Organic light-emitting diode (OLED) composite transparent cathode structure and preparation method thereof

A technology of transparent cathode and alloy material, applied in the field of OLED light-emitting, can solve the problems of poor conductivity or light transmittance, and the brightness cannot meet the requirements, and achieve the effect of good light transmittance and conductivity, and meet the brightness requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

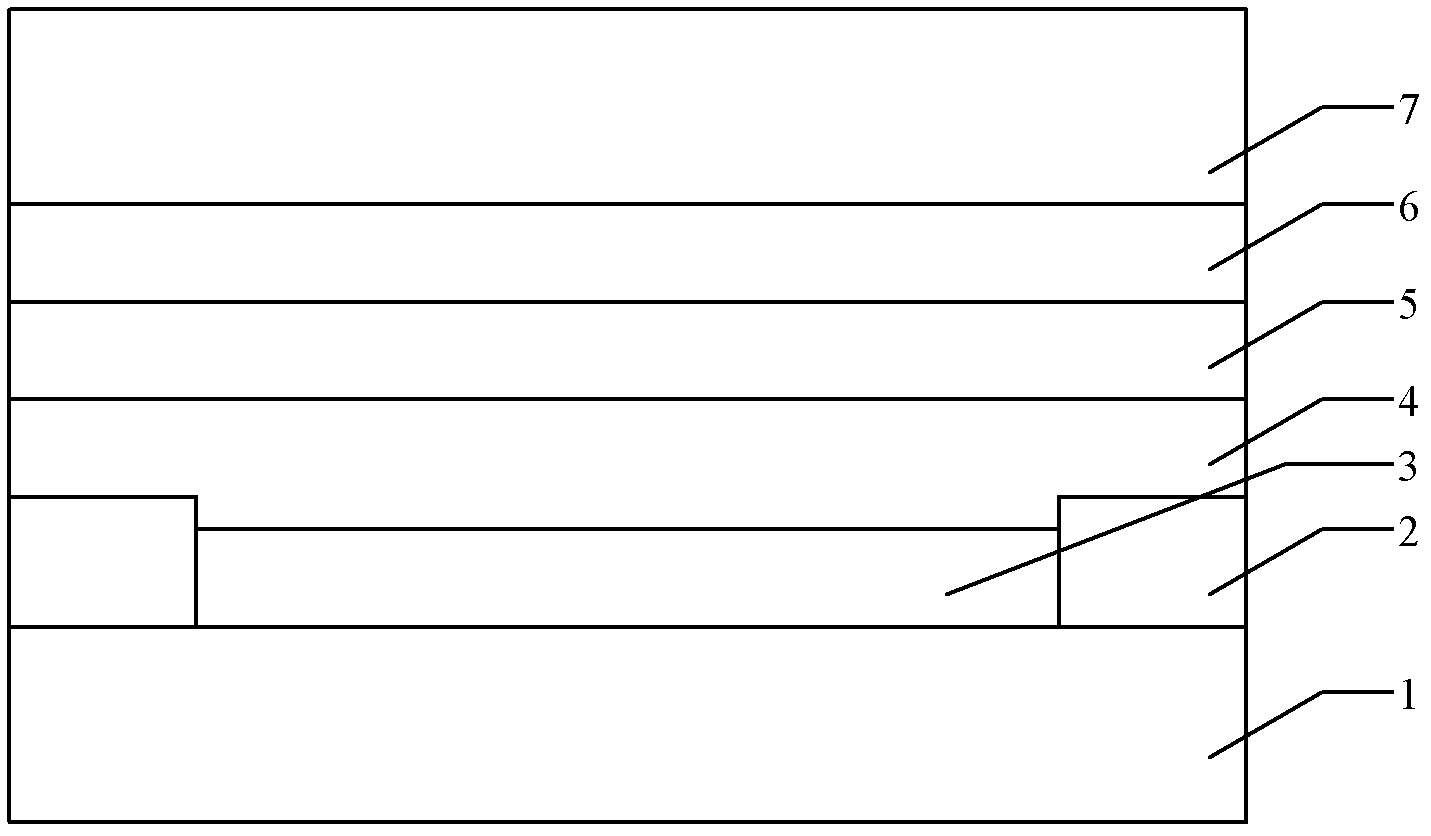

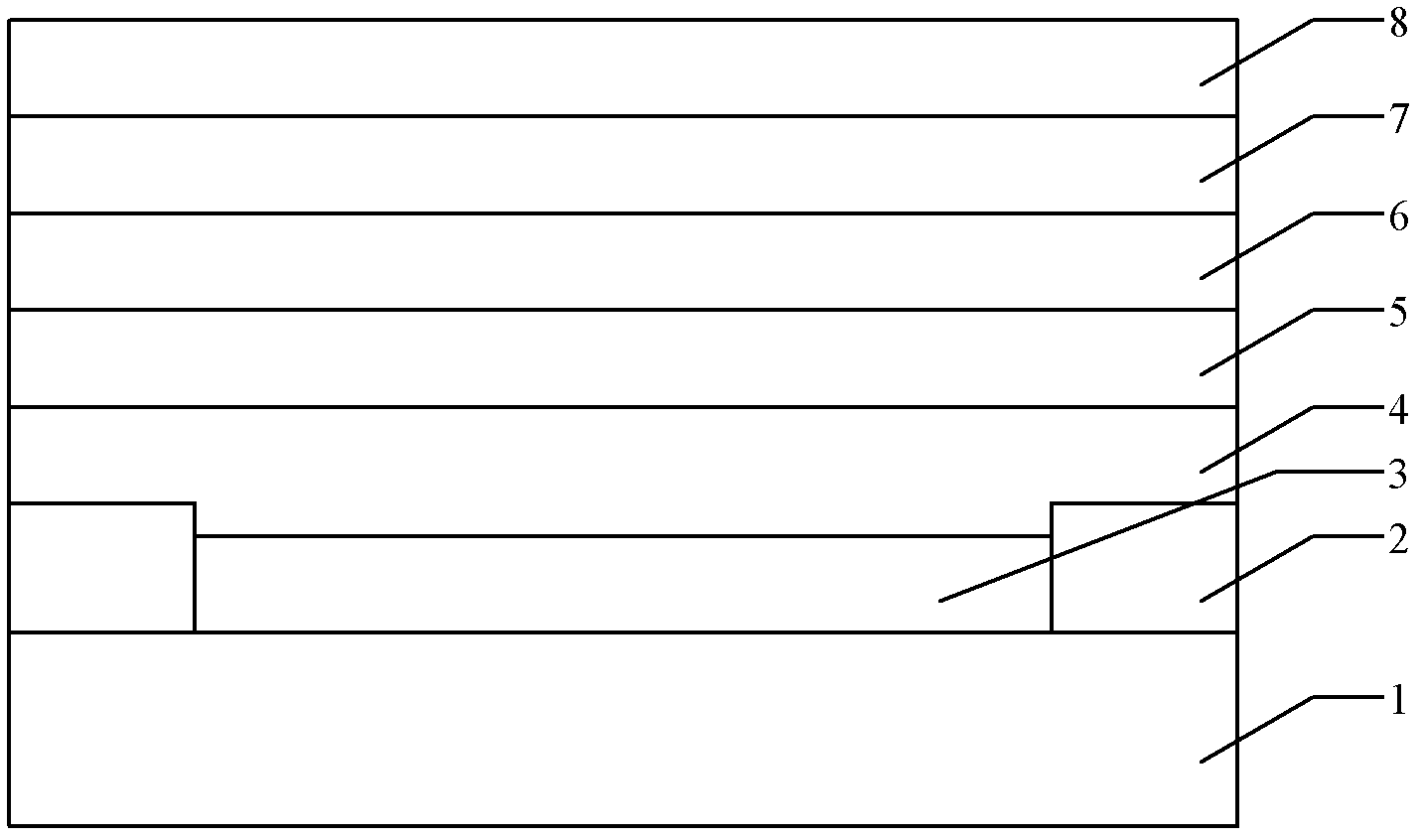

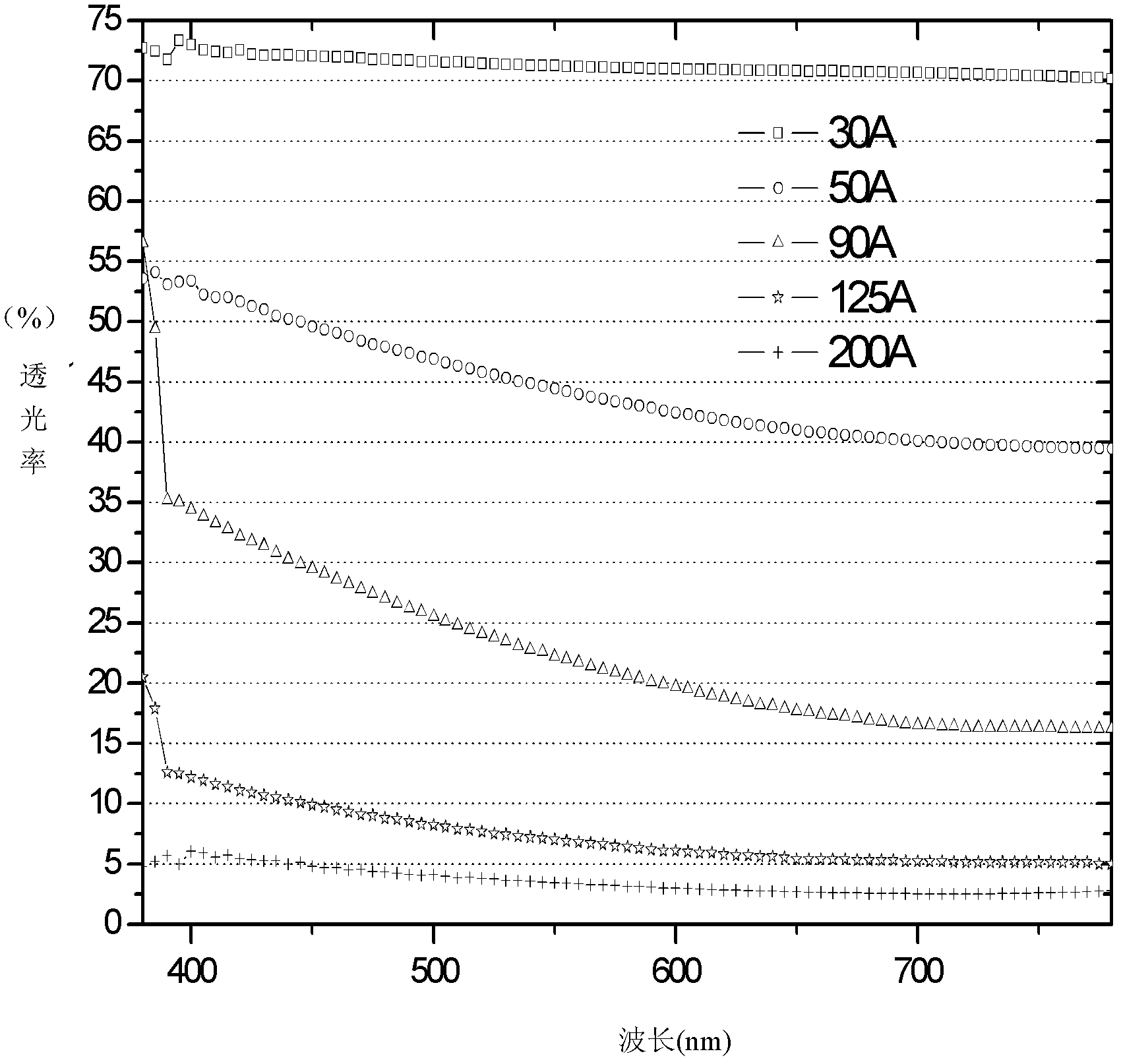

[0024] Aiming at the problem that the conductivity or light transmittance of the transparent cathode structure or the composite transparent cathode structure in the traditional technology is not good, and cannot meet the brightness requirement, the present invention proposes an OLED composite transparent cathode structure, using Al-Li alloy as the transparent The cathode layer uses Ag material as the auxiliary transparent cathode layer to form a composite transparent cathode structure with a double-layer structure, which has good light transmittance and electrical conductivity, and meets the brightness requirements. In addition, a preparation method of the composite transparent cathode structure of the OLED is also proposed.

[0025] The OLED composite transparent cathode structure in the present invention includes:

[0026] A transparent cathode layer and an auxiliary transparent cathode layer, the auxiliary transparent cathode layer is located above the transparent cathode l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com