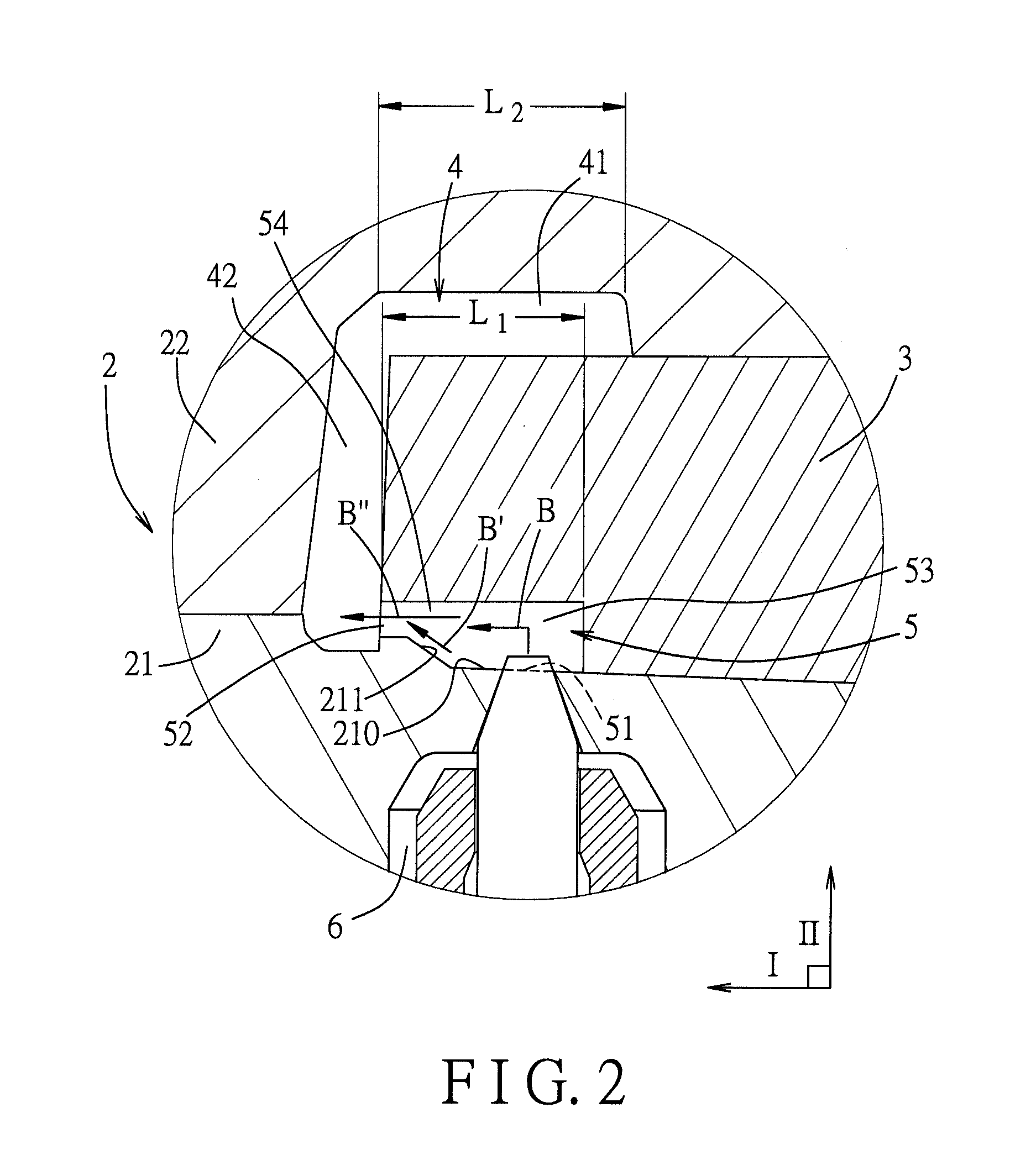

Vehicle headlamp

ActiveUS6951416B2Avoid widthVisibility of the distant area on the road surface ahead of the vehicle can be sufficiently ensuredVehicle headlampsPoint-like light sourceEngineeringLight-emitting diode

A vehicle headlamp is configured to have a plurality of lamp units employing light-emitting diodes as light sources. One lamp unit takes as a light source a light-emitting diode into which a single light-emitting chip is packaged. Other lamp units may take as light sources light-emitting diodes into which a plurality of light-emitting diodes are packaged. A diffusion area is formed by means of radiation of light output from the lamp units.

Owner:KOITO MFG CO LTD

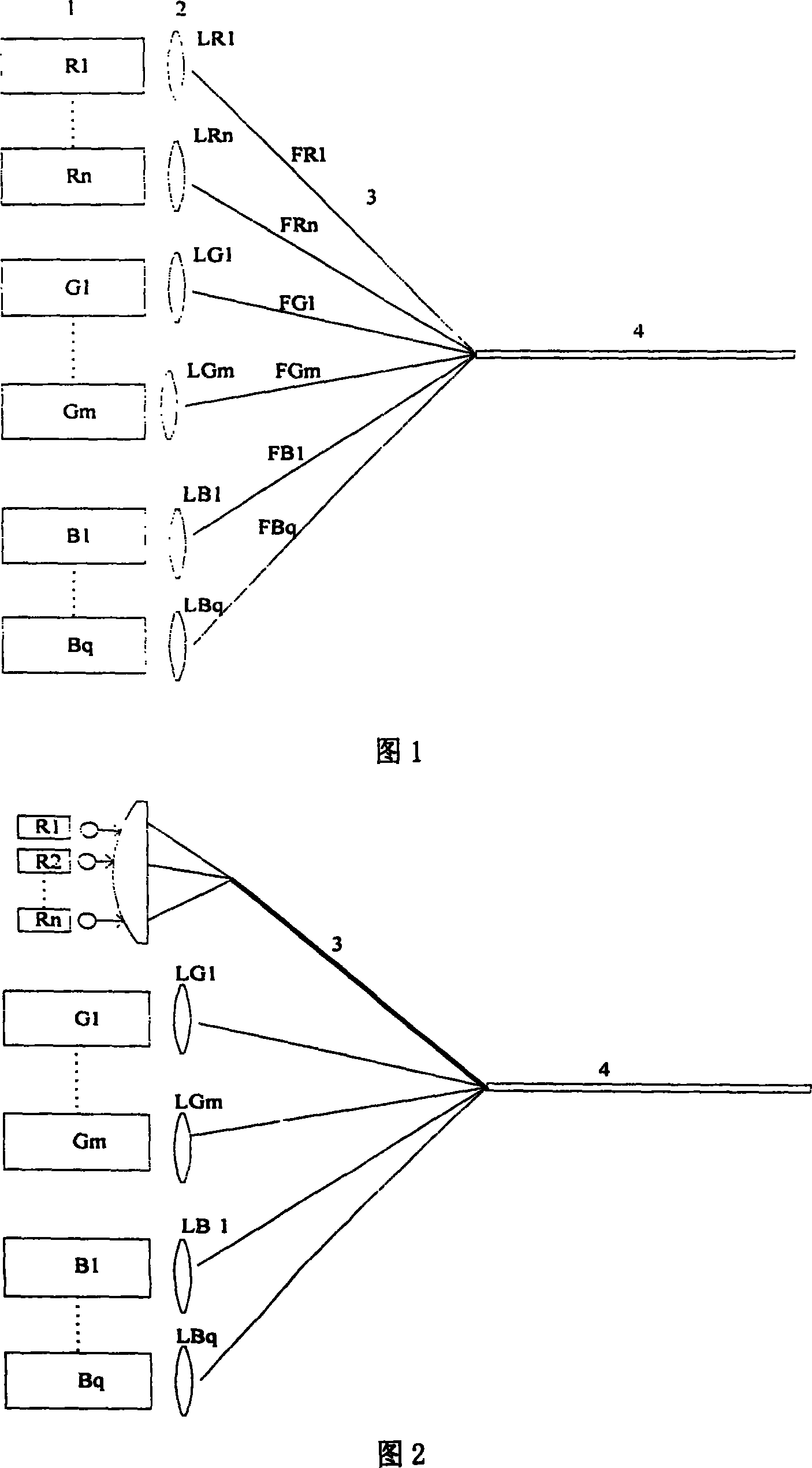

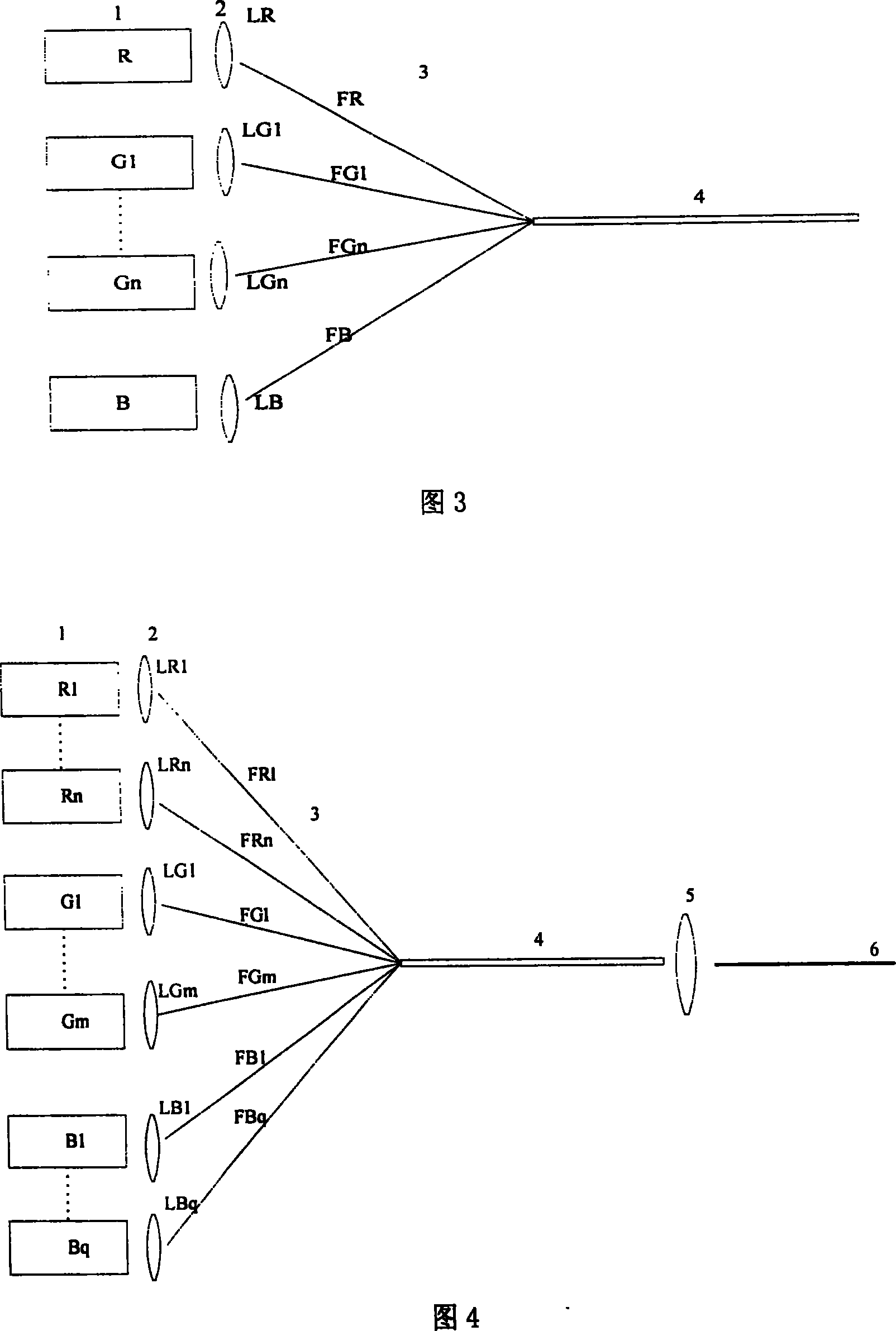

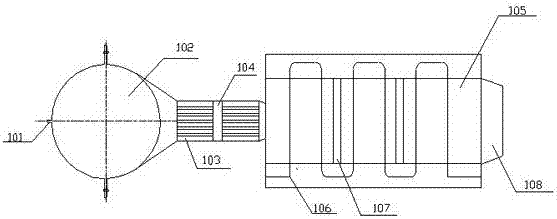

Laser homogenizing coupler device for laser display

The present invention discloses a laser equalization coupling device for laser display, and includes a trichromatic laser source and a focusing device. The trichromatic laser source comprises at least one red laser device, at least one green laser device, and at least one blue laser device. The focusing device includes a plurality of coupling optical fibers and a bushing. All coupling optical fibers correspond to the laser devices one-to-one. The laser emitted by the laser device couples and enters into the corresponding coupling optical fiber, and all output ends of the coupling optical fibers are packed in the bushing to form a combined beam of output laser. The present invention can meet the brightness requirement of the big-screen laser display, can reduce the volume of the whole coupling device, and can eliminate the beam speckle.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

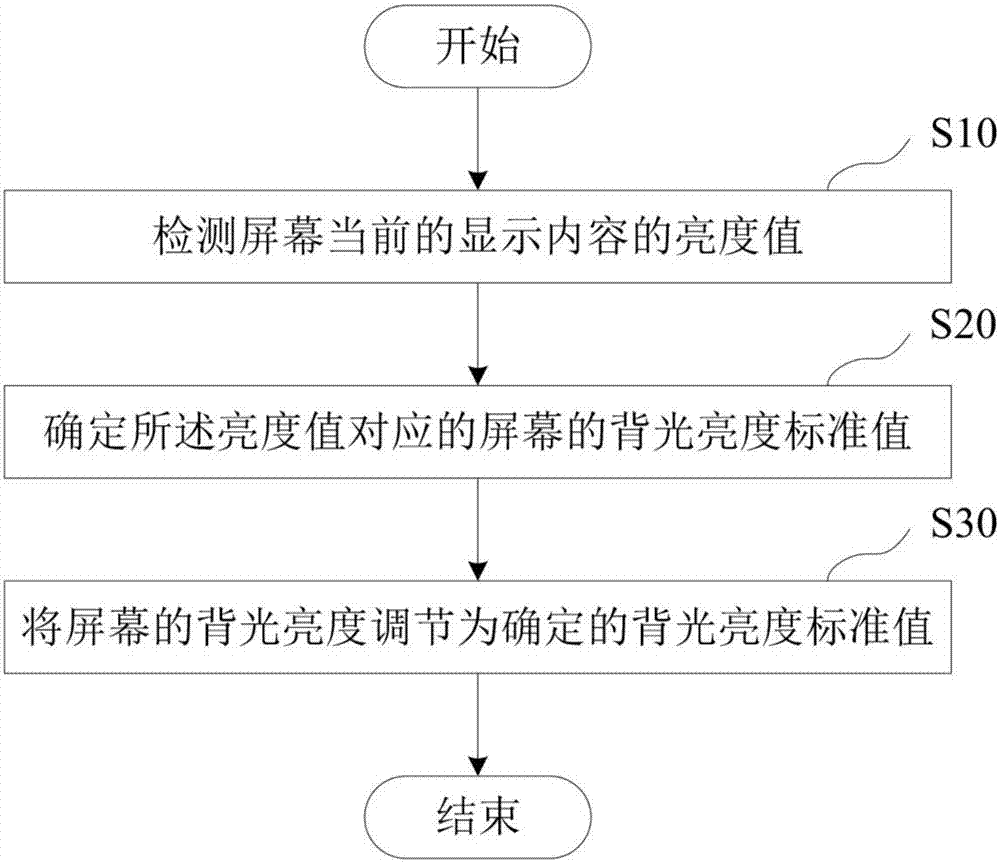

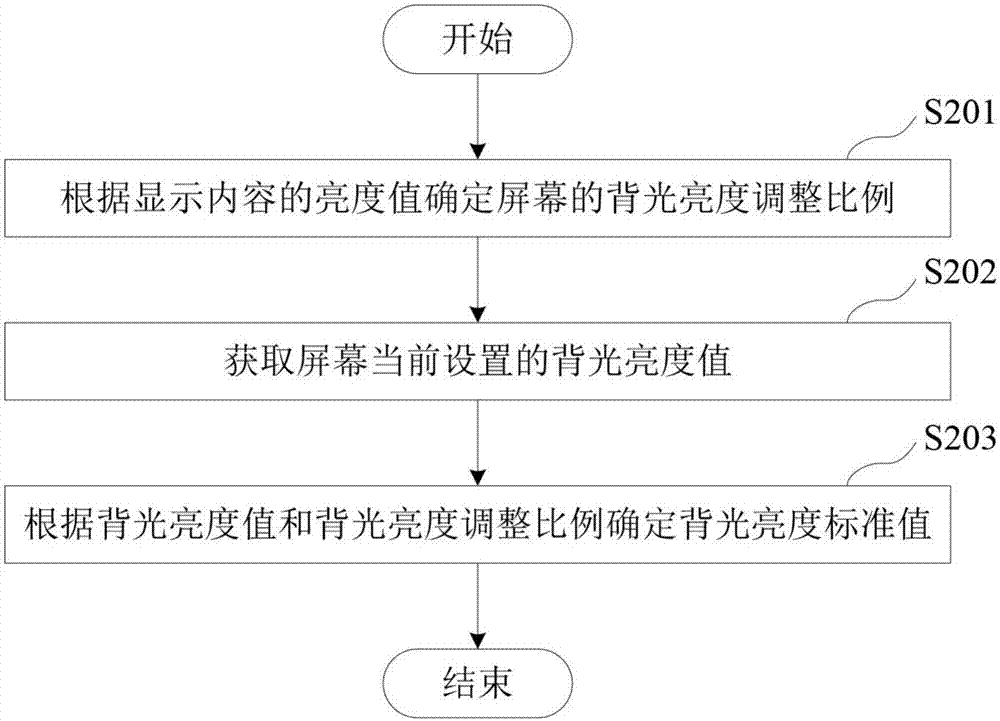

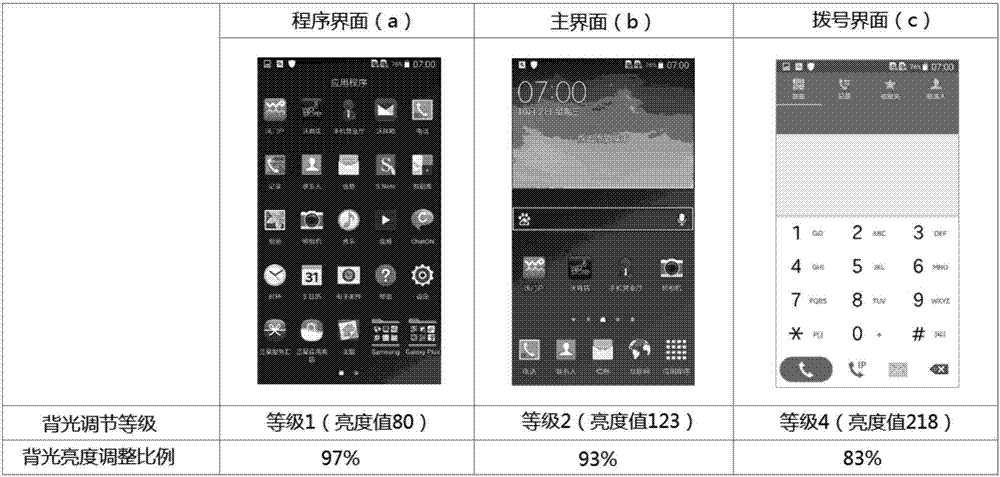

Screen brightness adjusting method and device of electronic terminal

InactiveCN106898311AAdjust backlight brightnessMeet brightness requirementsStatic indicating devicesComputer terminalBrightness perception

The invention provides a screen brightness adjusting method and device of an electronic terminal. The screen brightness adjusting method of an electronic terminal includes the steps: detecting the brightness value of the current displayed content of a screen; determining the backlight brightness standard value of the screen, corresponding to the brightness value of the current displayed content of the detecting screen; and adjusting the backlight brightness of the screen as the determined backlight brightness standard value. The screen brightness adjusting method and device of an electronic terminal can adjust the backlight brightness of the screen according to the displayed content of the screen of the electronic terminal, thus according with the brightness demand of a user, and saving the brightness loss of the system.

Owner:SAMSUNG GUANGZHOU MOBILE R&D CENT +1

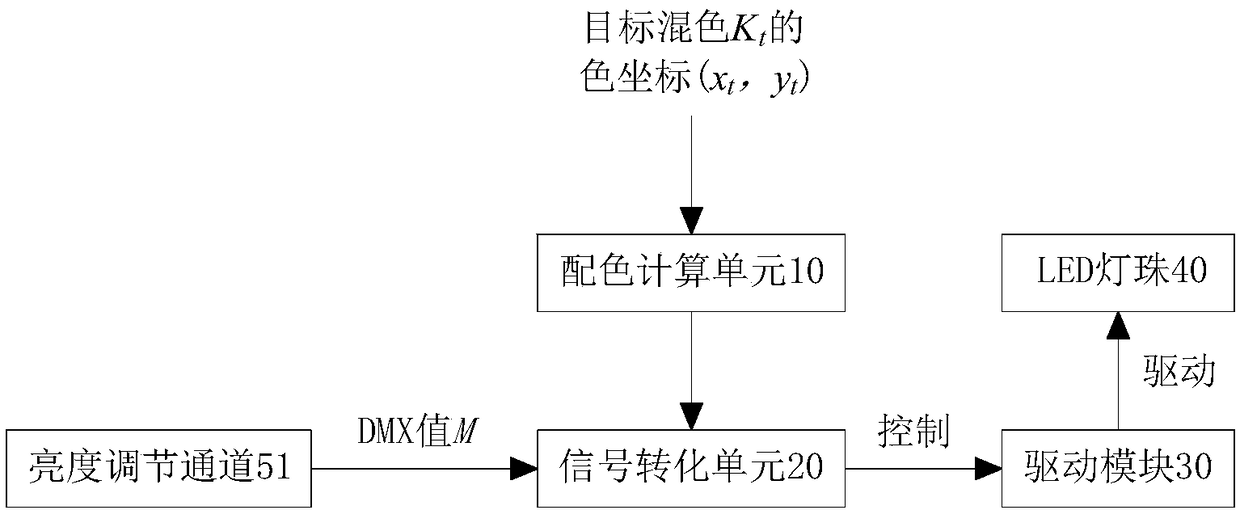

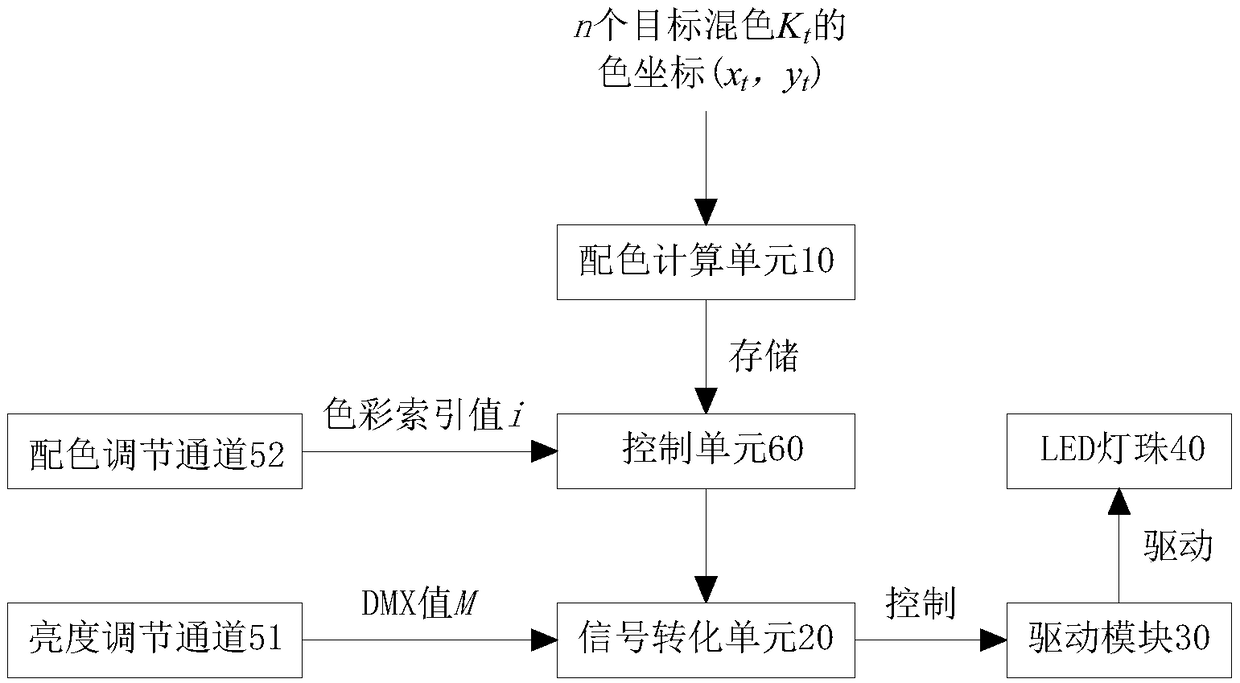

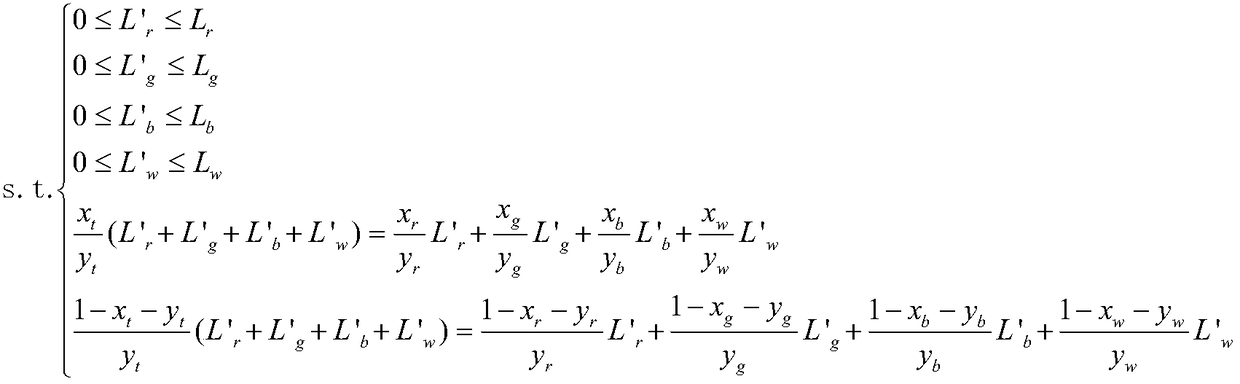

Automatic maximum brightness color matching realizing method for color lamp and color modulation method and system

ActiveCN109496035ATake advantage ofColor matching is faster and more accurateElectrical apparatusElectric light circuit arrangementGamutDimmer

The invention relates to the technical field of color lamp illumination, and in particular relates to an automatic maximum brightness color matching realizing method for a color lamp and a color modulation method and system. When the color lamp has three or more than three primary colors, multiple feasible solutions are provided for realizing a certain point in a color gamut space. According to the invention, the maximum brightness color matching algorithm is used to efficiently and accurately calculate the brightness formula of each primary color for the color lamp to realize the coordinate point of a certain color in the color gamut space; the brightness of the color lamp reaches the maximum after color matching; through the maximum brightness color matching algorithm, the brightness formula of a common target color in the color gamut space of the color lamp is calculated; the formulas are stored in a control unit of the lamp; a dimmer can easily call the desired color mixing formulaby adjusting a color matching channel on a console; automatic, fast and precise color mixing is realized with one button; and the maximum brightness is realized after color mixing, so that the brightness resources of the color lamp can be fully utilized.

Owner:GUANGZHOU HAOYANG ELECTRONICS CO LTD

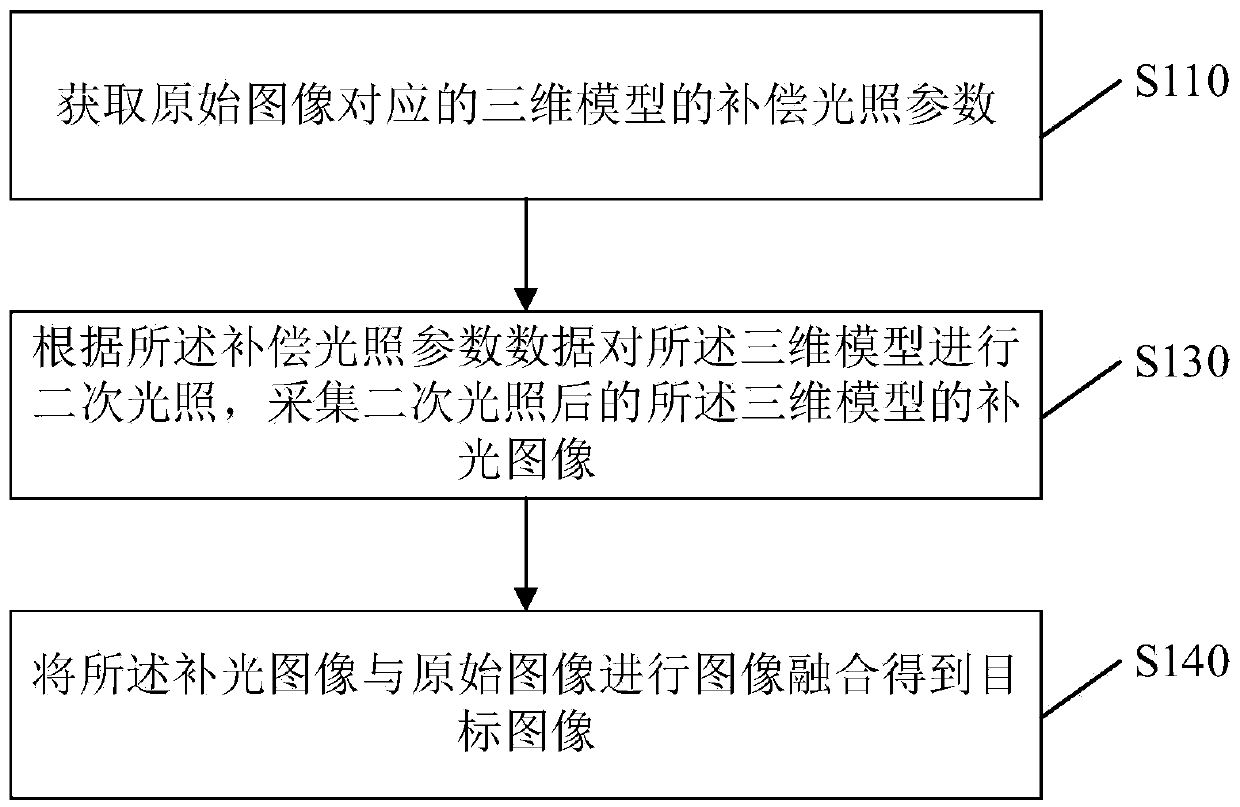

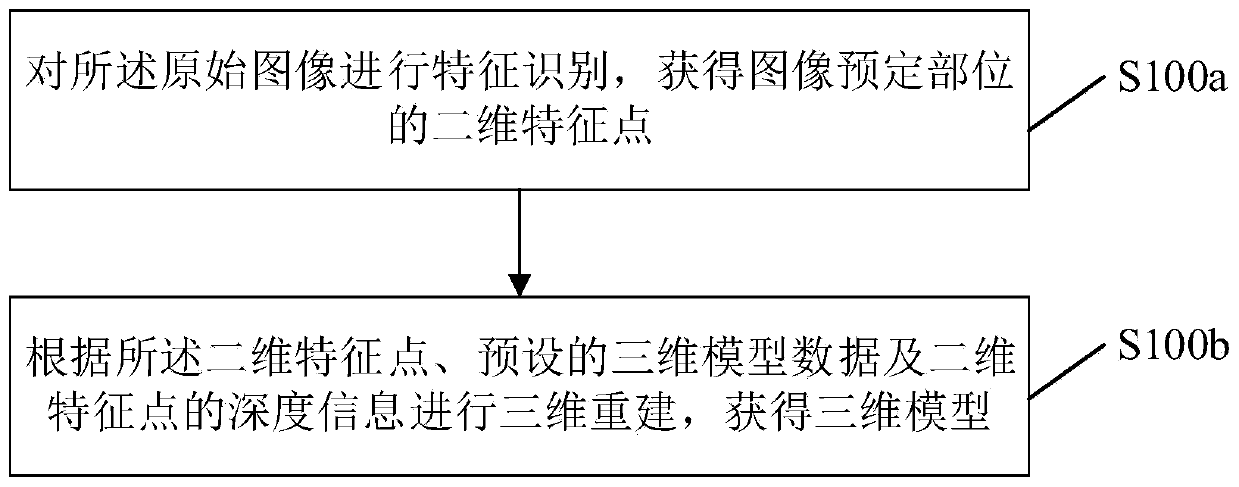

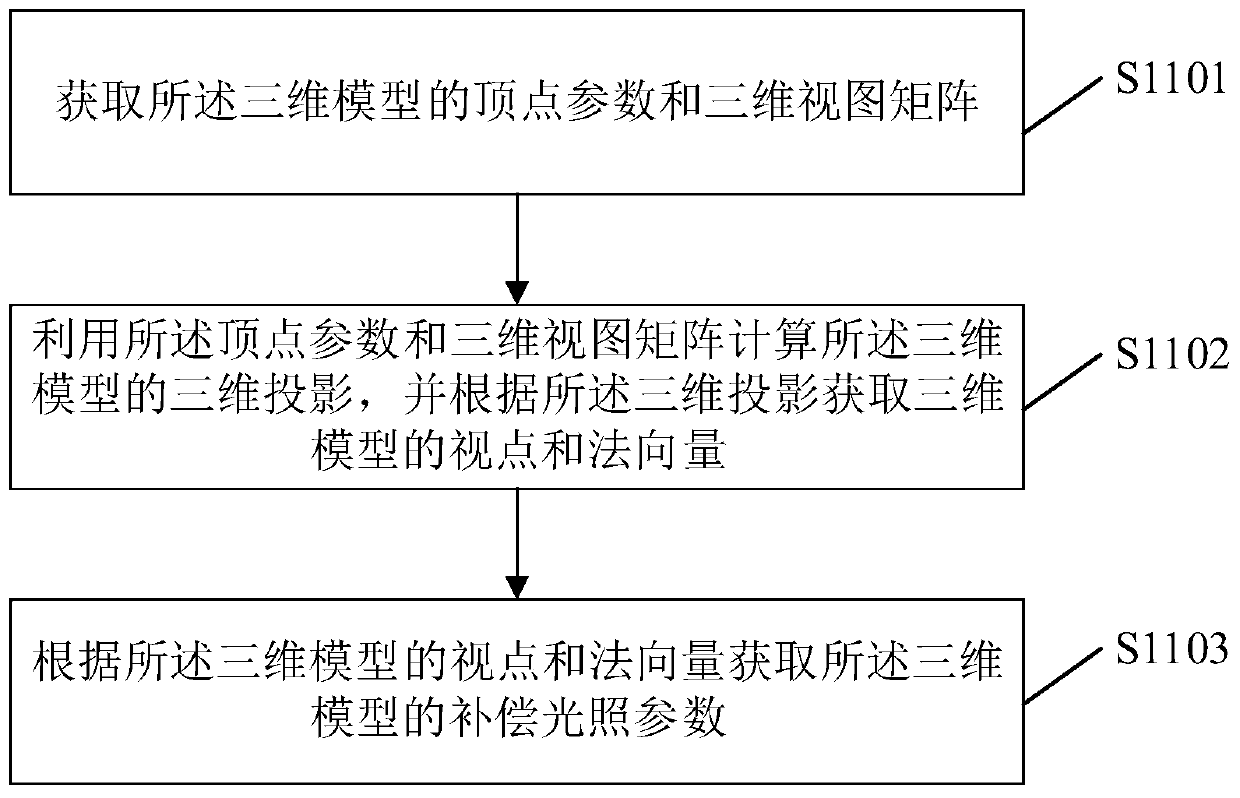

Image light supplementing method and device and computer device

ActiveCN109785423AIncrease ambient brightnessMeet brightness requirementsImage enhancement3D-image renderingImaging processingBrightness perception

The invention relates to the technical field of image processing, and especially relates to an image light supplementing method and device and a computer device. The image light supplementing method comprises the steps of obtaining a compensation illumination parameter of a three-dimensional model corresponding to an original image; performing secondary illumination on the three-dimensional modelaccording to the compensation illumination parameter data, and collecting a light supplementing image of the three-dimensional model after the secondary illumination; and carrying out image fusion onthe light supplementing image and the original image to obtain a target image. According to the scheme provided by the invention, the compensation illumination parameter of the three-dimensional modelcorresponding to the original image is acquired, and the to-be-compensated area in the original image is subjected to three-dimensional light compensation according to the compensation illumination parameter, so that the image brightness is effectively improved, and the real-time requirement of image light compensation can be met.

Owner:广州方硅信息技术有限公司

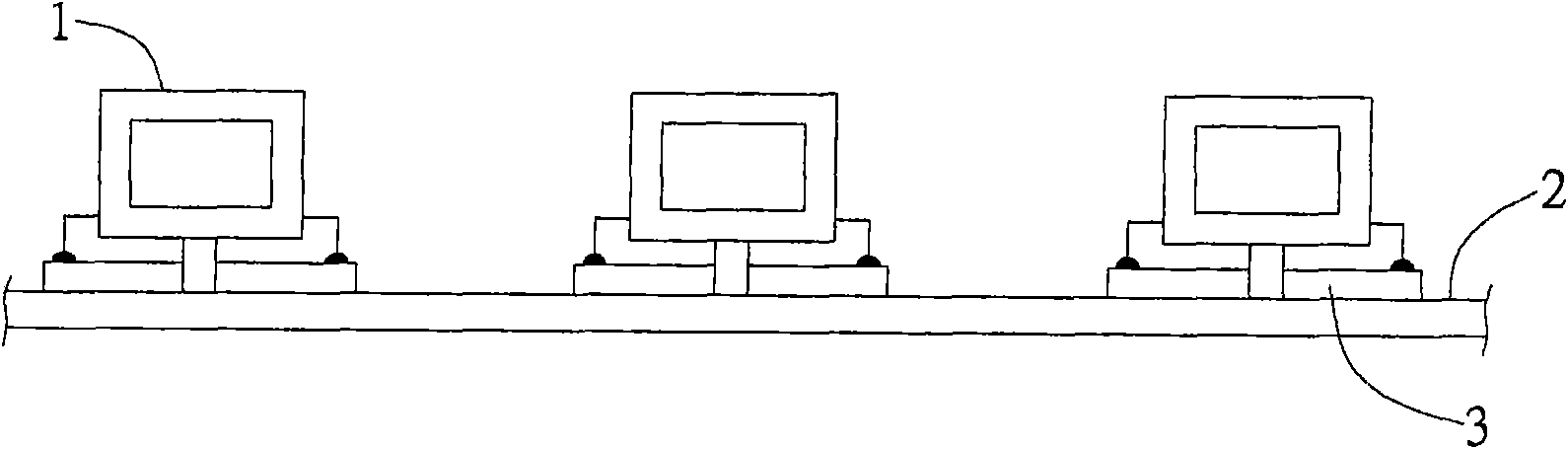

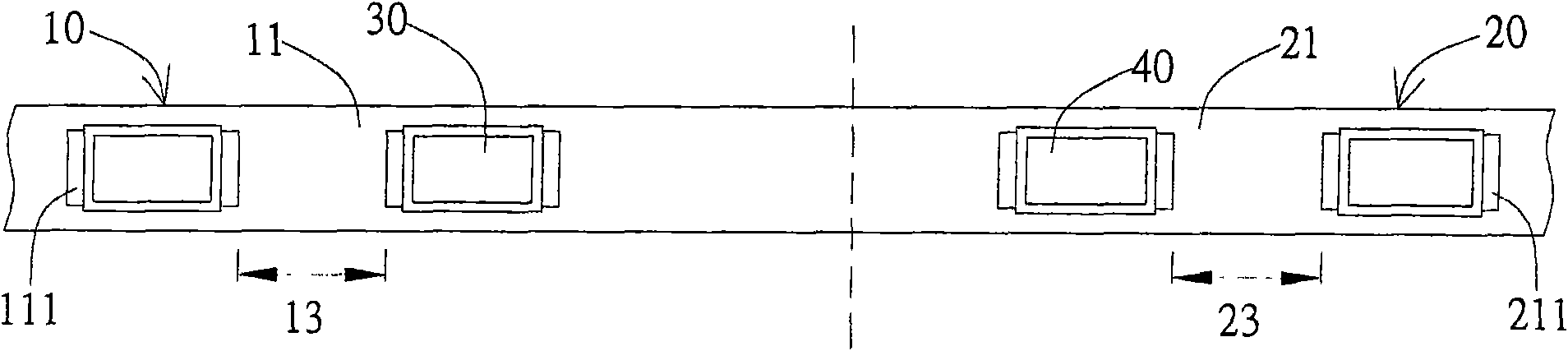

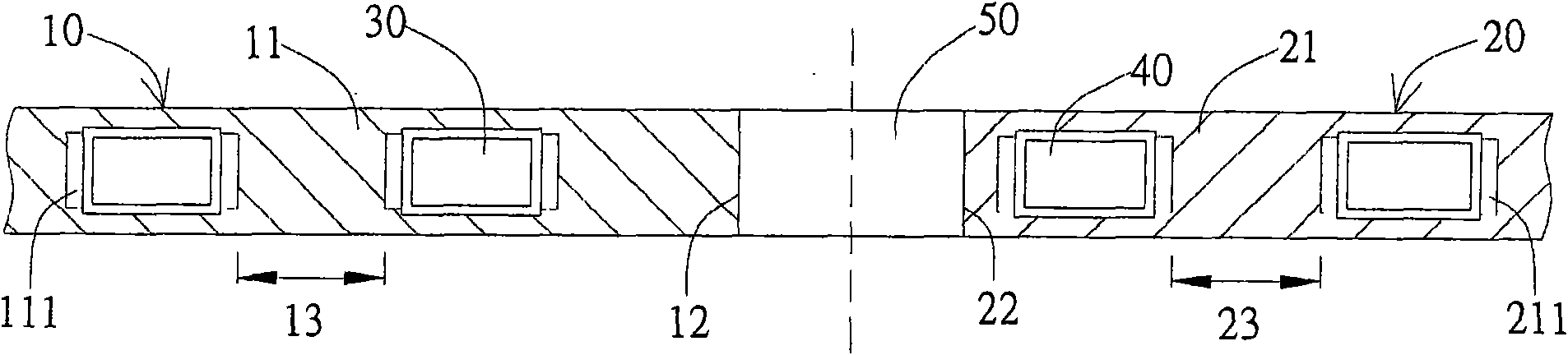

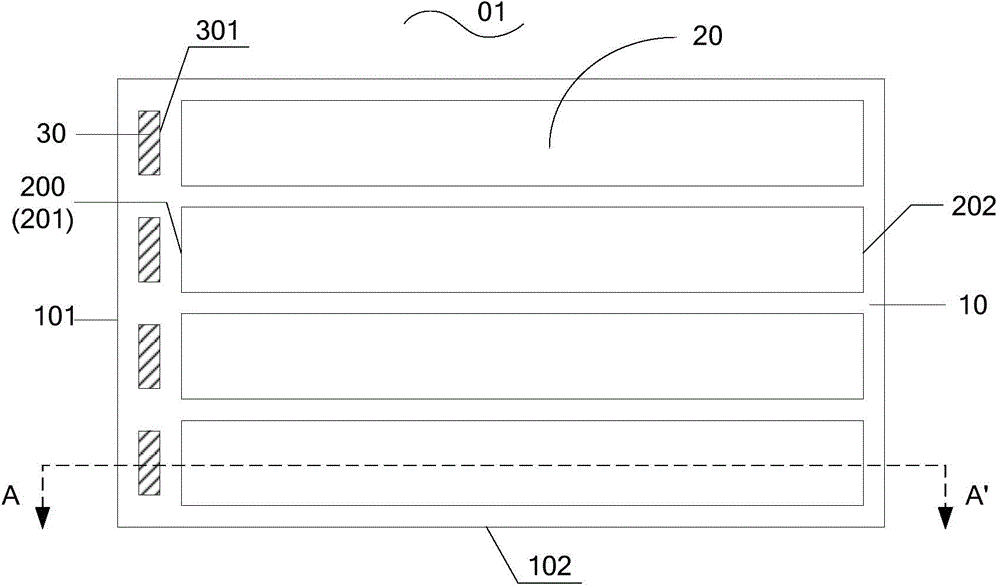

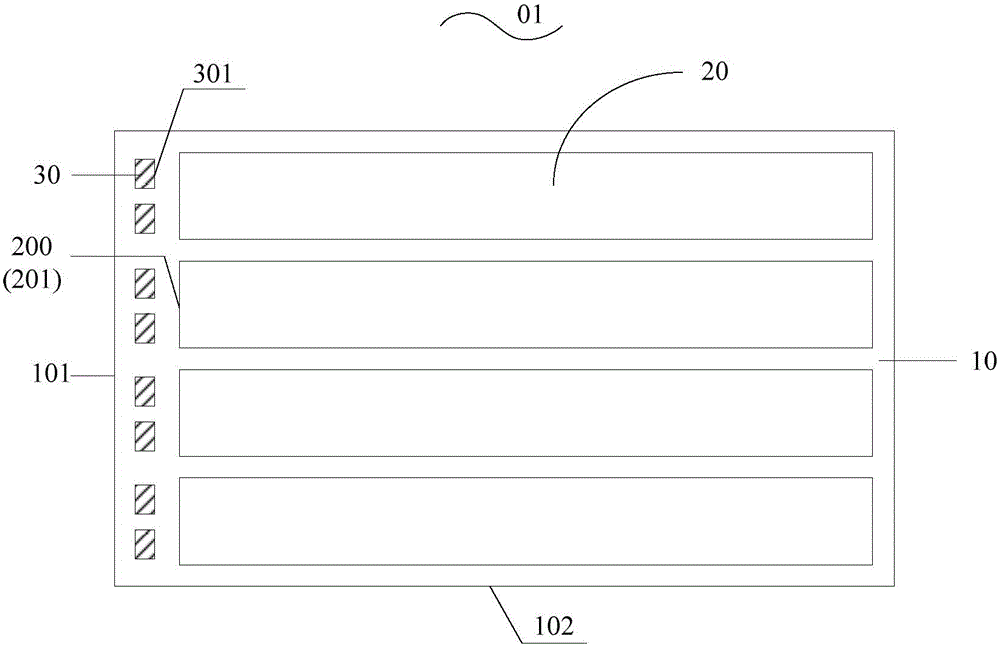

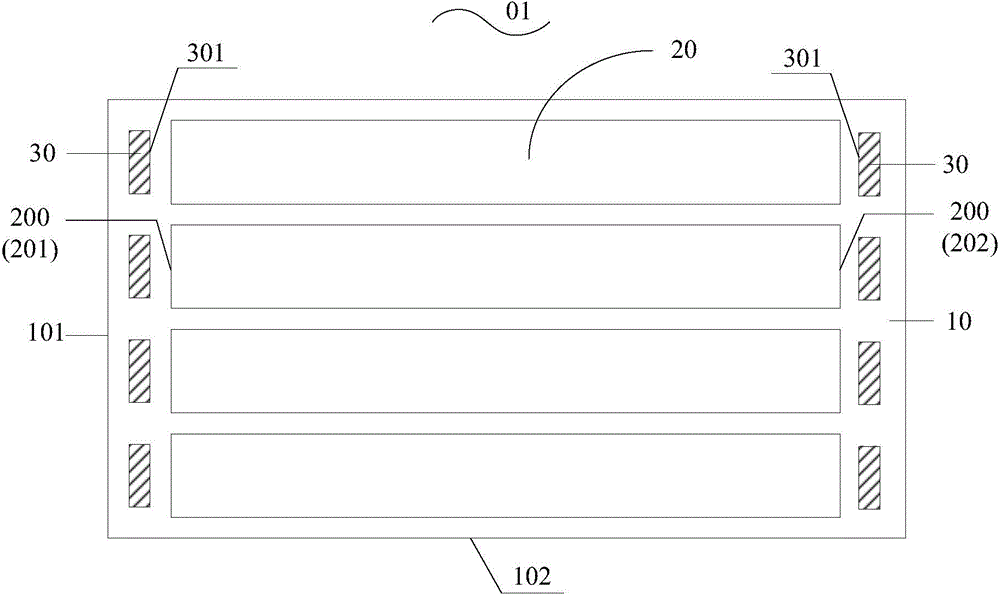

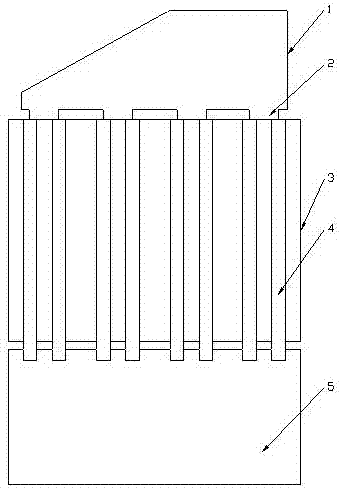

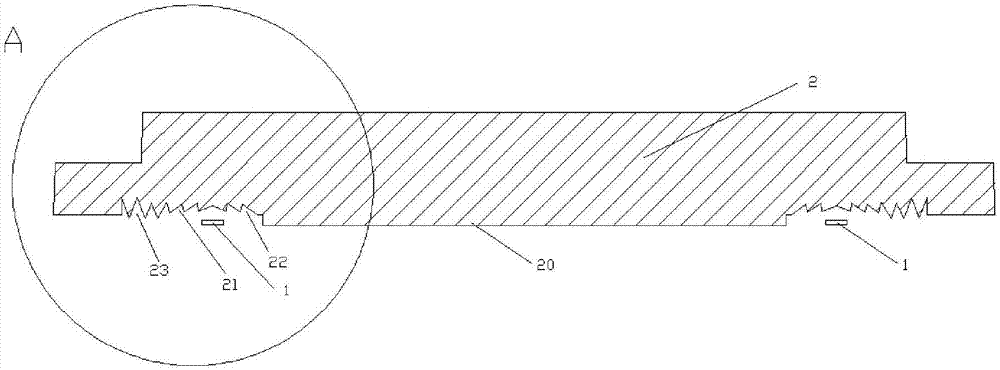

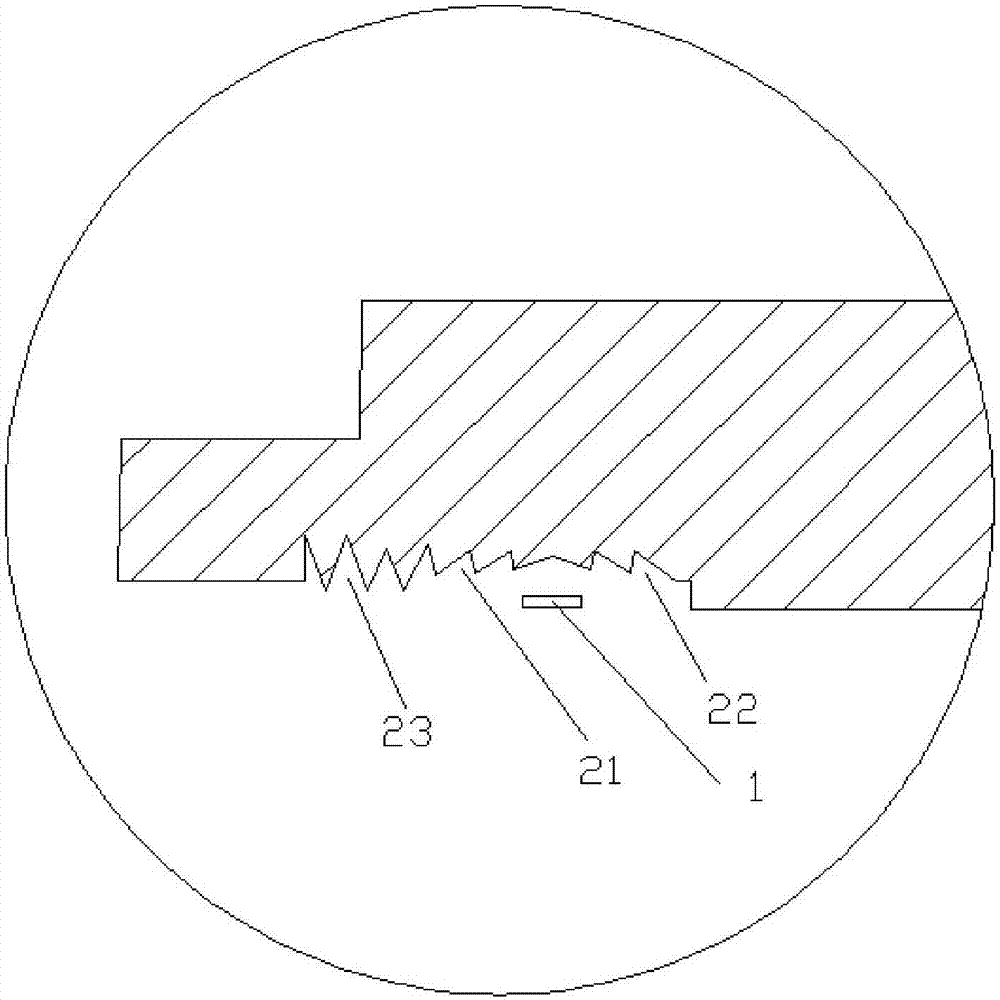

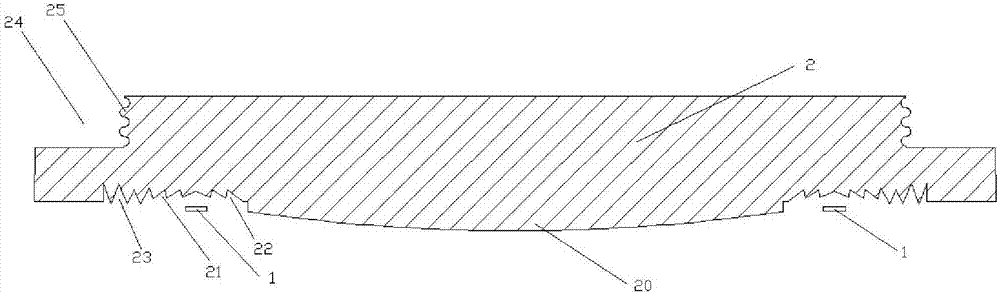

Light source module and backlight module

ActiveCN101672446AMeet the requirements of brightnessMeet brightness requirementsElectric circuit arrangementsNon-linear opticsComputer moduleDisplay device

The invention provides a light source module and a backlight module. The light source module comprises a first substrate, first light sources, a second substrate and second light sources, wherein thefirst substrate is provided with a first surface and a first connecting end; a plurality of first light sources are linearly arranged on the first surface; a first gap is arranged between every two adjacent first light sources; the second substrate is in parallel to the first substrate and is provided with a second surface and a second connecting end, the second surface faces the first surface, and the second connecting end is connected with the first connecting end; a plurality of second light sources are linearly arranged on the second surface; a second gap is arranged between every two adjacent second light sources; at least part of the second light sources respectively extend into the corresponding first gaps; and correspondingly, at least part of the first light sources respectively extend into the corresponding second gaps. By using the invention, when the side length of the effective display area of the panel display is fixed, more light sources can be arranged so as to meet higher requirements for the brightness of the panel display.

Owner:AU OPTRONICS CORP

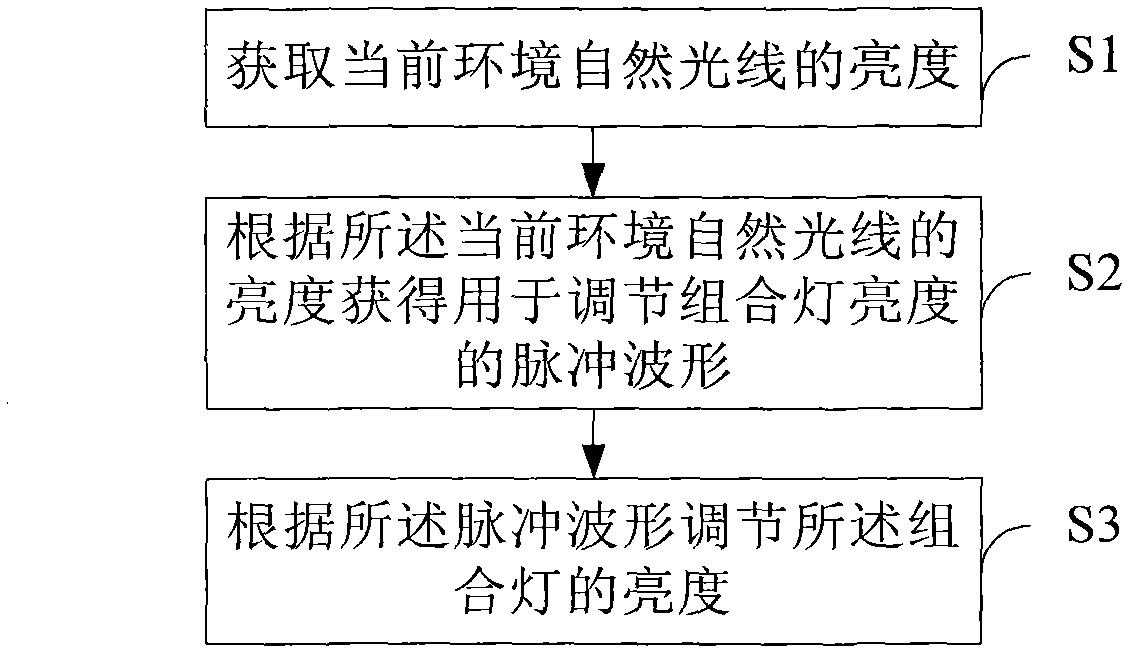

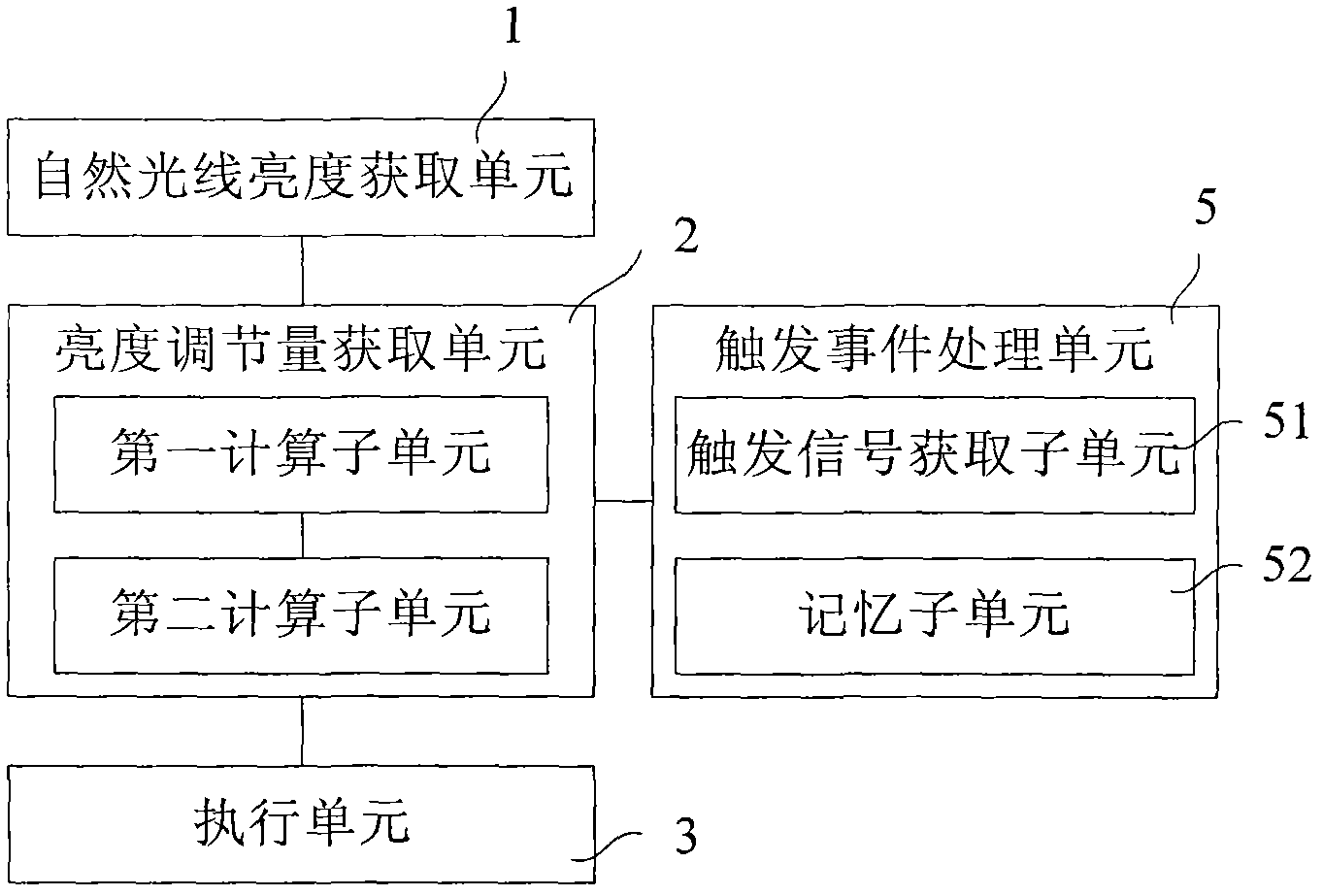

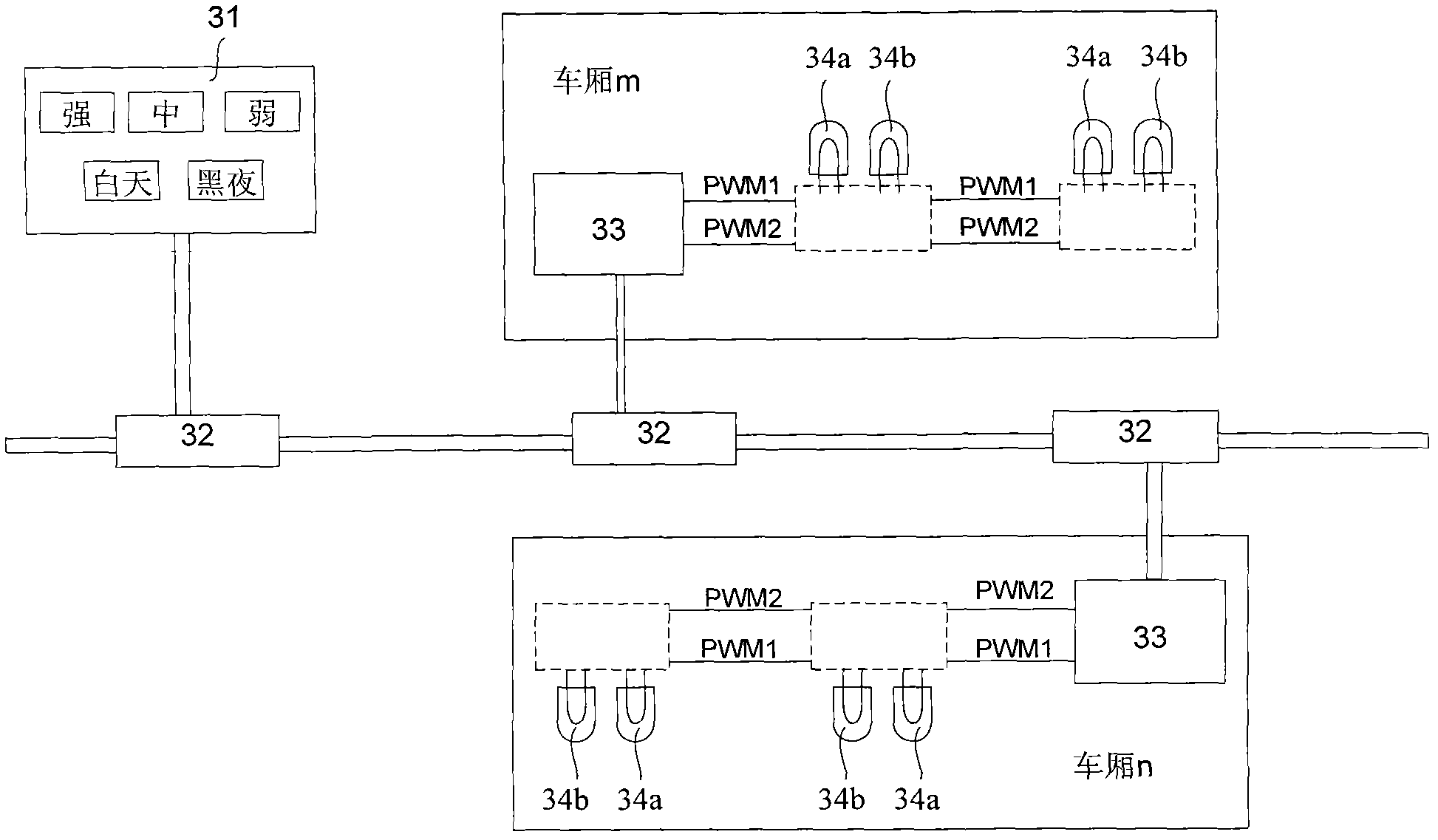

Method and device for controlling combined lamp light

InactiveCN102497702AMeet brightness requirementsReduce or even avoid wasteElectric light circuit arrangementOptoelectronicsPulse waveform

The invention provides a method and a device for controlling combined lamp light. The method for controlling the combined lamp light is used for regulating the brightness of a combined lamp and comprises the following steps of: acquiring the brightness of current natural ambient light rays; acquiring pulse waveforms used for regulating the brightness of the combined lamp according to the brightness of the current natural ambient light rays; and regulating the brightness of the combined lamp according to the pulse waveforms. The method for controlling the combined lamp light can be used for controlling the brightness of the combined lamp according to the intensity of the natural ambient light, so that not only can the requirement of users on the brightness of the ambient light be met, but also electric energy wastes can be reduced and even avoided.

Owner:北京九华互联科技有限公司

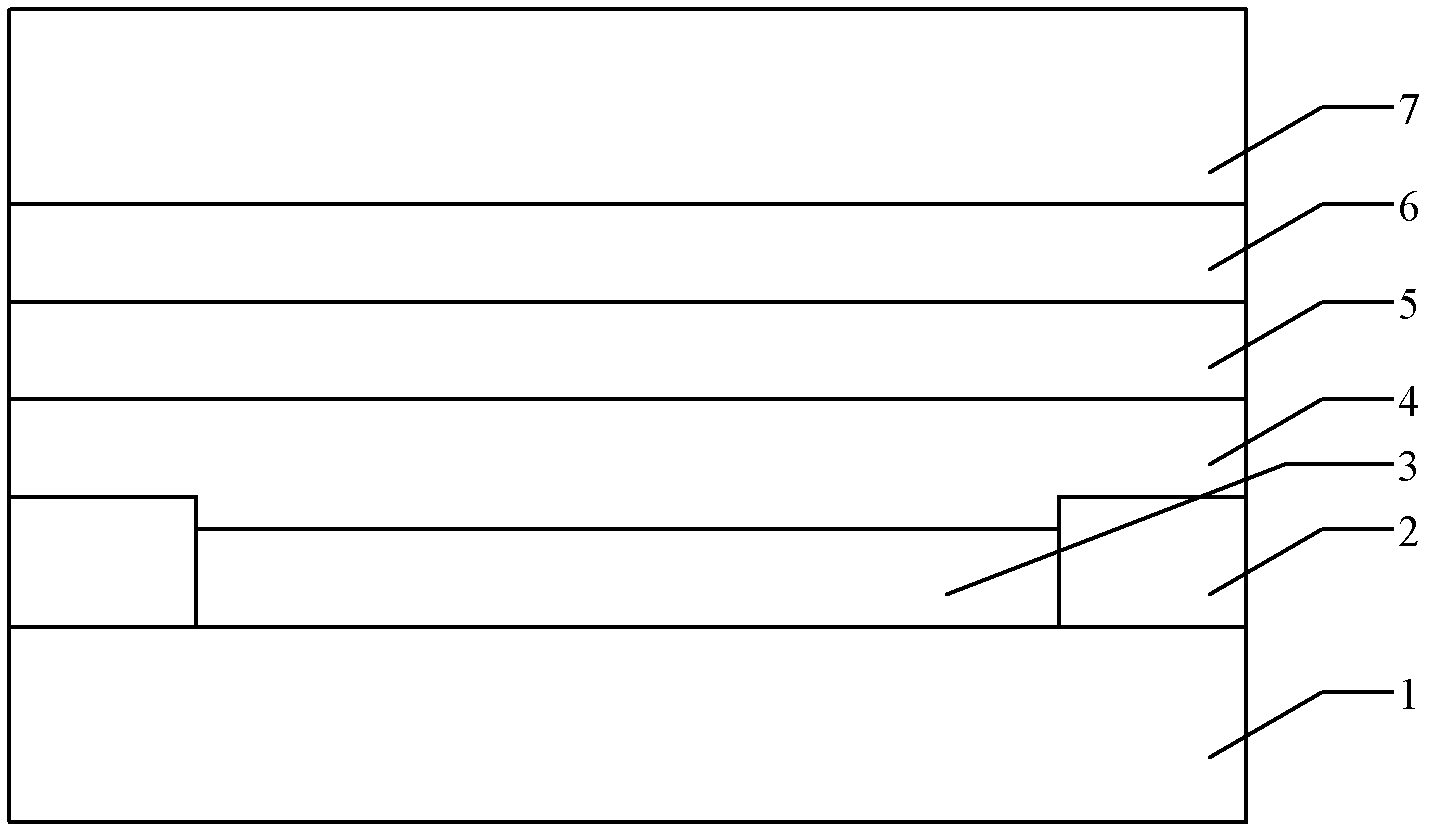

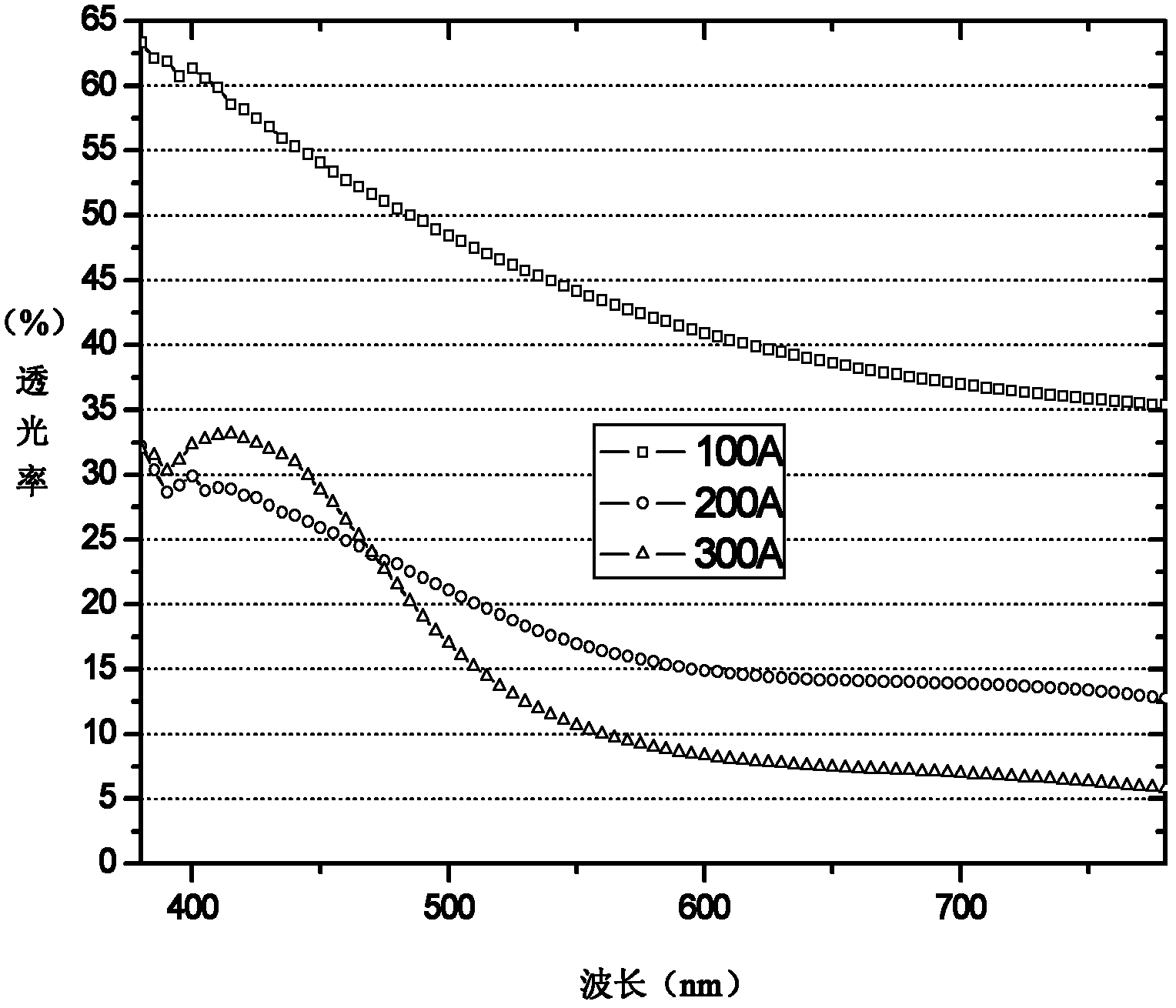

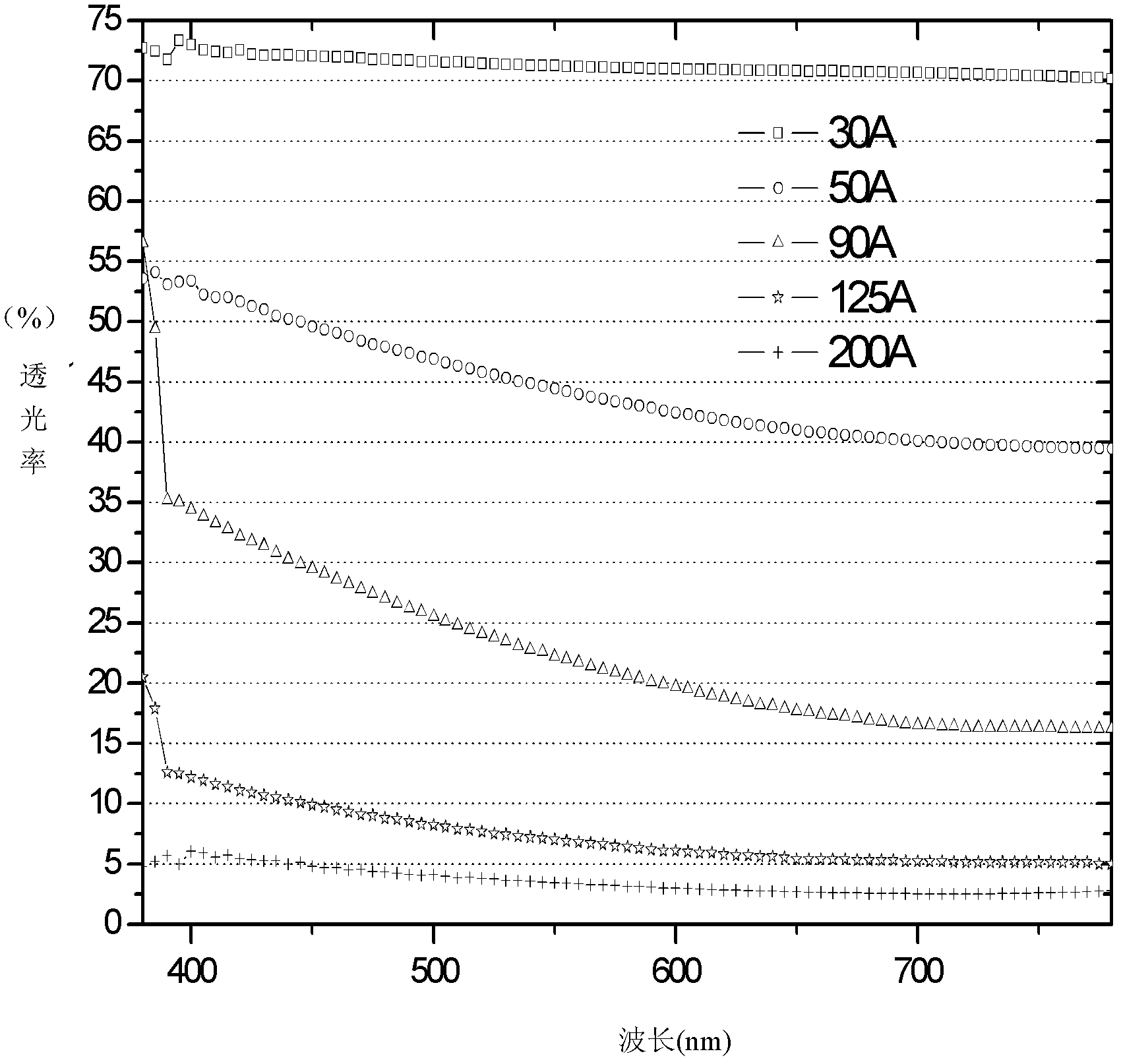

Organic light emitting diode (OLED) composite transparent negative pole structure and preparation method thereof

InactiveCN102593373AHigh light transmittanceImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingActive matrixEffect light

The invention relates to the technical field of organic light emitting diode (OLED) lighting, discloses an OLED composite transparent negative pole structure and solves the problem that the transparent negative pole structure or electrical conductivity or transmittance of the transparent negative pole structure in the prior art is poor so that the luminance cannot meet requirements. The technical scheme is characterized in that the OLED composite transparent negative pole structure comprises a transparent negative pole layer and an auxiliary transparent negative pole layer, and the auxiliary transparent negative pole layer is located above the transparent negative pole layer. The transparent negative pole layer is made of an Mg-Ag alloy material, and the auxiliary transparent negative pole layer is made of an Ag material. In addition, a preparation method of the OLED composite transparent negative pole structure is further disclosed. The OLED composite transparent negative pole structure is applicable to preparation of high luminance top emission active matrix / organic light emitting diode (AMOLED) devices.

Owner:SICHUAN CCO DISPLAY TECH

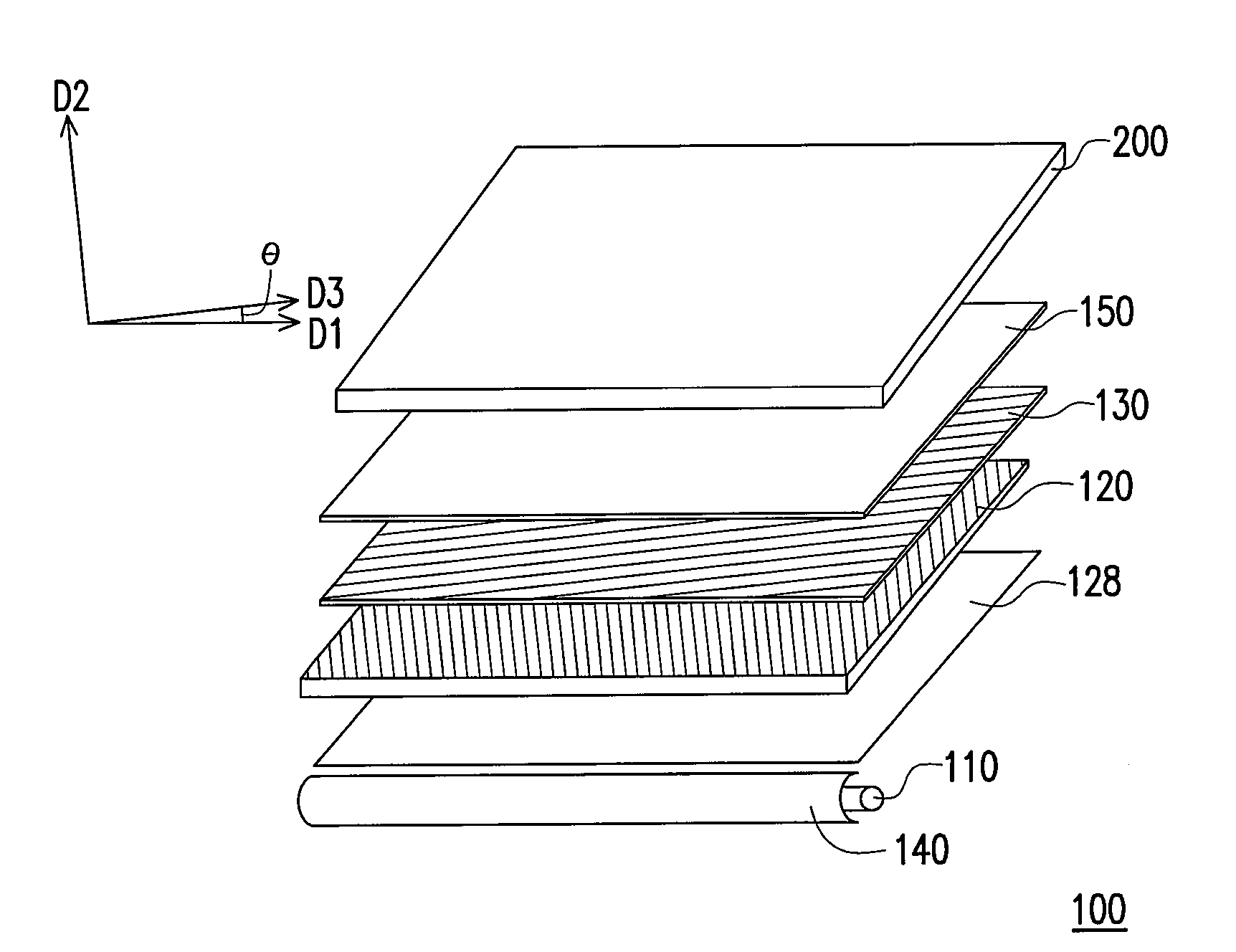

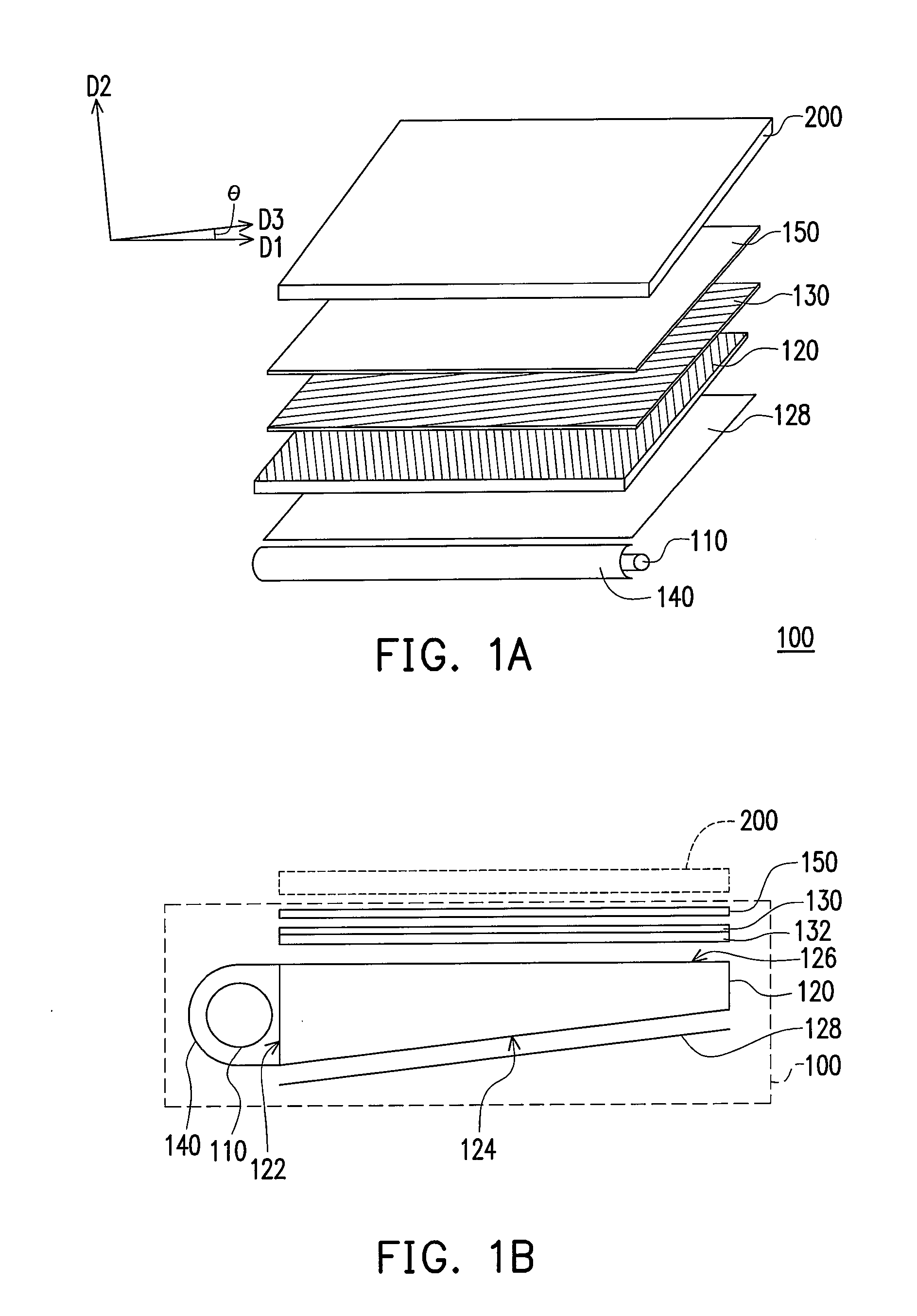

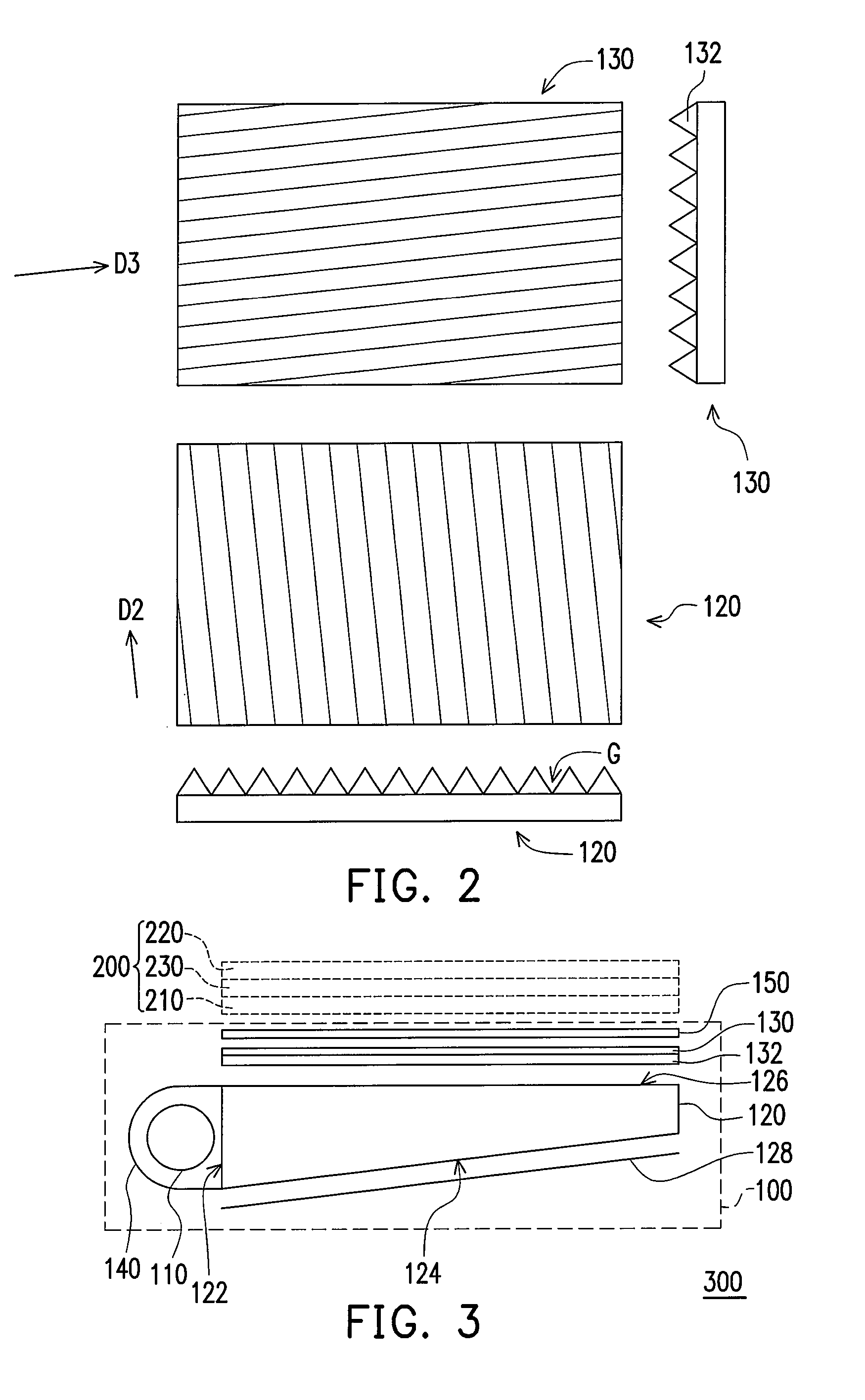

Backlight module and optical display device having the same

InactiveUS20090002592A1Improve display qualityReduce brightnessOptical light guidesNon-linear opticsAcute angleLight guide

A backlight module including a light source, a light guide plate and a prism sheet is provided. The light source is arranged along a first direction. The light guide plate having a light incident surface, a light refraction surface and a light emission surface is disposed on one side of the light source. The light refraction surface has a plurality of grooves parallel to one another in a second direction. The prism sheet is disposed on the light emission surface of the light guide plate, and has a plurality of prism portions parallel to one another in a third direction and on a surface of the prism sheet facing the light emission surface. The second direction is substantially perpendicular to the third direction, and an acute angle formed between the first direction and the third direction is less than or equal to 7 degrees.

Owner:CORETRONIC

Organic light-emitting diode (OLED) composite transparent cathode structure and preparation method thereof

InactiveCN102569670AHigh light transmittanceImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingActive matrixTransmittance

The invention relates to the technical field of organic light-emitting diode (OLED) luminescence, and discloses an OLED composite transparent cathode structure to solve the problem that the brightness cannot meet requirements because the electrical conductivity or the transmittance of a transparent cathode structure or a composite transparent cathode structure in the prior art is not good. The key point of the technical scheme is that the OLED composite transparent cathode structure comprises a transparent cathode layer and an auxiliary transparent cathode layer, wherein the auxiliary transparent cathode layer is positioned above the transparent cathode layer; and the transparent cathode layer is made of a Al-Li alloy material, and the auxiliary transparent cathode layer is made of an Ag material. Moreover, the invention also discloses a preparation method for the OLED composite transparent cathode structure. The OLED composite transparent cathode structure is suitable for preparing high-brightness top-emission active matrix / organic light-emitting diode (AMOLED) devices.

Owner:SICHUAN CCO DISPLAY TECH

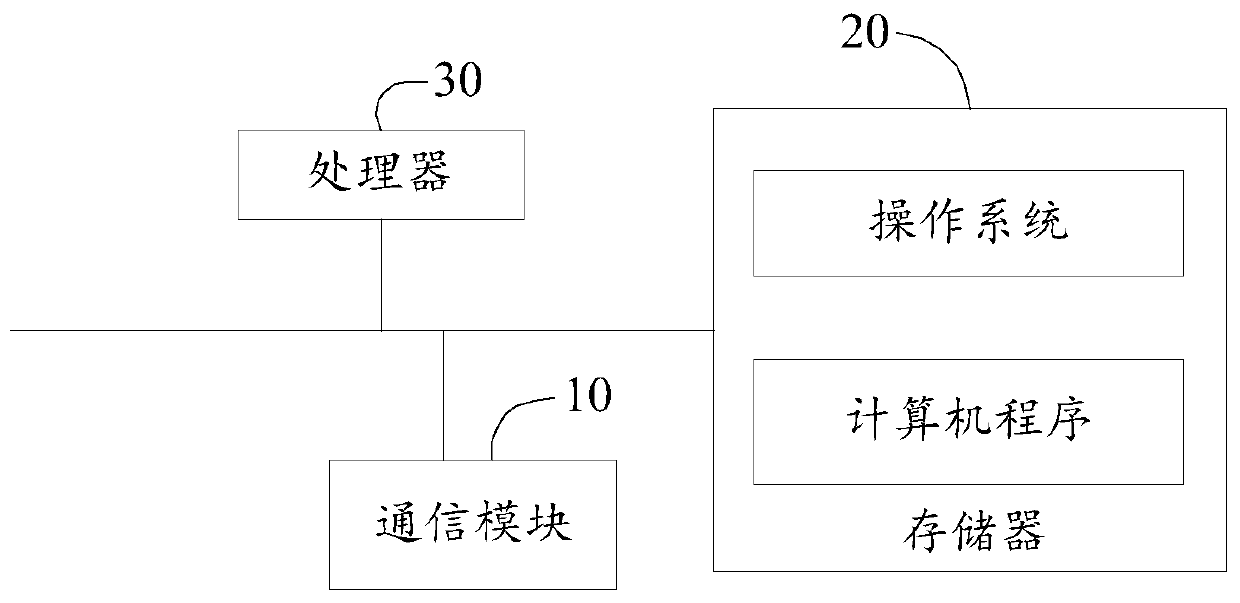

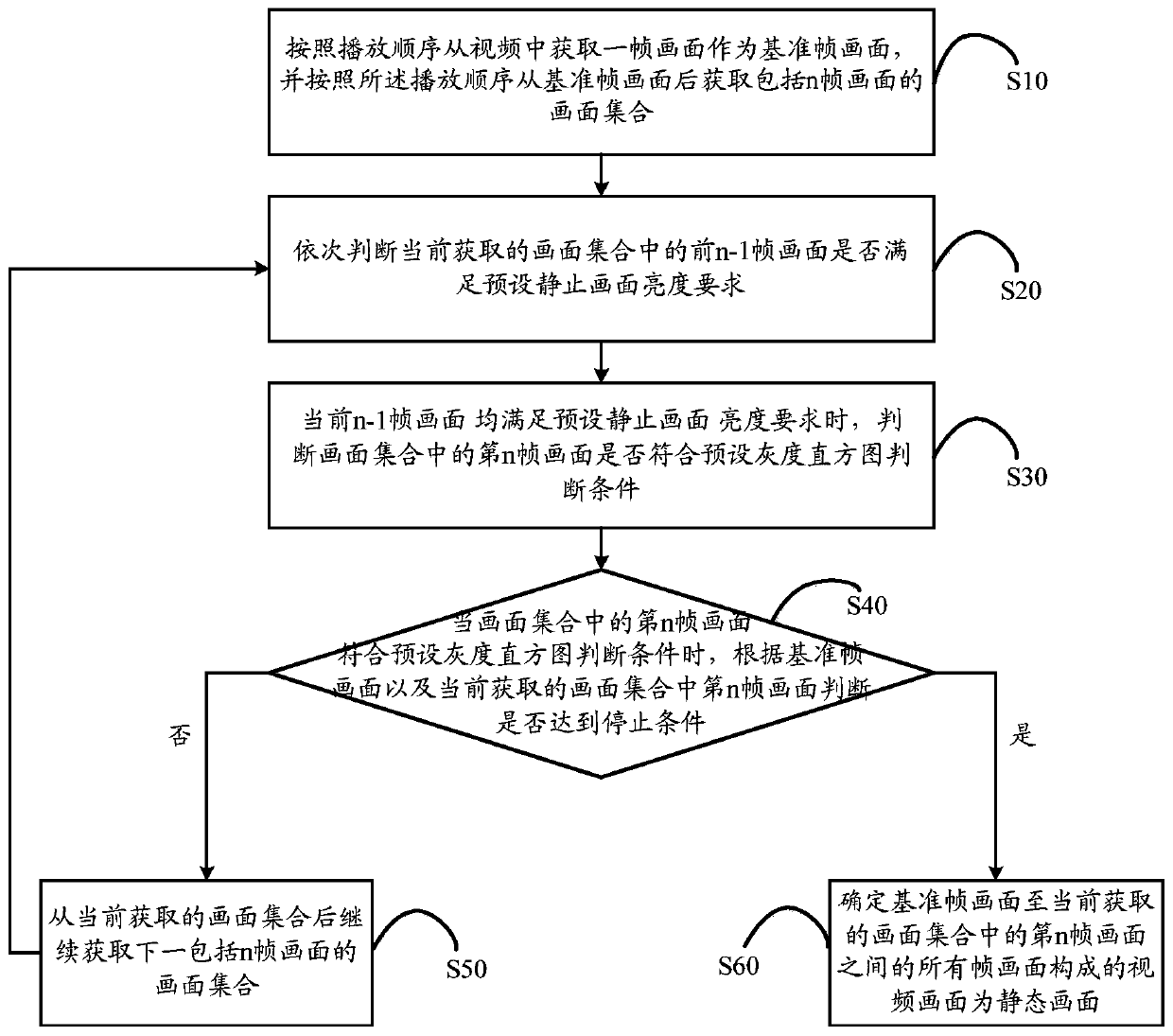

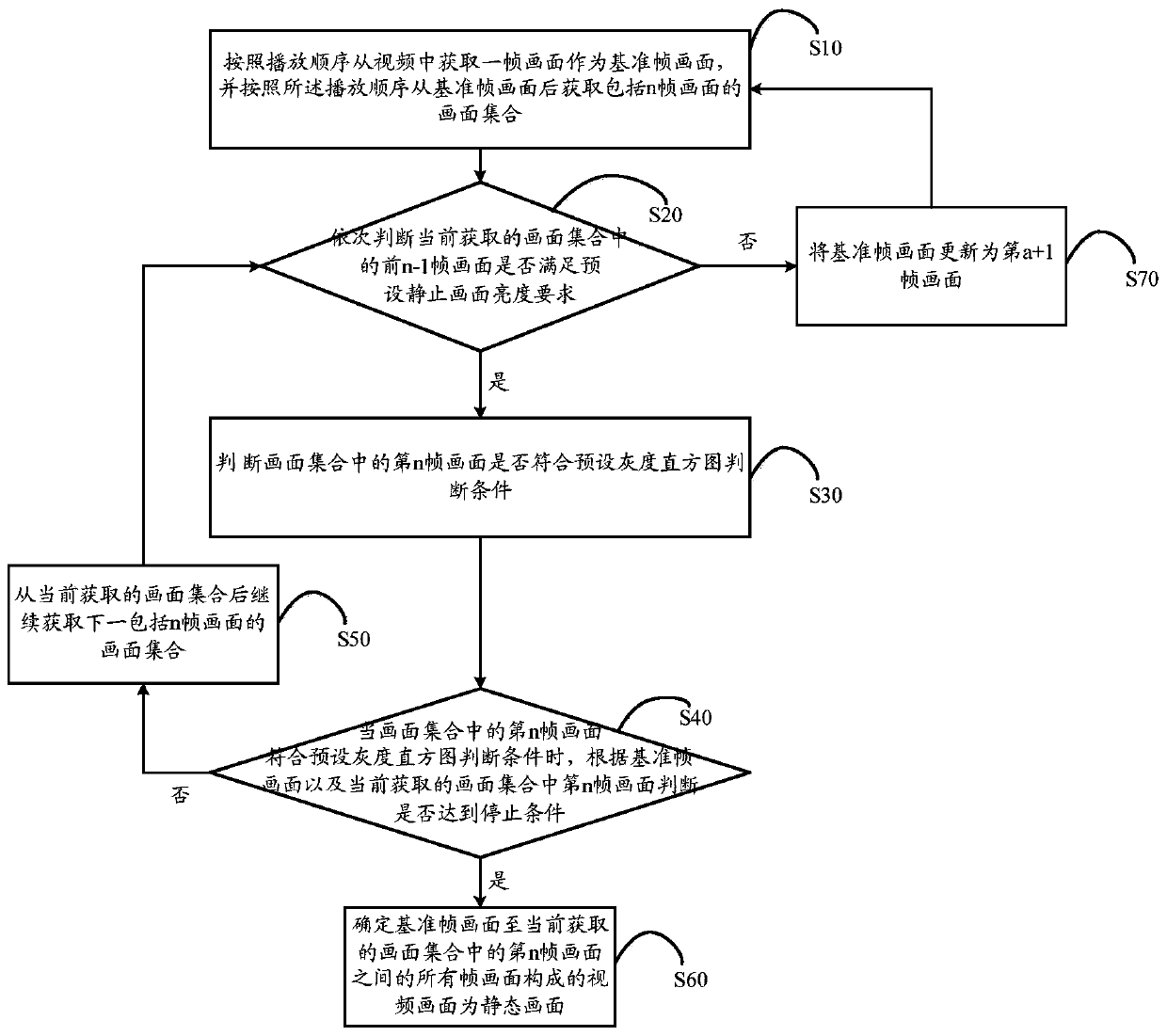

Video static picture detection method, terminal and computer readable storage medium

ActiveCN110392305AMeet brightness requirementsImprove accuracyTelevision system detailsColor television detailsComputer graphics (images)Computer terminal

The invention discloses a video static picture detection method, a video static picture detection terminal and a computer readable storage medium, and the method comprises the steps: obtaining a reference frame picture from a video, and obtaining a picture set comprising n frames of pictures from the back of the reference frame picture according to a playing sequence; sequentially judging whetherthe first n-1 frames of pictures in a currently acquired picture set meet the brightness requirement of a preset static picture or not; judging whether the nth frame of picture in the picture set meets a preset gray histogram judgment condition or not; and finally, judging whether a stop condition is met or not according to the reference frame picture and the nth frame picture in the currently obtained picture set; and when all the judgment results are yes, determining that a video picture formed by all the frames from the reference frame to the nth frame in the currently acquired picture setis a static picture. The technical problems that in the prior art, when whether an input picture is a static picture or not is judged, the accuracy is low, and the calculated amount is large are solved.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

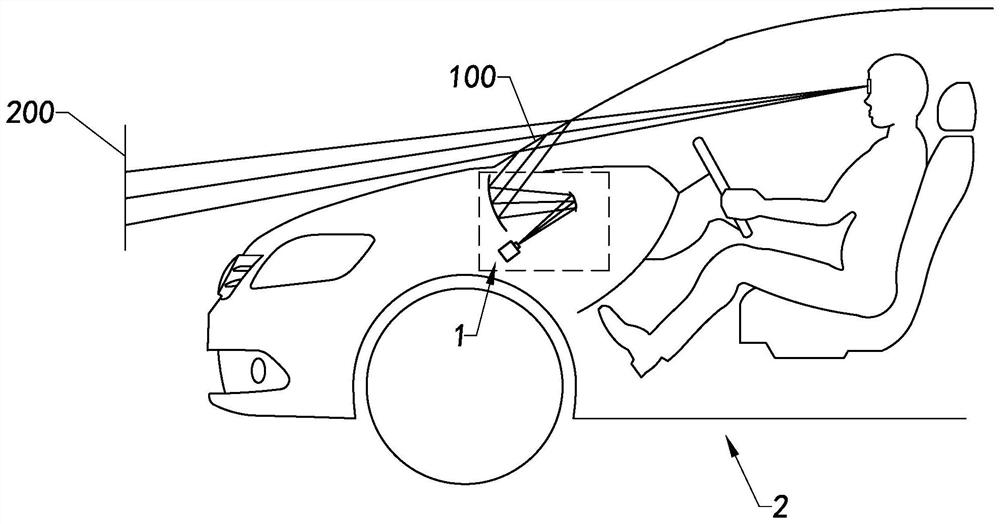

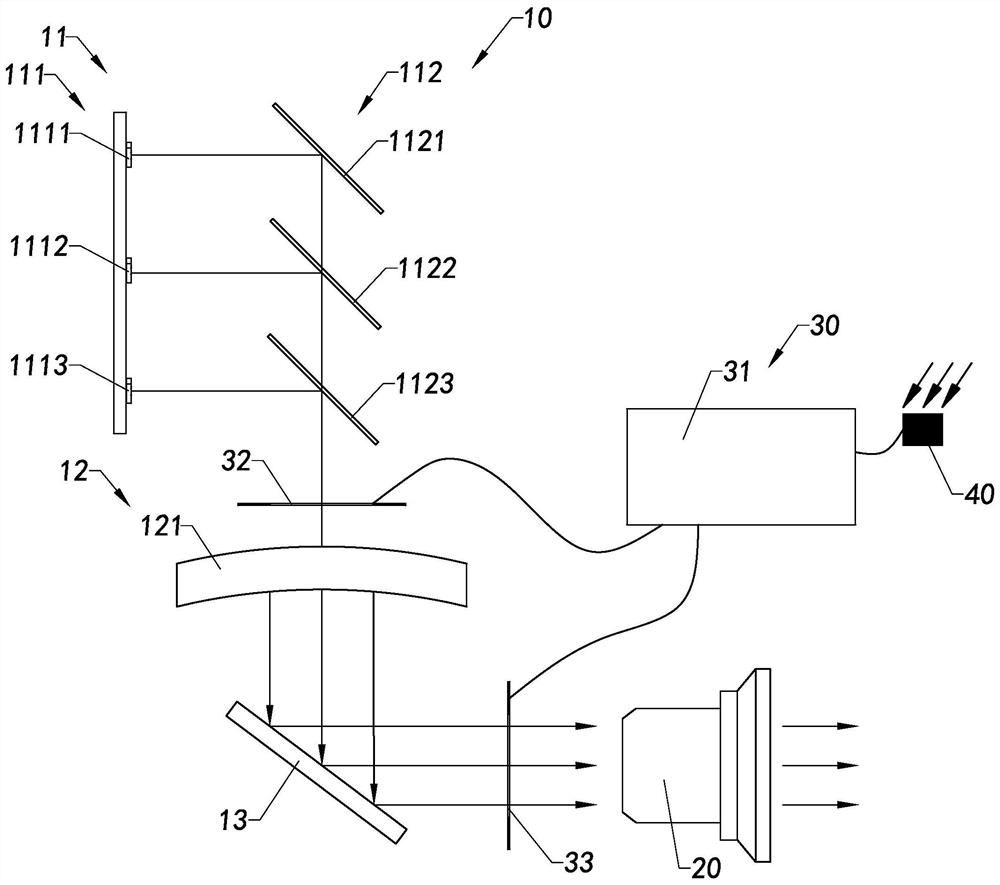

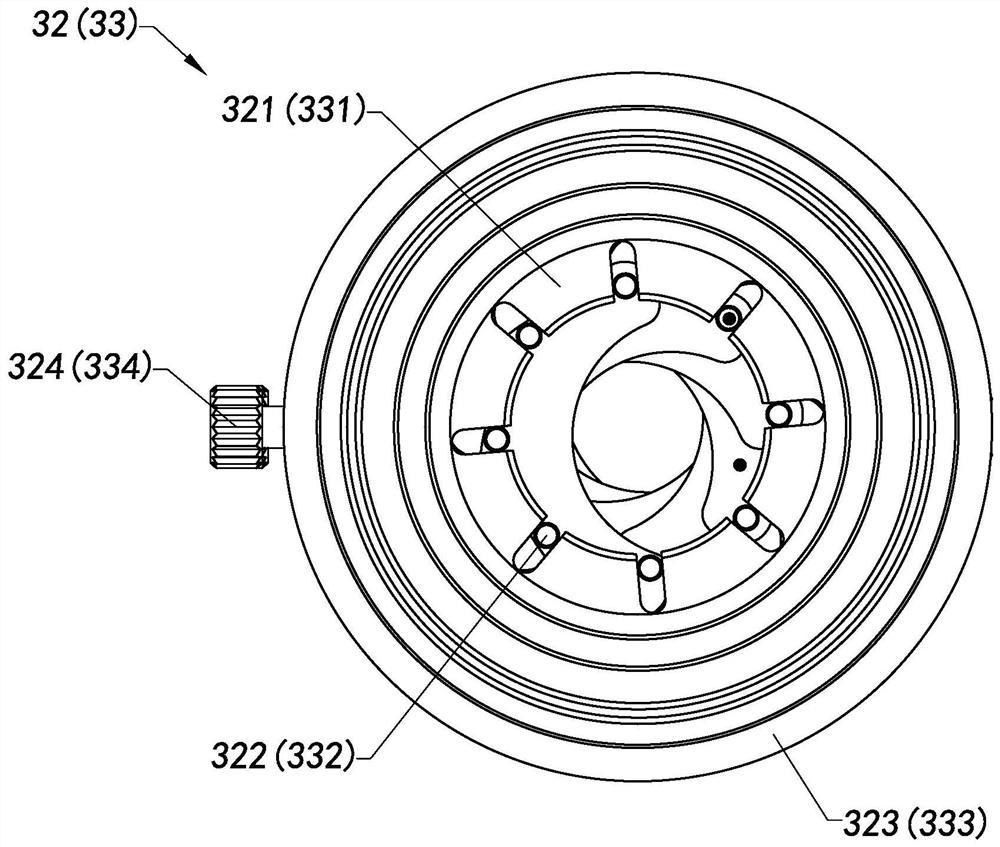

Projection adjusting system and projection adjusting method thereof

InactiveCN112099230ABrightness adjustableAdjust contrastProjectorsOptical elementsEngineeringMechanical engineering

The invention provides a projection adjusting system and a projection adjusting method thereof. The projection adjusting system comprises an illumination module, a projection module and an iris diaphragm control module, and the illumination module projects light carrying imaging information. The projection module obtains light rays carrying imaging information and projects the light rays outwardsto a projection surface, the iris diaphragm control module comprises at least one iris diaphragm and a controller, and each iris diaphragm adjusts the aperture of at least one diaphragm under the control of the controller. The light intensity of the light projected outwards is adjusted by zooming the aperture of the diaphragm.

Owner:NINGBO SUNNY AUTOMOTIVE OPTECH

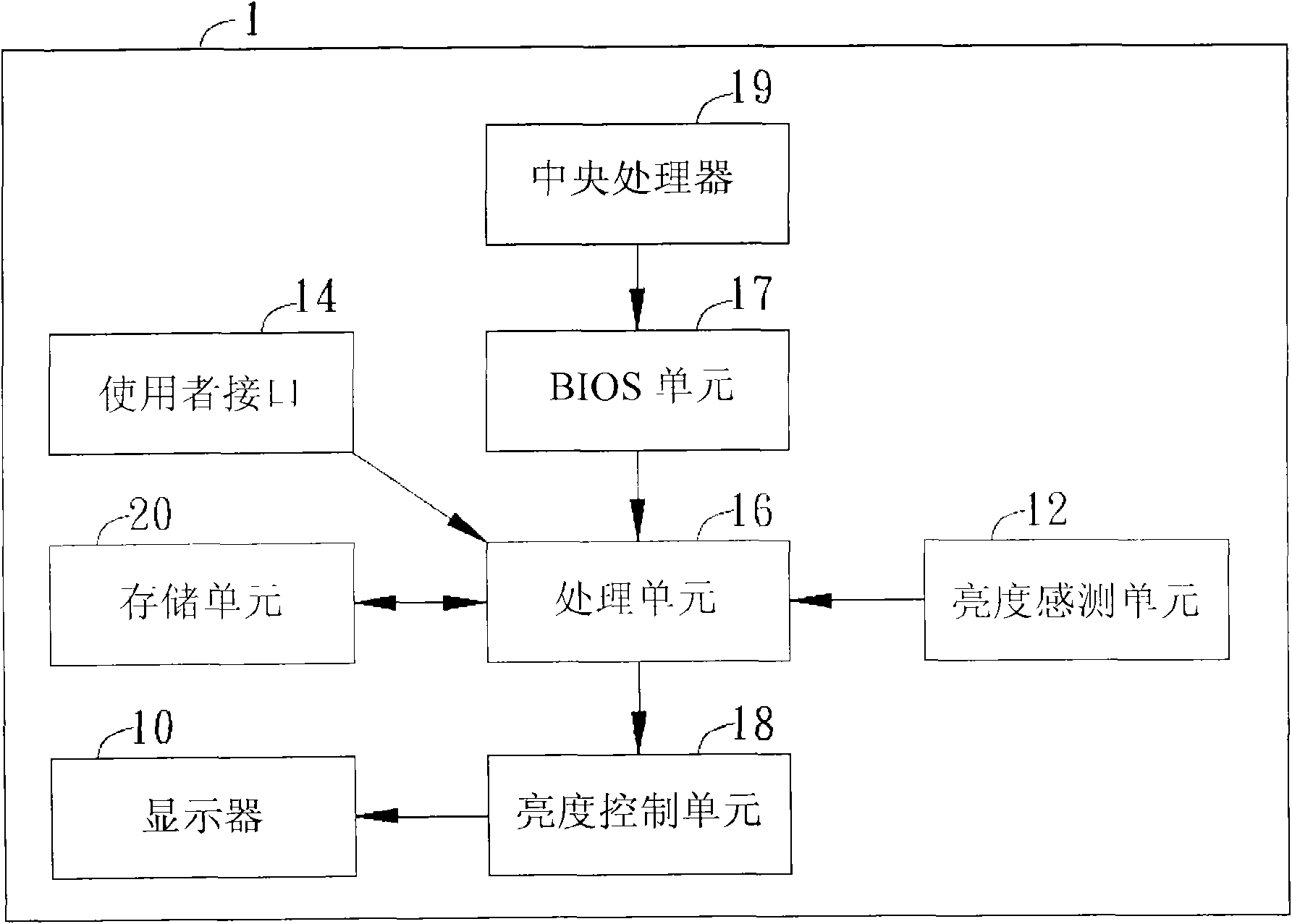

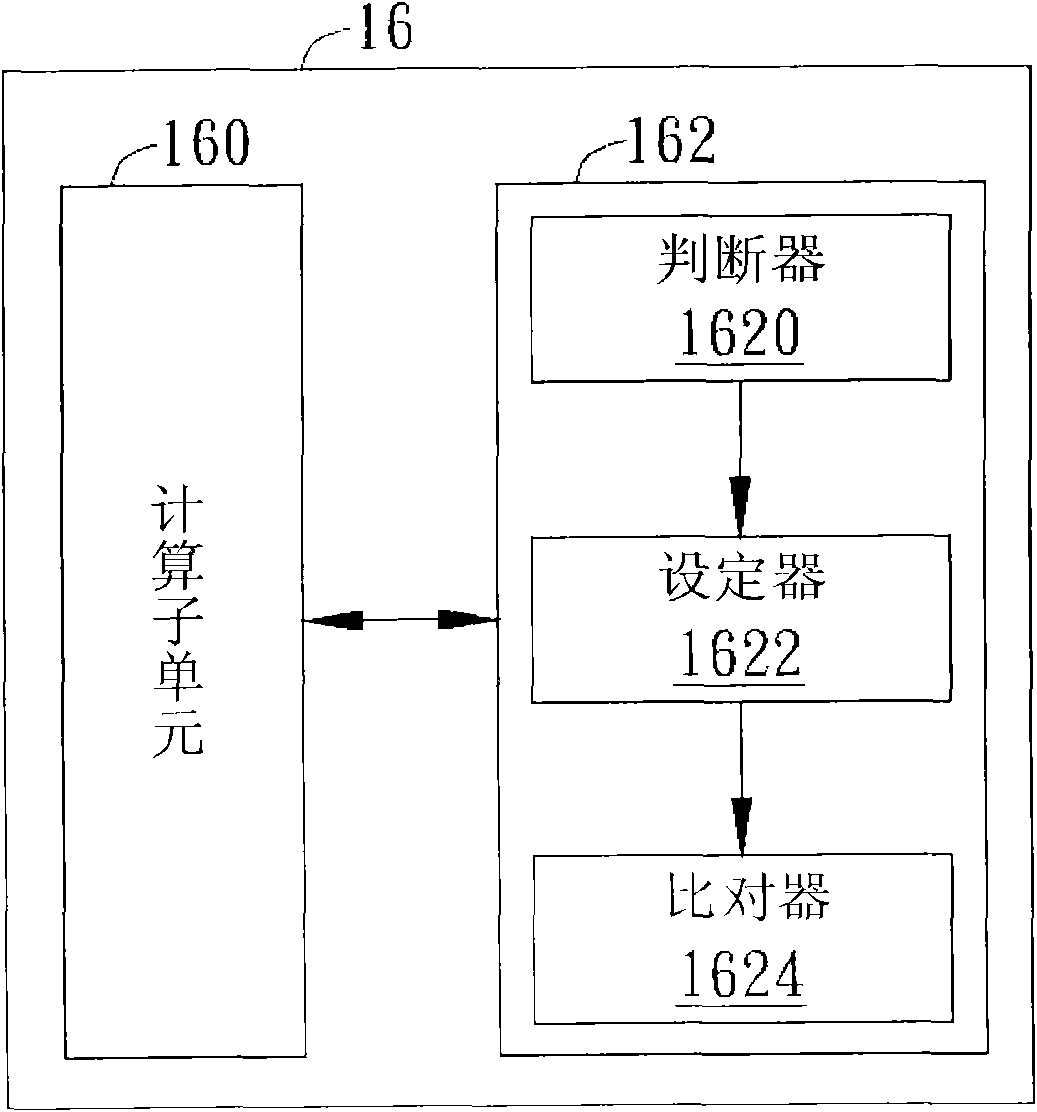

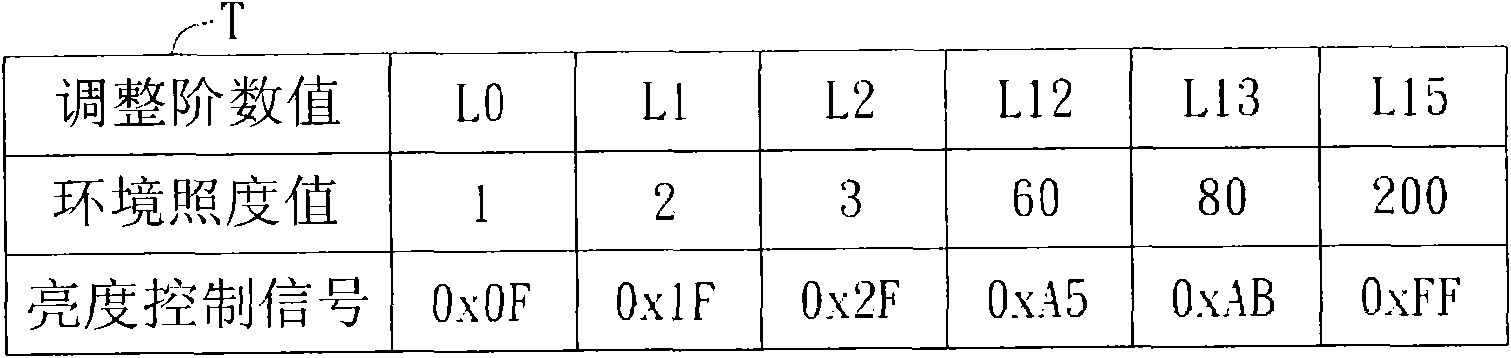

Method for automatically adjusting brightness of display and portable electronic device

InactiveCN102737611ABrightness adjustableMeet brightness requirementsCathode-ray tube indicatorsIlluminanceControl signal

The invention discloses a method for automatically adjusting brightness of a display and a portable electronic device. The method comprises the following steps: receiving a plurality of brightness sensing signals and calculating an average ambient illumination value based on the brightness sensing signals; receiving a user setting signal, wherein the user setting signal contains increase and decrease in value defined by the user; according to the average ambient illumination value and the increase and decrease in value defined by the user, finding a corresponding specific brightness control signal from a comparison table; and automatically adjusting the displaying brightness of the display according to the specific brightness control signal. According to the invention, the displaying brightness of the display can be automatically adjusted by utilizing ambient illumination sensed by an ambient light sensor.

Owner:PEGATRON

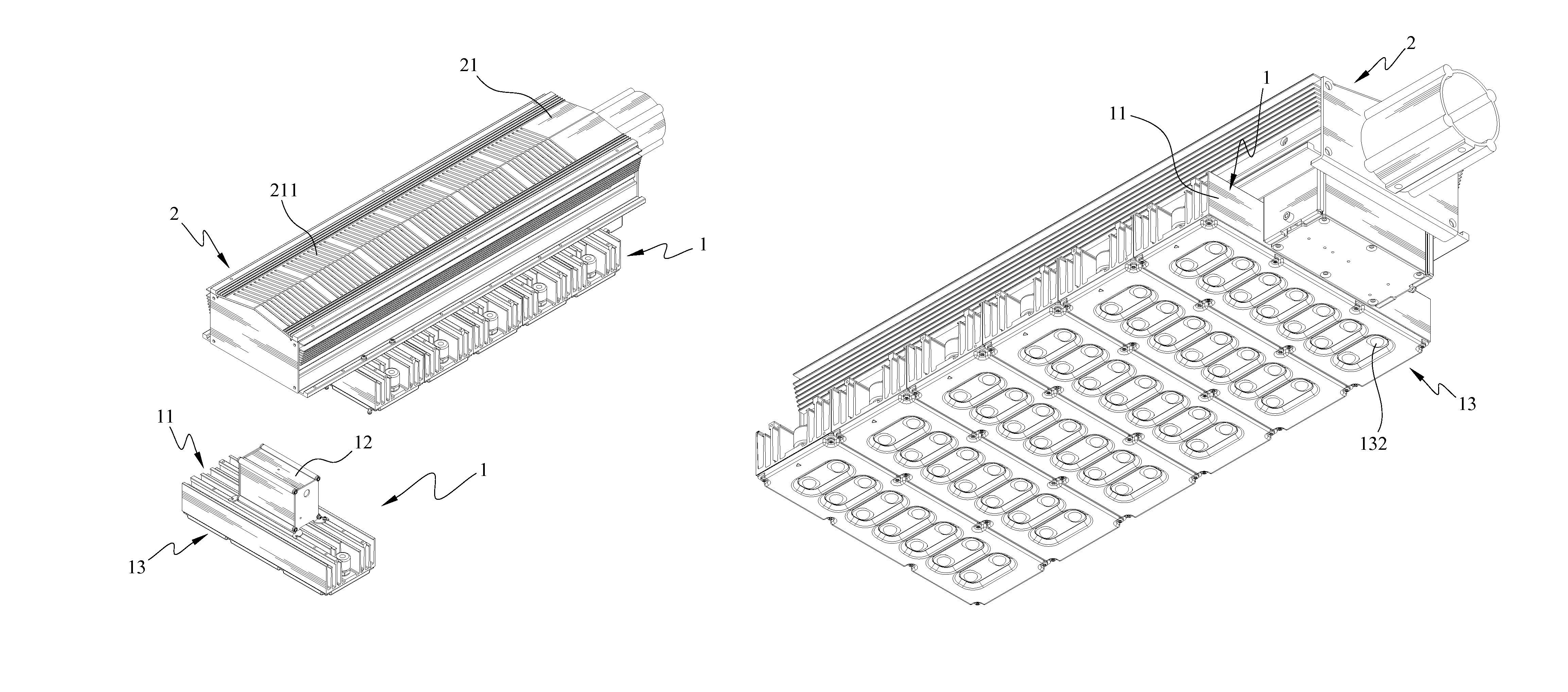

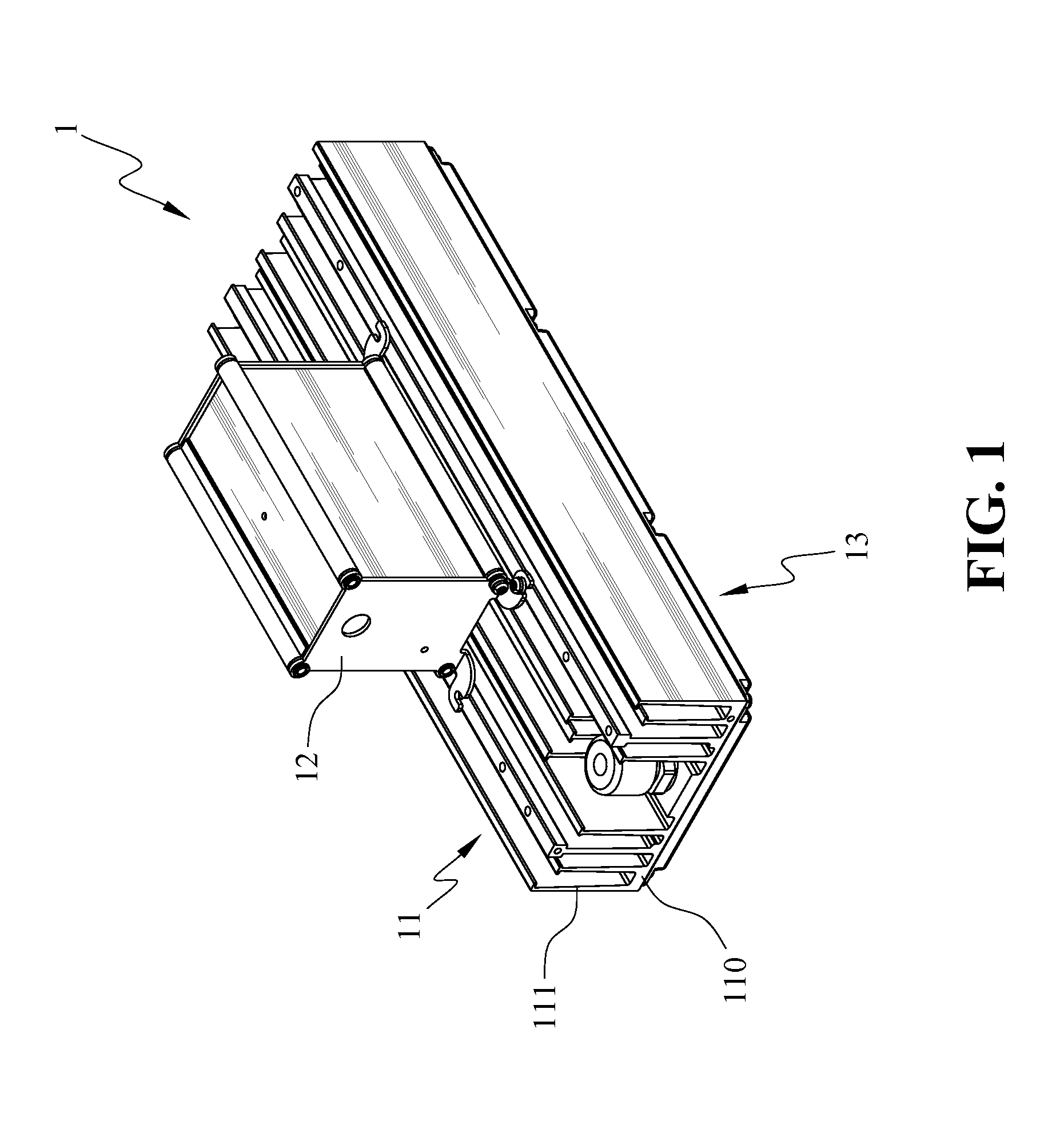

LED lighting device

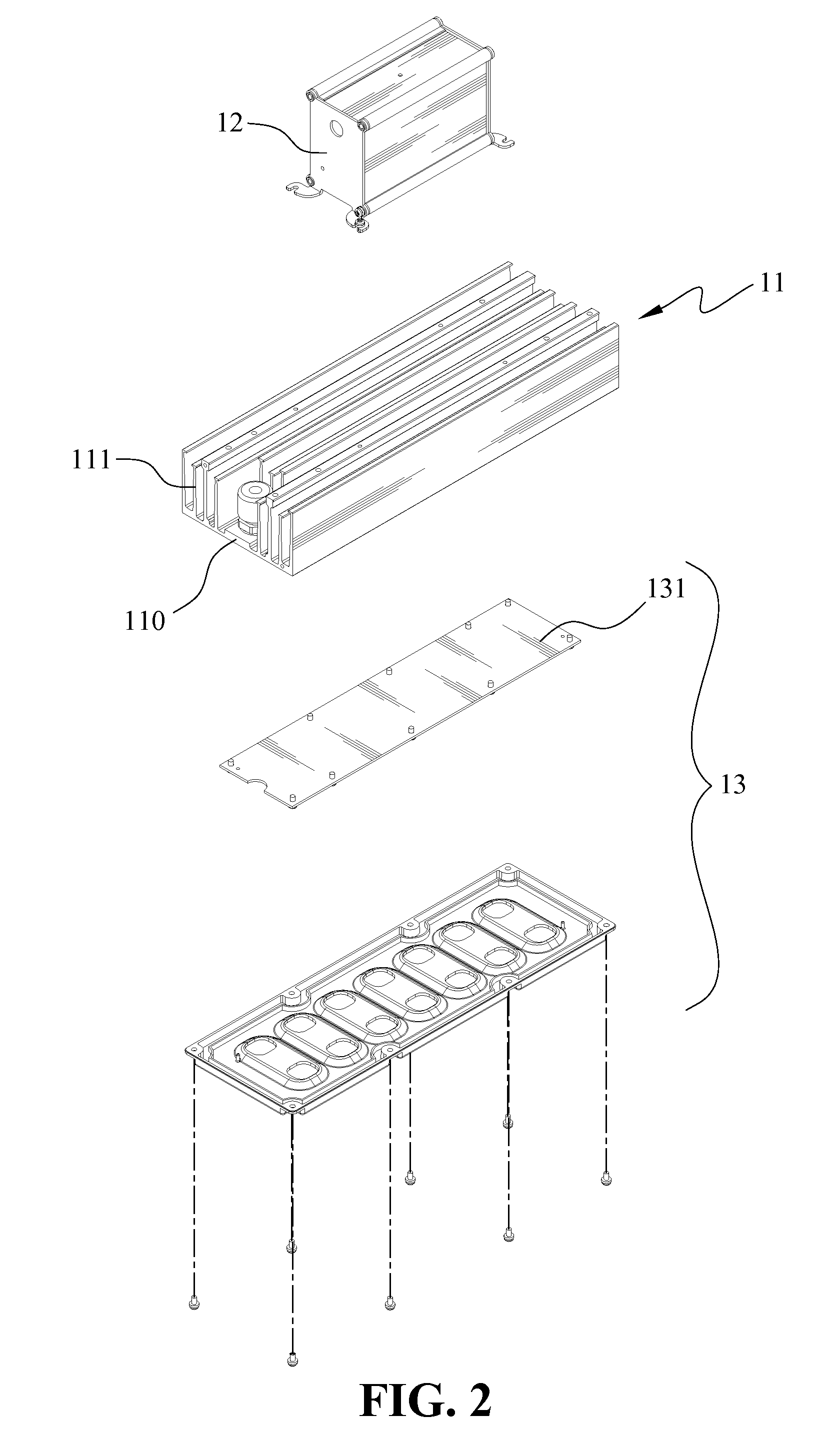

InactiveUS8444298B2Reduce areaQuantities can be increased reducedPlanar light sourcesMechanical apparatusEffect lightEngineering

A light emitting diode (LED) lighting device includes a light case, a plurality of heatsinks, a plurality of LED modules and a plurality of power supplies. Each of the heatsinks is connected with one of the LED modules and one of the power supplies correspondingly to form one LED light unit. The LED light units are assembled with the light case to form the LED lighting device.

Owner:LIN RONG GUI

Tunnel low-altitude auxiliary inducing illumination system and method

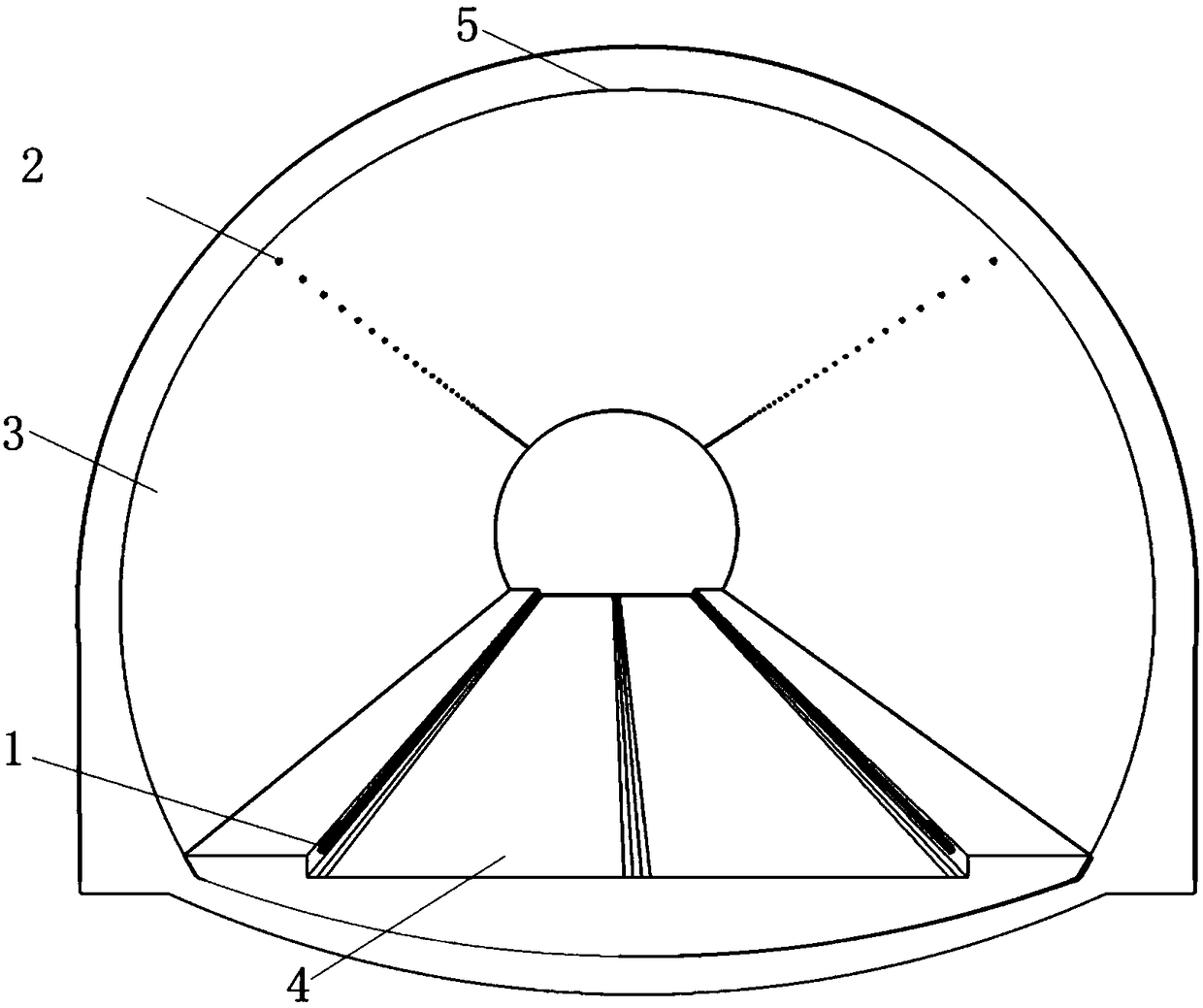

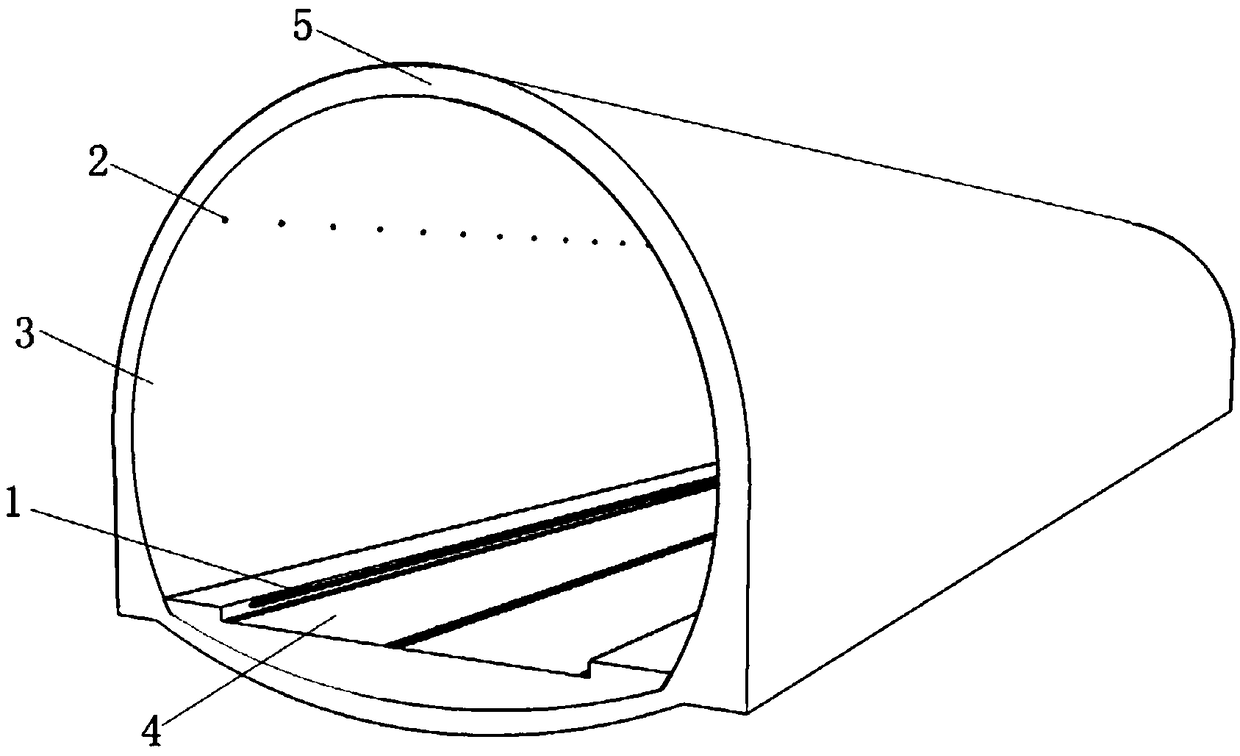

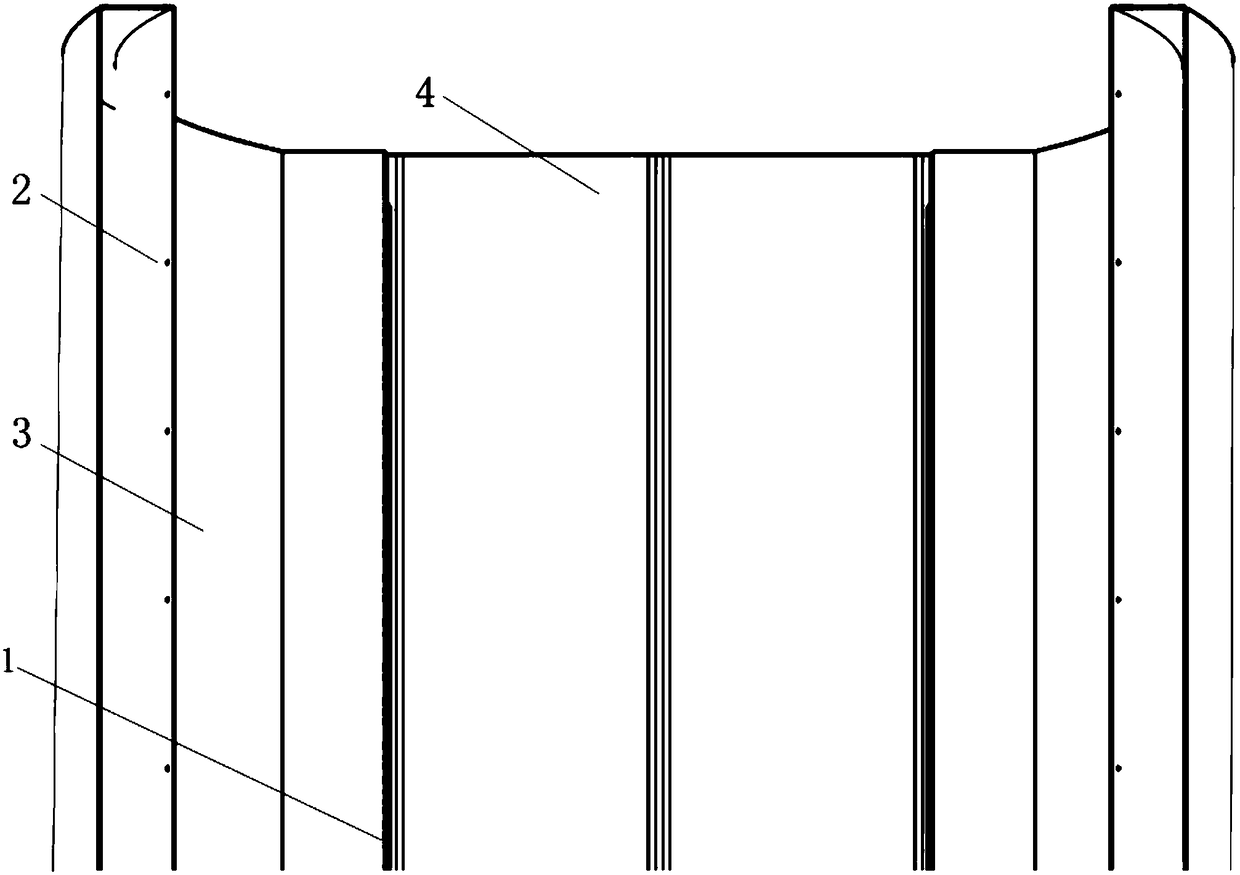

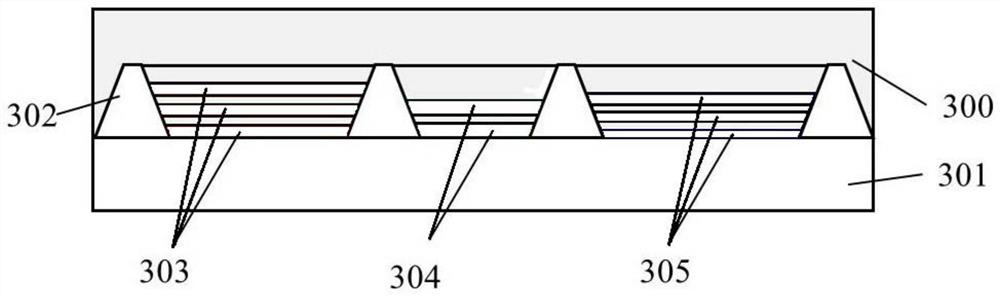

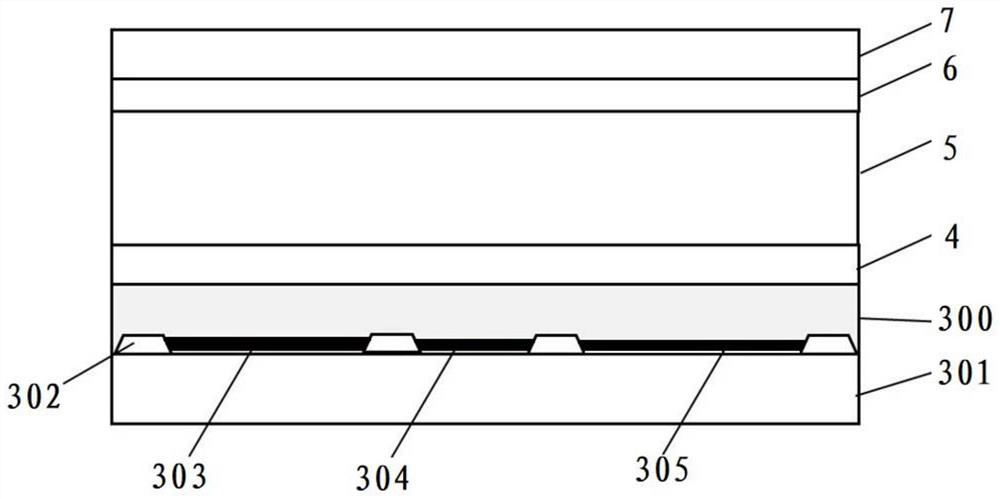

PendingCN109058839AEasy to replaceEasy maintenanceMechanical apparatusLighting support devicesHigh energyComputer module

The invention relates to the field of highway tunnel energy-saving illumination, in particular to a tunnel low-altitude auxiliary inducing illumination system and method. The illumination system comprises a kerb light strip lamp arranged on one side of a sidewalk or a maintenance way in a tunnel, and an inducing delineator auxiliary illumination lamp arranged on a tunnel wall; the inducing delineator auxiliary illumination lamp is from a tunnel pavement by a preset height; the preset height is smaller than a height from the top surface of the tunnel to the tunnel pavement; light of the inducing delineator auxiliary illumination lamp is irradiated to the tunnel pavement; light of the kerb light strip lamp is irradiated to the tunnel pavement; and the kerb light strip lamp and the inducing delineator auxiliary illumination lamp are both arranged in the longitudinal direction of the tunnel, and are both LED lamp modules. The illumination system solves the problems of dazzling and higher energy consumption caused by a high distribution mode of traditional tunnel illumination for traditional tunnels.

Owner:CHANGAN UNIV

Backlight source module and display device

InactiveCN103822139AMeet brightness requirementsUniform brightnessMechanical apparatusPoint-like light sourceLight guideDisplay device

An embodiment of the invention provides a backlight source module and a display device and relates to the technical field of display. The backlight source module comprises a back panel, at least two light guide strips and at least one LED luminous chip. The light guide strips are parallelly arranged at an interval on the same side of the back panel, and the LED luminous chips are arranged near incident surfaces of the light guide strips. The embodiment of the invention further provides production methods of the backlight source module and the display device comprising the same.

Owner:HISENSE VISUAL TECH CO LTD

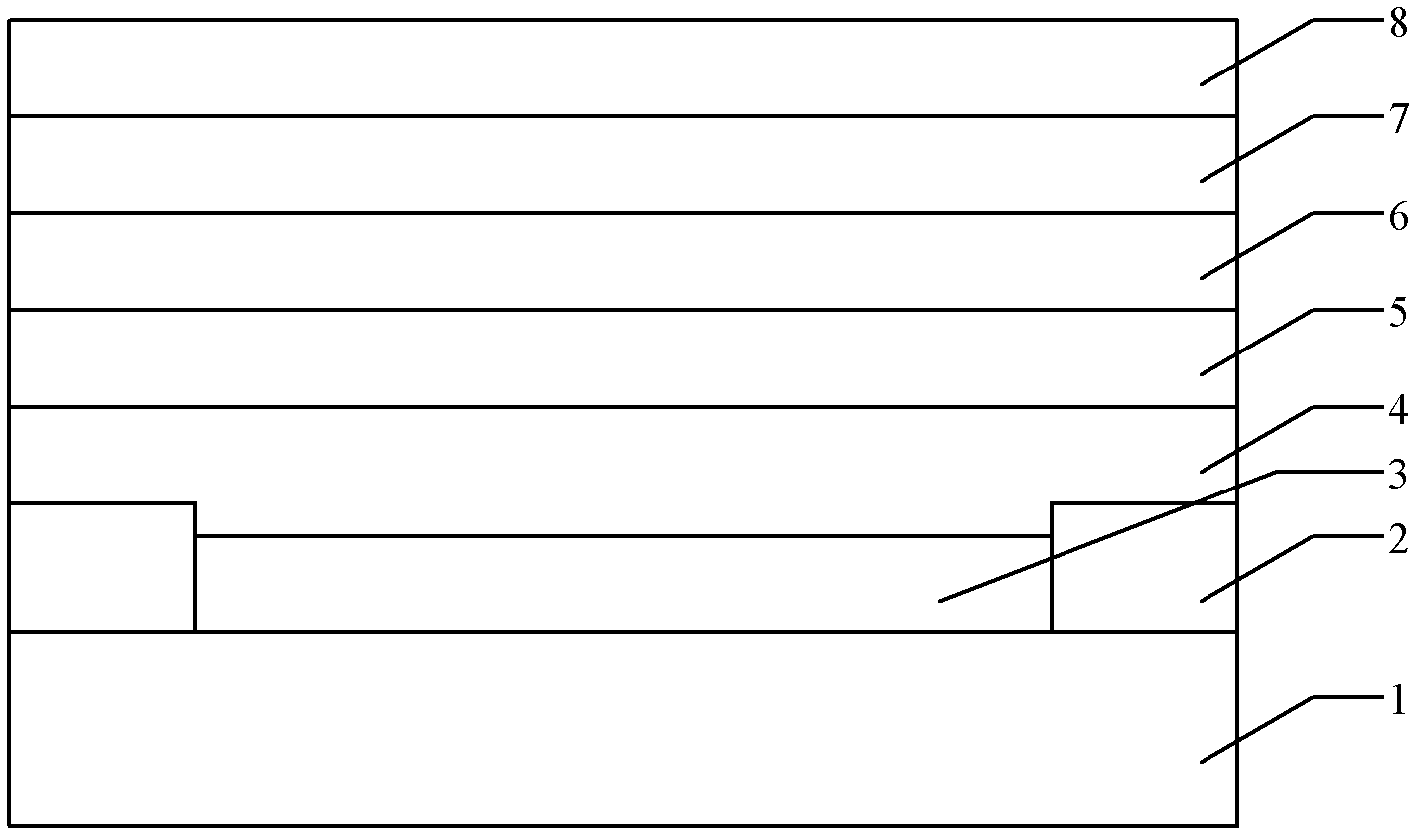

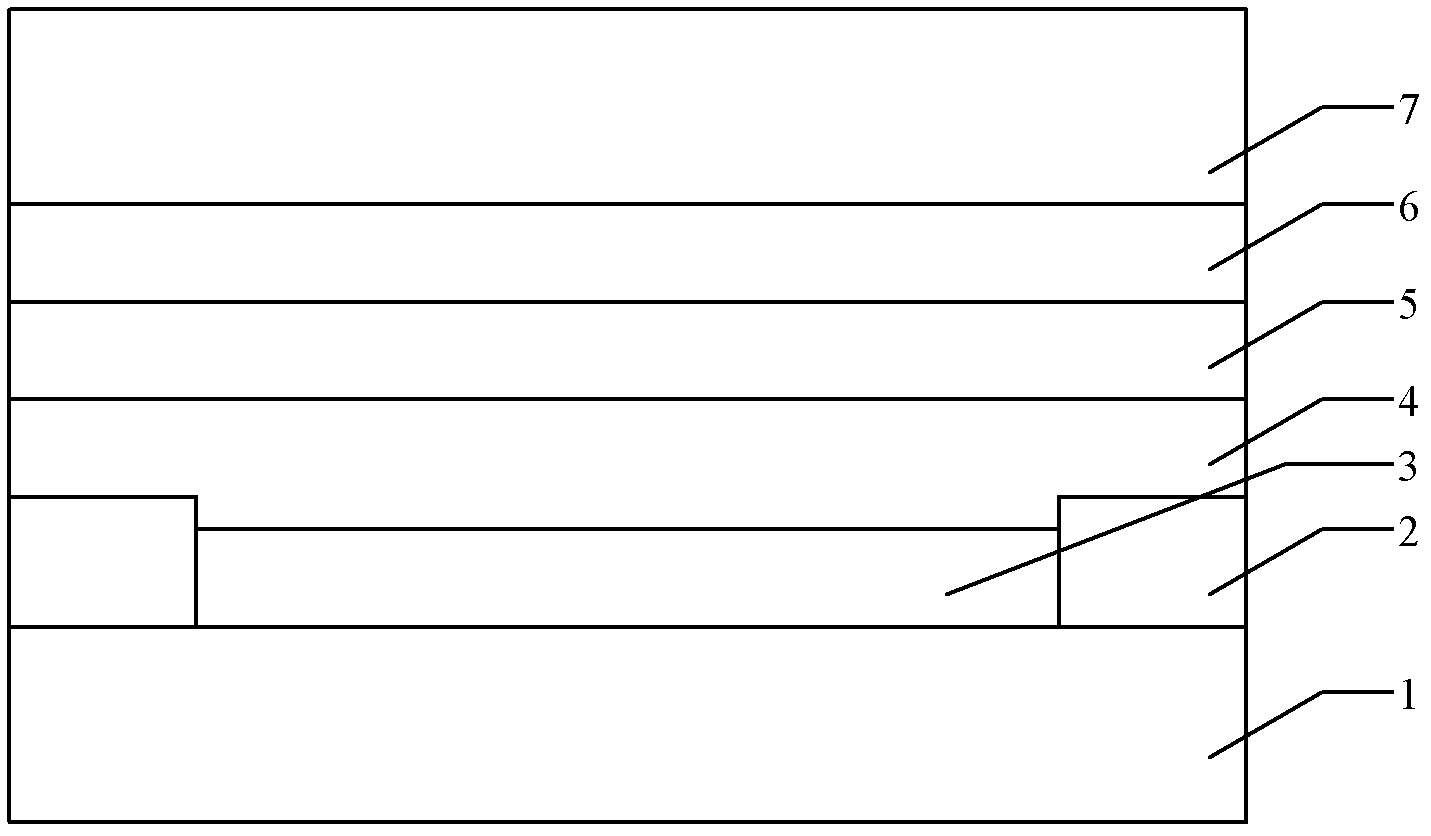

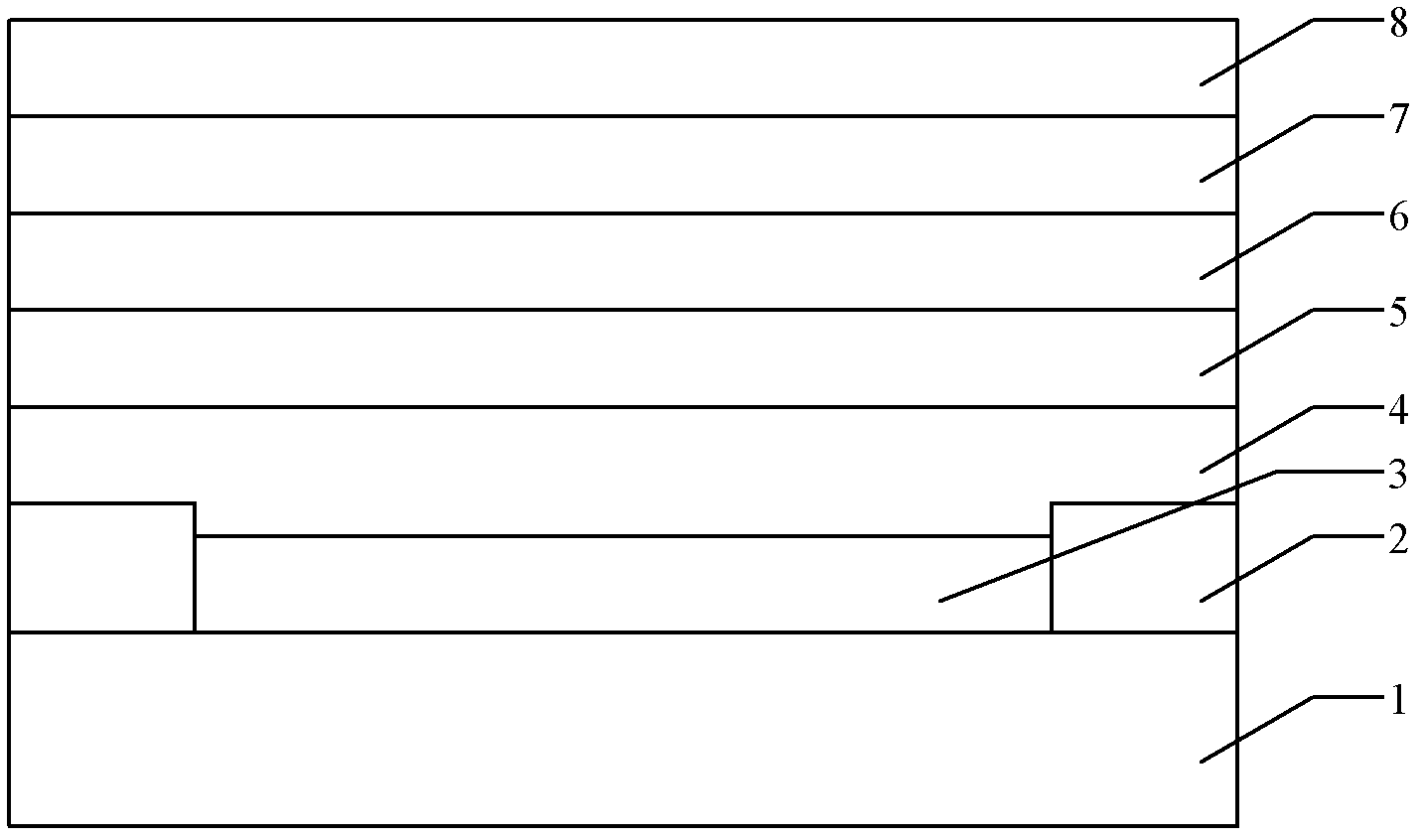

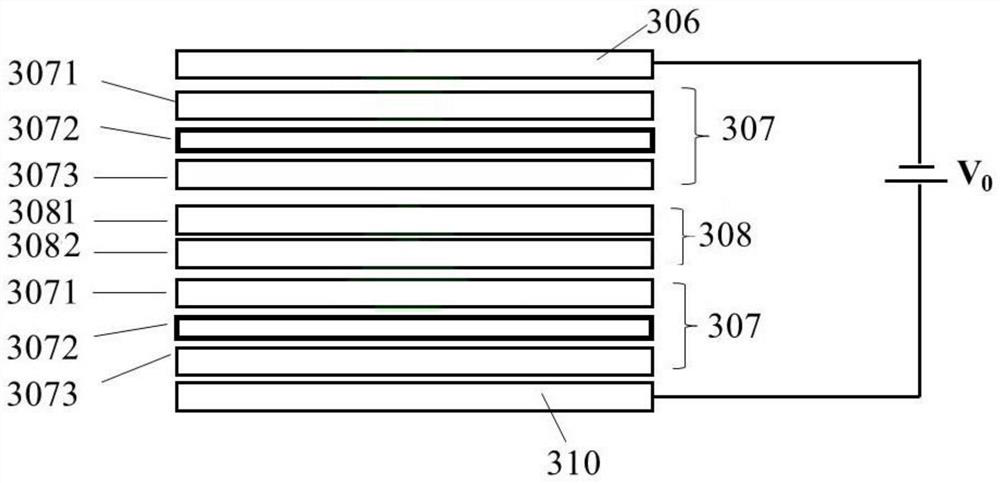

Electroluminescent unit, display panel and electronic device

PendingCN113299845AReduce aging speedImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingHemt circuitsAnode

The invention discloses an electroluminescent unit, a display panel and an electronic device. The electroluminescent unit is applied to an under-screen camera area, and the electroluminescent unit comprises a transparent cathode which is used for accessing a circuit cathode of the electroluminescent unit and emitting light of the electroluminescent unit; an anode, used for being connected to a circuit anode of the electroluminescent unit; pixel light-emitting units located between the transparent cathode and the anode and arranged in a stacked mode, and each pixel light-emitting unit comprising a pixel light-emitting layer, an electronic function layer arranged on one side of the pixel light-emitting layer and a hole function layer arranged on the other side of the pixel light-emitting layer; the electroluminescent unit further comprises a connecting layer arranged between every two adjacent pixel light-emitting units, an electronic function layer is arranged on one side of the connecting layer, a hole function layer is arranged on the other side of the connecting layer, and the connecting layer is used for providing electrons for the electronic function layer and providing holes for the hole function layer.

Owner:VIVO MOBILE COMM CO LTD

Water-based metal wire drawing liquid with good lubricating effect and preparation method thereof

InactiveCN104263486AMeet brightness requirementsMeet the dimensional accuracy requirementsLubricant compositionWater basedCoconut diethanolamide

The invention discloses a water-based metal wire drawing liquid with a good lubricating effect. The water-based metal wire drawing liquid is characterized in that the water-based metal wire drawing liquid is prepared from the following raw materials in parts by weight: 3-4 parts of sodium ricinoleate soap, 1-2 parts of coconut diethanolamide, 1.5-2 parts of polyepoxysuccinic acid, 5-7 parts of sulfurized lard oil, 3-4 parts of polyethylene glycol, 3-4.5 parts of sodium hydrogen carbonate, 3-5 parts of chlorinated paraffin, 3-4 parts of spindle oil, 2-4 parts of sodium carboxymethyl cellulose, 0.8-1.5 parts of sodium benzoate, 5-7 parts of additives and 900-950 parts of deionized water. The water-based metal wire drawing liquid disclosed by the invention has excellent lubricating performance and can meet the requirements of customers on brightness and dimensional precision at relatively low concentration; by adding the additives, the water-based metal wire drawing liquid has good wear resistance, dispersion, lubrication and film-forming property, is mutually matched with a surfactant, and can form a protective film on the surface of a metal to realize a corrosion inhibition effect. The water-based metal wire drawing liquid adopts a water-based formula, is good in cooling property and cleaning property, is easy to be moved after processing, and further ensures the cleanliness of a wire drawing operation environment.

Owner:ANHUI WANGDA COPPER DEV

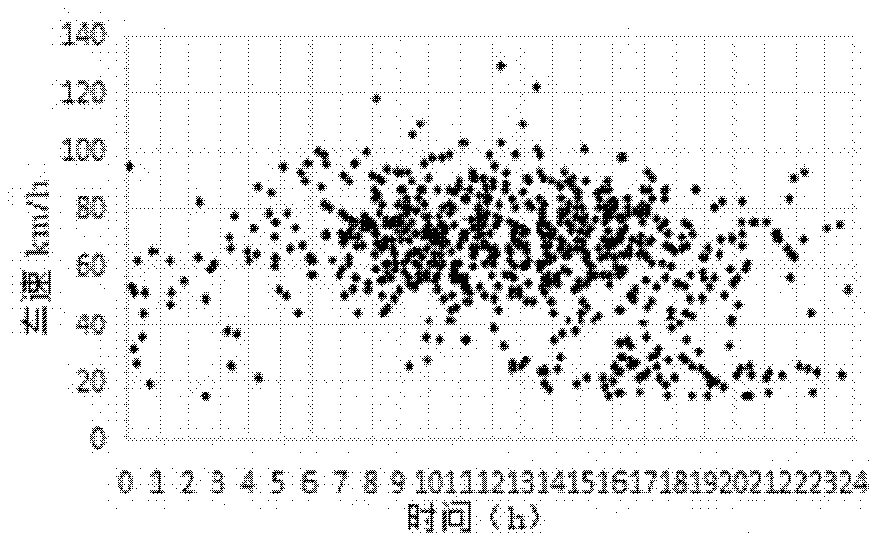

Vehicle information statistics-based intelligent control method and system for tunnel lighting

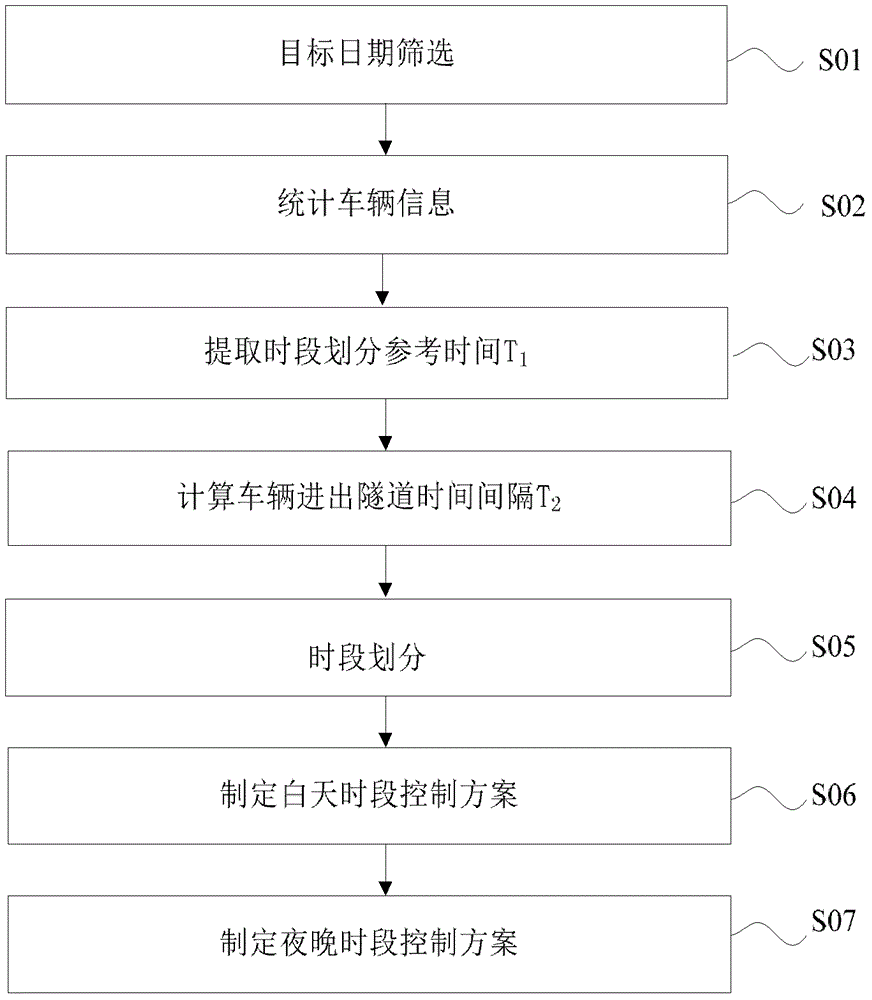

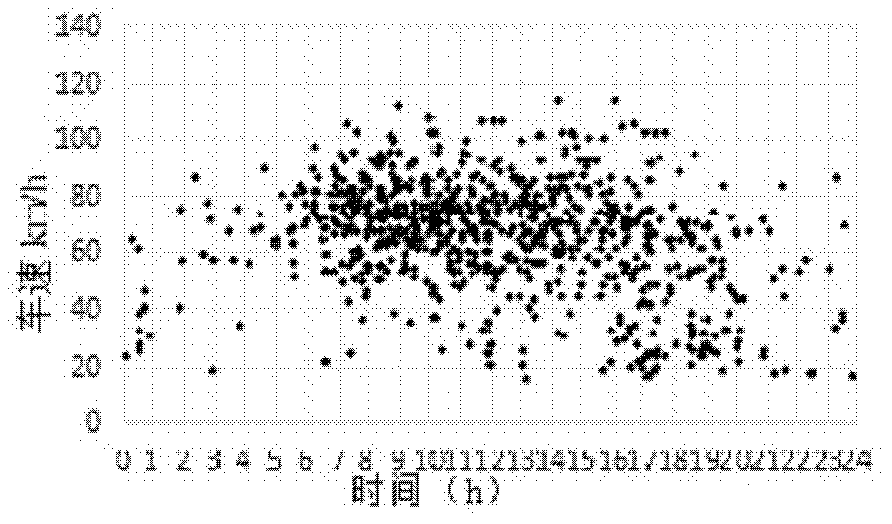

InactiveCN106793286AReduce energy wasteReduce wasteElectrical apparatusElectroluminescent light sourcesLighting systemEnergy consumption

The invention discloses a vehicle information statistics-based intelligent control method and system for tunnel lighting. The method comprises the following control steps of counting basic information and traffic flow information of vehicles which pass through a tunnel within representative 12 days in every quarter and determining period partition reference time according to the time spent by the vehicle with the minimum speed for passing in and out of the tunnel; defining a period through a comparison result of a time interval at which the adjacent vehicles enter the tunnel and the period partition reference time; and then making different intelligent control schemes for tunnel lighting during the day and at night separately. A segmentation node of day and night is found out according to the statistical result of the tunnel vehicle information, and different control schemes are adopted for a lighting system in the tunnel in two periods, so that the stability of the lighting system is ensured and the service life of the lighting system of the tunnel is prolonged on the basis of reducing energy consumption.

Owner:DALIAN MARITIME UNIVERSITY

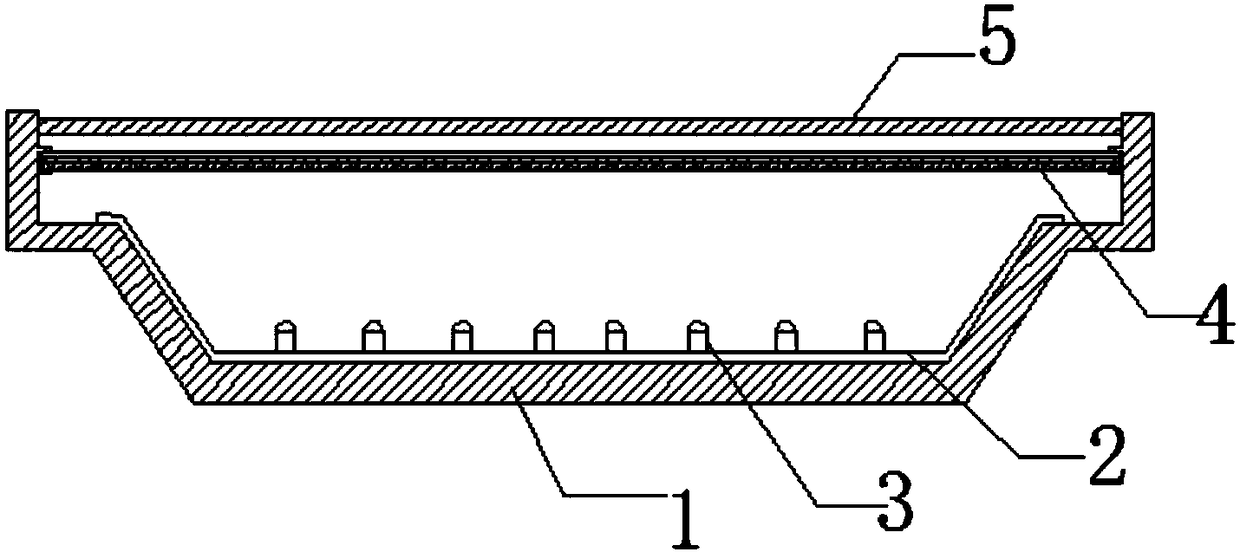

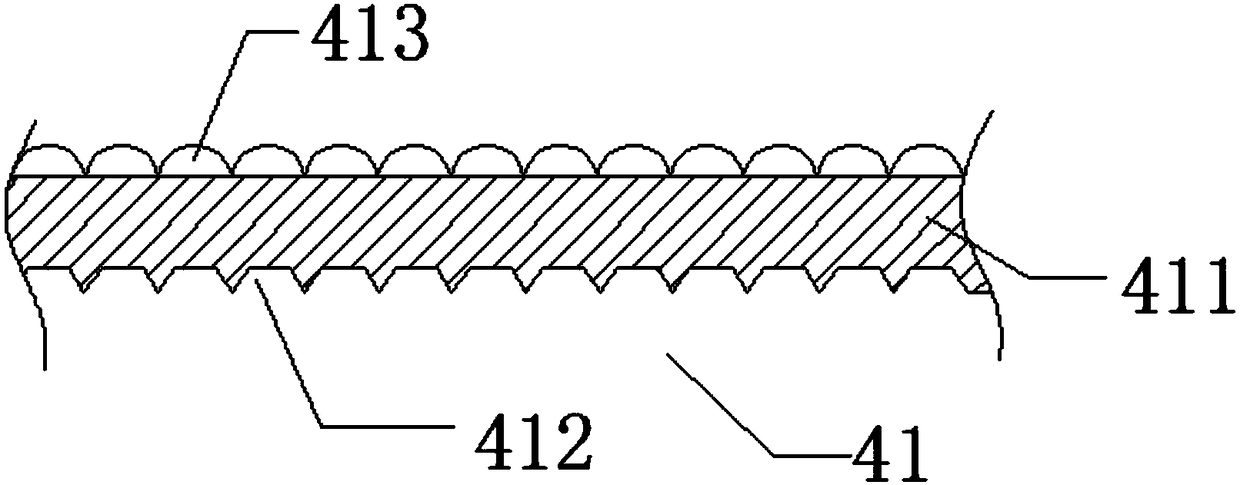

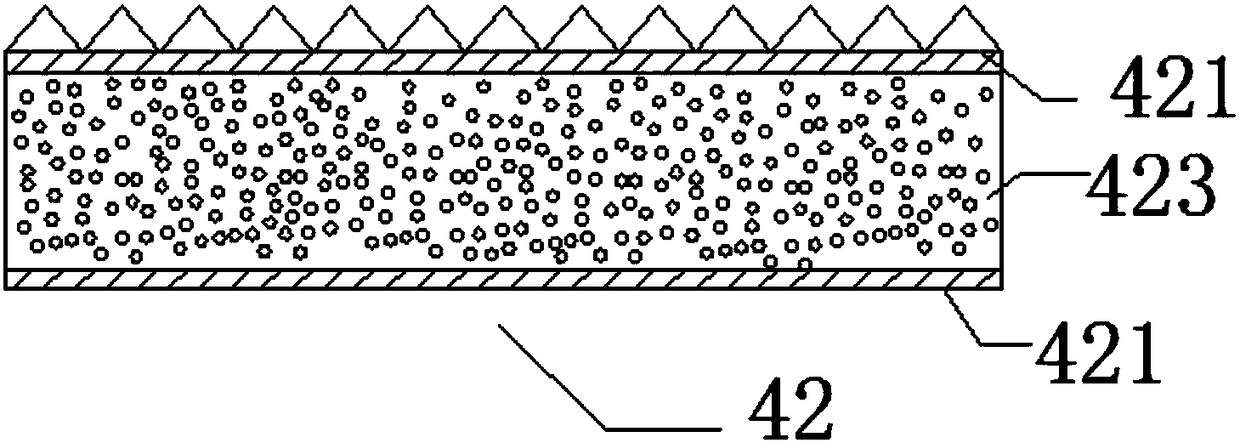

Economical direct-type backlight assembly

InactiveCN109001937AReduce manufacturing costMeet brightness requirementsNon-linear opticsDiffusionInter layer

An economical direct-type backlight assembly comprises a back plate, a reflecting plate, a backlight source, and two to four diffusion sheets. The diffusion sheets are formed by diffusion-type diffusion sheets or light-collecting diffusion sheets in a single or mixed assembly mode; the two faces of the diffusion-type diffusion sheets are each of a regular polygonal groove structure and a lenticular bulge correspondingly for diffusing light rays for multiple times, and thus the light brightness and brightness uniformity are improved; the light-collecting diffusion sheets are each of an ABA structure, one of the outer layer faces on the two sides of each light-collecting diffusion sheet is a pattern face and smooth face, and the other outer layer face is a circular-arc-shaped strip bulge ora triangular strip bulge, a middle layer is composed of a transparent matrix and a light diffusion agent, thus the light ray brightness is further increased while light rays are evenly diffused by thelight-collecting diffusion sheets, and the brightness uniformity of the light source is ensured while the production cost of the direct-type backlight assembly is lowered; and by arranging the relative number of the diffusion-type diffusion sheets and the light-collecting diffusion sheets, the using requirements of the backlight assembly for different brightness are met.

Owner:苏州东山新材料科技有限公司

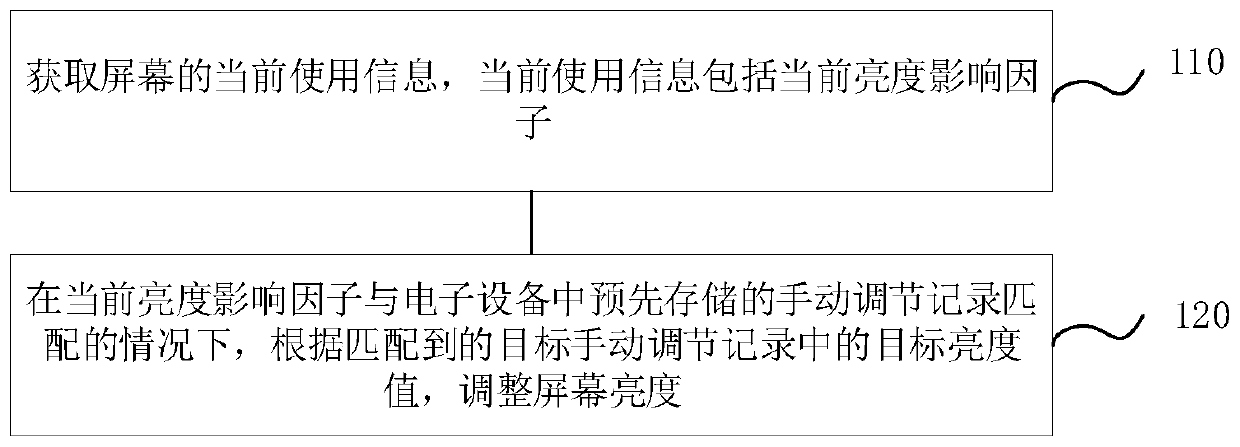

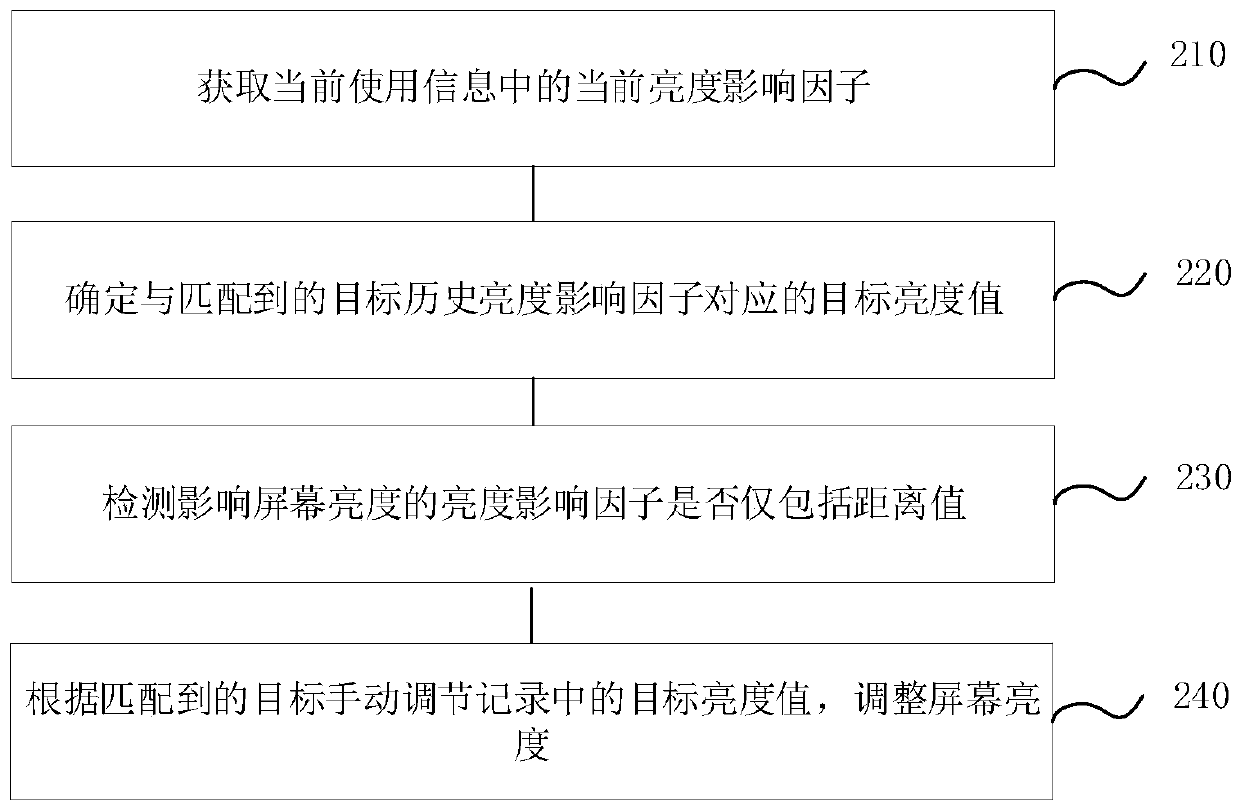

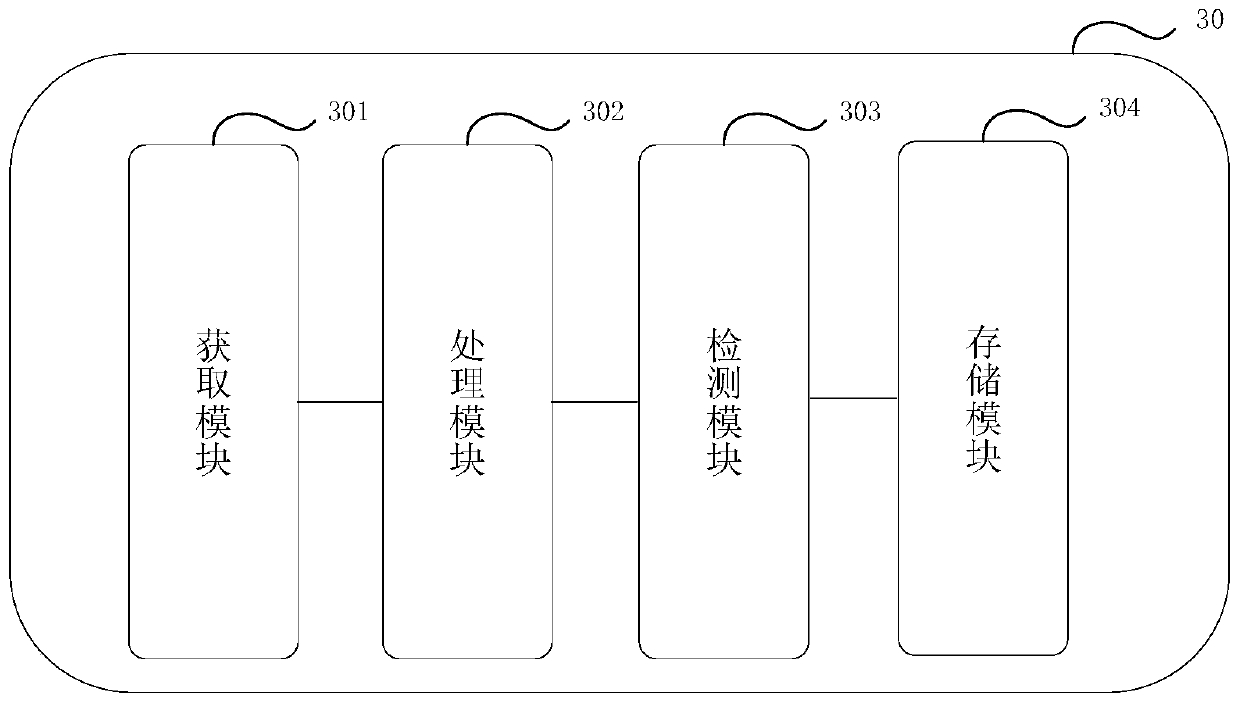

Screen brightness adjustment method and electronic equipment

ActiveCN111261128AAccurate adjustment of brightnessReduce the number of manual brightness adjustmentsCathode-ray tube indicatorsEngineeringComputer science

The embodiment of the invention discloses a screen brightness adjustment method and electronic equipment. The method can comprise the steps: acquiring current use information, comprising a current brightness impact factor, of a screen; under the condition that the current brightness impact factor matches a pre-stored manual adjustment record in the electronic equipment, adjusting the screen brightness according to a target brightness value in the matched target manual adjustment record. The current brightness impact factor comprises at least one of the following contents: a distance value between the electronic equipment and a user, environment information of an environment where the electronic equipment is located, and information of an application program running in a foreground of the electronic equipment; and the manual adjustment record comprises a record associated with the current use information. Therefore, a problem that the requirement of a user for different screen brightness in a complex environment cannot be met in the prior art is solved.

Owner:VIVO MOBILE COMM CO LTD

High-efficiency copper wire drawing liquid with long usage life and preparation method thereof

The invention discloses a high-efficiency copper wire drawing liquid with long usage life, which is characterized by comprising the following raw materials by weight: 4-6 parts of polyoxyethylene alkanolamide, 2.5-4 parts of dimethyl acetamide, 4-5 parts of liquid paraffin, 2-3 parts of eleaostearic acid, 3.5-4.5 parts of deionized water-soluble phosphate ester, 1-2 parts of sodium benzoate, 2.5-3.5 parts of triethanolamine oleate, 1-2 parts of DL602 Casson antiseptic, 8-10 parts of silicon powder, 5-7 parts of auxiliary agent and 900-950 parts of deionized water. According to the invention, the added sodium benzoate and the DL602 Casson antiseptic have good anticorrosion effect, and odor and blackening condition of the wire drawing liquid can not be easily generated, and the added auxiliary agent has good antiwear, dispersion, lubrication and film forming ability. The high-efficiency copper wire drawing liquid has excellent lubrication performance, can satisfy the requirement of client brightness and size precision under low concentration, water base has good heat radiation effect, and the high-efficiency copper wire drawing liquid has the advantages of easy preservation and long usage life, and is suitable for copper wire drawing.

Owner:ANHUI TATSU PRECISION ALLOY

Lamp and light-emitting device

InactiveCN106879132AImprove experienceSolve the problem of easy damage due to user's wrong operationElectrical apparatusLighting elementsEngineeringLight emitting device

The invention relates to a lamp and a light-emitting device. The lamp includes a housing in which the light emitting device is arranged, a touch screen is arranged on the housing, a brightness adjustment section is arranged on the touch screen, a brightness adjustment signal is generated when the brightness adjustment section is touched, and the lamp further comprises a control unit, and the control unit adjusts the light emission brightness of the light-emitting device according to the brightness adjustment signal. Compared with the adjusting manner with the light emitting device brightness of the lamp with a button, the lamp adjusts the light emitting device brightness of the lamp in a manner that a user touches the touch screen to generate a brightness adjustment signal without the need for setting several brightness in advance, so that the adjustment range of the light emitting device brightness of the lamp is wider and the user adjust the proper brightness for himself / herself according to the extraneous environment and the feeling, thereby improving the user's experience and feeling.

Owner:贵州恩纬西光电科技发展有限公司

Automatic polishing wire of precision ball

PendingCN107413753AMeet cleanliness requirementsMeet brightness requirementsSievingPolishing machinesEngineeringEddy current

The invention relates to an automatic polishing wire of a precision ball. The automatic polishing wire comprises a cleaning unit, a separating unit and a heating conveying unit, wherein the cleaning unit comprises a cleaning cylinder which is of a hollow cylindrical structure with an upper opening, a cleaning water outlet is formed in the bottom end of the cleaning cylinder, and the cleaning cylinder can be driven to swing by a pouring mechanism; the separating unit comprises a separating screen which is arranged on the discharge end of the cleaning cylinder, and an air knife A is arranged on the upper end of the separating screen; and the heating conveying unit is arranged on the discharge end of the separating screen and comprises a conveying track, a pair of air knives B which are distributed in parallel in the conveying direction of the conveying track are arranged on the upper end of the conveying track, and a heating pipe is arranged on the lower end of the conveying track. The automatic polishing wire has the advantages that on the basis that technological requirements are guaranteed, the influence of cloth putty is reduced, environmental pollution is reduced, and the requirements of eddy current inspection on the surface clearness and brightness of the ball can be fully met.

Owner:JIANGSU LIXING GENERAL STEEL BALL

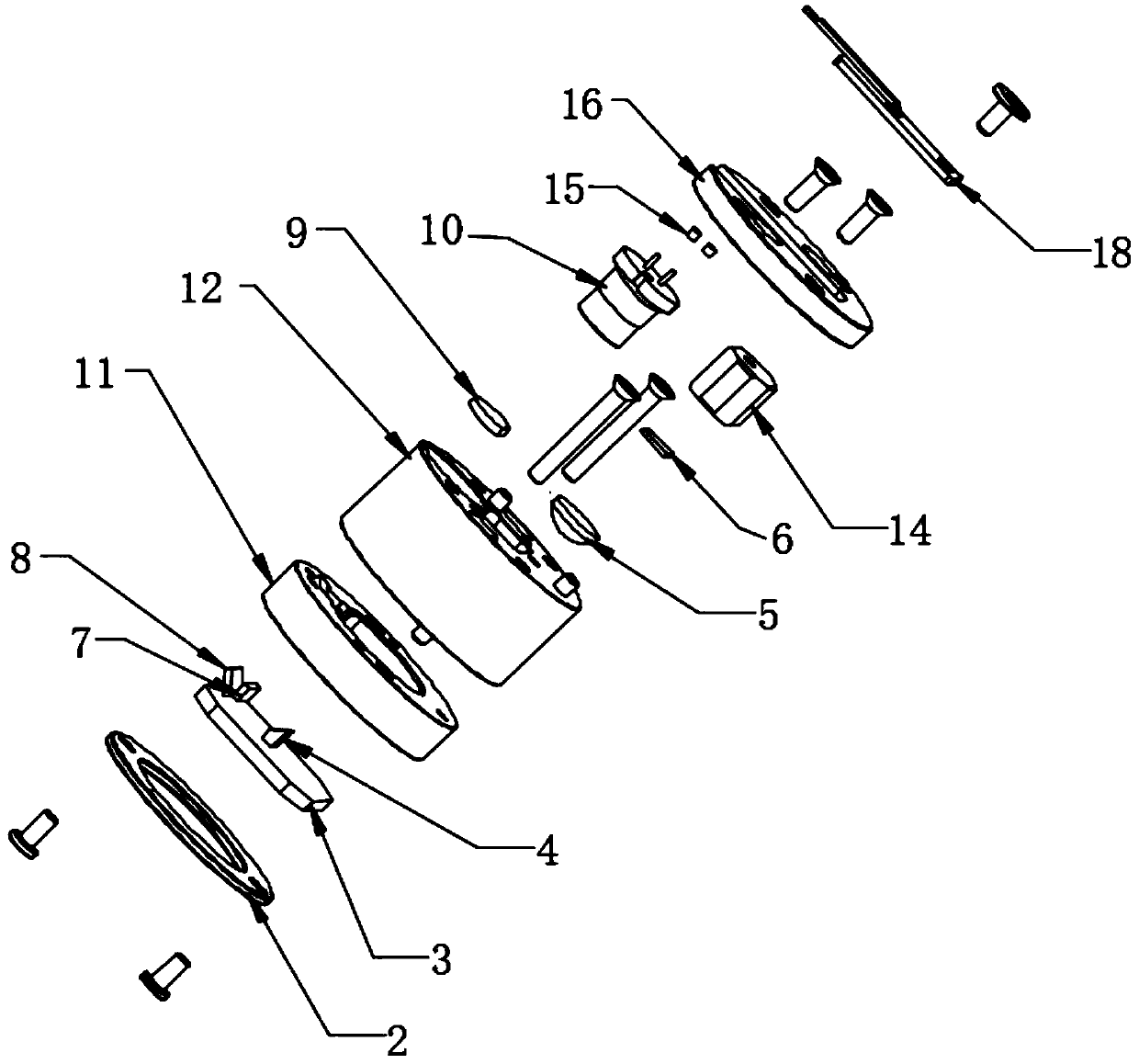

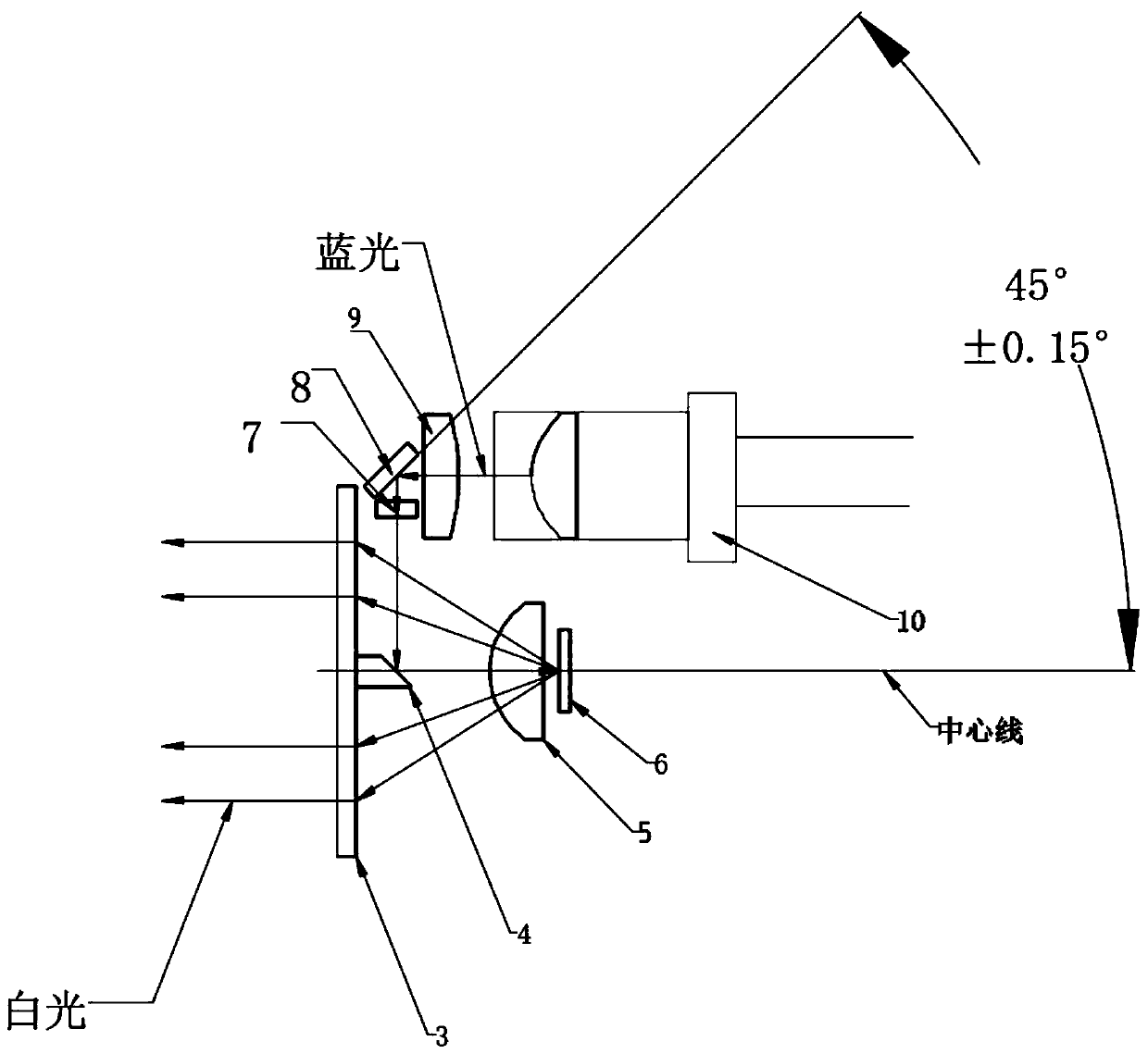

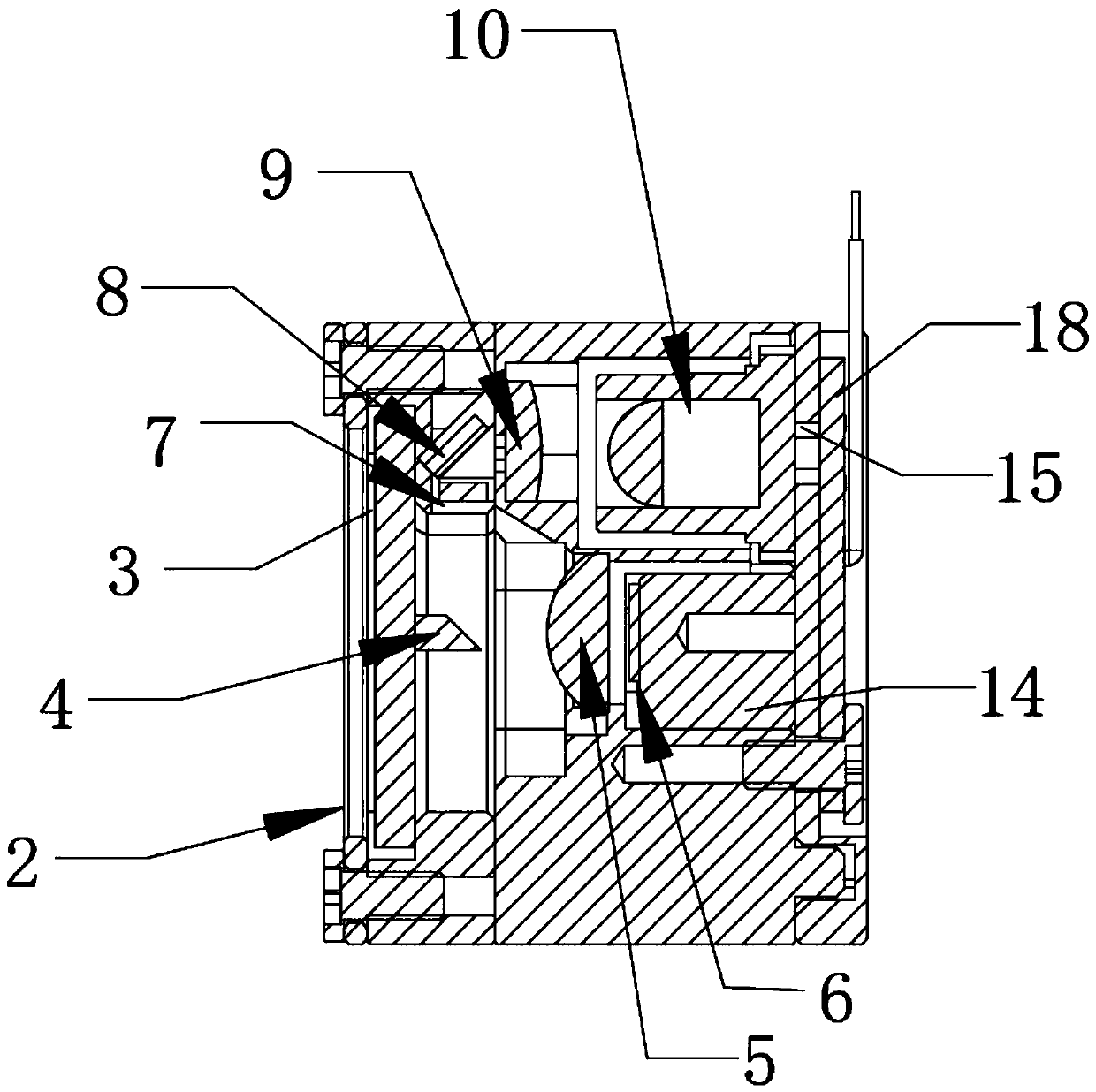

LD laser light source module

PendingCN110159942ARich choiceExtended design domainSpectral modifiersLight fasteningsPhosphorLaser light

The invention relates to the technical field of illumination parts, and discloses an LD laser light source module. The LD laser light source module includes an LD light source, a reflection componentand a powder piece which are successively arranged in the light radiating the direction of the LD light source; and lights radiated by the LD light source are blue rays, the powder piece and the LD light source are arranged in a parallel mode, the powder piece is coated with yellow phosphor powders which are combined with the blue rays to be white lights, the reflection component is used for reflecting the lights radiated by the LD light source to the powder piece, and then the lights are reflected off through the powder piece. Compared with the prior arts, the LD laser light source module hasthe beneficial effects that the luminous power is high, the brightness is high, the definition is high, the luminous distance is long, and the size is small.

Owner:GUANGZHOU UNIONLUX ELECTRONICS TECH CO LTD

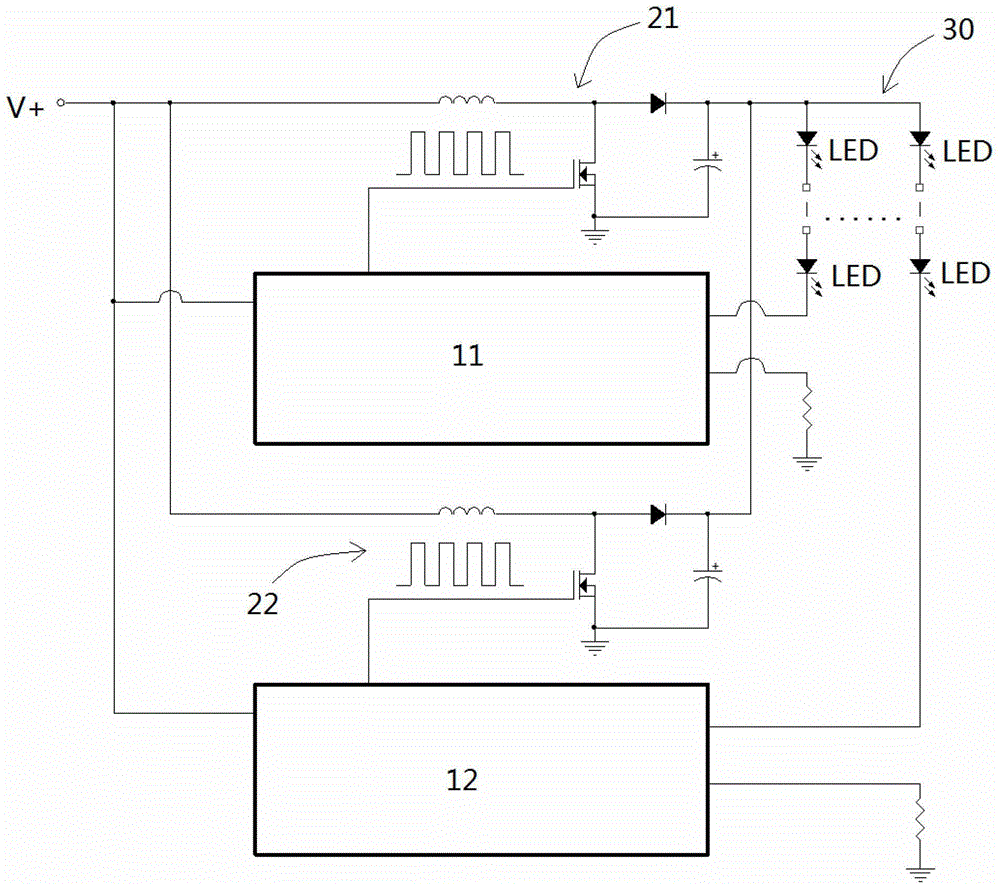

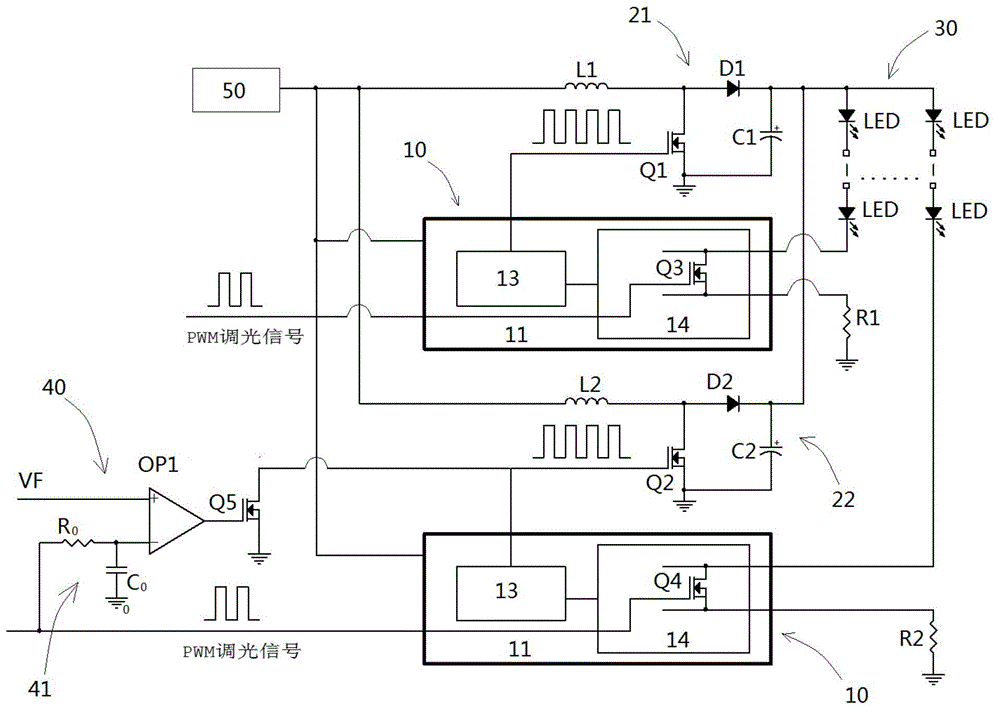

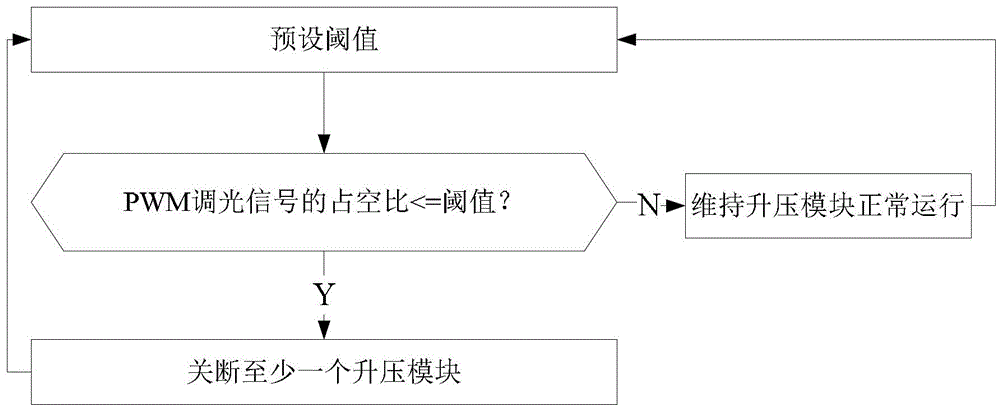

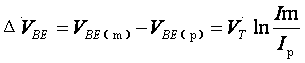

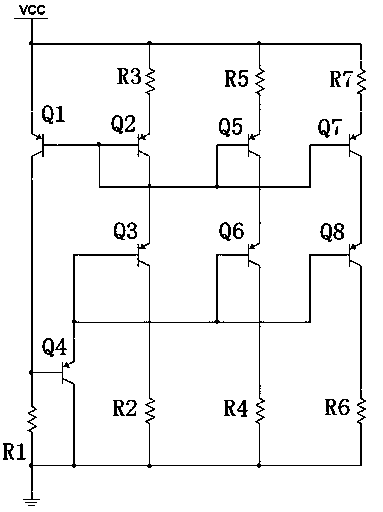

Led backlight driving circuit, liquid crystal display device and a driving method

ActiveCN103280191BMeet brightness requirementsImprove conversion efficiencyElectrical apparatusStatic indicating devicesLiquid-crystal displayEngineering

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

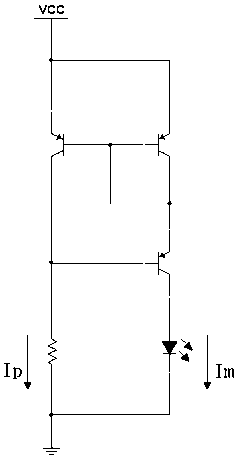

Light emitting block constant current driving circuit

InactiveCN104661381AMeet brightness requirementsStrong targetingElectric light circuit arrangementDriving currentLight equipment

The invention discloses a constant current source driving circuit with an adjustable output current value. The constant current source driving circuit is characterized in that each mirror image branch comprises a first triode and a second triode; the collector of the first triode of each mirror image branch is connected with the emitter of the second triode; the base of the first triode of each mirror image branch is connected with that of a control end triode; the emitter of the first triode of each mirror image branch is connected with the positive end of a power supply through a resistor; the emitter of the second triode of each mirror image branch is connected with the base of the control end triode; the collector of the second triode of each mirror image branch is grounded through the resistor. On the basis of an Ebers-Moll equation and a mirror image current source technology, multiple paths of light emitting block driving current output are achieved and are independent of one another, and the current value of each path can be configured gradually through the resistor. The constant current source driving circuit can be used for constant-current driving of aircraft lamp light alarm equipment and built-in lighting equipment.

Owner:SHANGHAI AVIATION ELECTRIC

Injection molding module and injection molding method utilizing the same

InactiveUS20150004278A1Destroy directionalityEasily brokenFood shapingEngineeringMechanical engineering

Owner:WISTRON CORP

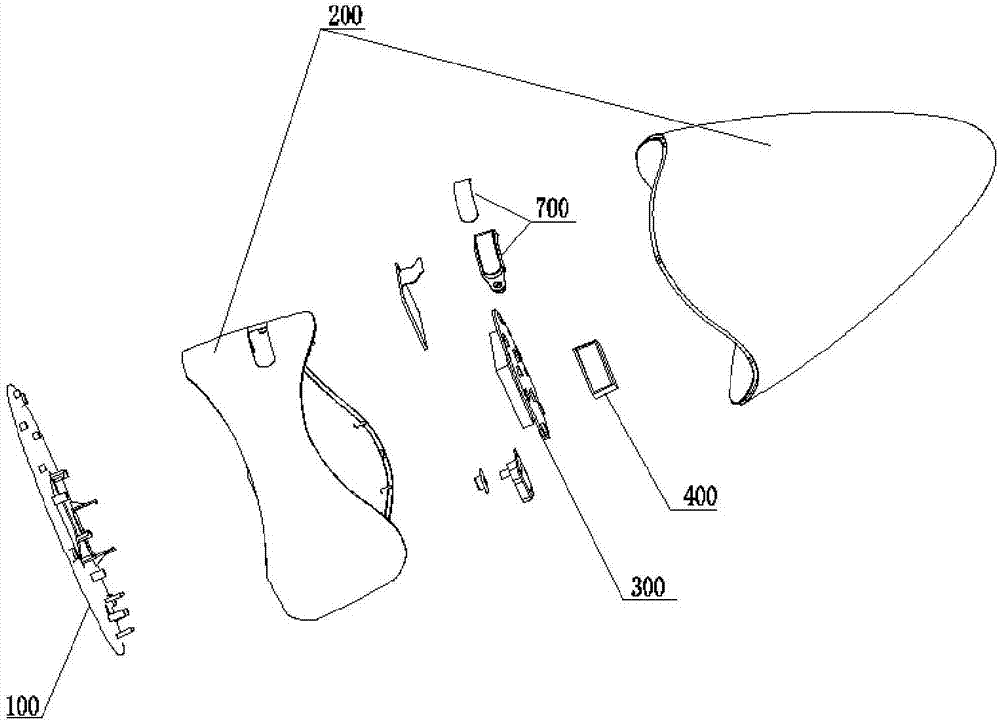

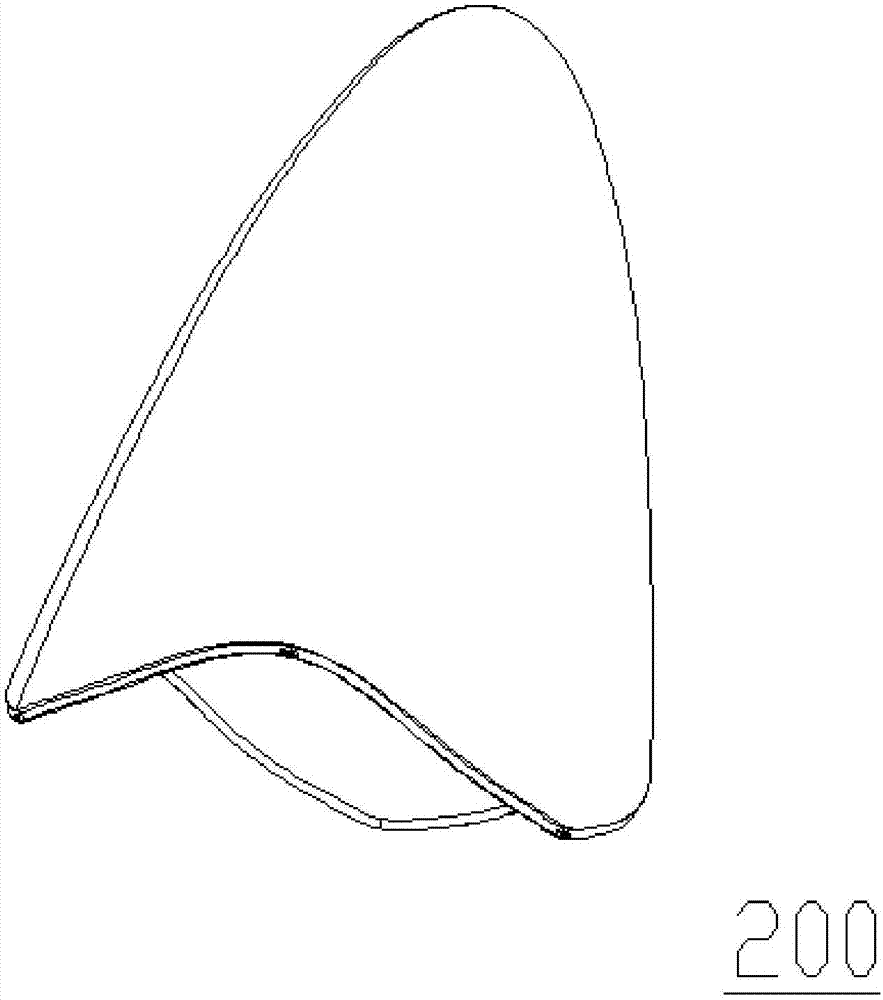

Ten-flash lamp structure for mobile phone lighting

PendingCN106993069AImprove shot qualityMeet brightness requirementsTelevision system detailsColor television detailsEngineeringMechanical engineering

The invention discloses a ten-flash lamp structure for mobile phone lighting. The ten-flash lamp structure comprises ten flash lamps and a lamp shade above the flash lamp; a base circle and Fresnel thread structures are arranged at the bottom of the lamp shade, the Fresnel thread structures are arranged at two sides of the base circle; each Fresnel thread structure comprises a first annular lens, a second annular lens connected with the first annular lens, and a third annular lens connected with the second annular lens; the first annular lens and the second annular lens are symmetrically arranged, and a section of the connecting part of the first annular lens and the second annular lens is V-shaped, ten flash lamps are arranged below the V-shaped opening and uniformly arranged along the circumference of an axis of the base circle. The ten-flash lamp structure disclosed by the invention has the advantages that the lamp shade is the Fresnel structure, and the first annular lens and the second annular lens form a local Fresnel structure; the center brightness of the structure reaches 5301X, and satisfies the demand on the brightness by a high-pixel camera in photographing, and the shooting quality of a picture is greatly improved.

Owner:CHINA LTD

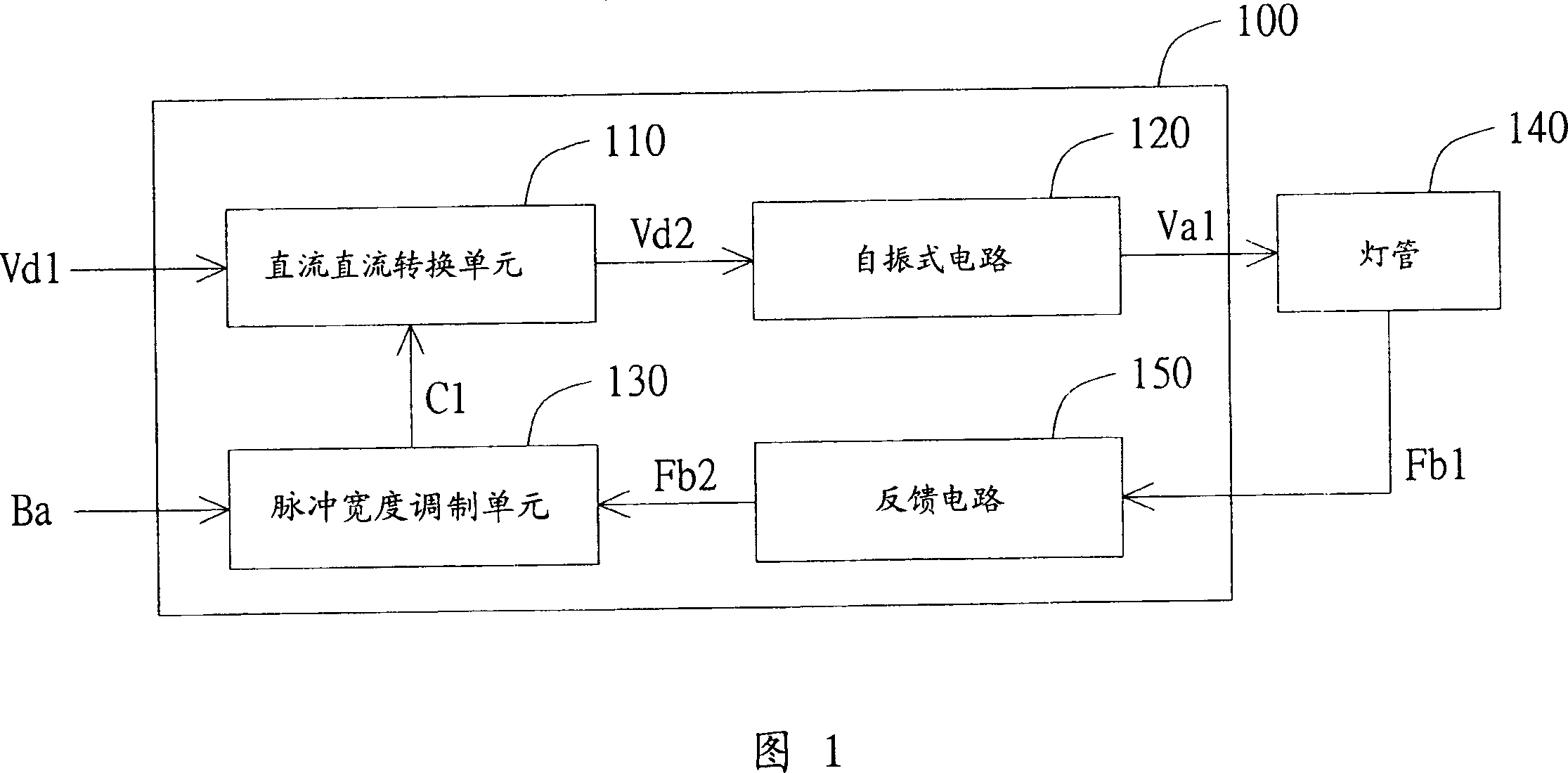

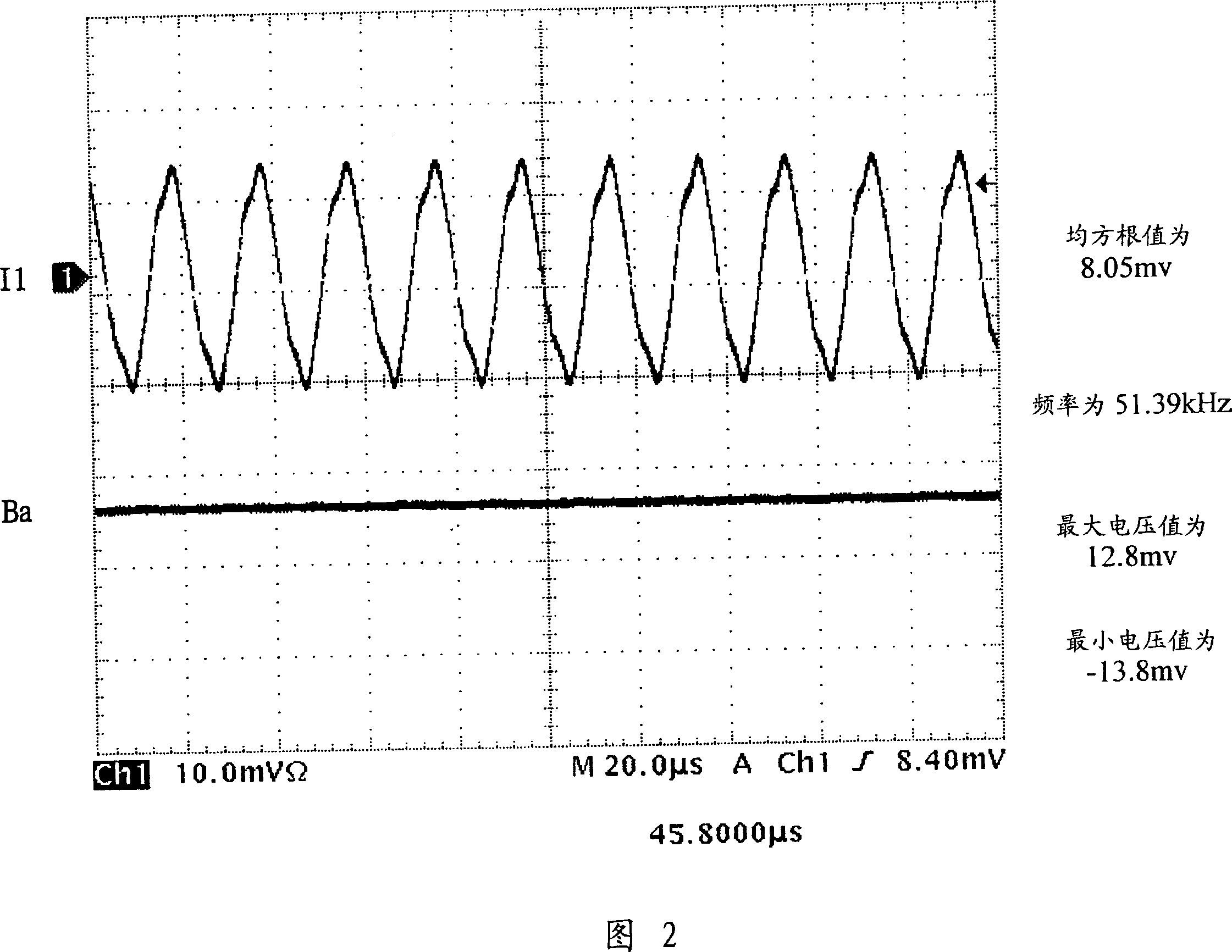

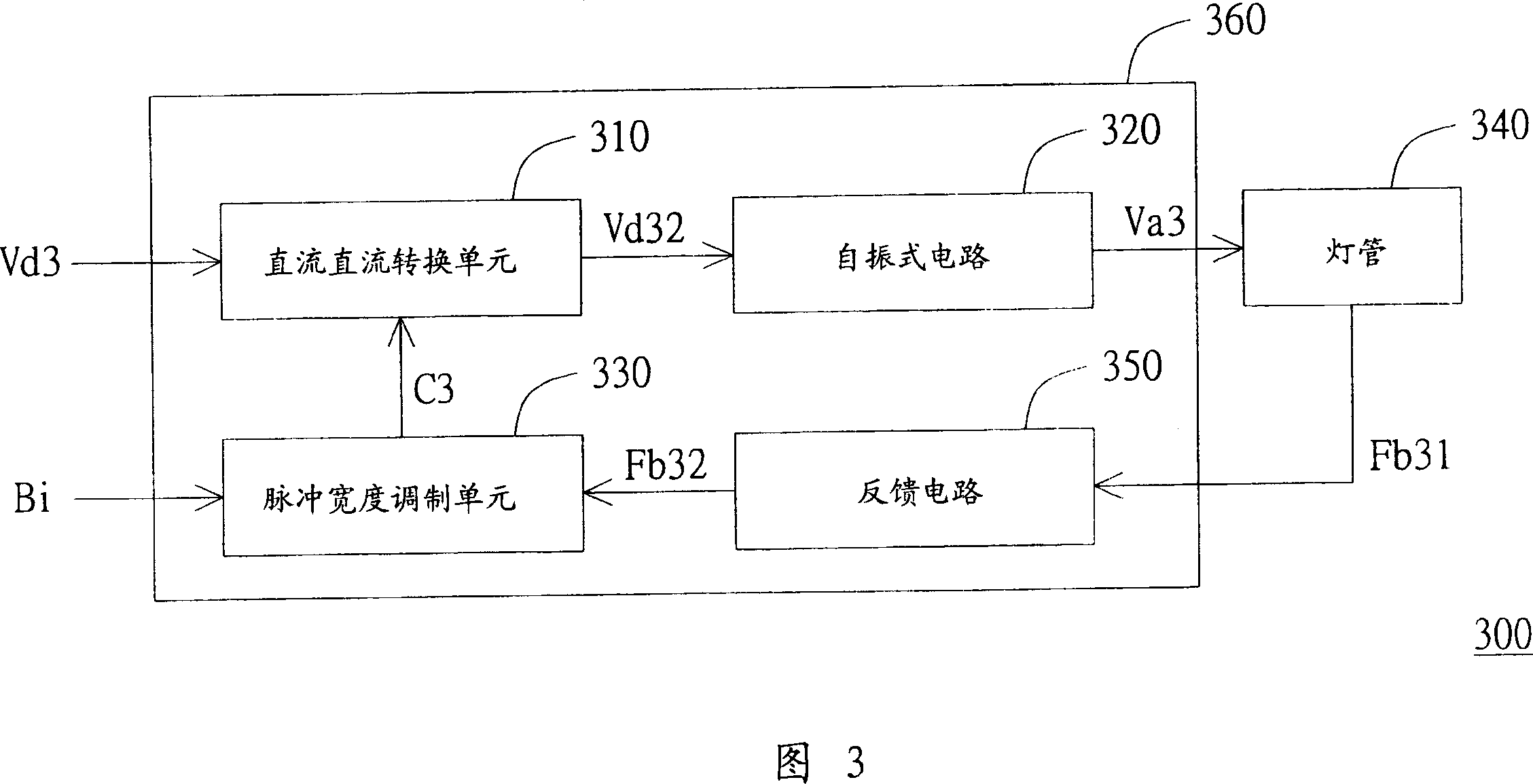

Display, and DC / AC converter

InactiveCN1960153AMeet brightness requirementsStatic indicating devicesElectric lighting sourcesSelf-oscillationDisplay device

The monitor consists of the lamp tube and DC / AC convertor (DAC). DAC consists of the impulse width modulation unit (IWM), the DC / DC conversion unit (DDC) and the self-oscillation circuit (SO). IWM outputs the PWM signal. The impulse width of the PWM signal is decided by the level signal. Receiving the 1st DC voltage, DDC converts it into the 2nd DC voltage. The level of the 2nd DC voltage is decided by PWM signal. According to the 2nd DC voltage, SO produces the AC voltage and sends it to the lamp tube. According to the level signal, the DC / AC converter defines the level of output AC voltage. When DAC works under the burst mode, the level signal is an interlaced hi and low level to cause the output AC voltage burst.

Owner:BENQ CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com