Led backlight driving circuit, liquid crystal display device and a driving method

A technology of backlight drive circuit and LED light bar, which is applied in the direction of electrical components, static indicators, instruments, etc., can solve the problem of large heat loss, achieve the effect of reducing energy loss and increasing conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

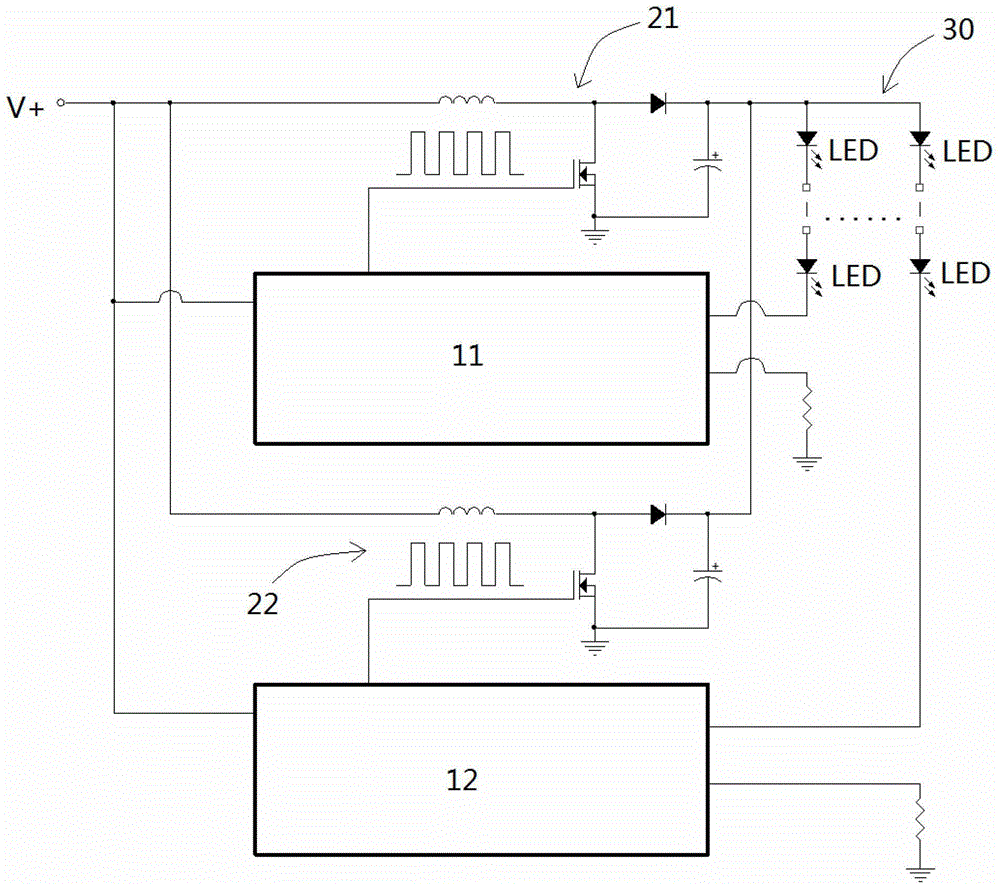

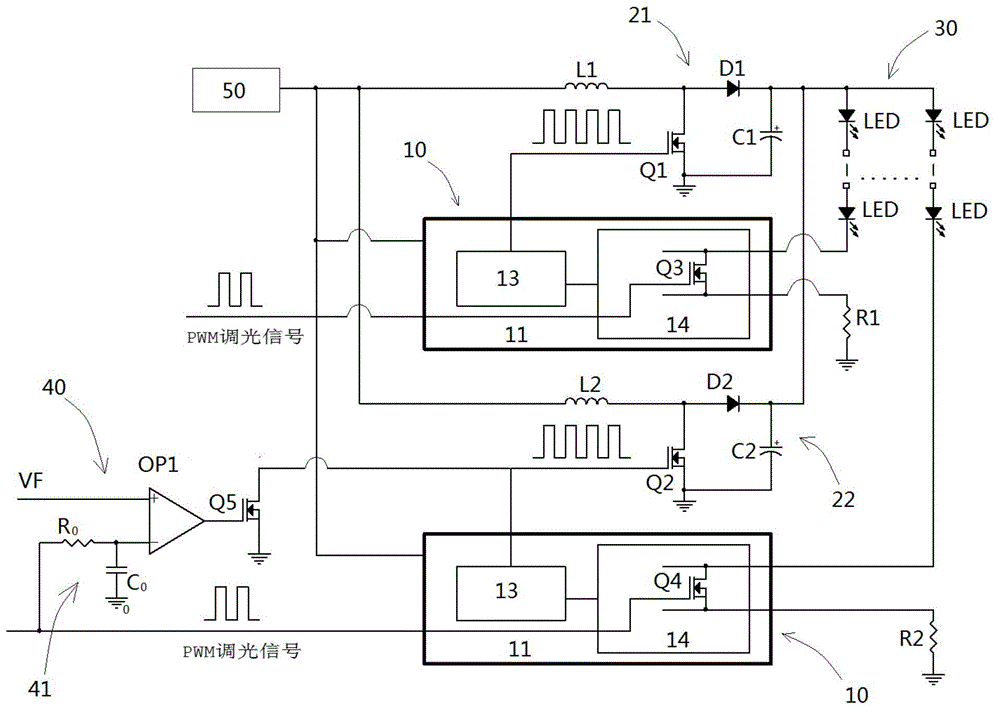

[0045] Such as figure 2 As shown, the LED backlight driving circuit includes a power module 50, an LED light bar 30, and a constant current driver chip 10 for adjusting the brightness of the LED light bar 30, and the constant current driver chip 10 is coupled with a PWM dimming signal; the power module 50 and the LED light bar N booster modules arranged in parallel are connected in series between the light bars 30 , and the control terminals of 1˜(N−1) booster modules are coupled with a comparison module 40 . The LED backlight driving circuit in this embodiment includes a first boost module 21 and a second boost module 22 , wherein a comparison module 40 is coupled to the control terminal of the second boost module 22 .

[0046] The comparison module 40 includes a comparator OP1, the non-inverting input terminal of the comparator OP1 is coupled with a reference voltage VF, and the inverting input terminal is coupled with a conversion unit 41 that converts the PWM dimming sign...

Embodiment 2

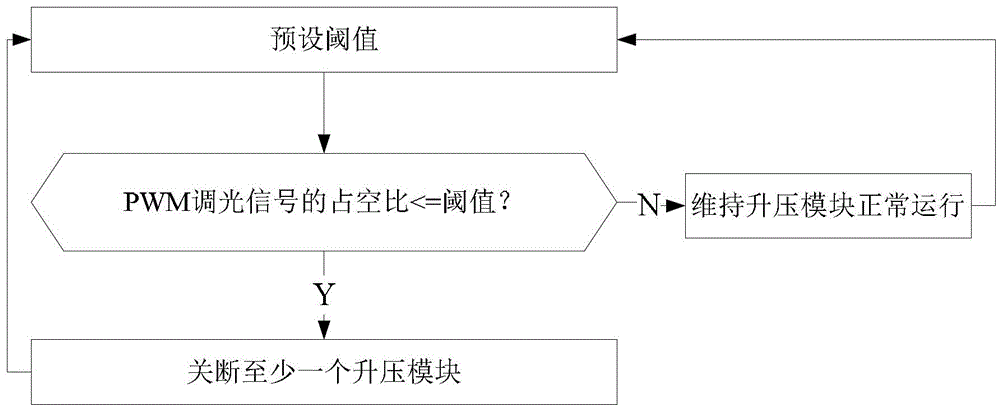

[0055] The invention also discloses a driving method of an LED backlight driving circuit. The LED backlight driving circuit includes a power supply module, an LED light bar, and a constant current driving chip for adjusting the brightness of the LED light bar. The constant current driving chip is coupled with PWM dimming Signal; N booster modules arranged in parallel are connected in series between the power module and the LED light bar. Such as image 3 As shown, the driving method of the LED backlight driving circuit includes:

[0056] A. Preset a duty cycle threshold of a PWM dimming signal;

[0057] B. Detect the duty cycle of the PWM dimming signal, and when the duty cycle is less than the preset threshold, go to step C; otherwise, go to step D;

[0058] C. Control at least one boost module to shut down; return to step A;

[0059] D. Maintain the normal operation of the booster module; return to step A;

[0060] The N is an integer greater than or equal to 2.

[0061...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com