Economical direct-type backlight assembly

A backlight assembly, direct type technology, used in optics, nonlinear optics, instruments, etc., can solve the problems of high display brightness requirements, high cost of prism sheets, and bulkiness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

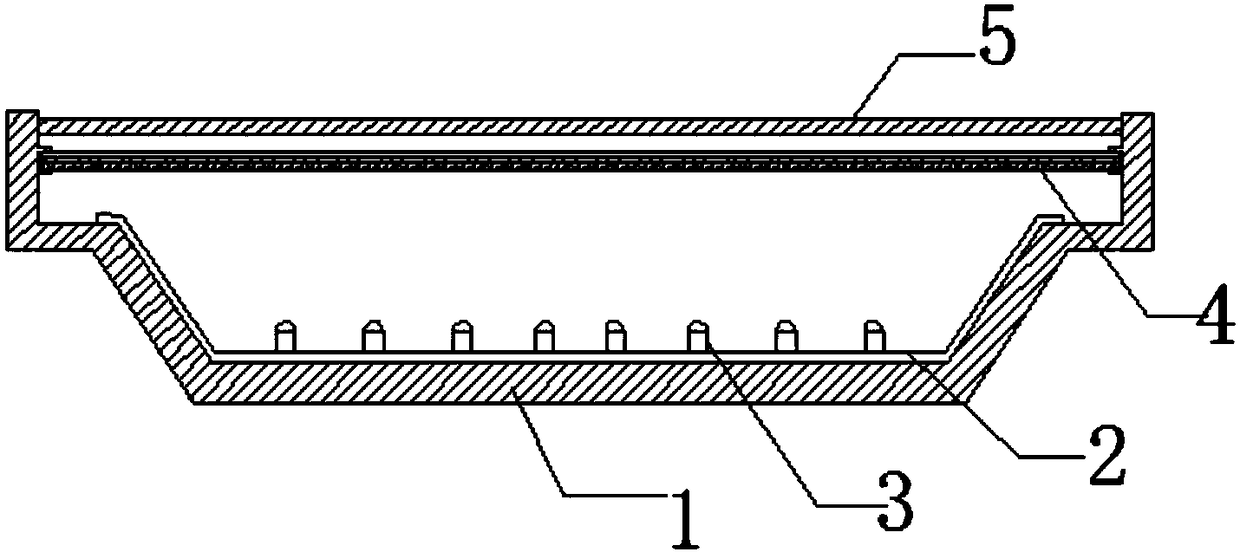

[0025] An economical direct-lit backlight assembly, comprising: a backplane 1, a reflection plate 2, a backlight source 3, and a diffusion sheet 4, the number of the diffusion sheets 4 is 2 to 4, the reflection plate 2 is installed on the inner surface of the backplane 1, and the backlight The source 3 is set above the reflector 2, through the reflector 2, the light emitted from the backlight 3 to the rear and both sides is reflected into the front diffusion sheet 4, and the surface light source processed by the diffusion sheet 4 is provided to the diffusion sheet 4 For the liquid crystal panel 5 in front, the two sides of the back plate 1 are provided with the same number of buckle grooves as the number of diffusion sheets 4. They are in contact with each other, and the distance between the diffusion sheet 4 closest to the liquid crystal panel 5 and the liquid crystal panel 5 is 1-2.5 mm.

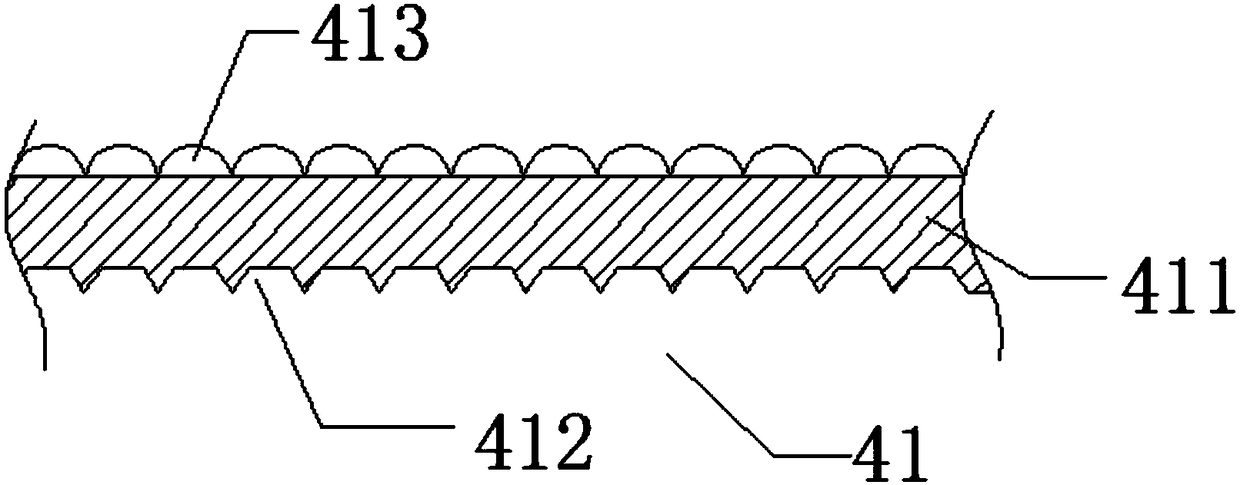

[0026] Further, the plurality of diffusion sheets 4 in the direct type backlight assem...

specific Embodiment example 2

[0029] An economical direct-lit backlight assembly, comprising: a backplane 1, a reflection plate 2, a backlight source 3, and a diffusion sheet 4, the number of the diffusion sheets 4 is 2 to 4, the reflection plate 2 is installed on the inner surface of the backplane 1, and the backlight The source 3 is set above the reflector 2, through the reflector 2, the light emitted from the backlight 3 to the rear and both sides is reflected into the front diffusion sheet 4, and the surface light source processed by the diffusion sheet 4 is provided to the diffusion sheet 4 For the liquid crystal panel 5 in front, the two sides of the back plate 1 are provided with the same number of buckle grooves as the number of diffusion sheets 4. They are in contact with each other, and the distance between the diffusion sheet 4 closest to the liquid crystal panel 5 and the liquid crystal panel 5 is 1-2.5 mm.

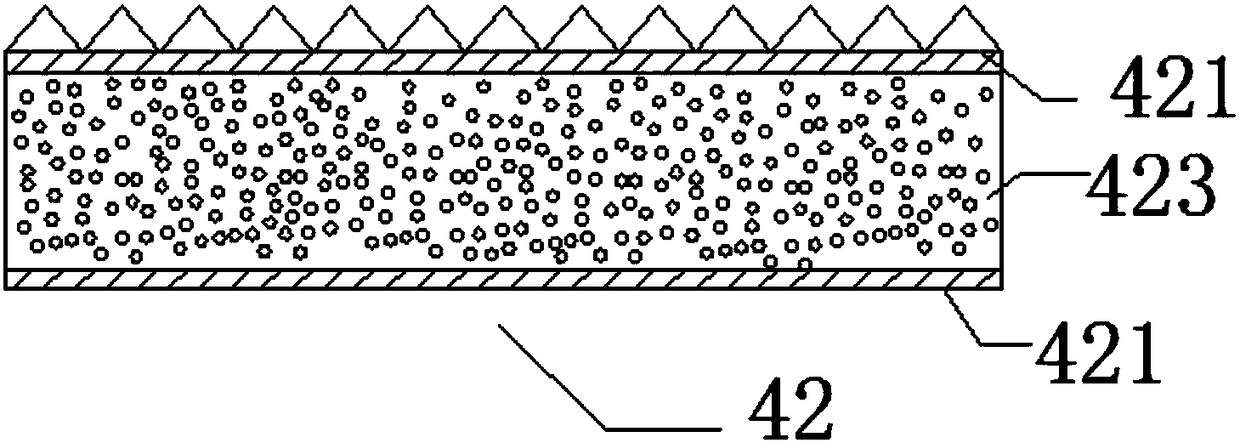

[0030]Further, the plurality of diffusers 4 in the direct-lit backlight assembly are a...

specific Embodiment 3

[0034] An economical direct-type backlight assembly, comprising: a backplane 1, a reflection plate 2, a backlight source 3, and a diffusion sheet 4, the number of the diffusion sheets 4 is 3, the reflection plate 2 is installed on the inner surface of the backplane 1, and the backlight source 3 It is installed above the reflector 2, through the reflector 2, the light emitted by the backlight 3 to the rear and both sides is reflected into the front diffusion sheet 4, and the surface light source processed by the diffusion sheet 4 is provided to the front of the diffusion sheet 4 The two sides of the back plate 1 are provided with the same number of snap grooves as the number of diffusion sheets 4, and the diffusion sheets 4 are all placed in the snap grooves on both sides of the back plate 1, and between adjacent diffusion sheets 4 They are in contact with each other, and the distance between the diffusion sheet 4 closest to the liquid crystal panel 5 and the liquid crystal pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com