Patents

Literature

36results about How to "Efficient impregnation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of producing a composite structure via intermediate products, the related apparatus and a composite structure obtainable by the method

ActiveUS20100304170A1High fiber densityFirmly connectedLaminationLamination apparatusFiberLiquid resin

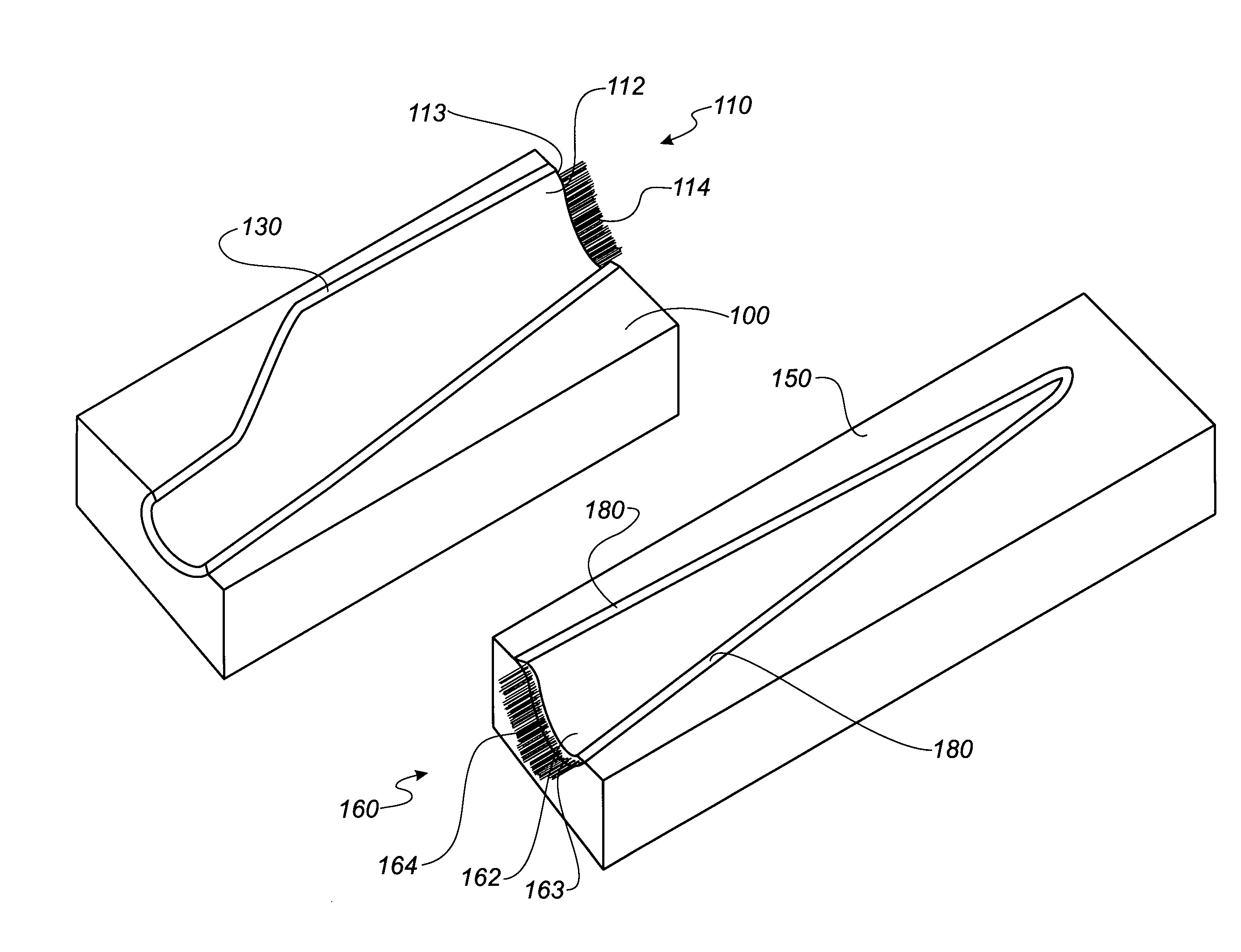

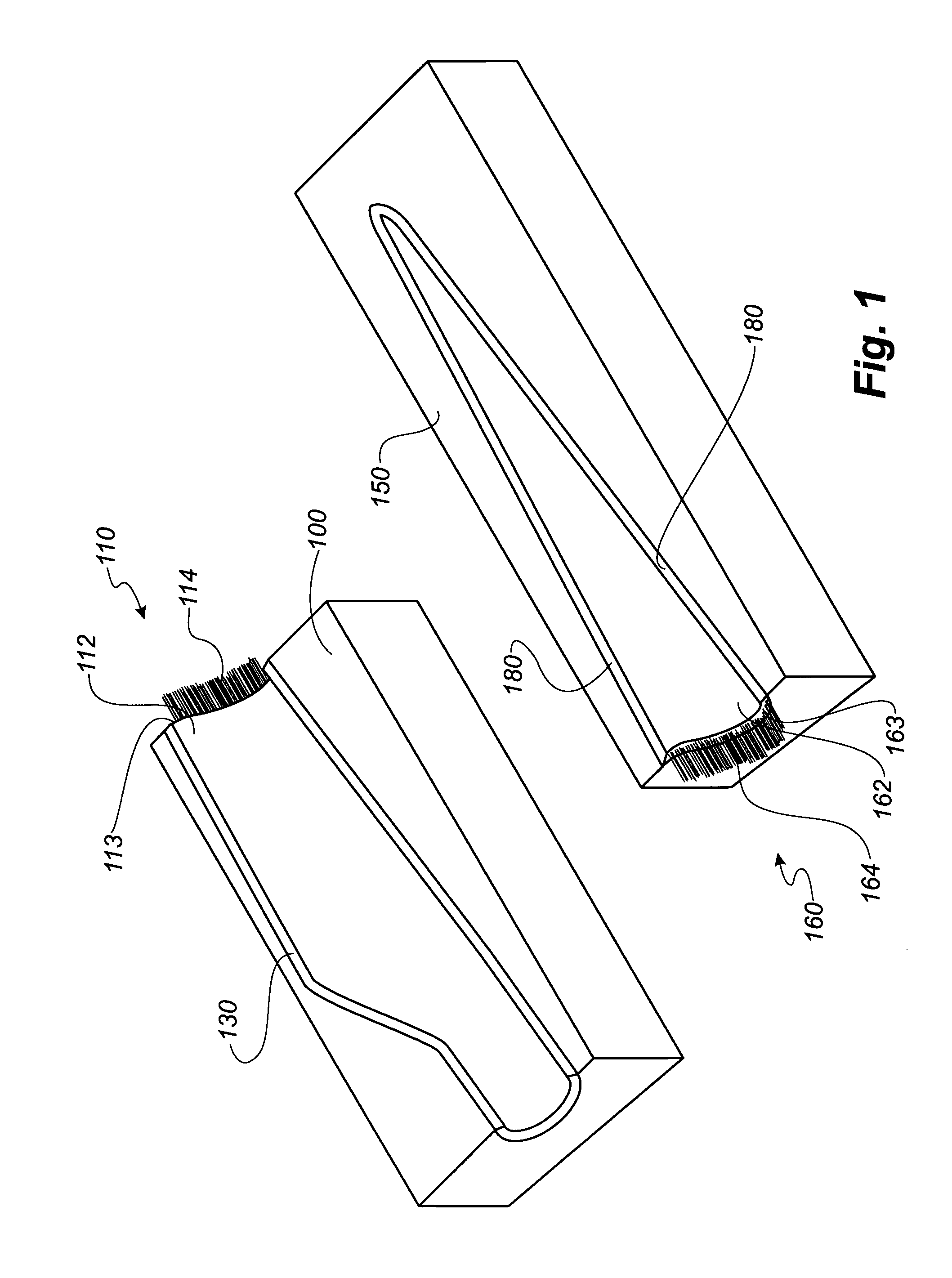

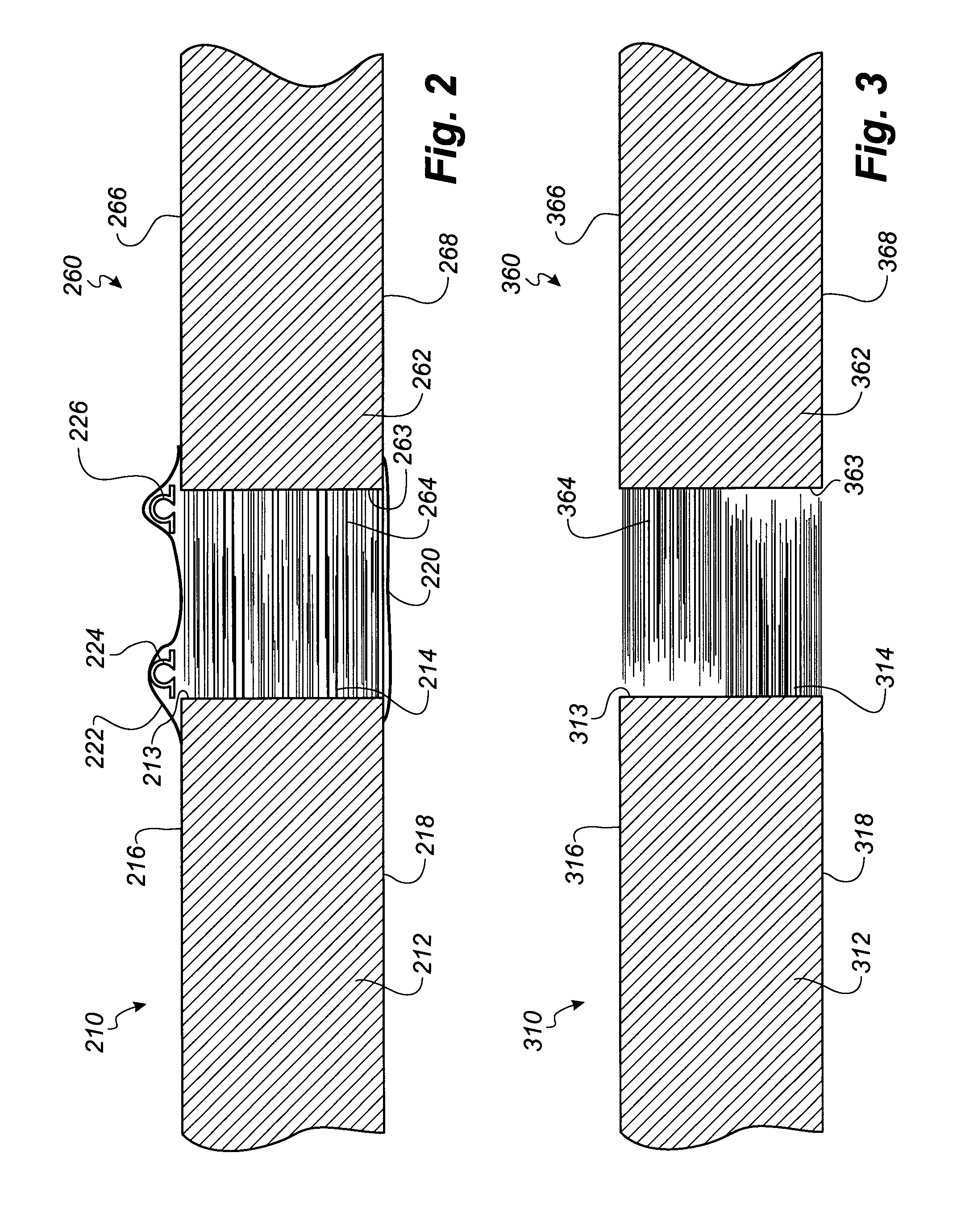

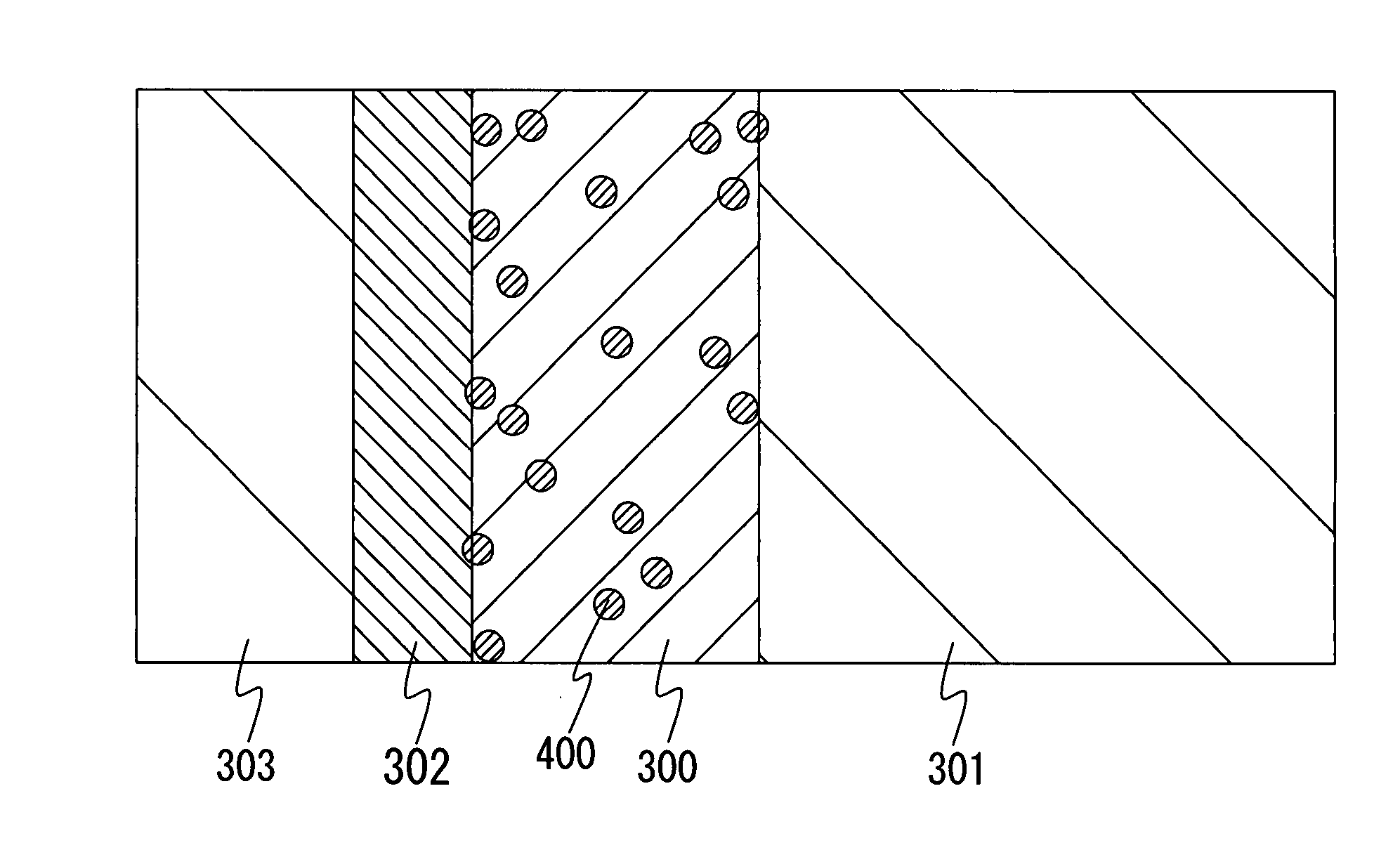

A method of producing a composite structure comprising fibre reinforced material and having a longitudinal direction is described. The method comprises the following steps: a) manufacturing a first structure comprising a first cured composite part having a first thickness and a longitudinal direction with a first end, and a number of first fibre layers extending from the first end, b) manufacturing a second structure comprising a second cured composite part having a second thickness and a longitudinal direction with a second end, and a number of second fibre layers extending from the second end, and c) arranging the first structure and the second structure so that the first end faces towards the second end, and arranging the first fibre layers and the second fibre layers so that at least a part of the first fibre layers overlap at least a part of the second fibre layers in the longitudinal direction, d) supplying liquid resin in order to impregnate the first fibre layers and the second fibre layers, and e) curing the liquid resin in order to form the composite structure comprising the first cured composite part, the second cured composite part, and an intermediate composite part including the first fibre layers and the second fibre layers.

Owner:LM GLASSFIBER

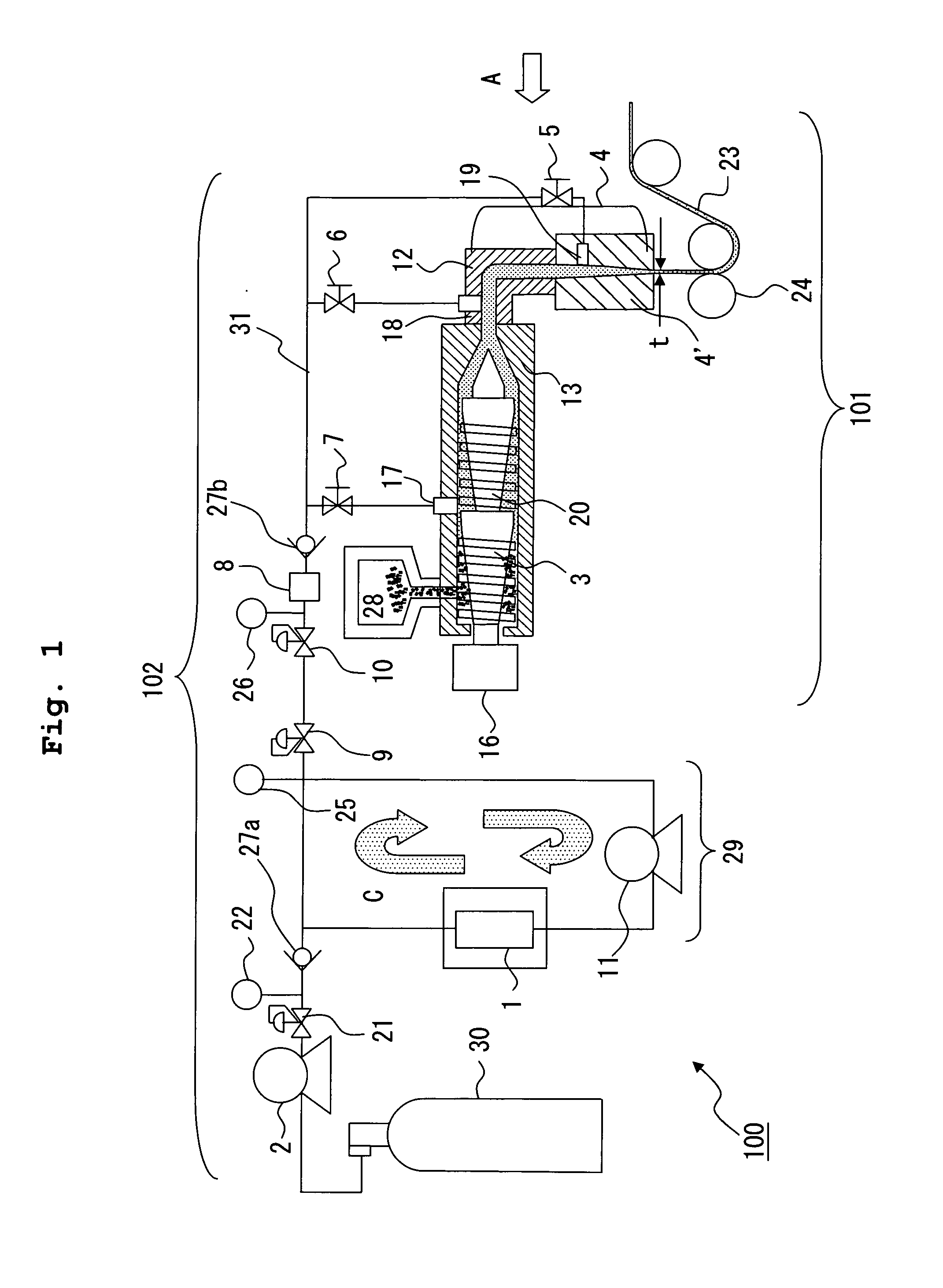

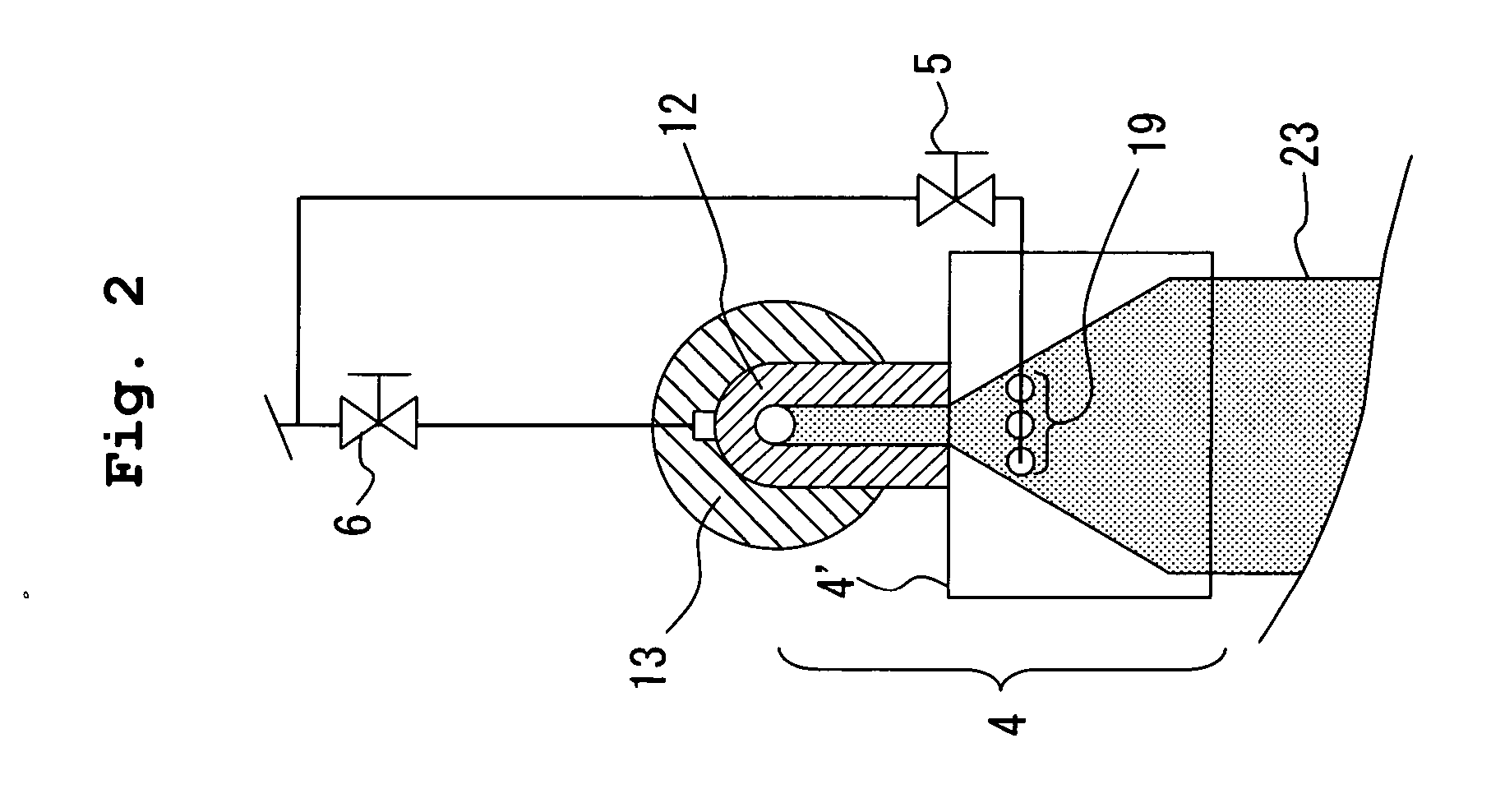

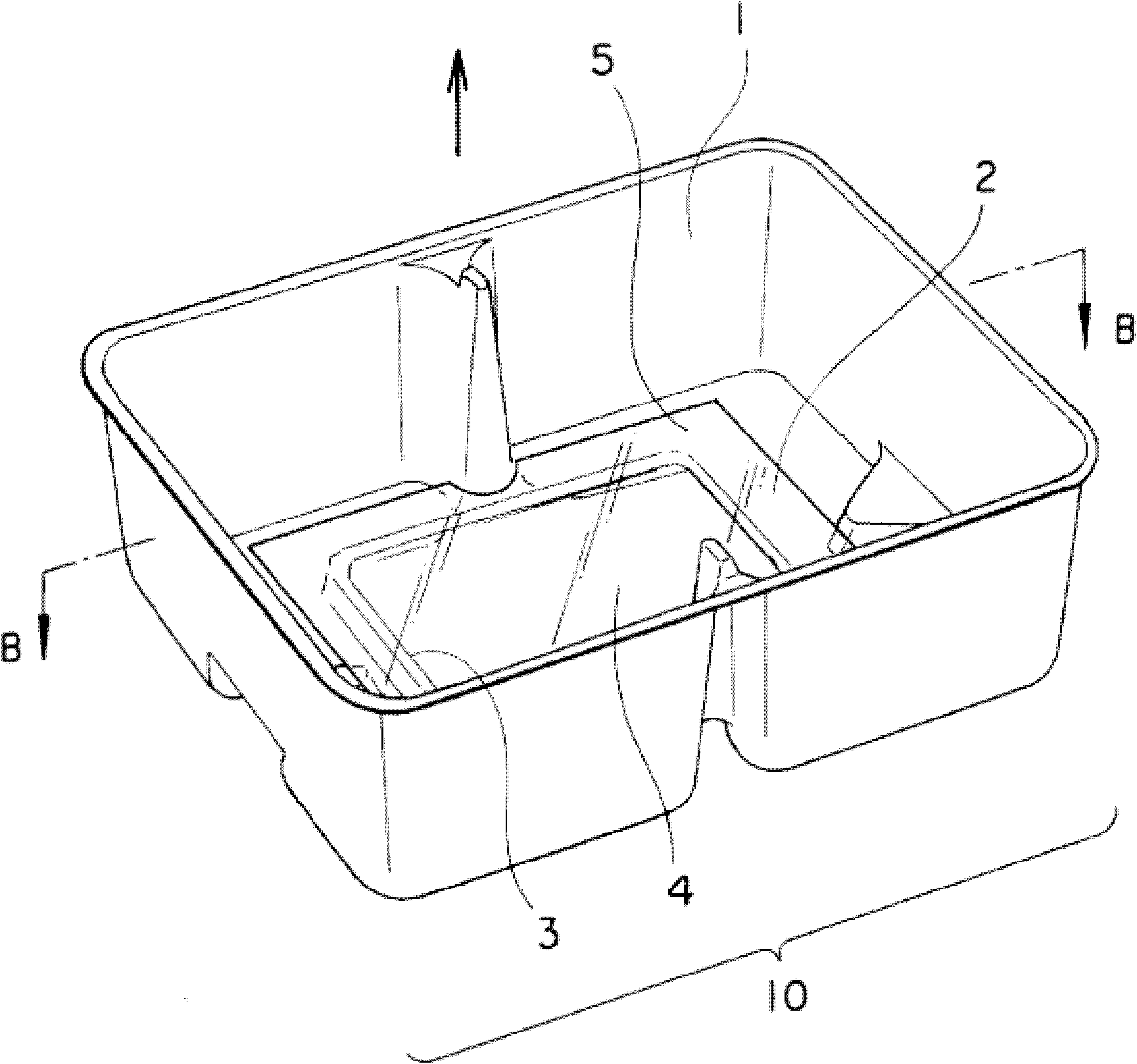

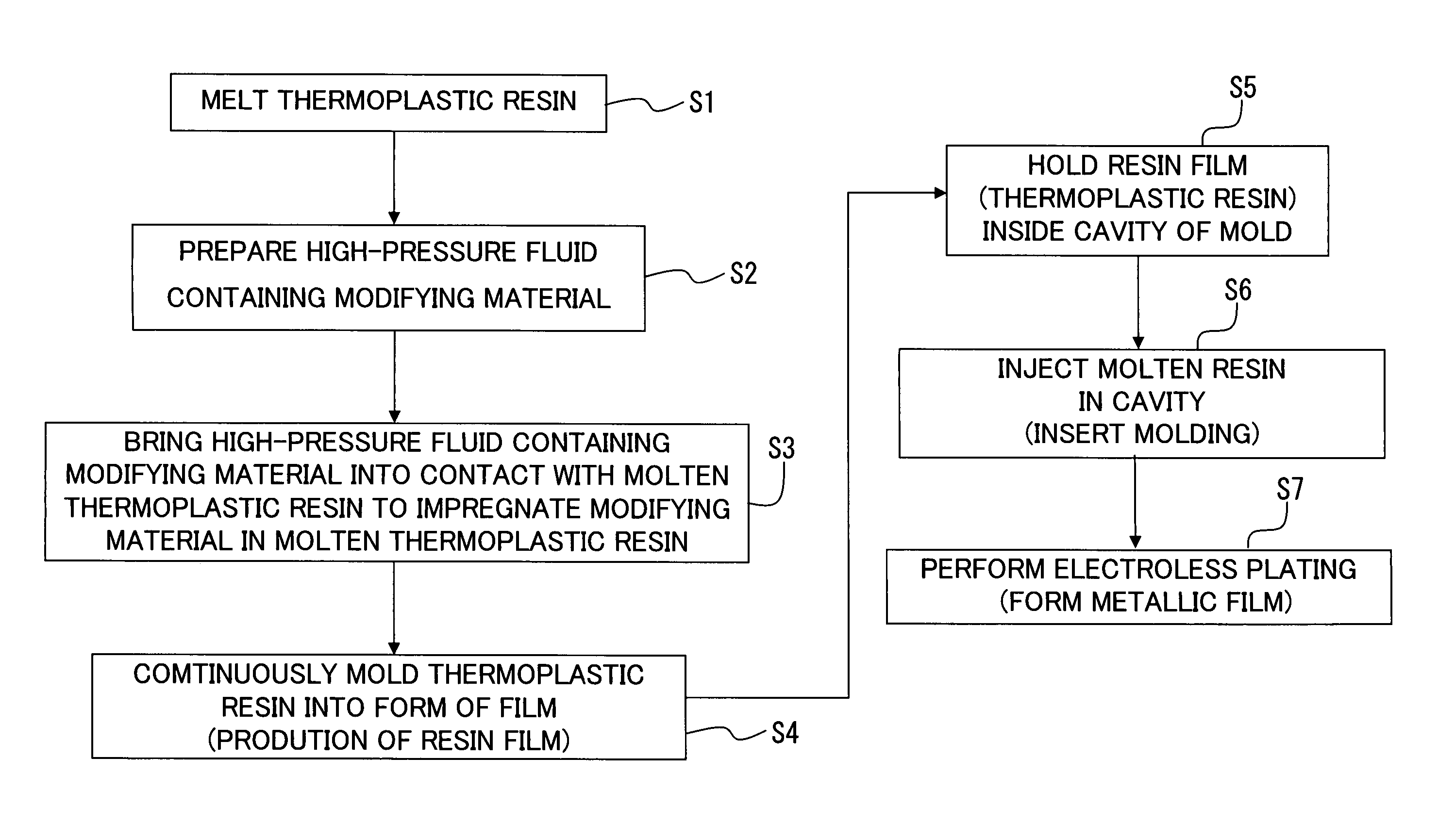

Method of producing molded article, extruder, and molded article

InactiveUS20070190310A1Mass productionEfficient impregnationSynthetic resin layered productsPretreated surfacesHigh pressurePolymer chemistry

The present invention provides a method of producing a molded article, which can be perform the continuous processes and effectively impregnate a modifying material such as metal complexes in the thermoplastic resin for short period of time. The above object is achieved by providing the method of producing the thermoplastic resin molded article which includes impregnating the high-pressure fluid having a modifying material dissolved therein, in thermoplastic resin, and continuously molding the thermoplastic resin in which the modifying material has been impregnated, into the form of a film.

Owner:MAXELL HLDG LTD

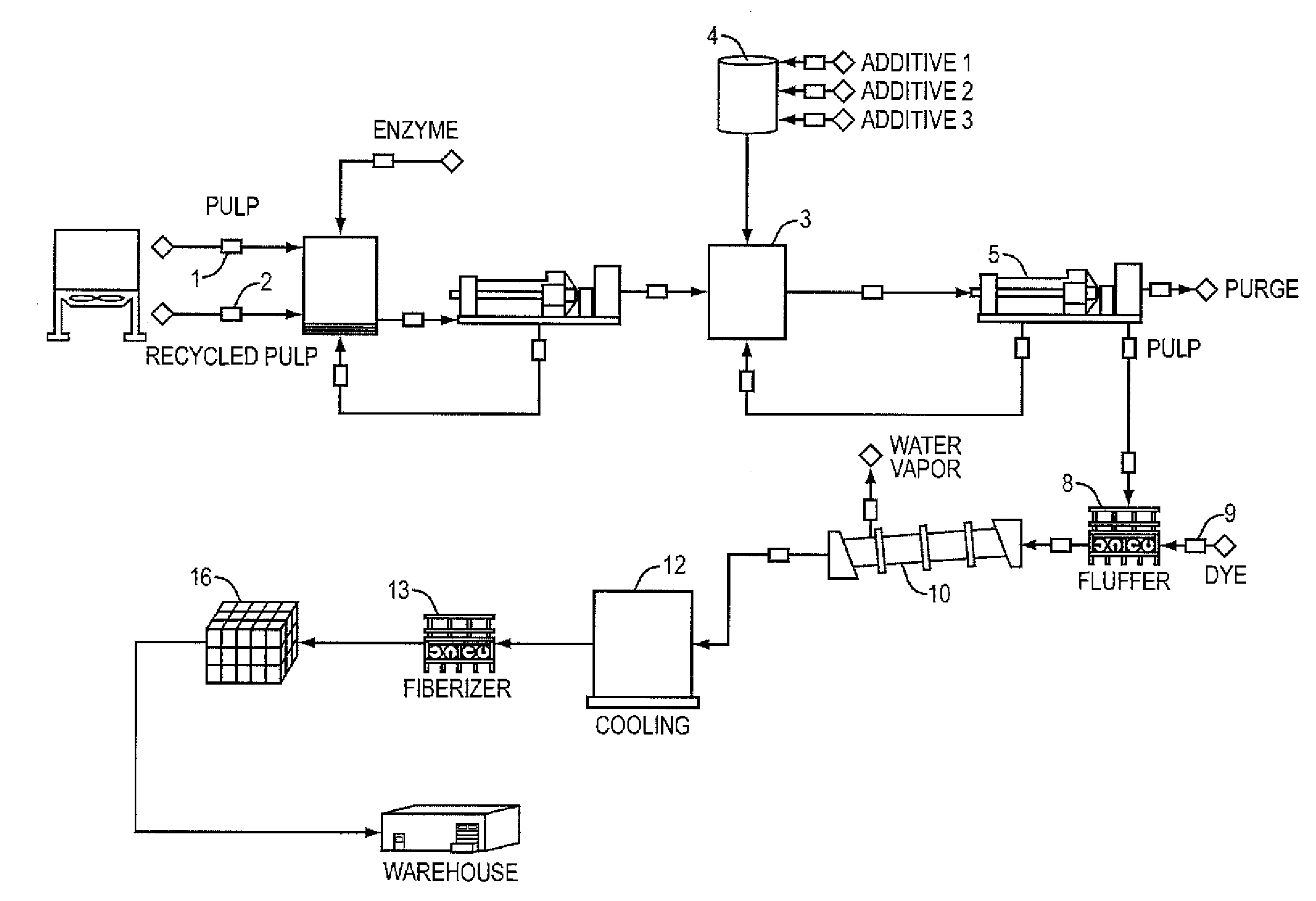

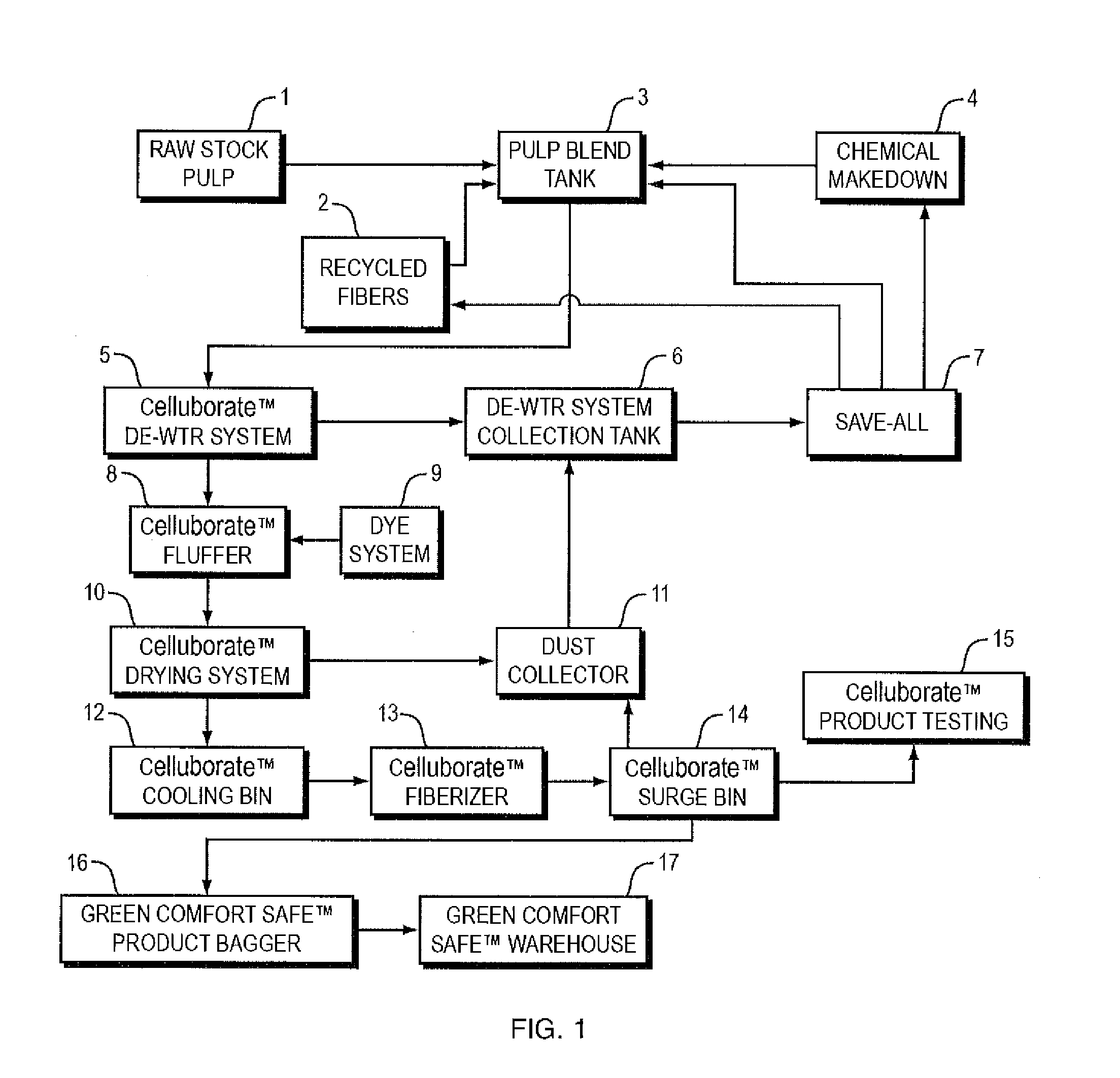

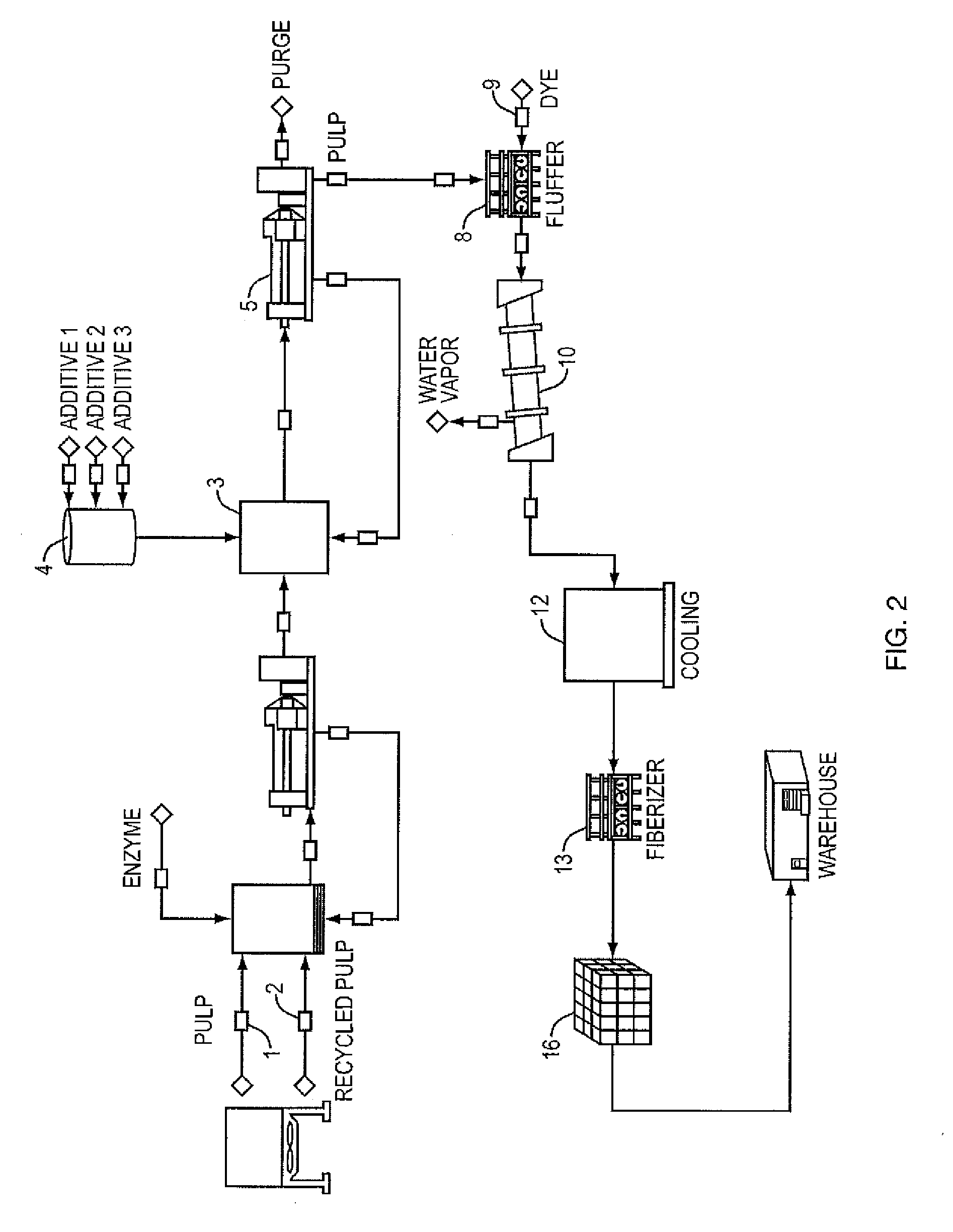

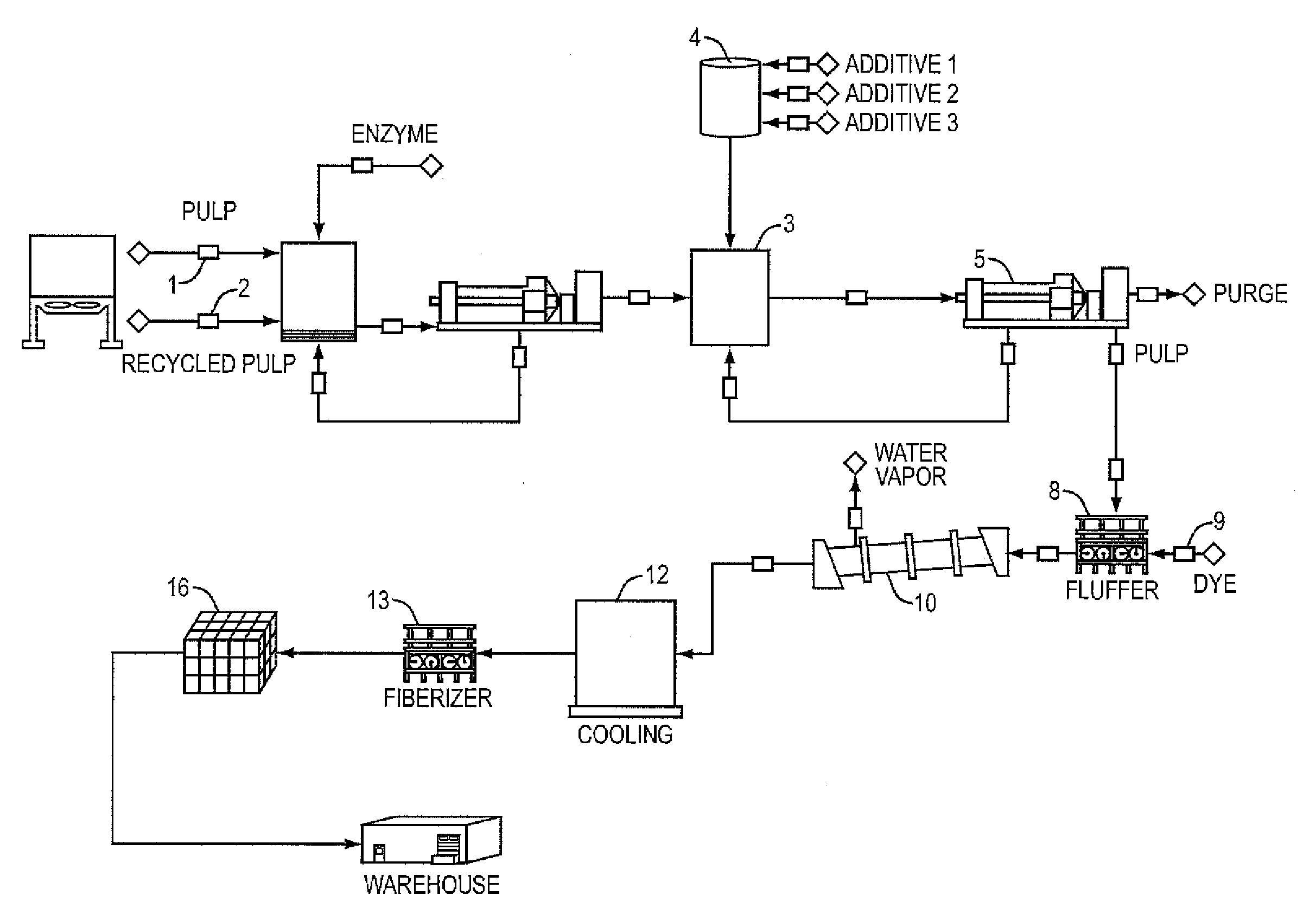

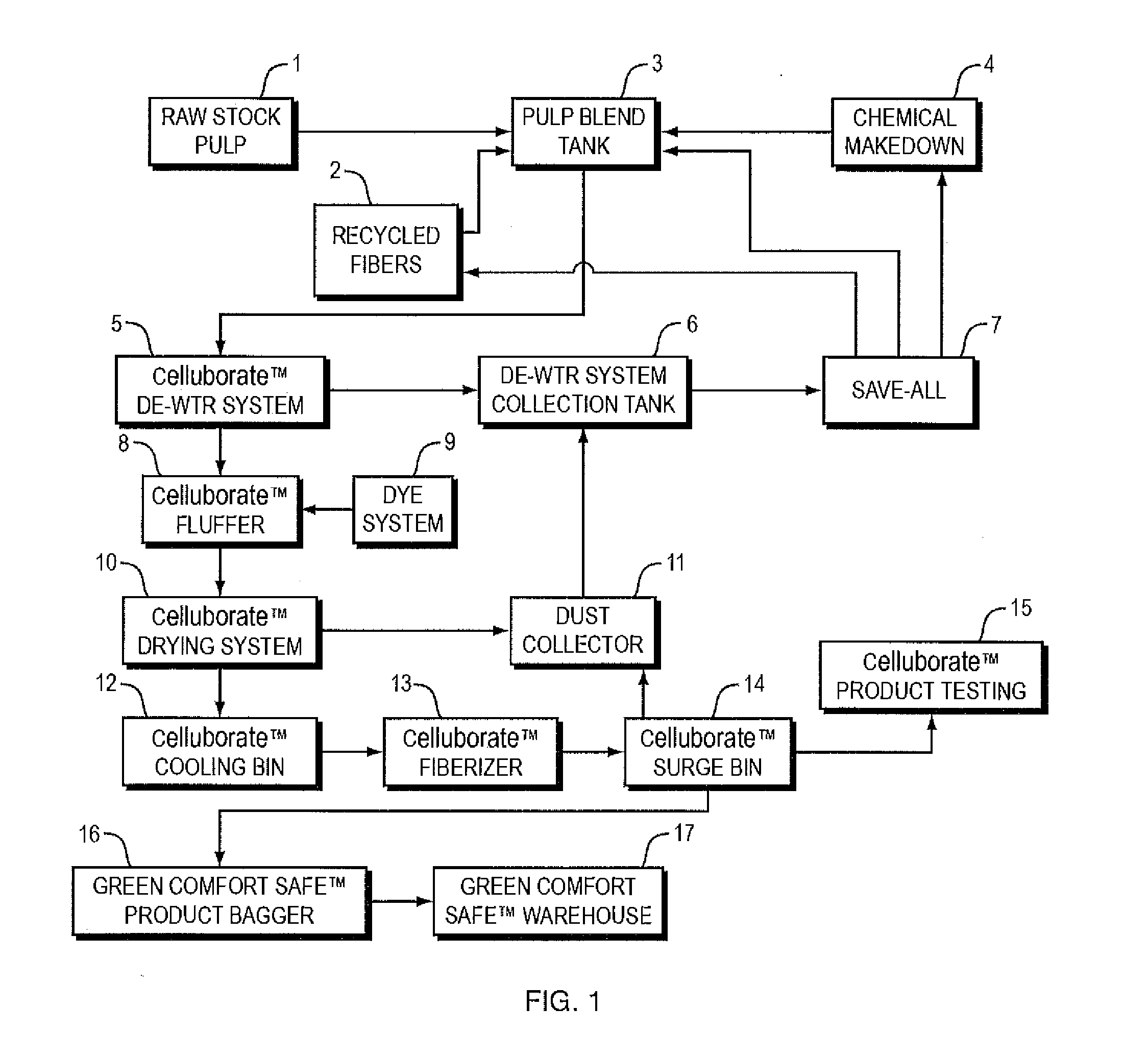

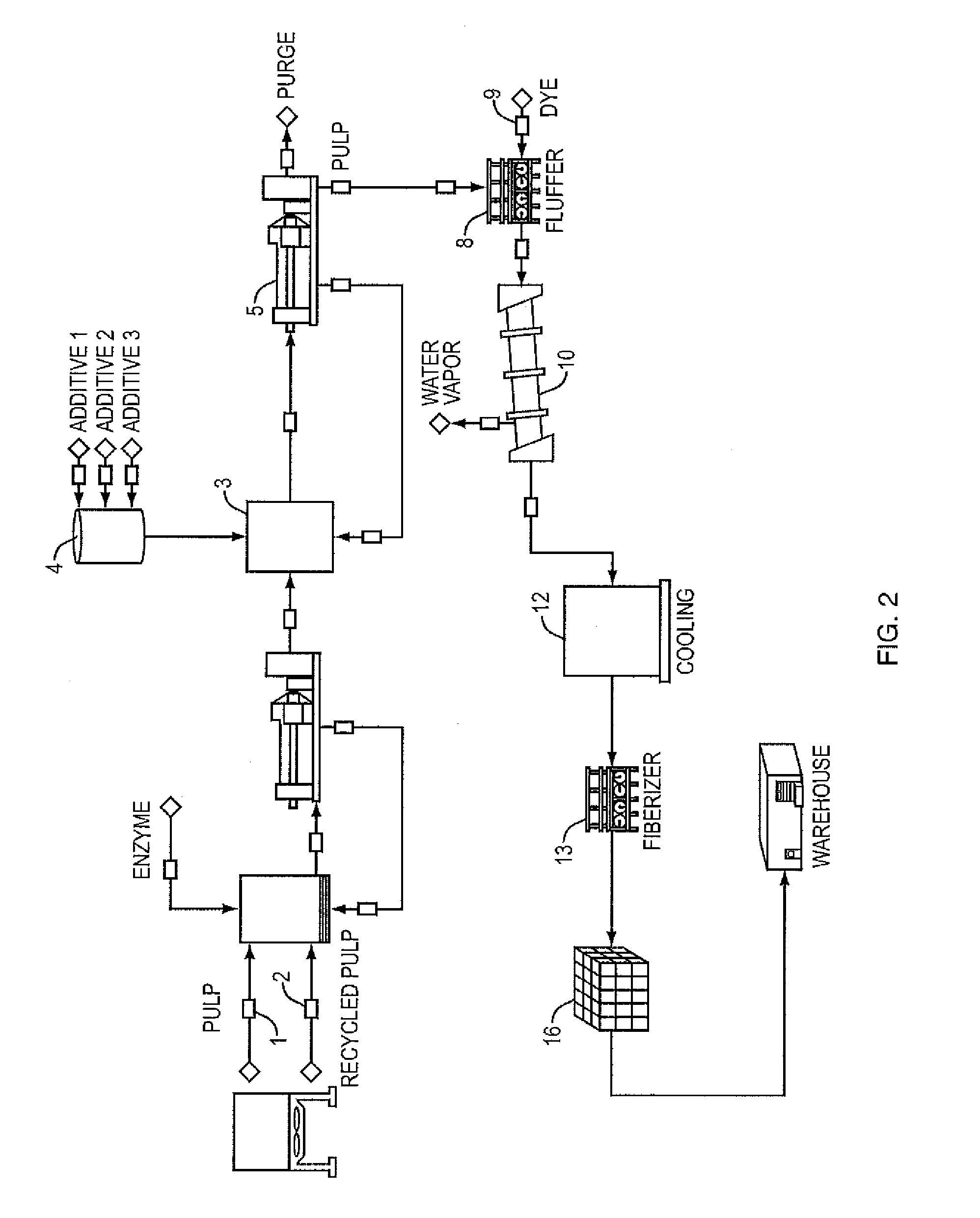

Method for Making Fire Retardant Materials and Related Products

InactiveUS20110095245A1Improves fire retardant application methodWide rangePaper recyclingIgnifugeants additionFiberChemical compound

A method for making fire retardant material including fire retardant cellulosic insulation. The method includes an arrangement for adding one or more feedstocks and a fire retardancy chemical compound to a common blend tank prior to feedstock drying. The one or more feedstocks may include at least one virgin pulp stock feed and at least one recycled material stock feed. The amount and type of both the virgin feedstock and the recycled material feedstock is selectable. Old newsprint (ONP) may be one type of recycled material feedstock. Another suitable type of recycled material feedstock is old corrugated containers (OCC). The method further includes retaining the fiber feedstock and the chemical compound together for enough time to ensure adherence or impregnations of enough of the chemical to the fibers after the drying process. Fluffing or fiberizing of the treated fibers may be accomplished under less severe conditions than ordinarily employed when making conventional cellulose insulation.

Owner:ULTRACELL INSULATION LLC +1

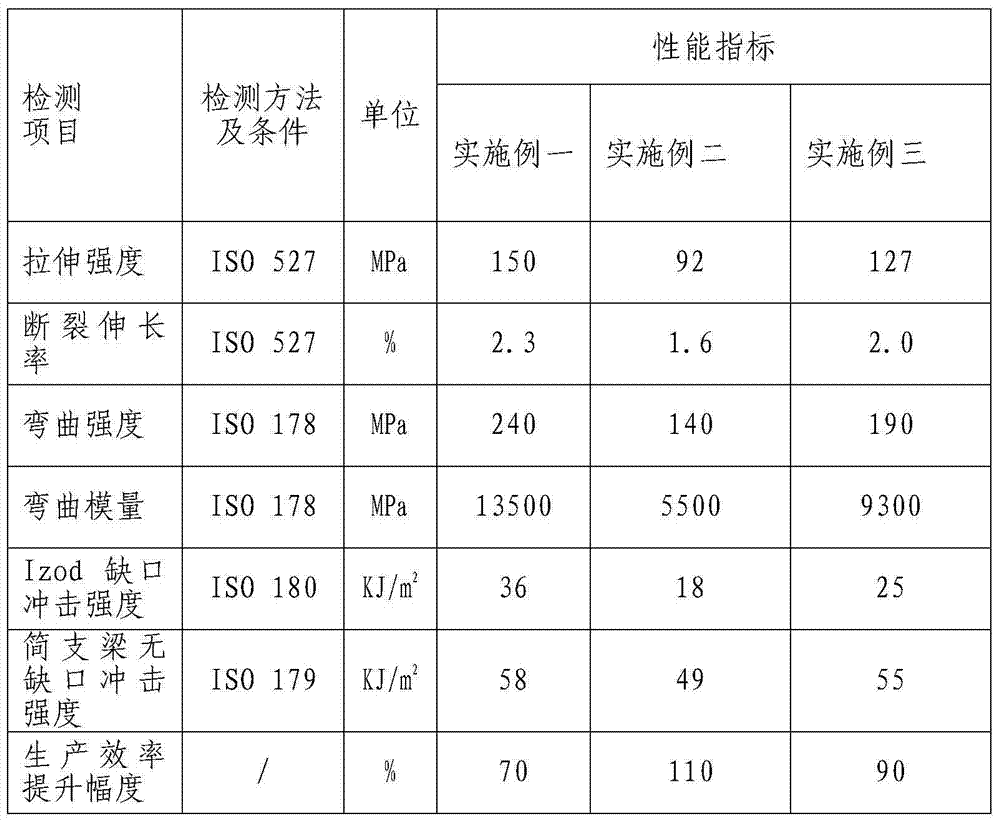

Long glass fiber reinforced polypropylene material adopting foaming technique and preparation method thereof

The invention relates to a material and a preparation method thereof, and particularly relates to a long glass fiber reinforced polypropylene material adopting a foaming technique and a preparation method thereof, belonging to the technical field of materials. The long glass fiber reinforced polypropylene material comprises the following components by mass percent: 30-75wt% of polypropylene, 20-60wt% of long glass fiber, 0.5-5wt% of chemical foaming agent and 1-5wt% of compatibilizer. The viscosity of the resin is further reduced by adopting a micro-foaming technology, meanwhile, the chance that a glass fiber strong dispersing device reduces or avoids direct contact of a glass fiber bundle and a roller or a convex part is reduced, the damage to the glass fiber is reduced, and the traction resistance of a material bar is reduced. The long glass fiber reinforced polypropylene material has the beneficial effects that the product performance, quality stability and production efficiency are improved when the impregnation effect on the glass fiber caused by polypropylene resin is ensured.

Owner:NANJING JULONG SCI&TECH CO LTD

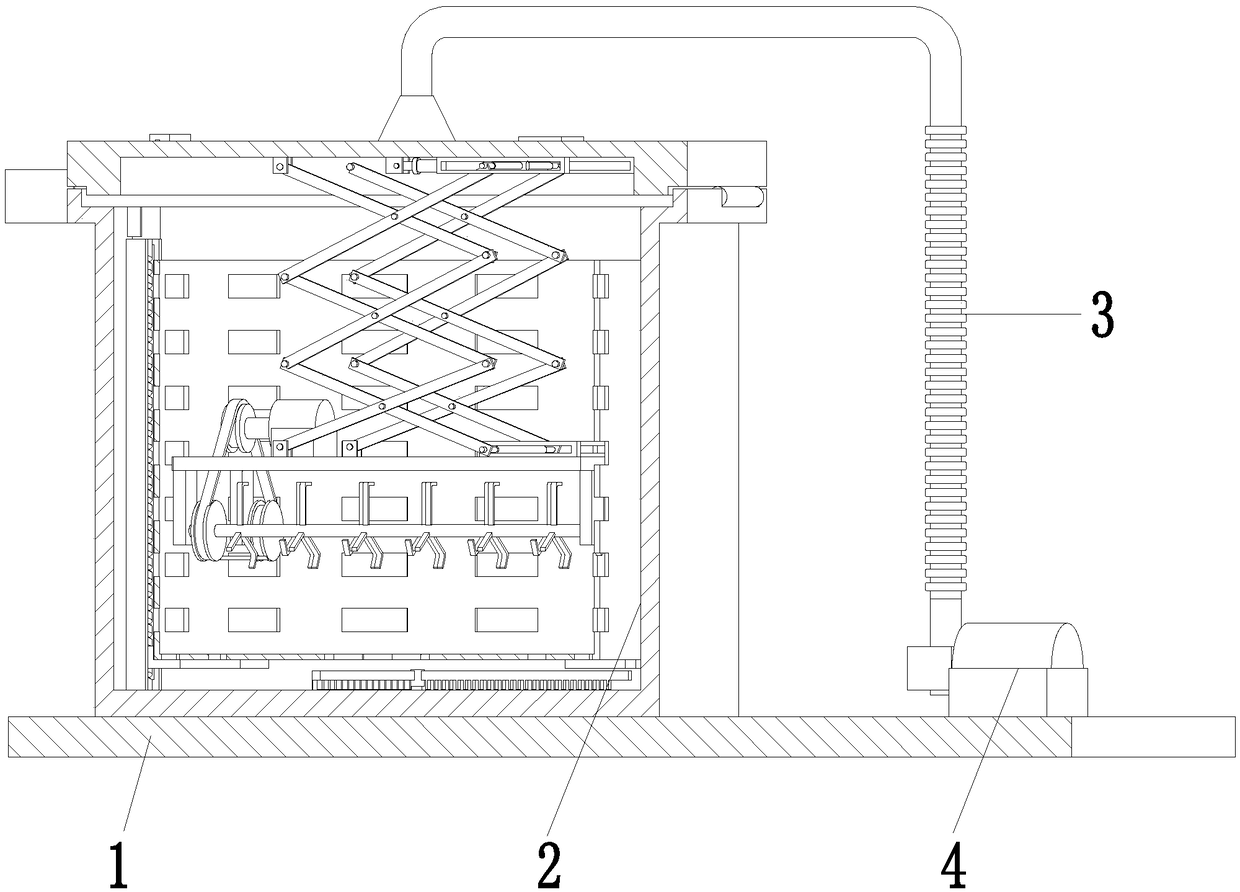

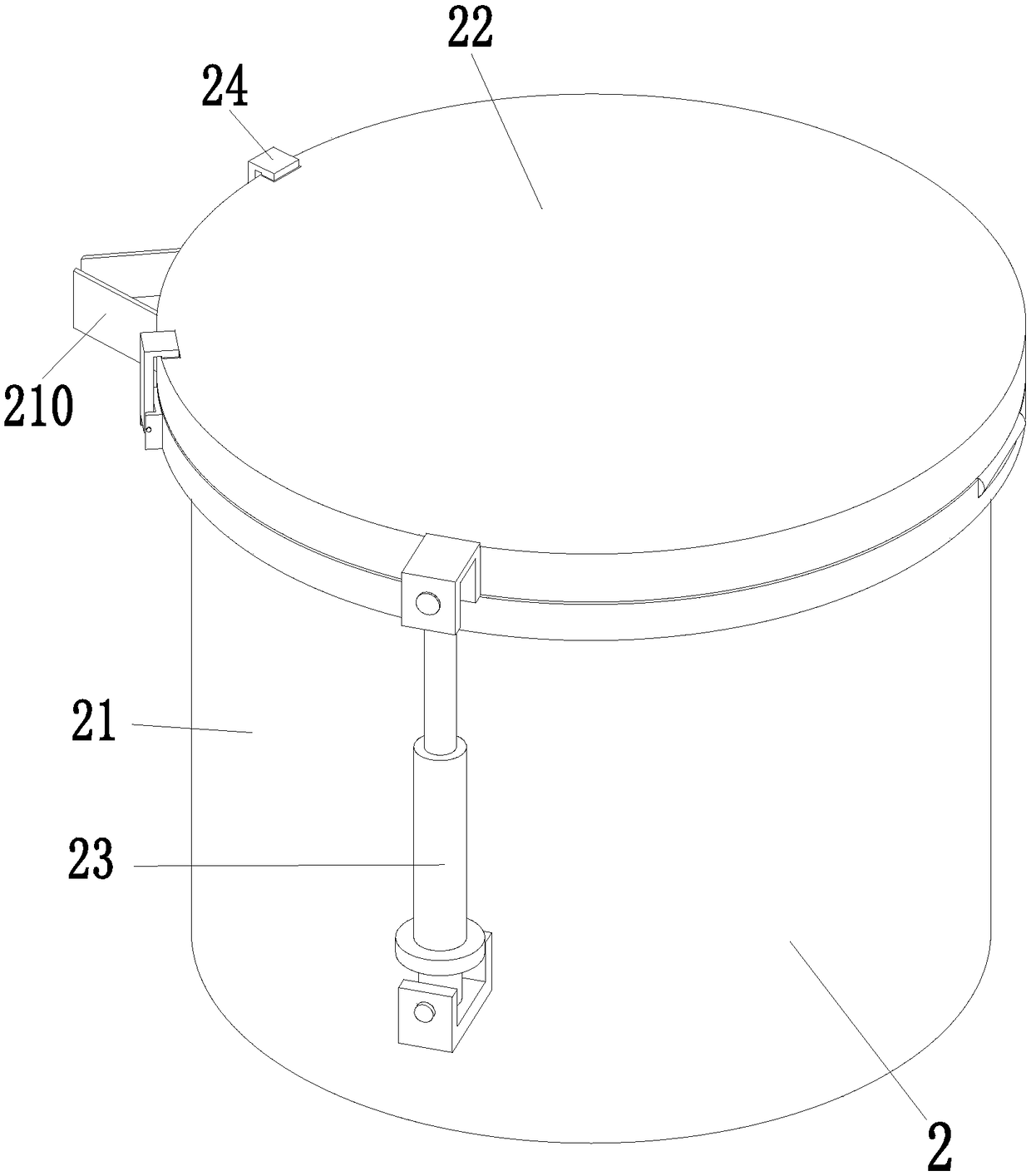

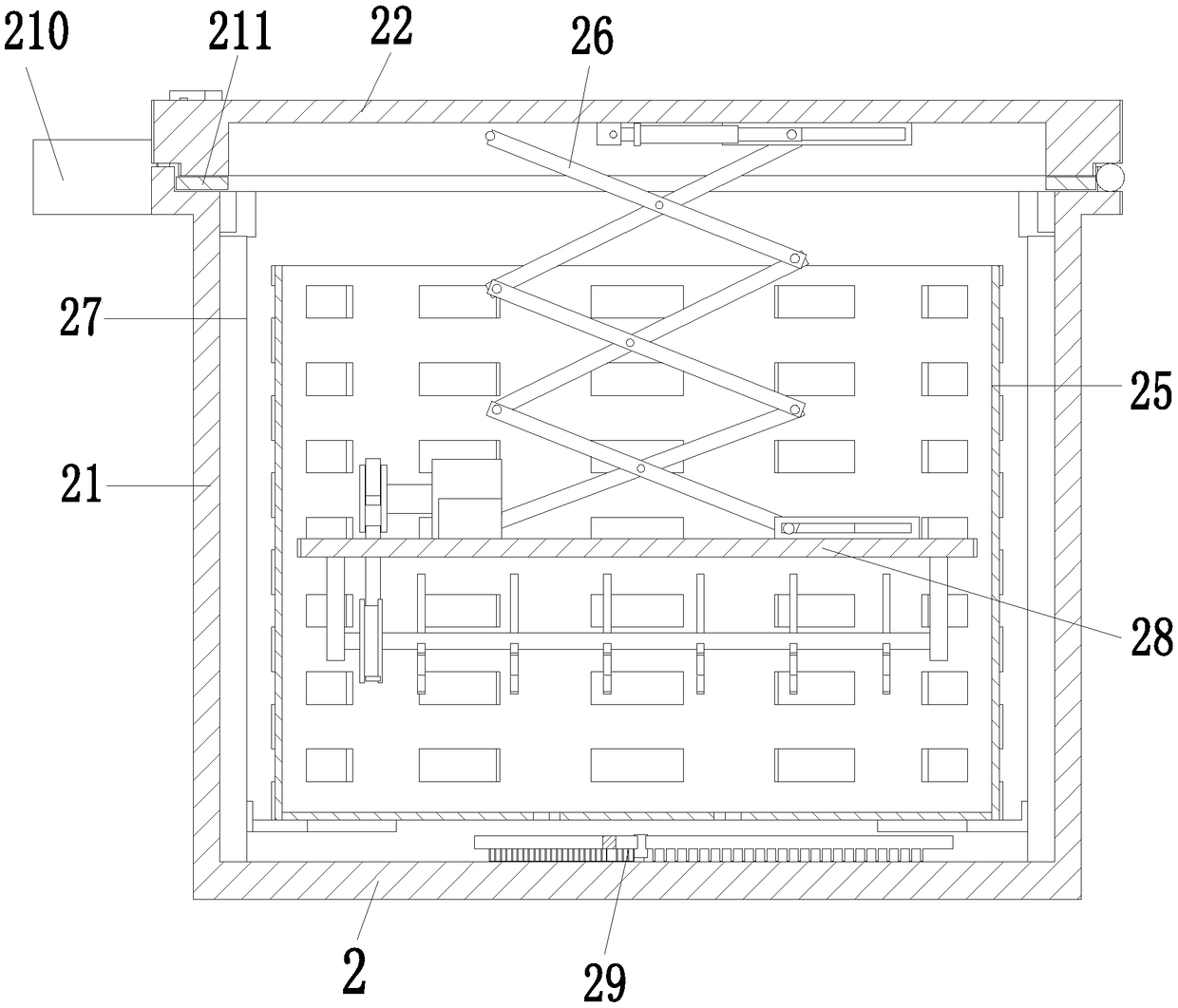

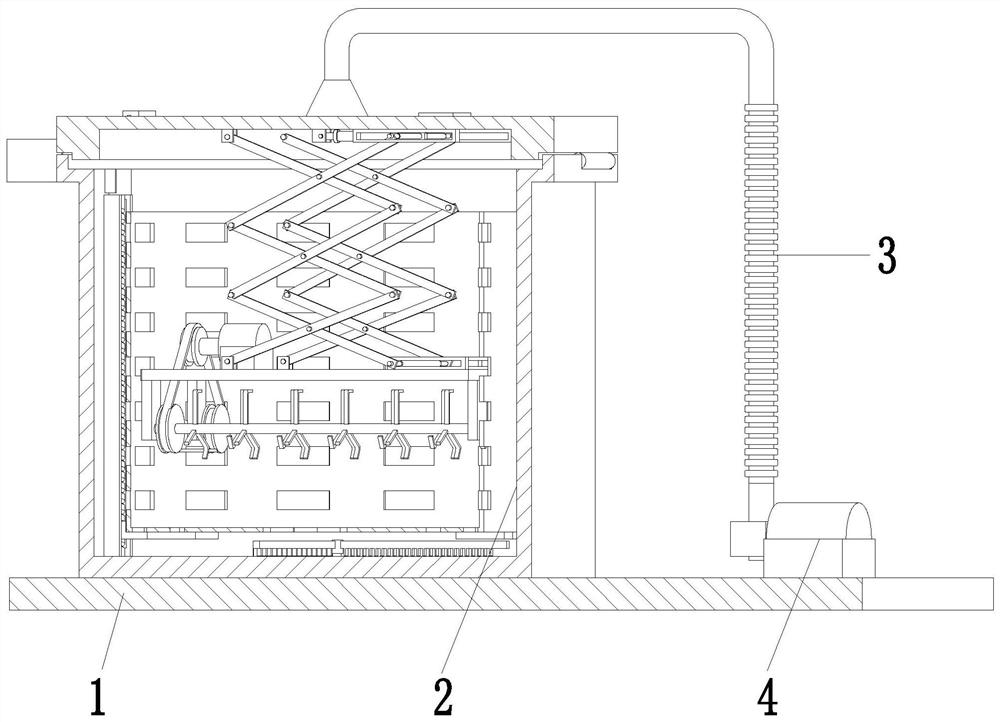

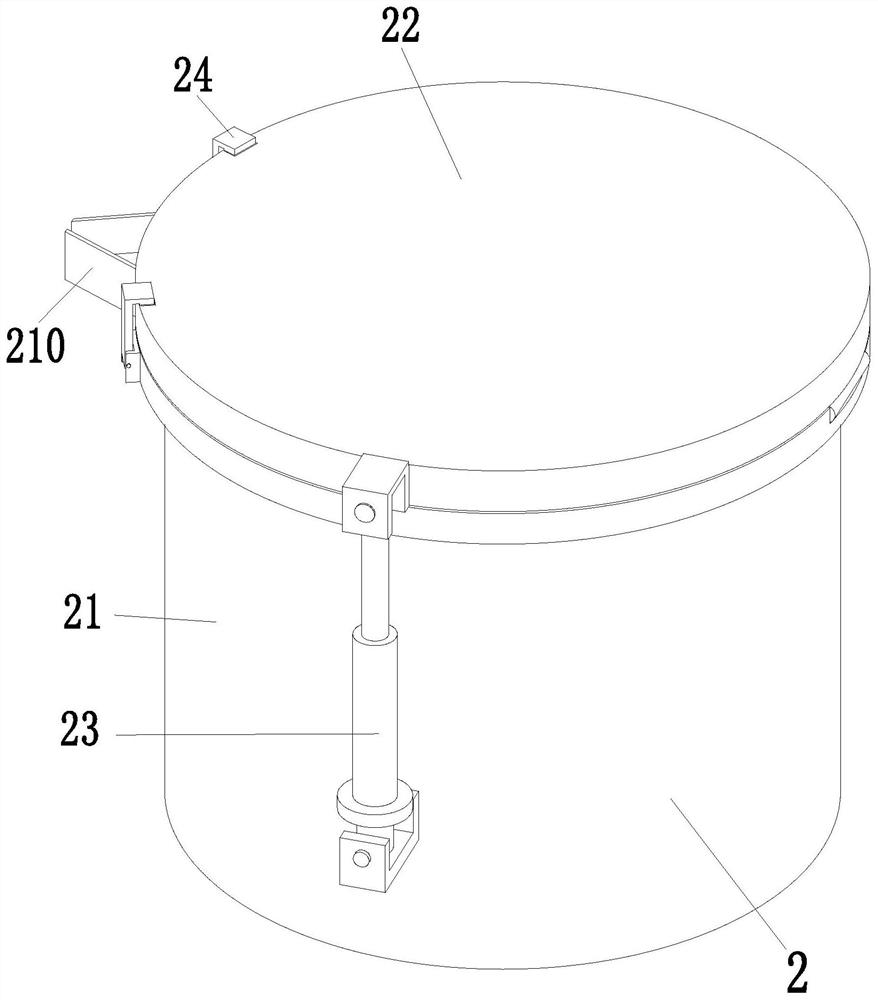

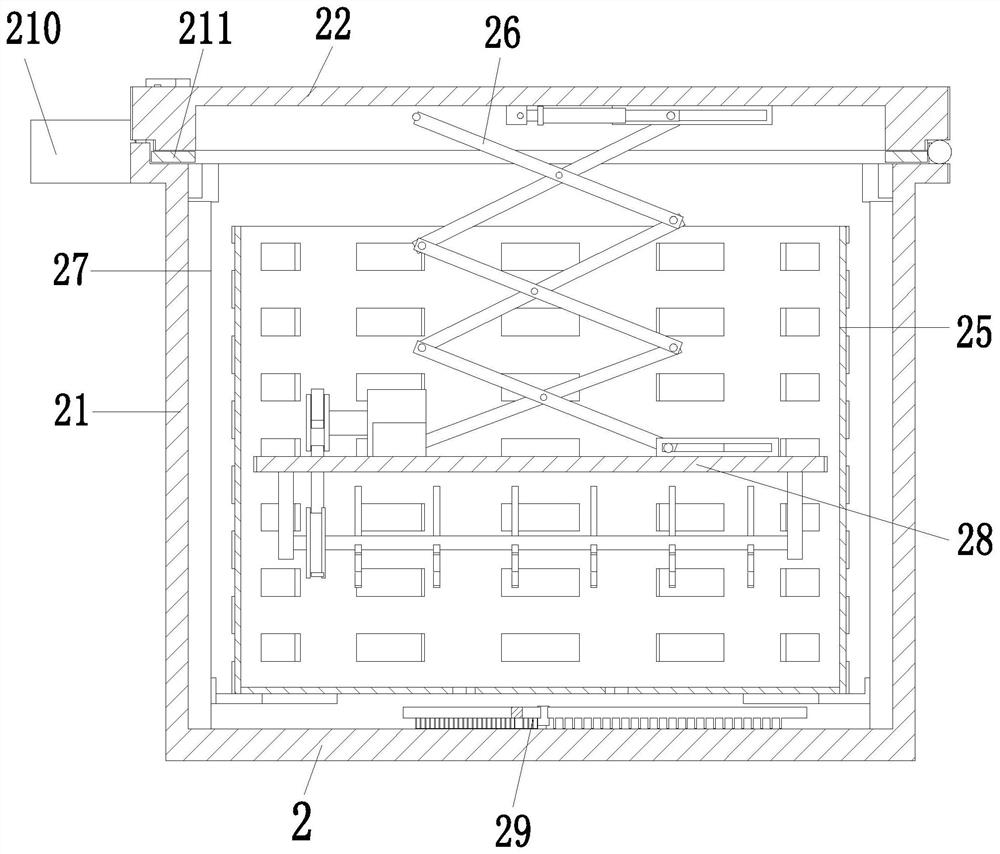

A Chinese medicinal decoction slice quick impregnation device and automatic impregnation method of Chinese medicinal decoction slices

ActiveCN109157415AGood impregnationShorten soaking timePharmaceutical product form changeChemistryHigh pressure

A Chinese medicine in that form of decoction slice is prepared from 11 Chinese-medicinal material through immersing them in decoction slices, immersing them in water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them withwater, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them, mixing them with water, mixing them, mixingthem with water, mixing them, mixing, mixing, mixing, mixing, mixing, mixing and mixing. The invention can solve the problem that when the prior Chinese medicinal decoction pieces are impregnated, Toolong impregnation time, It usually takes a long time to get there, and soaked for a long time, Chinese herbal slices are prone to decay, Traditional Chinese medicine slices usually float above the water surface when impregnated, impregnation is not complete, traditional Chinese medicine slices usually accumulate together when impregnated, affecting the impregnation effect, complicated operation,slow impregnation, low efficiency and other difficult problems, can realize the function of automatic and high-efficient impregnation of traditional Chinese medicine slices, and has the advantages ofsimple operation, rapid impregnation, high efficiency and so on.

Owner:安徽冯了性中药材饮片有限公司

Method for Making Fire Retardant Materials and Related Products

ActiveUS20110117354A1Method can be appliedLow costFibre treatmentPaper recyclingFiberChemical compound

A method for making fire retardant material including fire retardant cellulosic insulation. The method includes an arrangement for adding one or more feedstocks and a fire retardancy chemical compound to a common blend tank prior to feedstock drying. The one or more feedstocks may include at least one virgin pulp stock feed and at least one recycled material stock feed. The amount and type of both the virgin feedstock and the recycled material feedstock is selectable. Old newsprint (ONP) may be one type of recycled material feedstock. Another suitable type of recycled material feedstock is old corrugated containers (OCC). The method further includes retaining the fiber feedstock and the chemical compound together for enough time to ensure adherence or impregnations of enough of the chemical to the fibers after the drying process. Fluffing or fiberizing of the treated fibers may be accomplished under less severe conditions than ordinarily employed when making conventional cellulose insulation.

Owner:CLEANFIBER INC +1

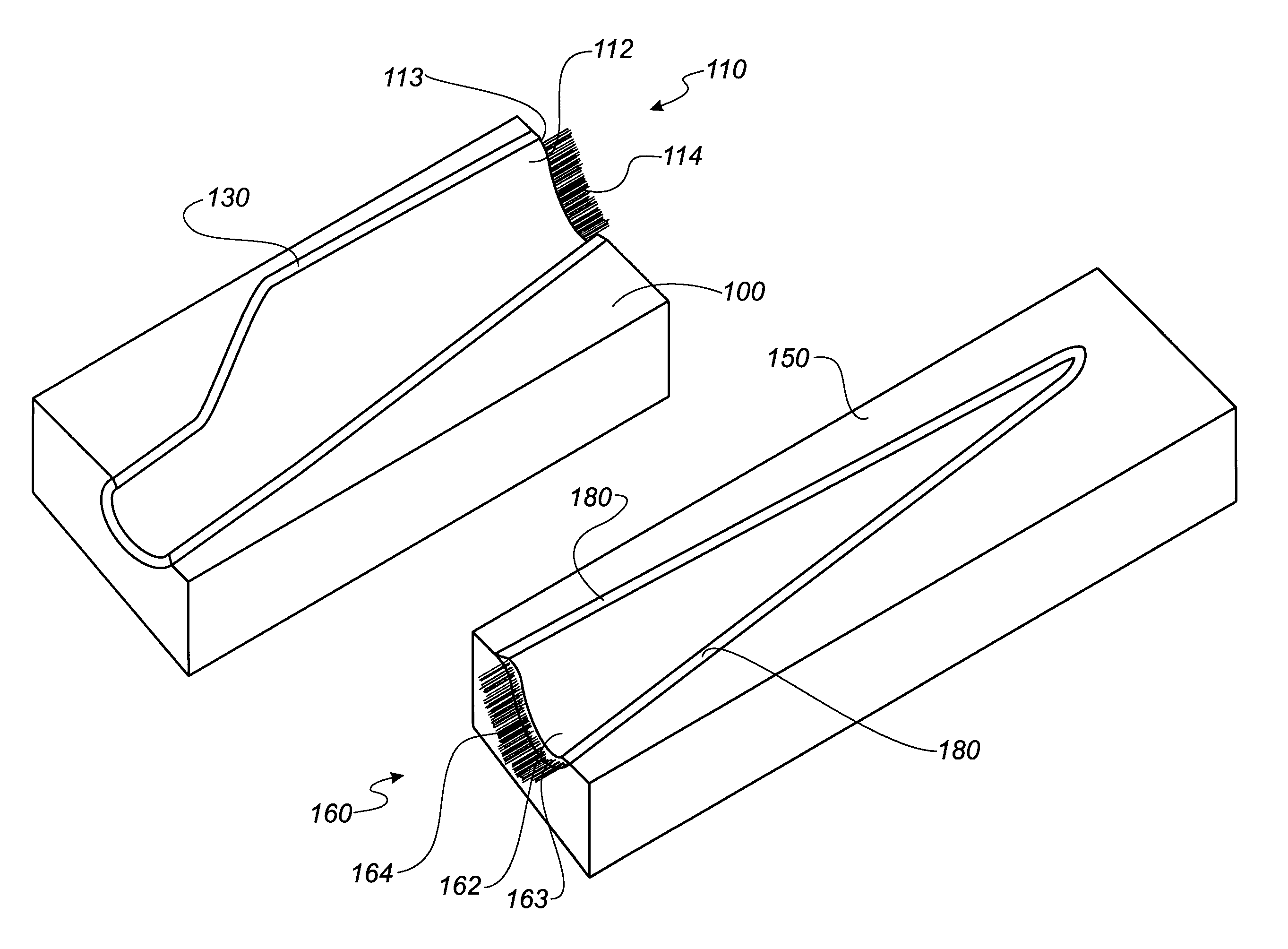

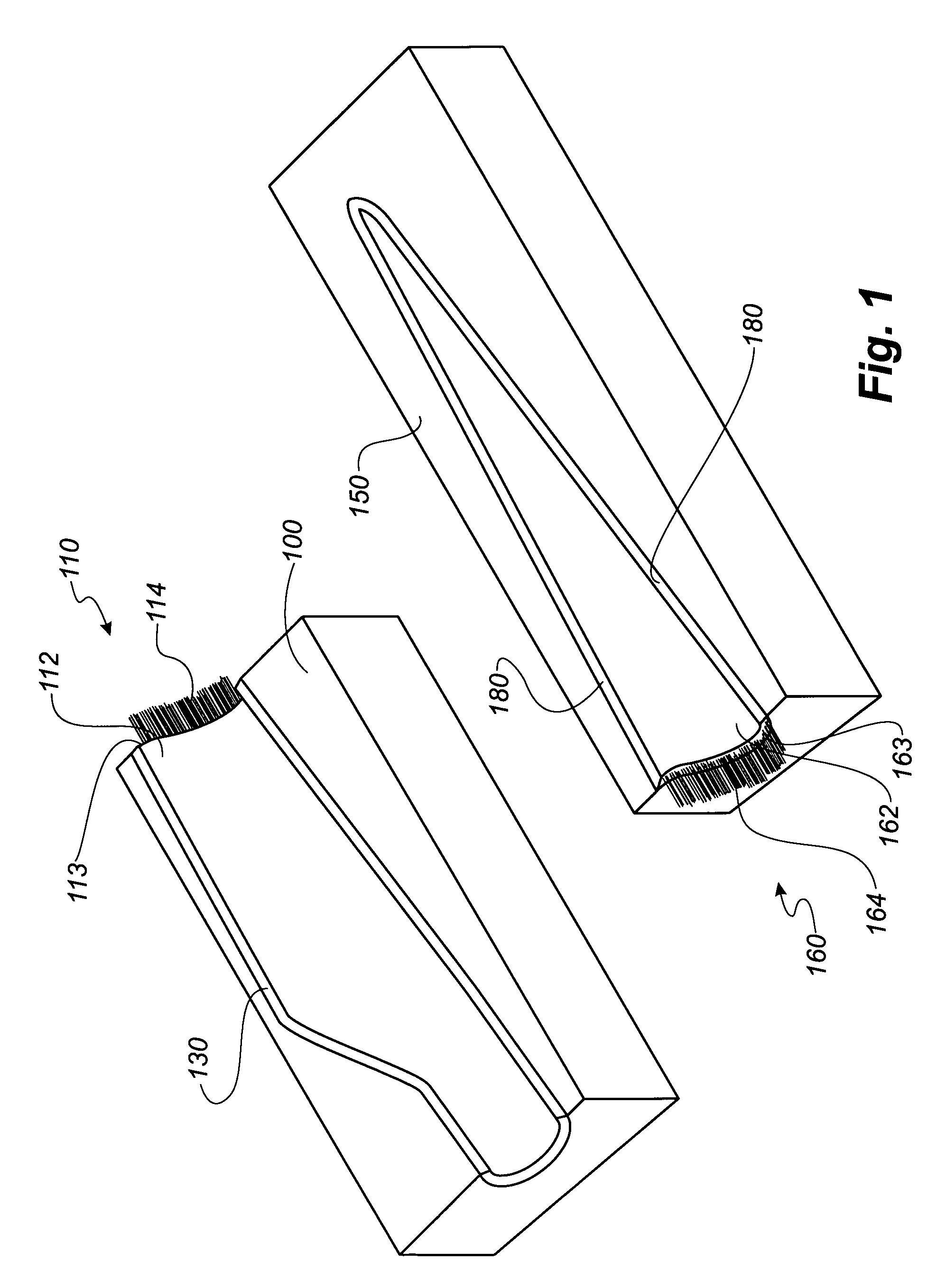

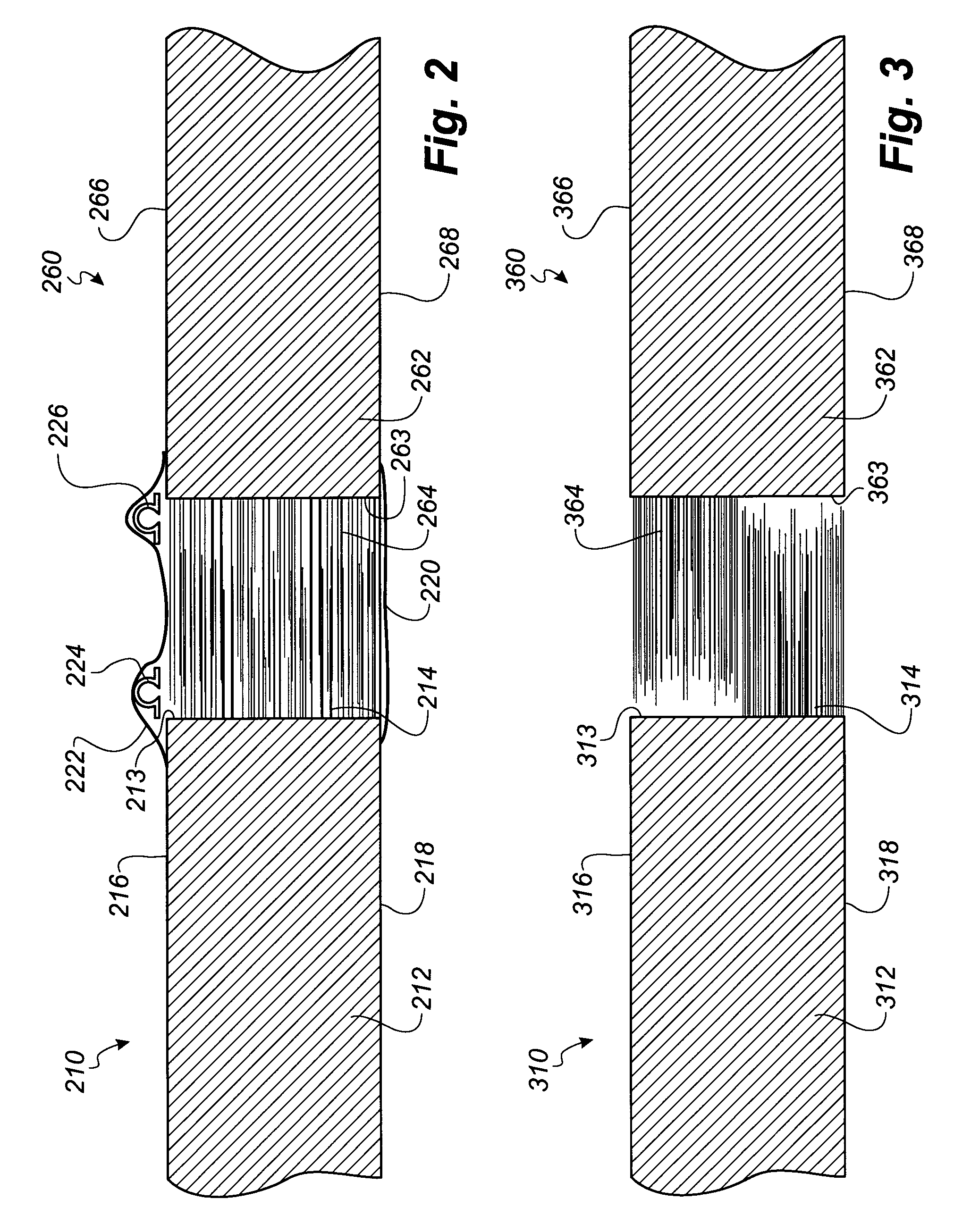

Method of producing a composite structure via intermediate products, the related apparatus and a composite structure obtainable by the method

ActiveUS9221219B2High fiber densityFirmly connectedFinal product manufactureLaminationLiquid resinMaterials science

A method of producing a composite structure comprising fiber reinforced material and having a longitudinal direction is described. The method comprises the following steps: a) manufacturing a first structure comprising a first cured composite part having a first thickness and a longitudinal direction with a first end, and a number of first fiber layers extending from the first end, b) manufacturing a second structure comprising a second cured composite part having a second thickness and a longitudinal direction with a second end, and a number of second fiber layers extending from the second end, and c) arranging the first structure and the second structure so that the first end faces towards the second end, and arranging the first fiber layers and the second fiber layers so that at least a part of the first fiber layers overlap at least a part of the second fiber layers in the longitudinal direction, d) supplying liquid resin in order to impregnate the first fiber layers and the second fiber layers, and e) curing the liquid resin in order to form the composite structure comprising the first cured composite part, the second cured composite part, and an intermediate composite part including the first fiber layers and the second fiber layers.

Owner:LM GLASSFIBER

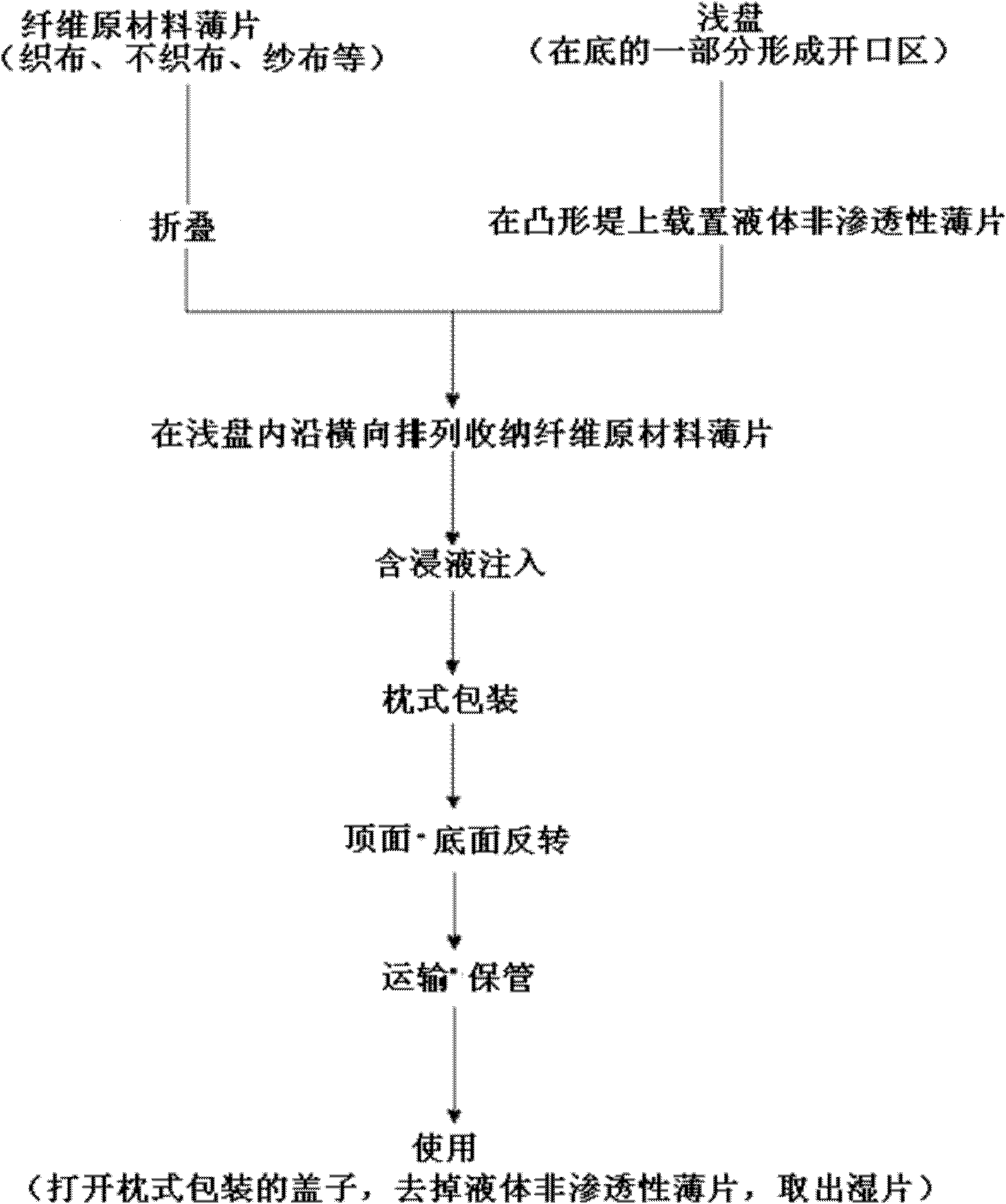

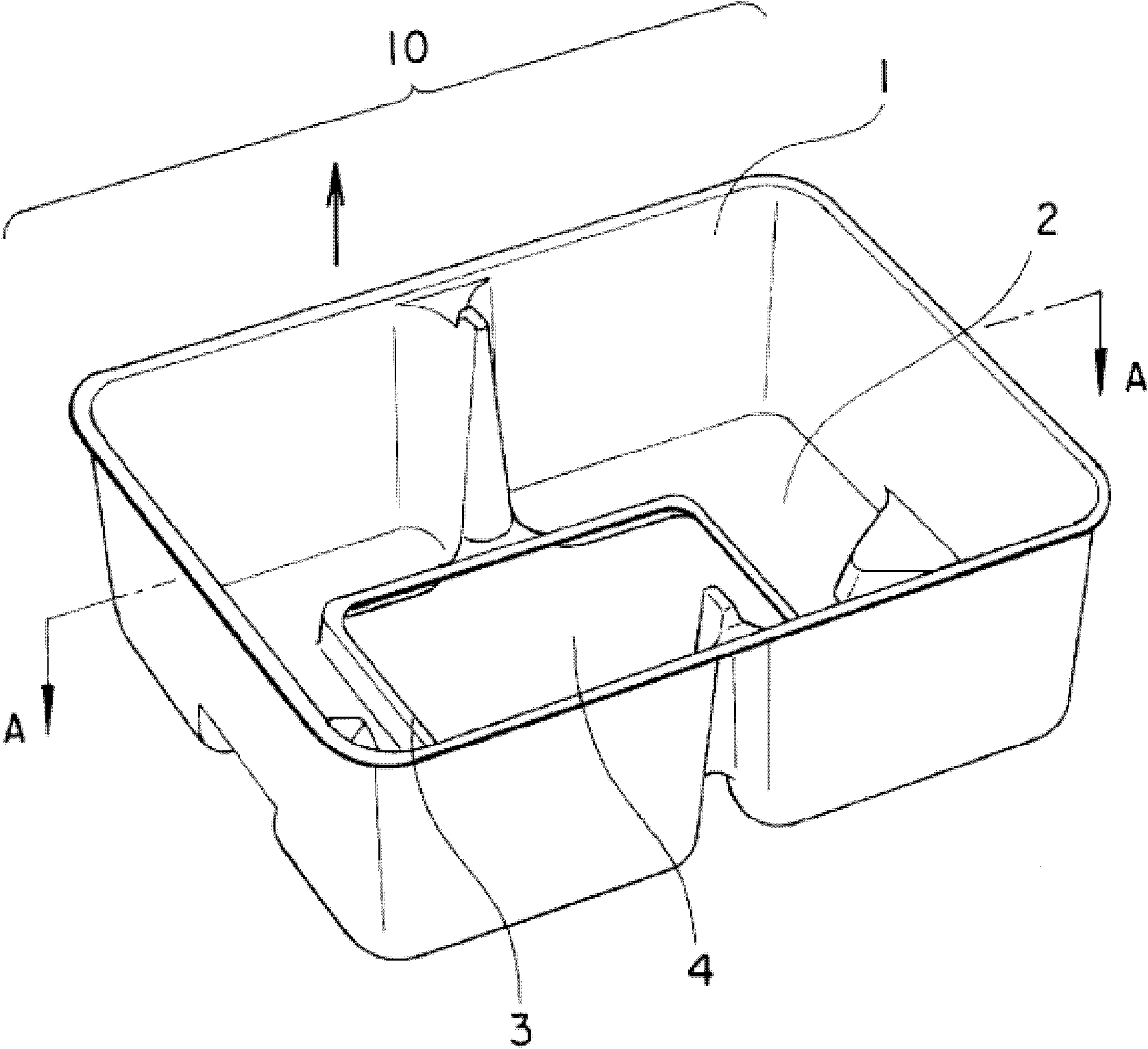

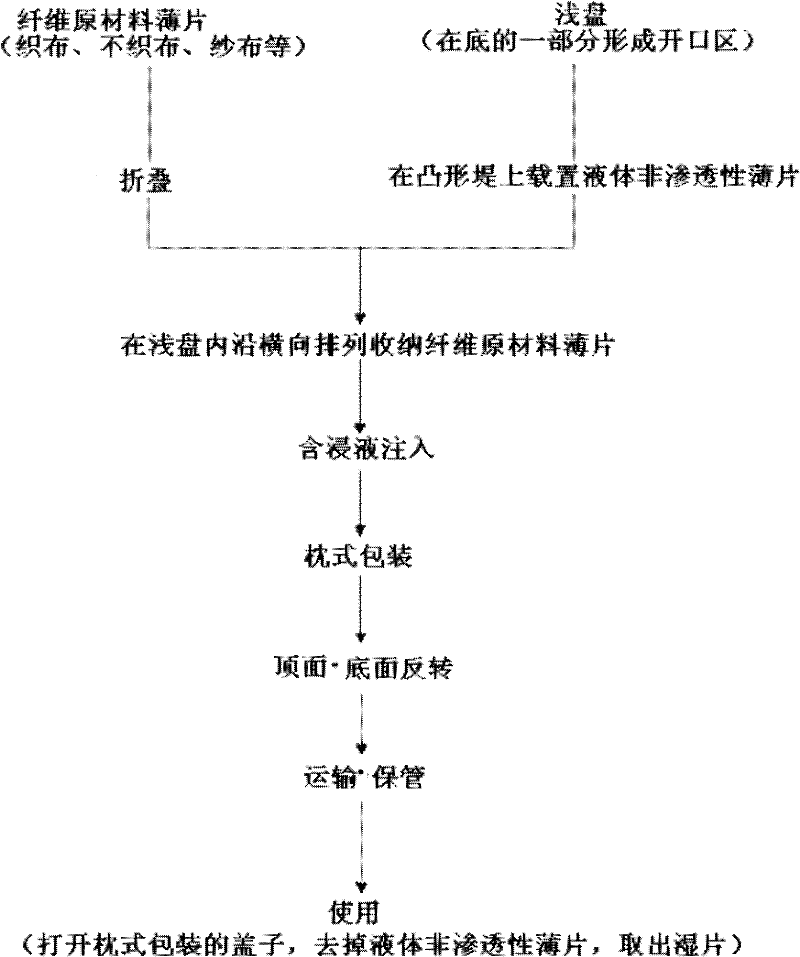

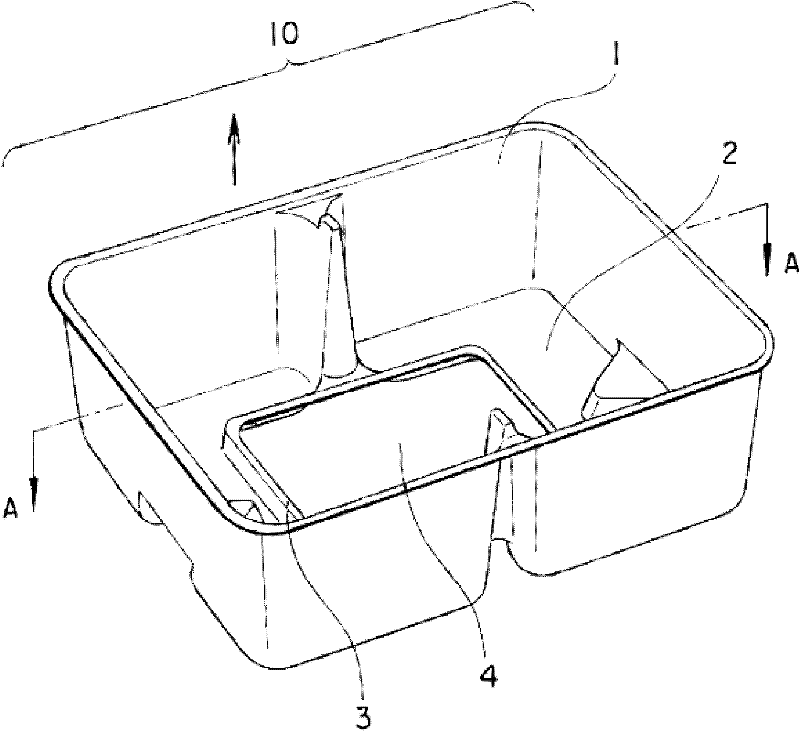

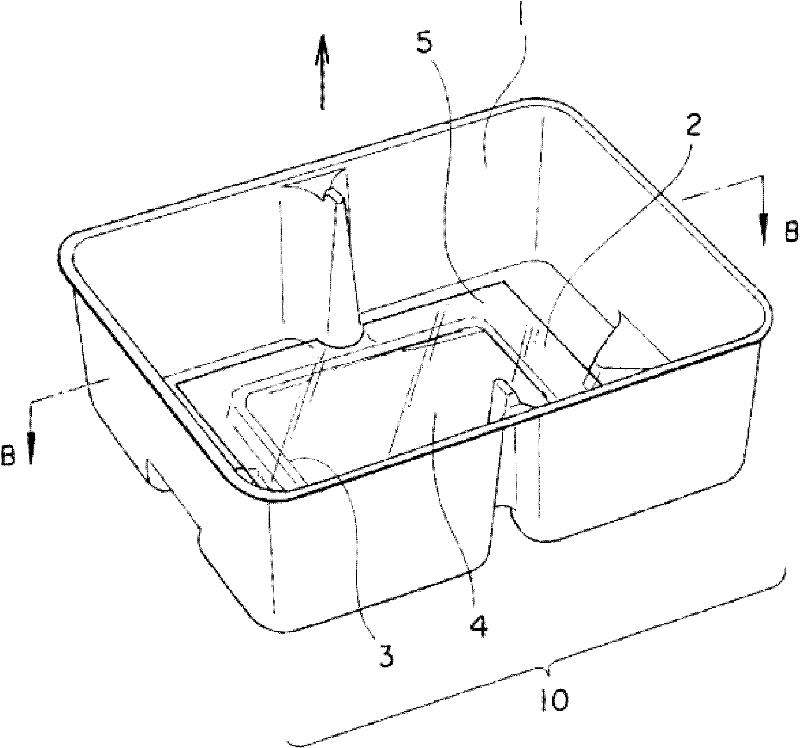

Wet sheet pillow package

ActiveCN102119109ASpeed up removalImprove stabilityBathroom accessoriesFlat article dispensingMechanical engineering

Provided is a wet sheet pillow package wherein a tray that individually arranges and contains individually-folded wet sheets is pillow-packaged, an opening that serves as a wet sheet removal opening is provided in the approximate center of the bottom of the tray, the opening is located on the flat part of the side opposite the butt seam of the pillow package, and a wet sheet removal opening is provided in said flat part. The wet sheet pillow package can adequately impregnate wet sheets economically using the minimum required amount of impregnating solution.

Owner:中村宪司 +1

Method of producing a metallized molded article utilizing a pressurized fluid containing a metal complex

InactiveUS7758923B2Efficient impregnationMass productionSynthetic resin layered productsOptical articlesShell moldingHigh pressure

Owner:MAXELL HLDG LTD

Method of impregnation with agent

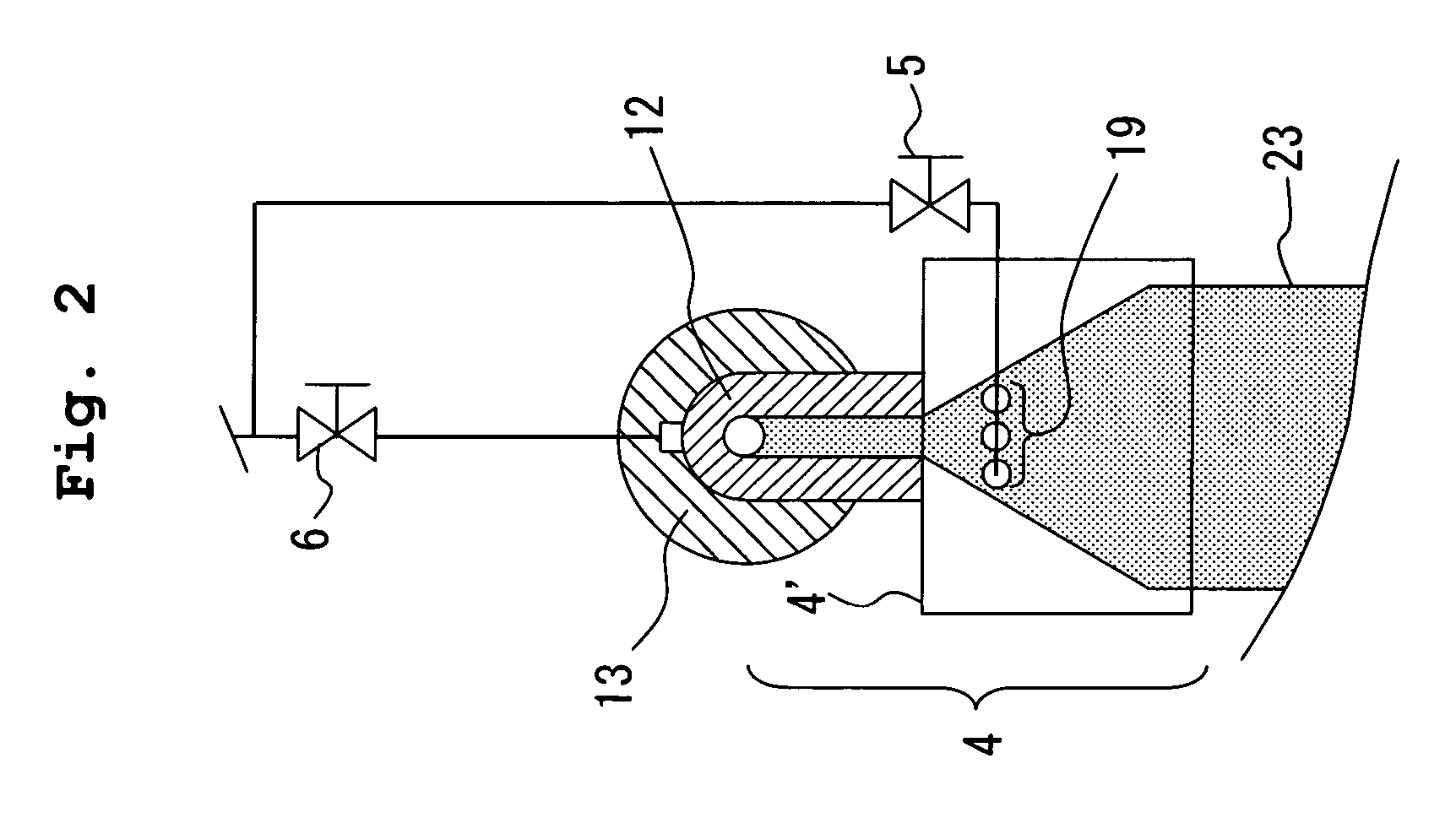

InactiveUS20050196539A1Effectively impregnated with agentReliably penetrate deep into materialPressurized chemical processWood treatment detailsVolumetric Mass DensityLow density

A method impregnates a material with an agent, by forming an agent-containing phase having a low density and containing an agent and carbon dioxide in a supercritical or subcritical state, and increasing the density of the agent-containing phase. This method can effectively impregnate a material having fine voids or pores with an agent in a short time by using supercritical or subcritical carbon dioxide.

Owner:KOBE STEEL LTD

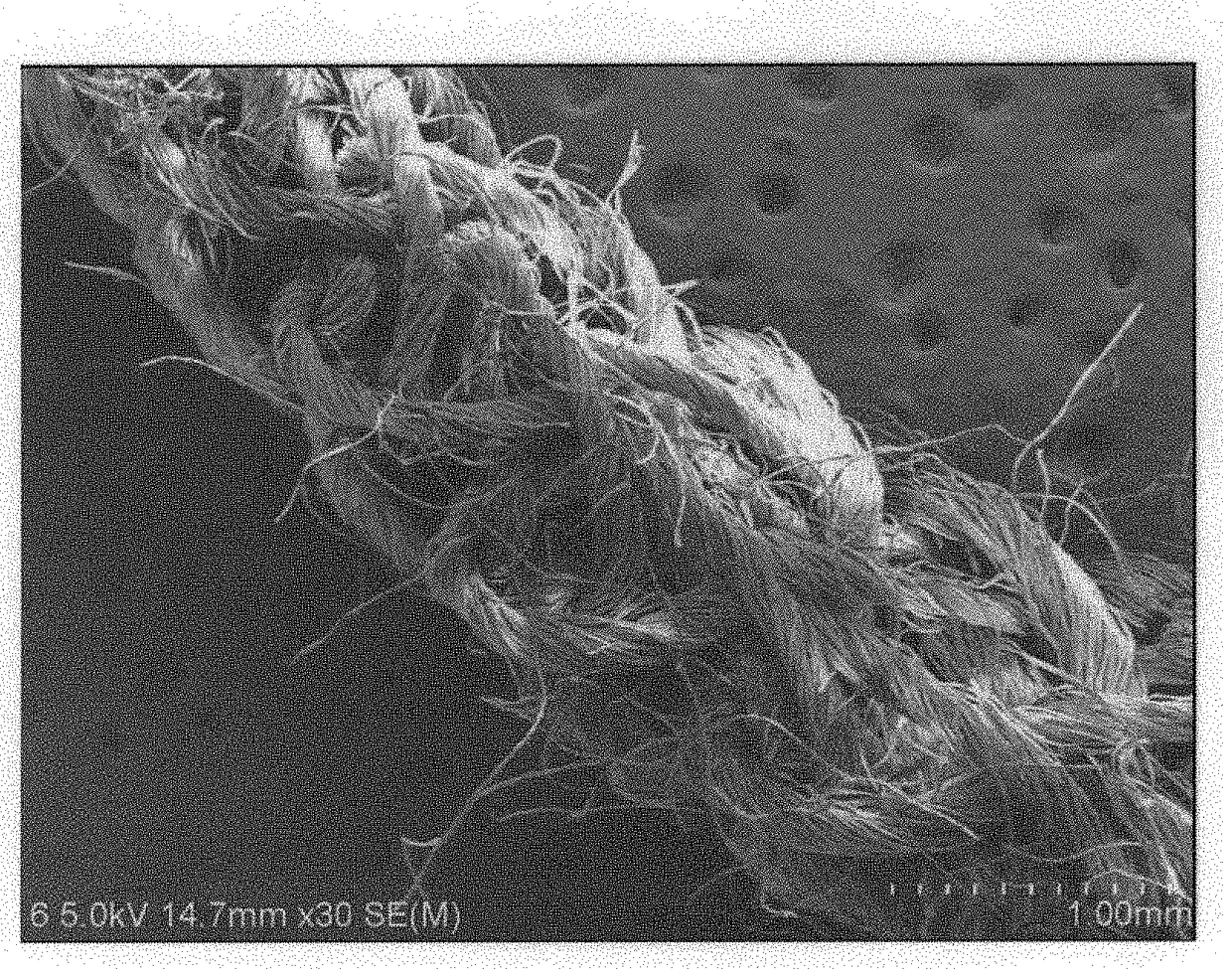

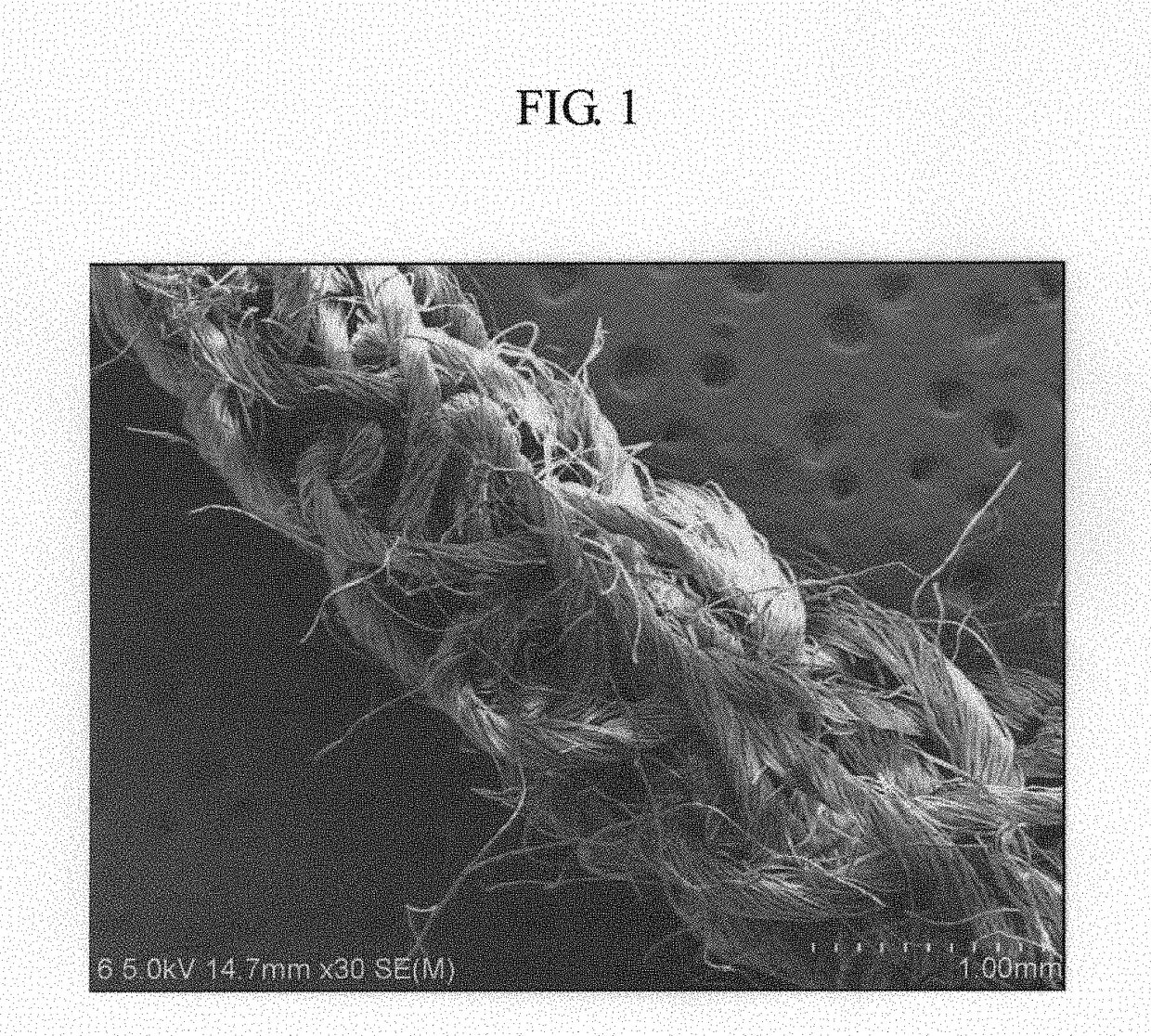

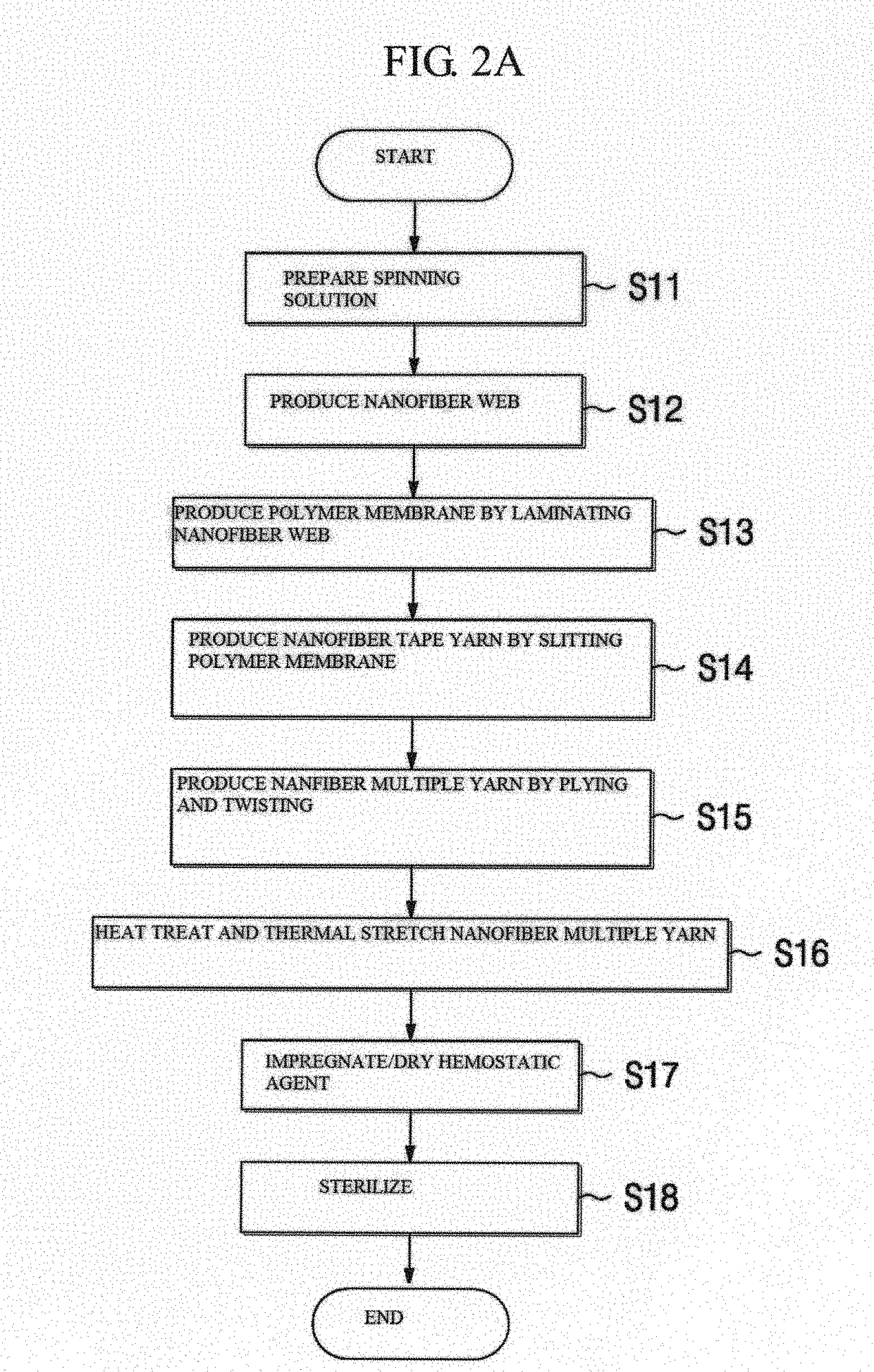

Dental cord using nanofiber conjugate yarn, and manufacturing method therefor

InactiveUS20170312056A1Small fiber diameterLarge specific surface areaImpression capsSurgeryDrugAverage diameter

Provided is a dental cord using a nanofiber multiple yarn having a large specific surface area and a large number of three-dimensional pores, thereby effectively impregnating a drug such as a hemostatic agent, and a method of manufacturing the dental cord. The dental cord includes: a nanofiber multiple yarn which is obtained by plying and twisting at least two nanofiber tape yarns and which is impregnated with a drug, wherein the at least two nanofiber tape yarns are integrated by nanofibers made of fiber moldability polymer materials and having an average diameter of less than 1 μm, to thus be formed of a nanofiber web having three-dimensional micropores.

Owner:AMOGREENTECH CO LTD

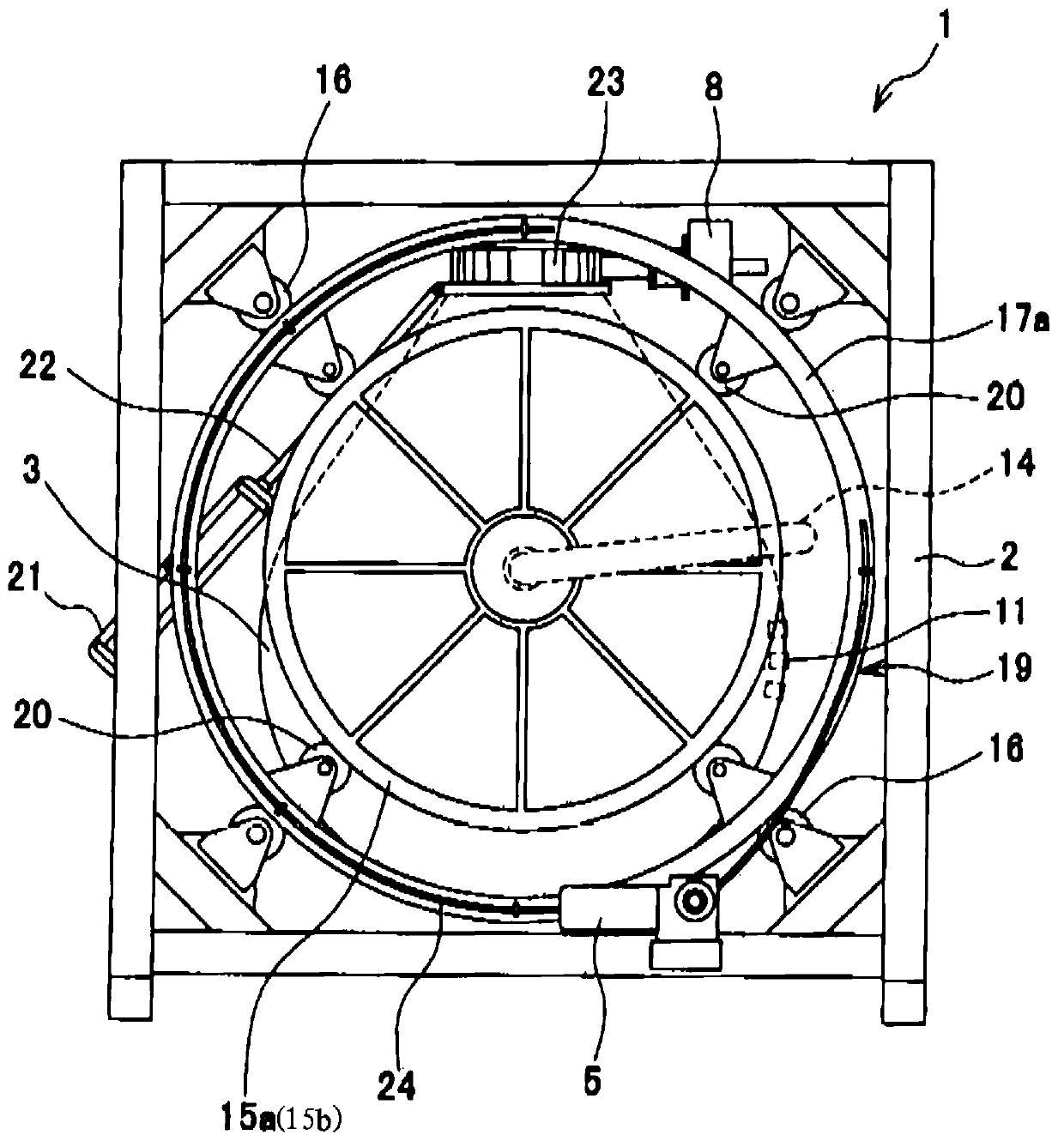

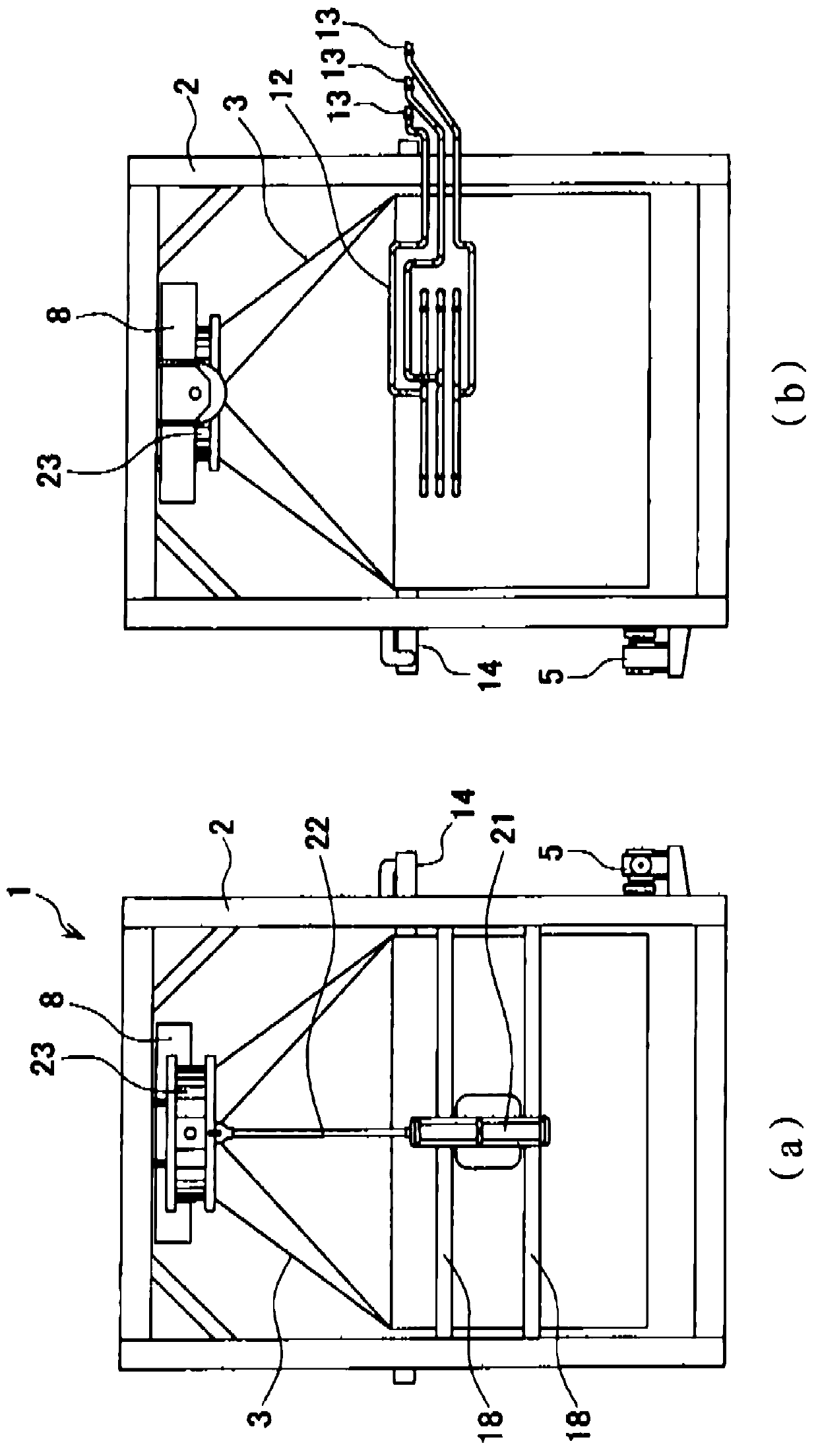

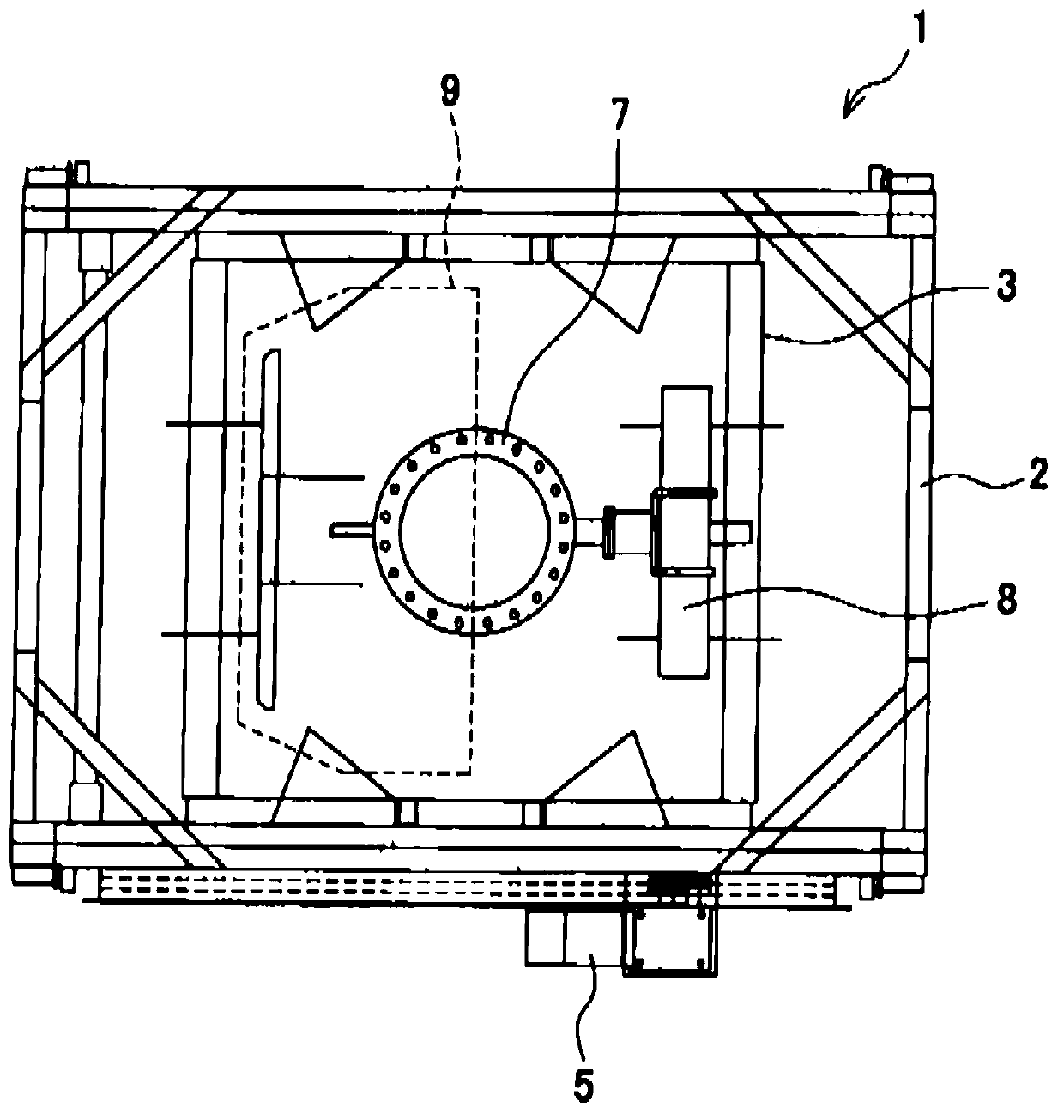

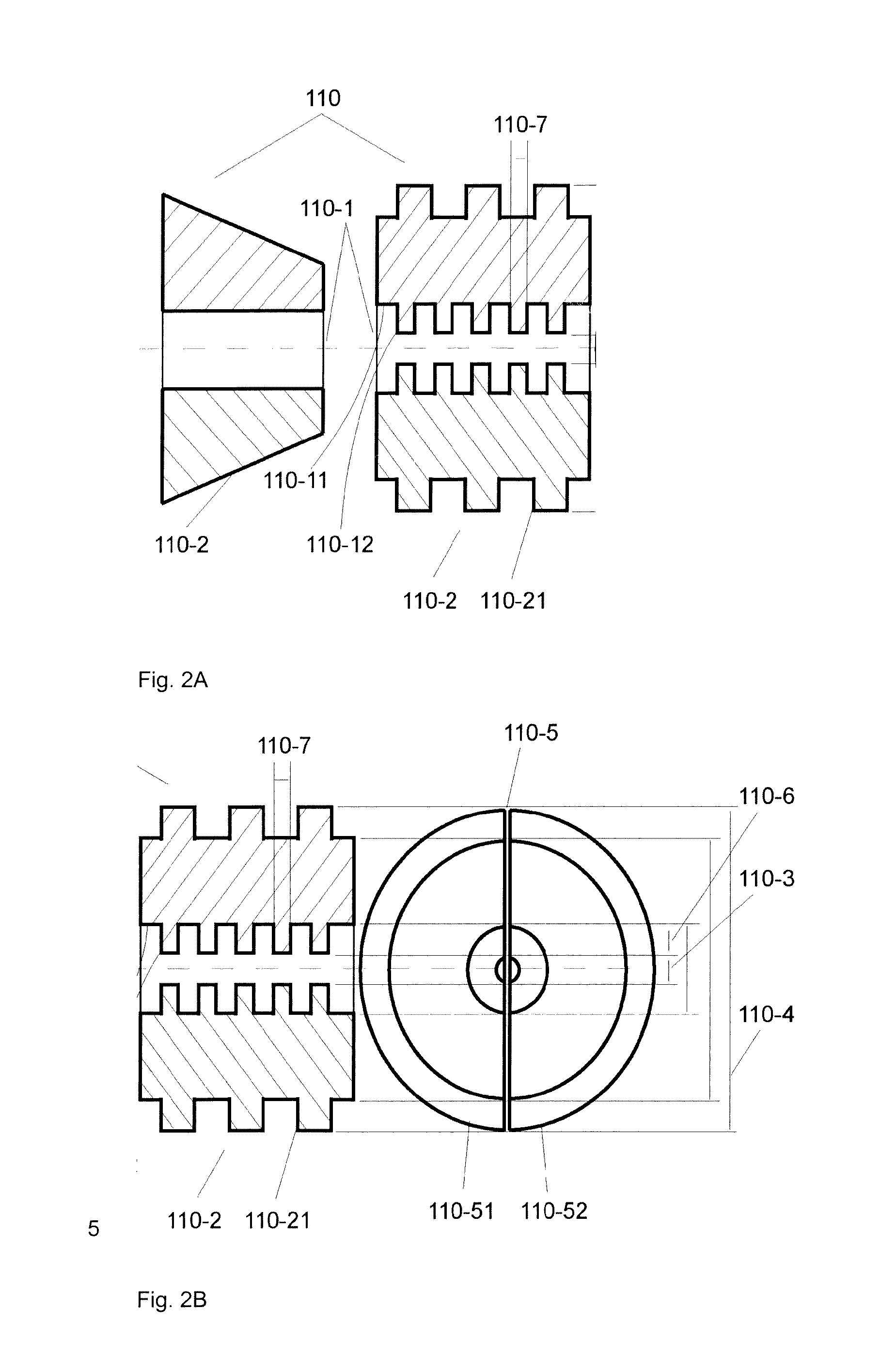

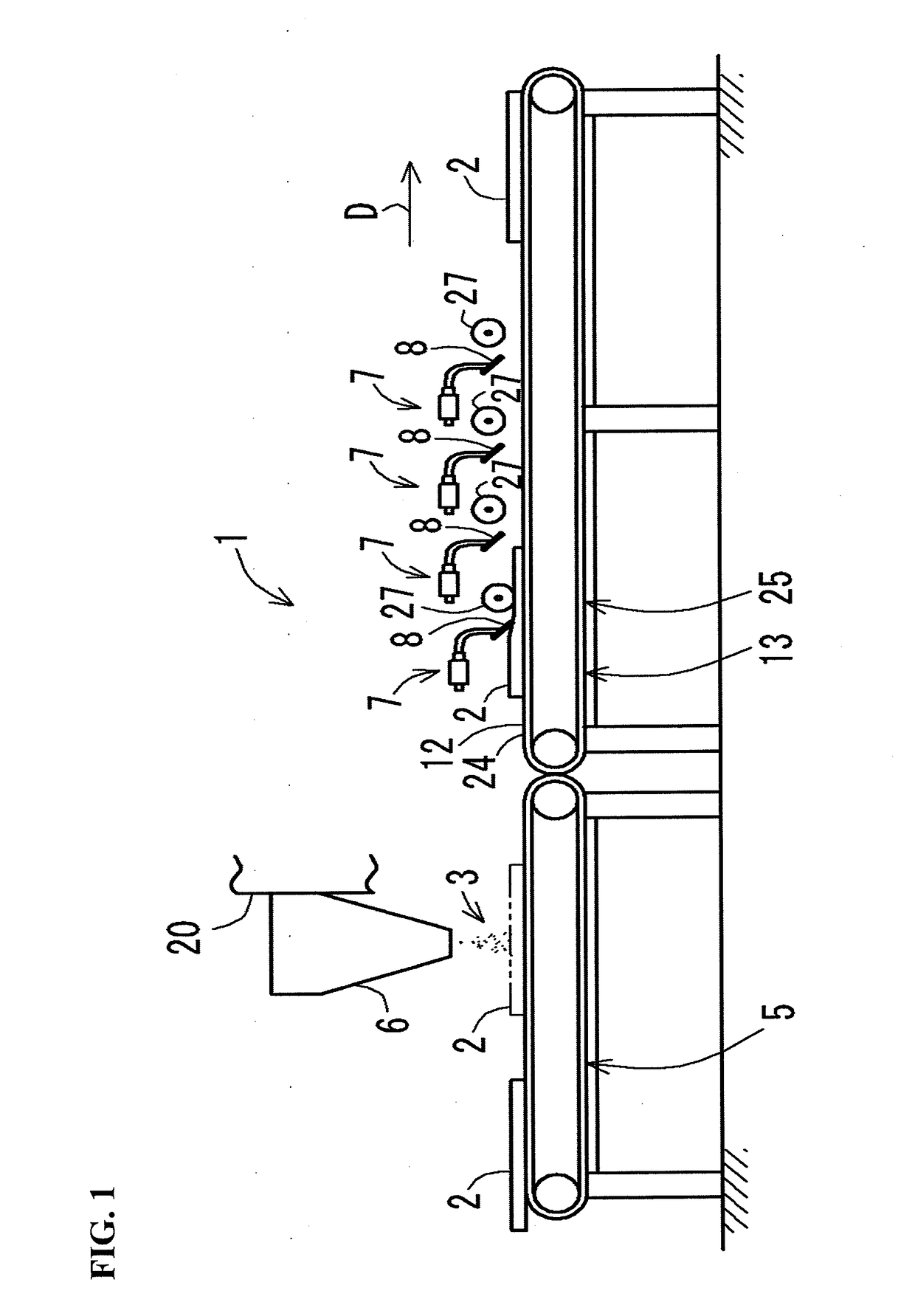

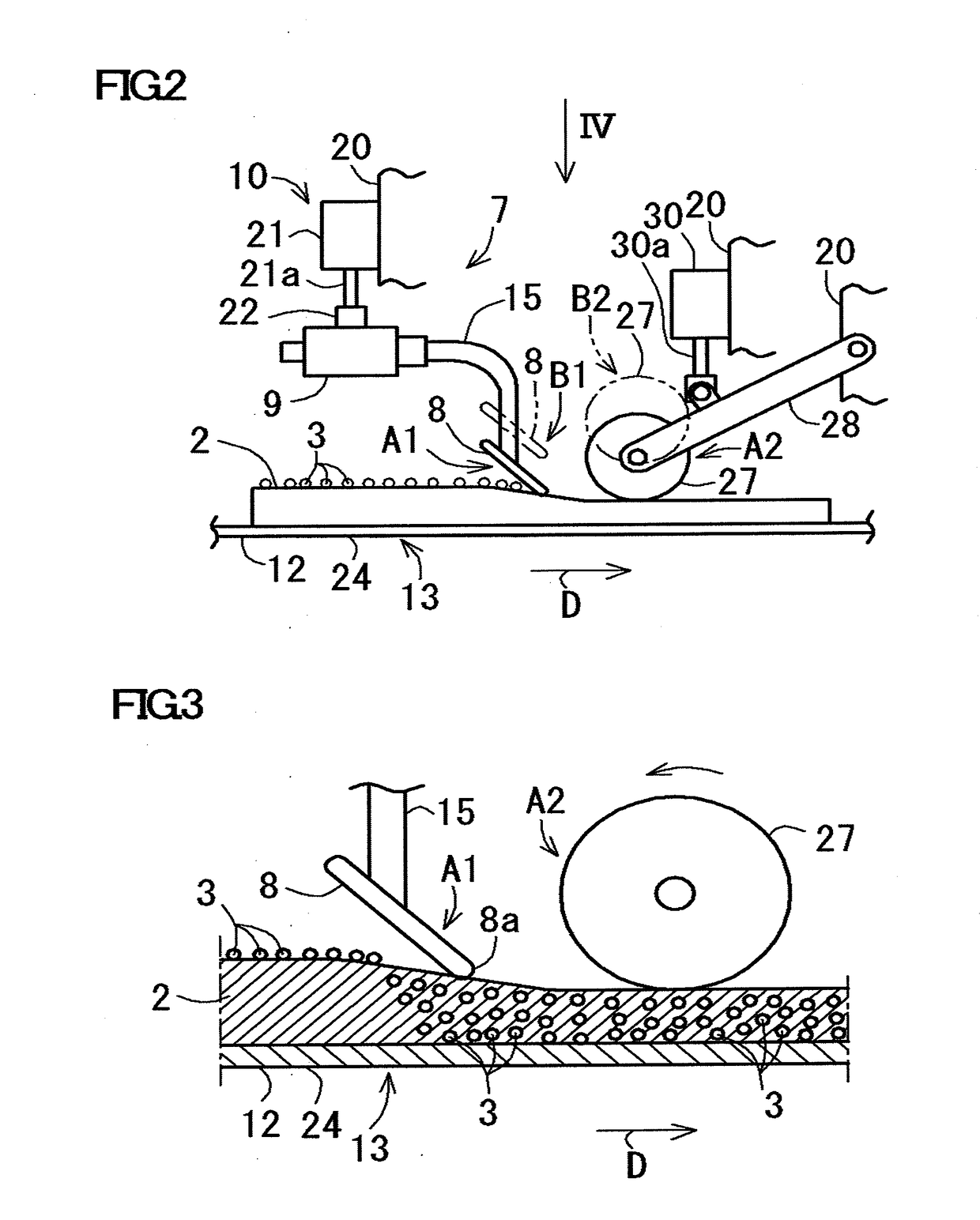

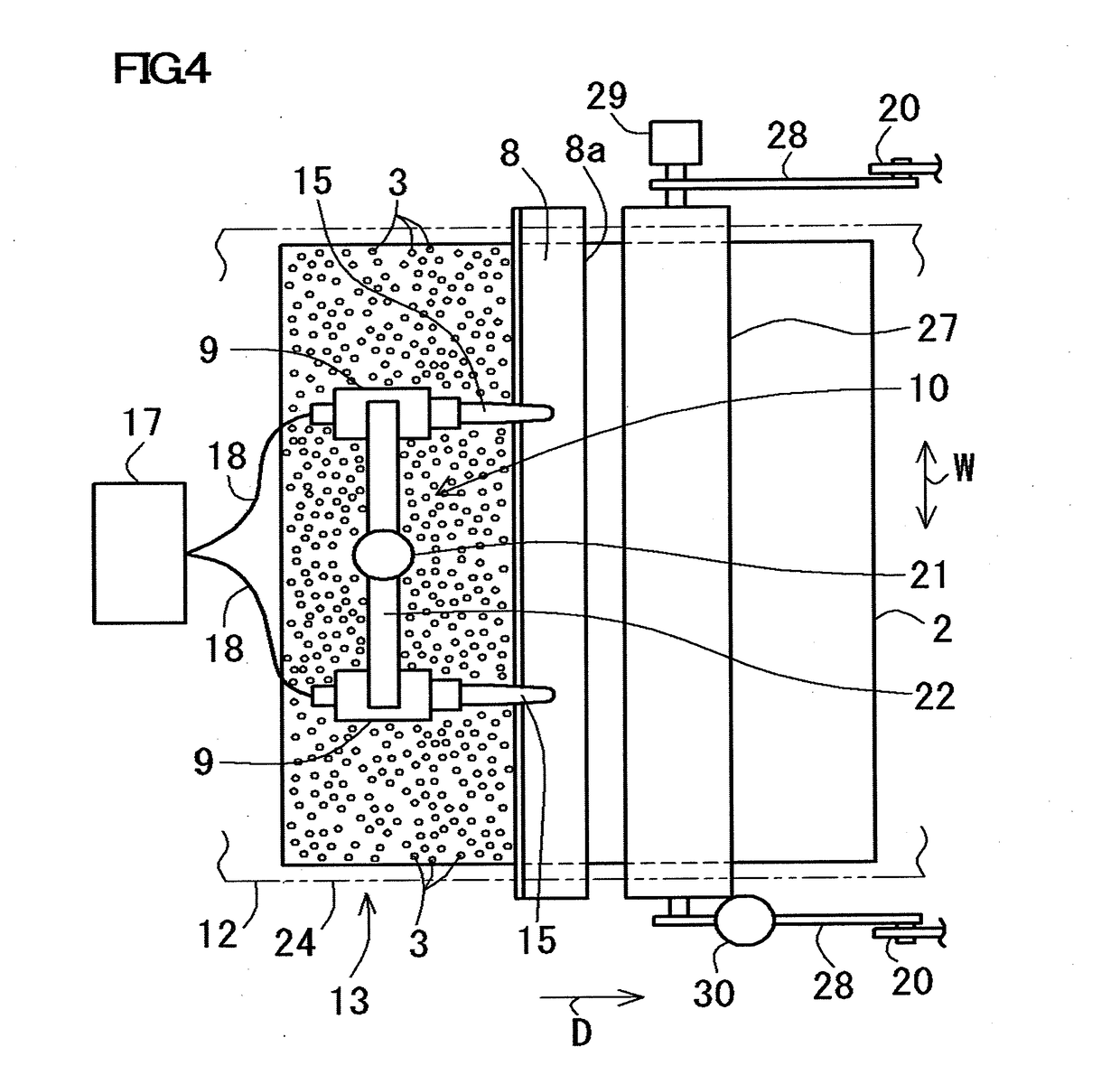

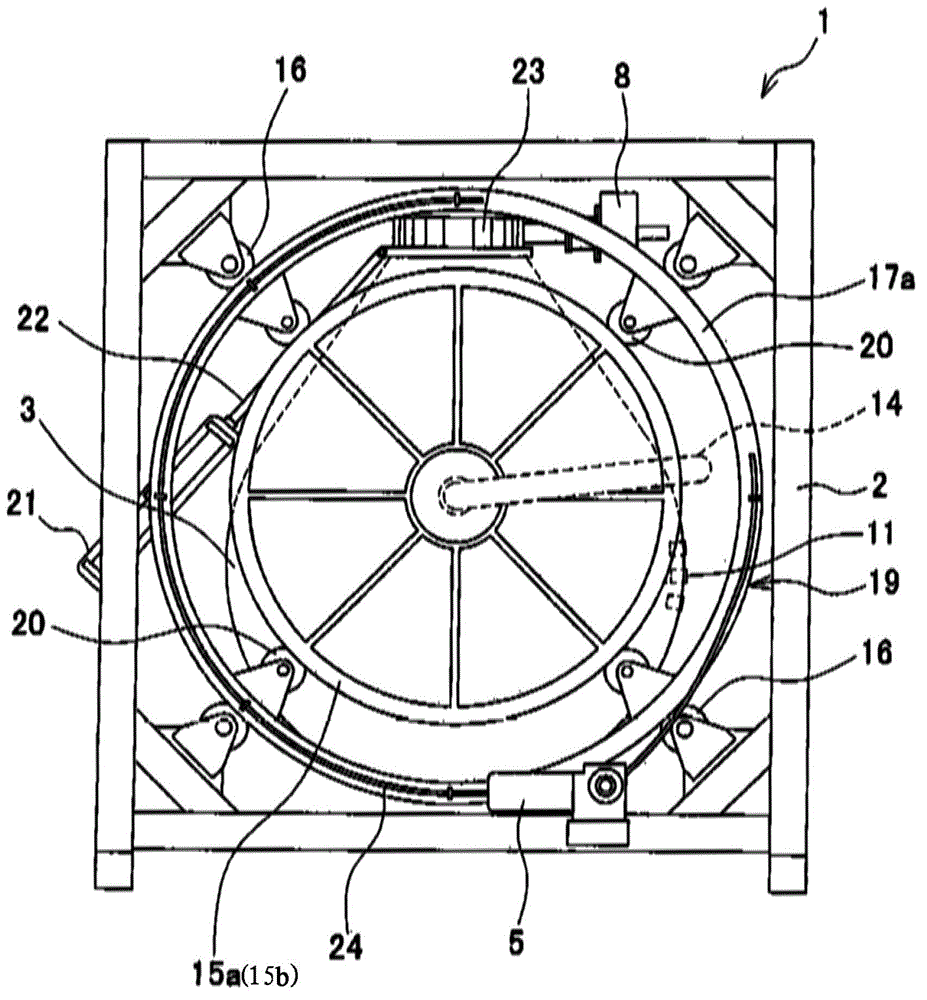

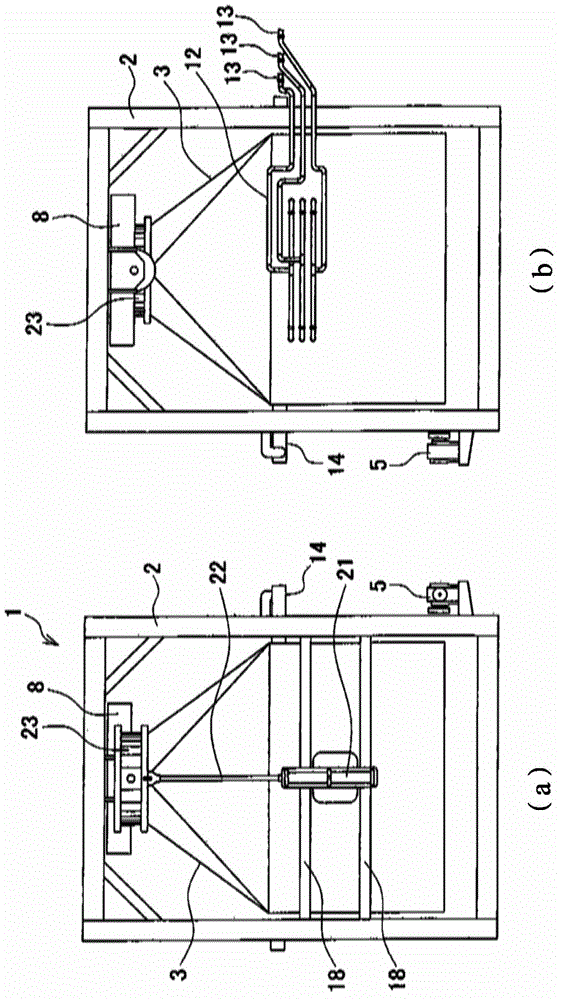

Liquid impregnation device

InactiveCN103315369AEfficient impregnationPrevent agglutinationFeeding-stuffAgglutinationPulp and paper industry

The invention provides a liquid impregnation device, which can make liquids uniformly impregnated in particles without being limited by the types of liquids and particles and adjust the particle oil impregnation rate in a high-precision way. The liquid impregnation device (1) comprises a roller (3) accommodating the particles; a frame (2) supporting the roller (3) to freely rotate; nozzles (11, 11..) spraying oil towards the particles; oil supply pipes (12, 12...) supplying oil to the nozzles (11, 11..); an electric motor (5) driving the roller (3) to rotate; an exhaust pipe (14) reducing pressure inside the roller (3); and a cylinder (21) making the roller (3) swing in high speed. A protruding separation projection (9) protruding towards the inner side of the roller (3) is arranged inside the roller (3). Agglutination prevention walls (10a-10e) are vertically arranged on the upper surface of the separation projection (9). Agglutination prevention walls (10f-10h) are further vertically arranged on the lower surface of the separation projection (9).

Owner:OMC

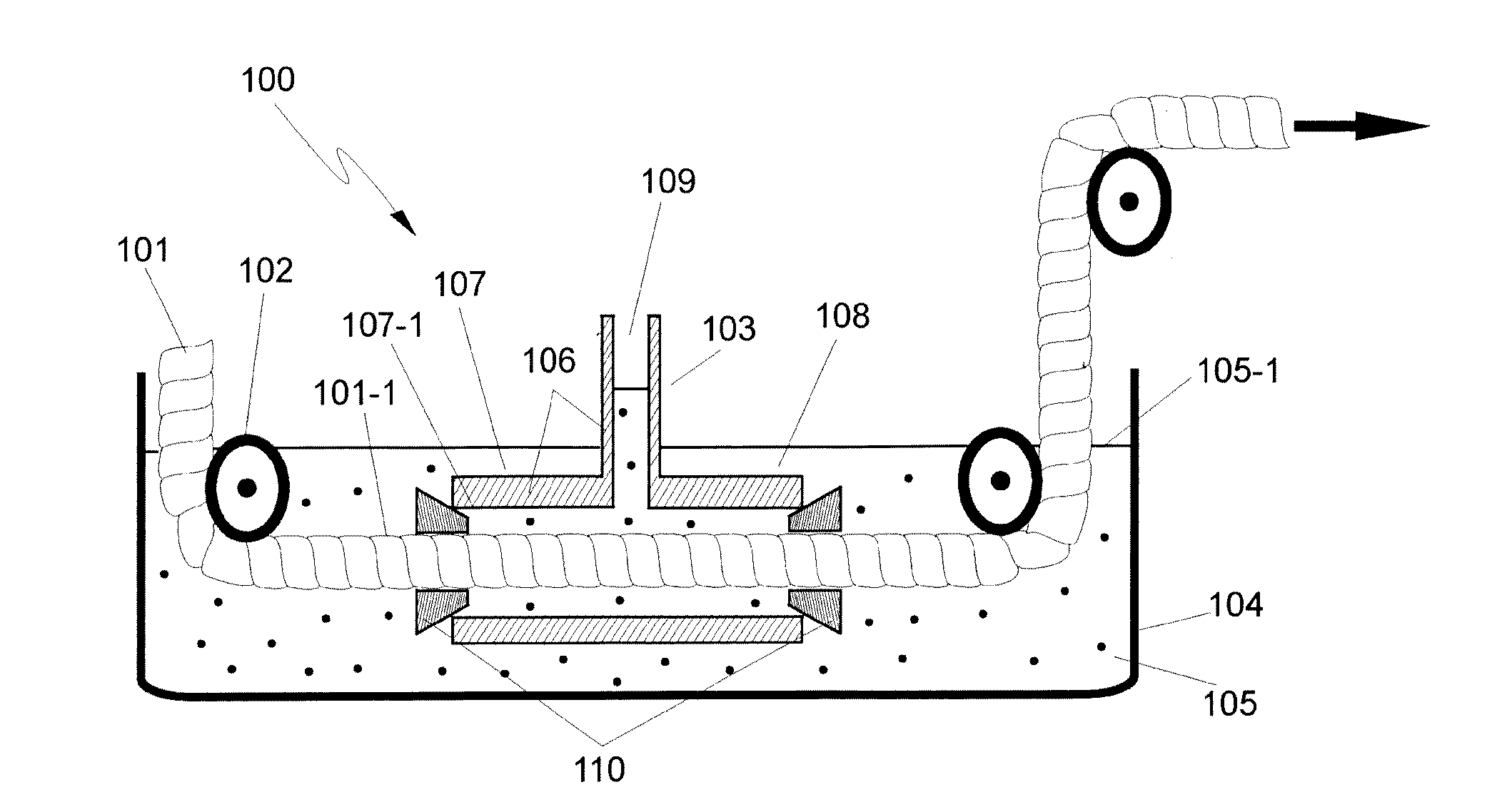

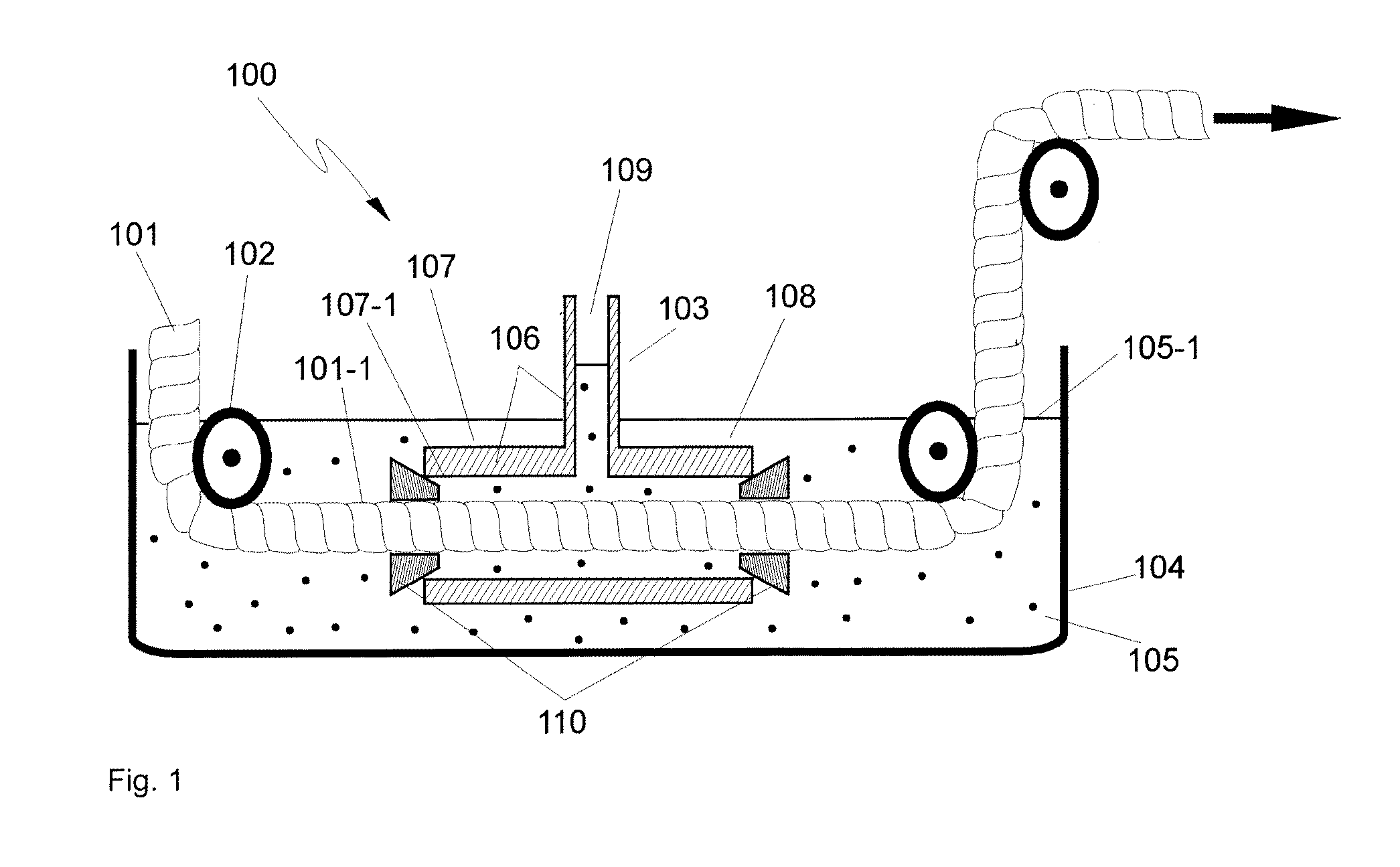

Method and device for impregnating a rope with a liquid material

InactiveUS20150101306A1Improve safety factorGood reproducibilityAgriculture tools and machinesSynthetic fibresFiberEngineering

A method for impregnating a liquid material (105) into a rope (101) comprising a plurality of fibers and interstices between said fibers, said method comprising the steps of: (a) Providing a liquid material in a tank, (104) said liquid material defining a level of liquid (105-1) in said tank (104); (b) Providing an impregnation unit (103) containing a chamber (106) at least partially immersed in said liquid material (105), said chamber (106) comprising: (i.) a rope-inlet (107) for at least partially tightly receiving the rope (101), wherein said rope-inlet (107) is positioned below the level of liquid (105-1); (ii) a rope-outlet (108) for at least partially tightly discharging said rope (101); iii) a vacuum-outlet (109); and (c) Providing a vacuum-device operatively connected to said vacuum-outlet (109) for lowering the pressure in said chamber (106) below the atmospheric pressure; (d) Passing the rope (101) through the liquid material (105) in the tank (104) and then inside and outside said chamber (106) via the rope-inlet (107) and rope-outlet (108), while maintaining the pressure inside said chamber (106) below the atmospheric pressure to force the liquid material (105) to fill at least part of said interstices between the fibers of the rope (101) by penetrating between said fibers. A corresponding device, rope an use of the rope is also disclosed.

Owner:DSM IP ASSETS BV

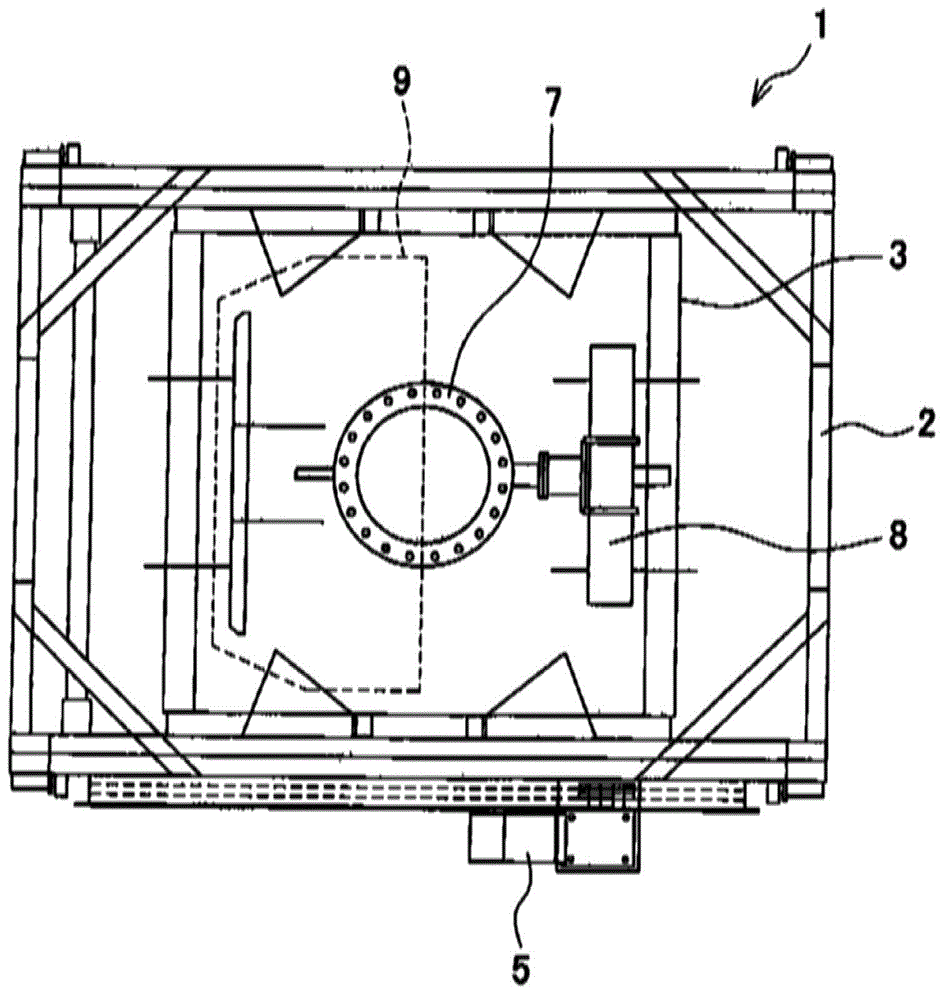

Particle impregnating device

ActiveUS20180340294A1Easy to moveInhibitionLiquid surface applicatorsLiquid/gas/vapor removalEngineeringUltrasonic vibration

The particle impregnating device includes a placing body for placing a nonwoven fabric having a surface on which particles are sprayed; a vibrating member which is provided above the placing body and extends in the width direction of the nonwoven fabric placed on the placing body; a vibrator which applies ultrasonic vibration to the vibrating member; a lifting mechanism which lifts up and down the vibrating member; and a moving mechanism which relatively moves the nonwoven fabric and the vibrating member in a surface direction orthogonal to the width direction of the nonwoven fabric. When the nonwoven fabric and the vibrating member are relatively moved by the moving mechanism, the vibrating member is lowered by the lifting mechanism, so that the nonwoven fabric is pressed and compressed by the vibrating member and ultrasonic vibration is applied to the vibrating member by the vibrator.

Owner:TOYOTA BOSHOKU KK

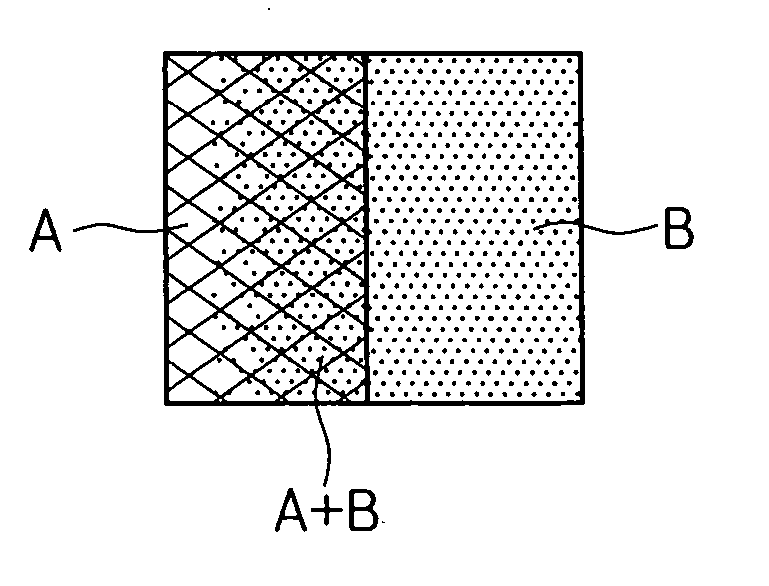

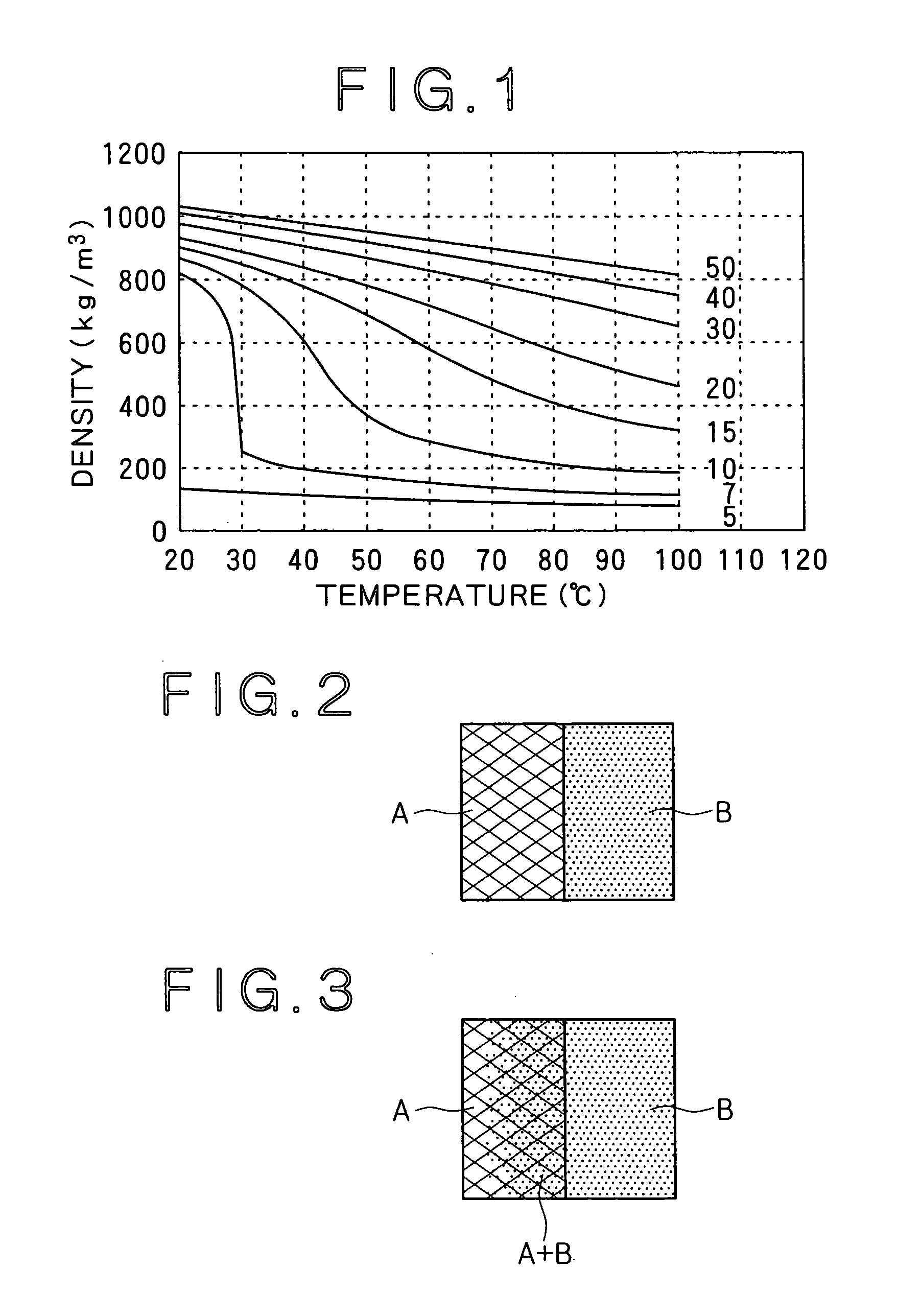

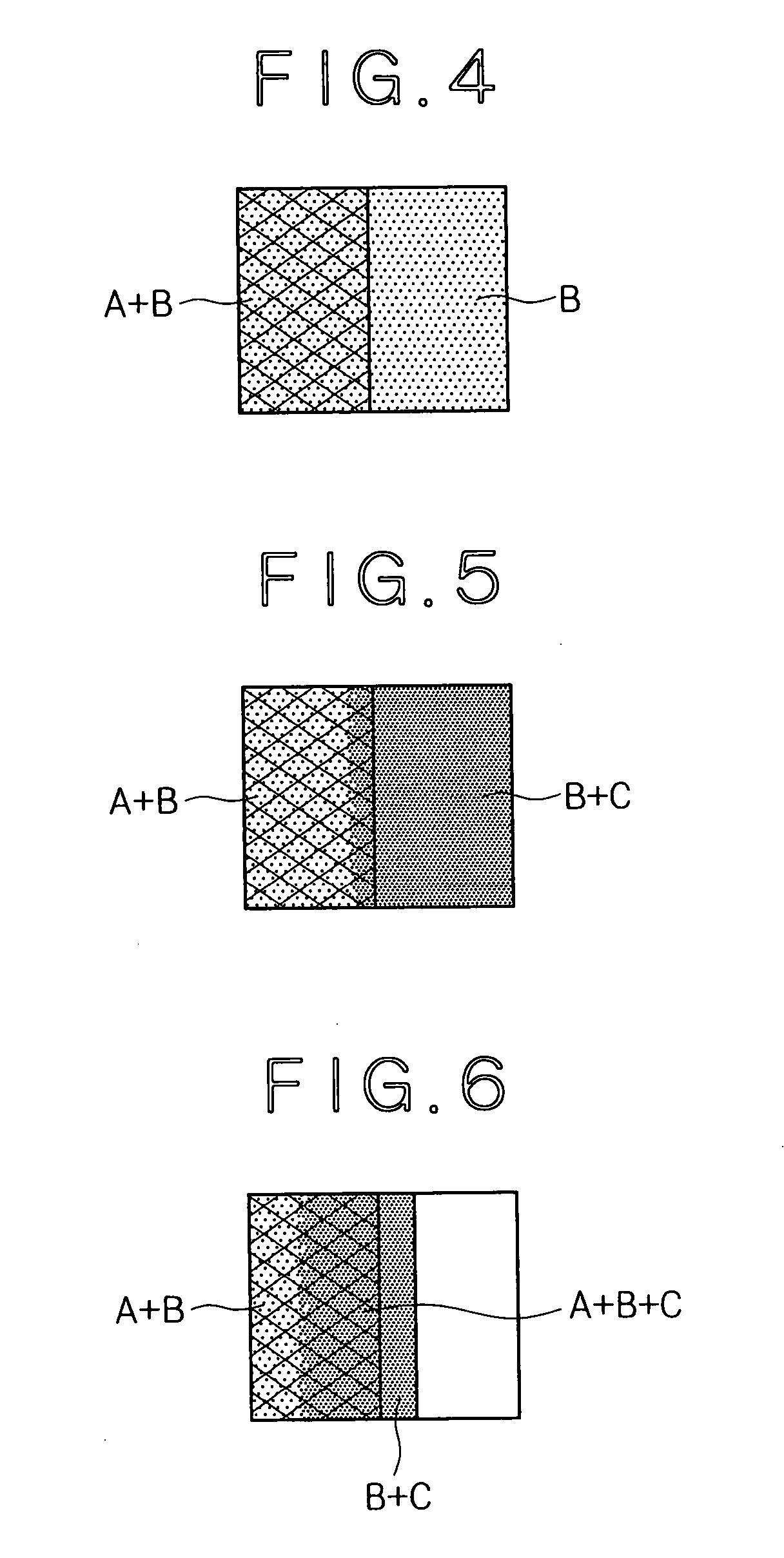

Epoxy resin composition, cured epoxy resin product, prepreg, and fiber-reinforced composite material

Provided are: an epoxy resin composition having exceptional performance with regard to impregnating reinforcing fibers, enabling optimal control of resin flow during molding, and having exceptional in-plane shear strength; a cured epoxy resin product; and a prepreg. An epoxy resin composition comprising at least the following constituent elements [A], [B], and [C]: [A] an epoxy resin, [B] a polyether sulfone having a weight-average molecular weight of 2000-20000 g / mol, [C] a curing agent

Owner:TORAY IND INC

Fiber substrate stacking method, manufacturing method of roll of fiber substrate group, fiber substrate group, and aircraft

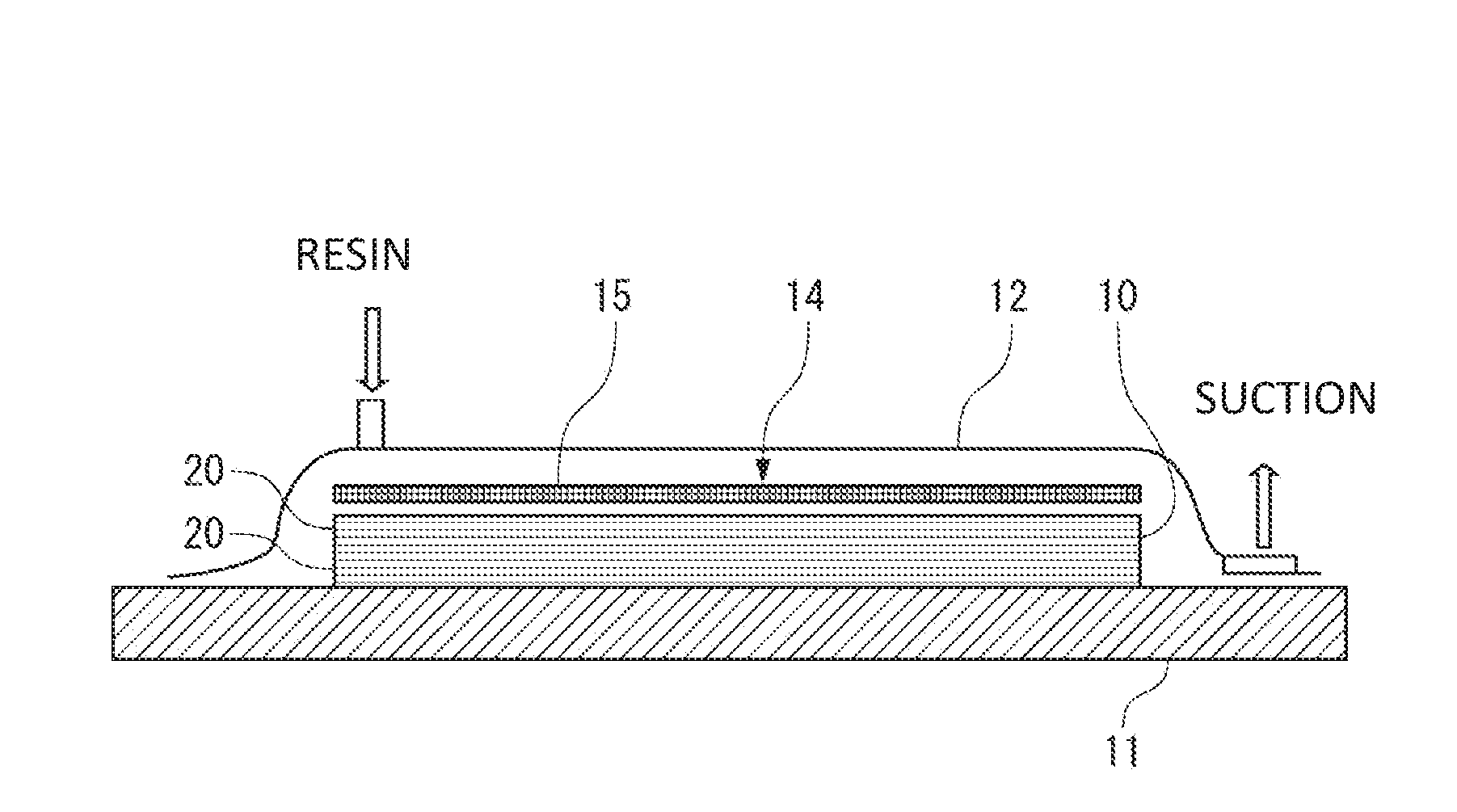

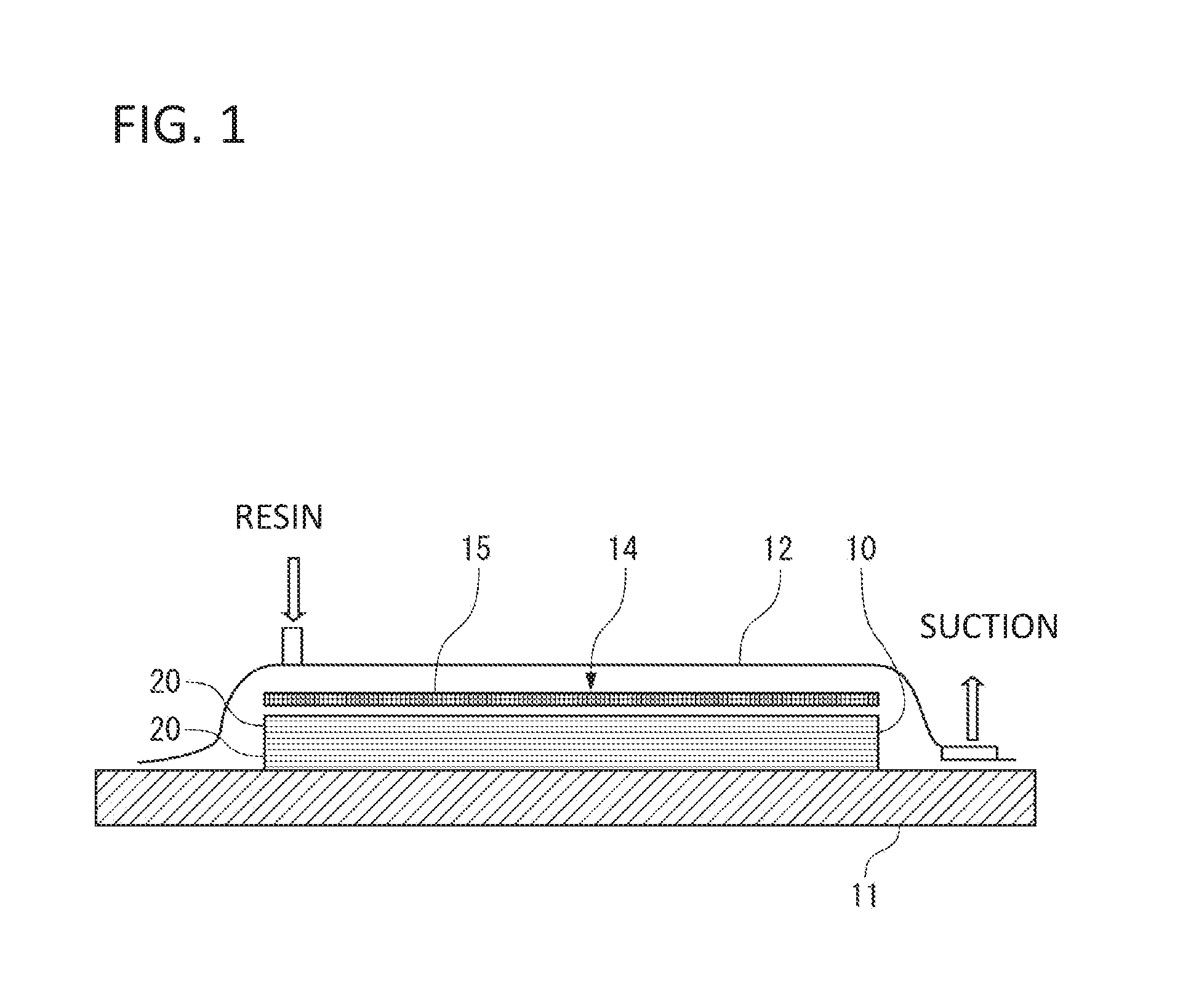

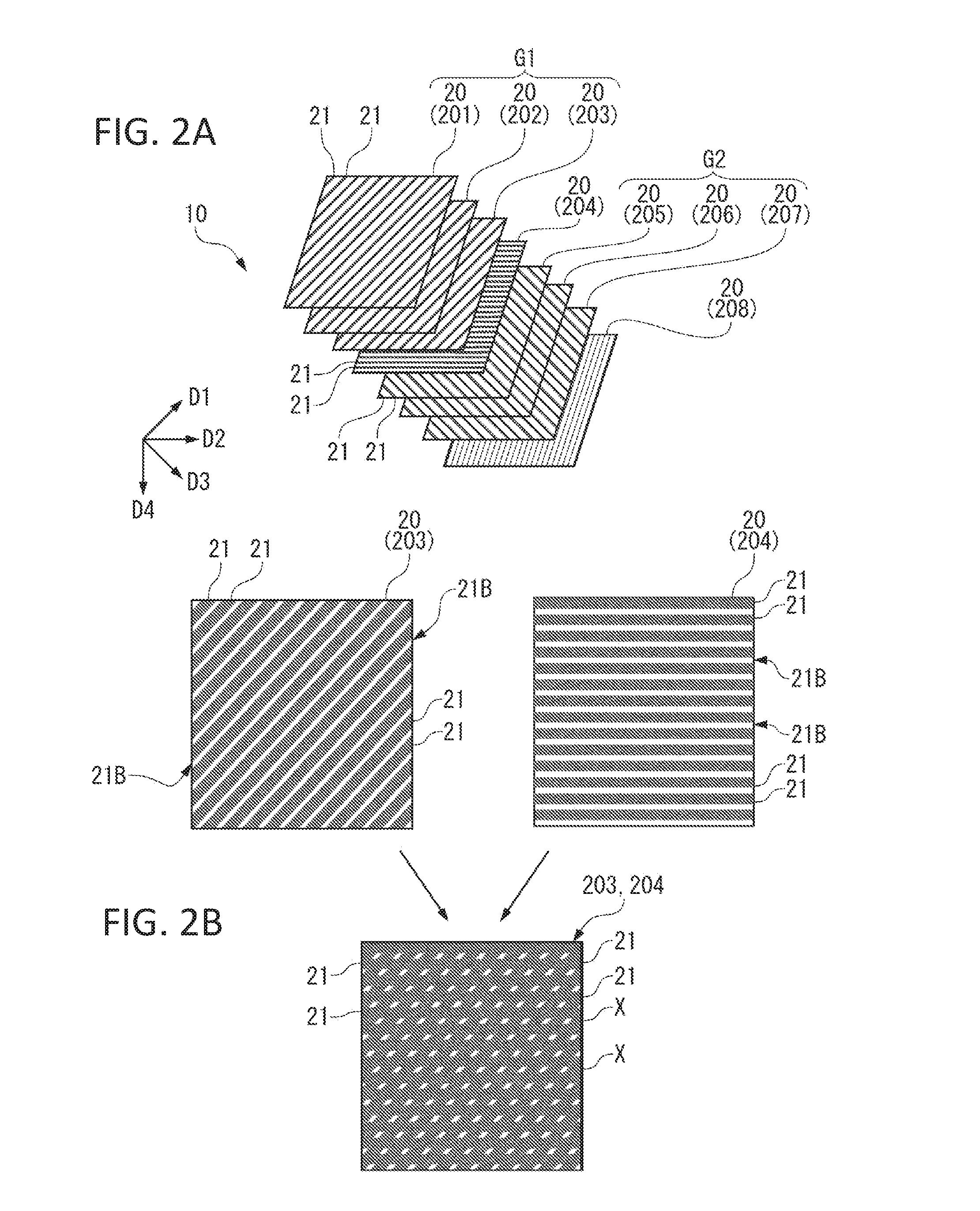

ActiveUS20160243770A1Fully impregnatedIncrease flexibilityLaminationLamination apparatusFiber bundleOptoelectronics

The present invention aims to sufficiently impregnate each layer of a fiber substrate group composed of fiber substrates, which are used for fiber-reinforced resin molding by a resin injection method, with a resin. To successively stack a plurality of fiber substrates, each of which has arrayed fiber bundles and is a material composing a fiber-reinforced resin along with a resin, with their fiber bundles oriented in the same direction, the plurality of fiber substrates are integrated in a state where border zones between the fiber bundles adjacent to each other in an array direction are aligned with one another among the fiber substrates.

Owner:MITSUBISHI AIRCRAFT

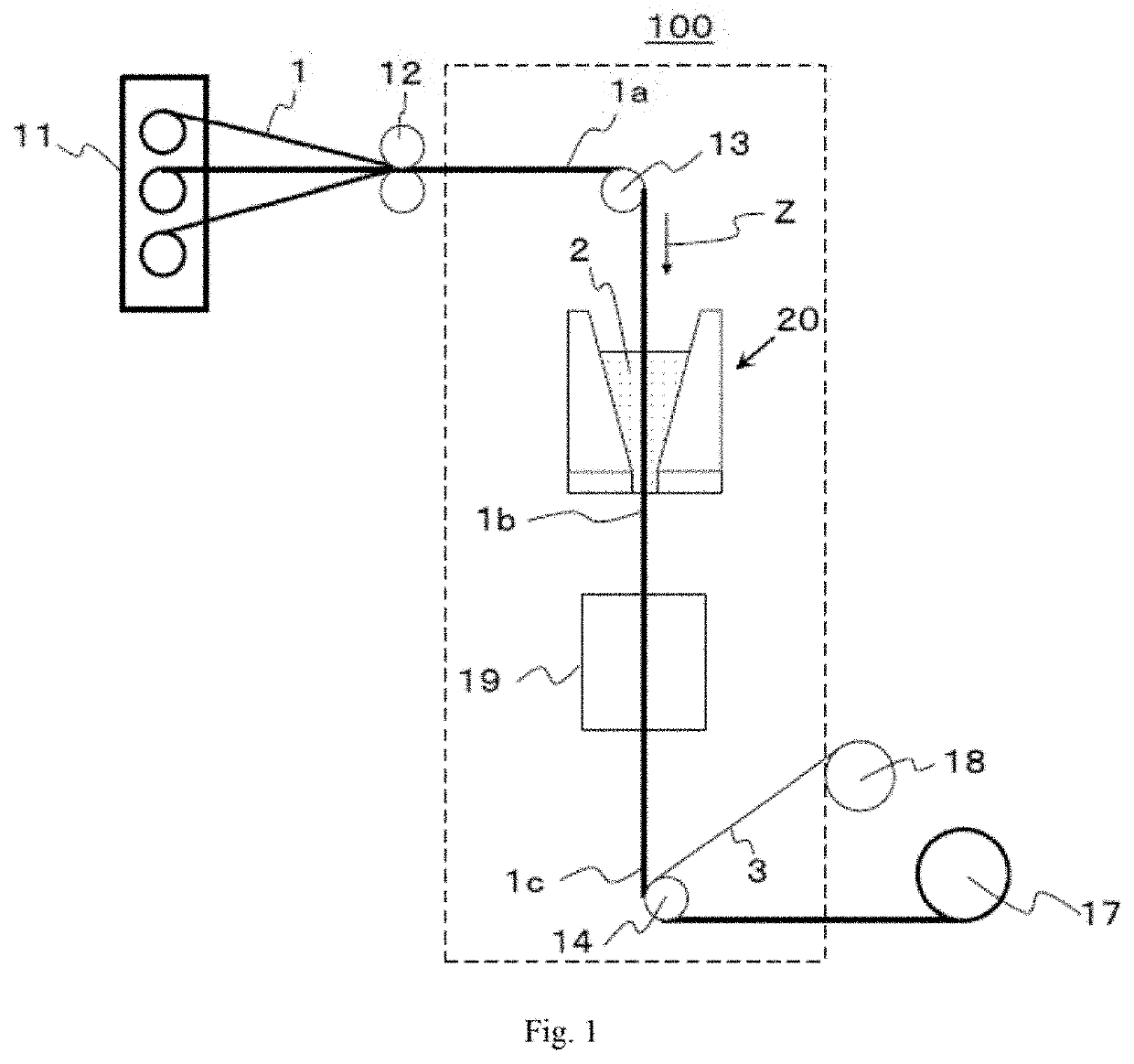

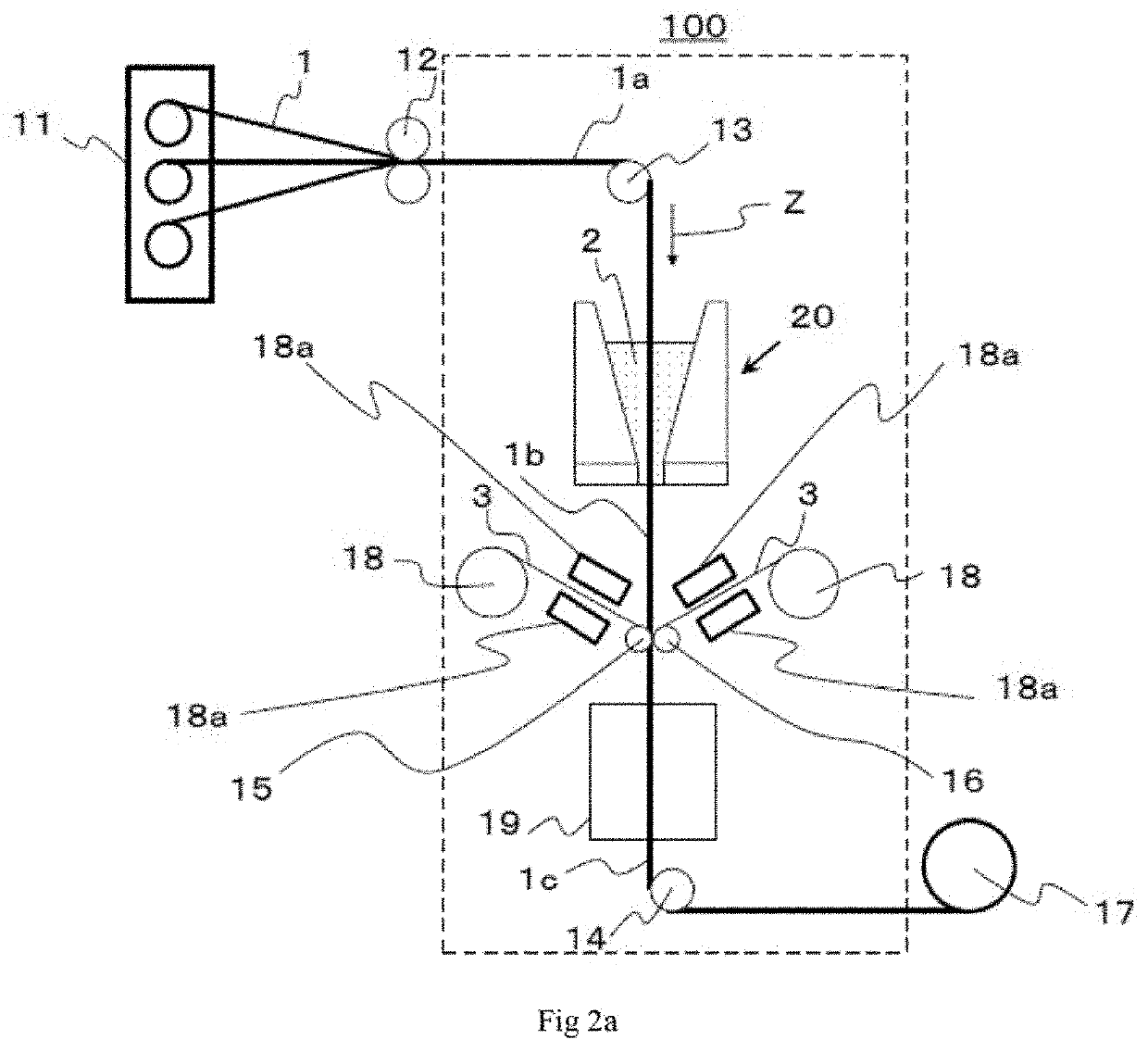

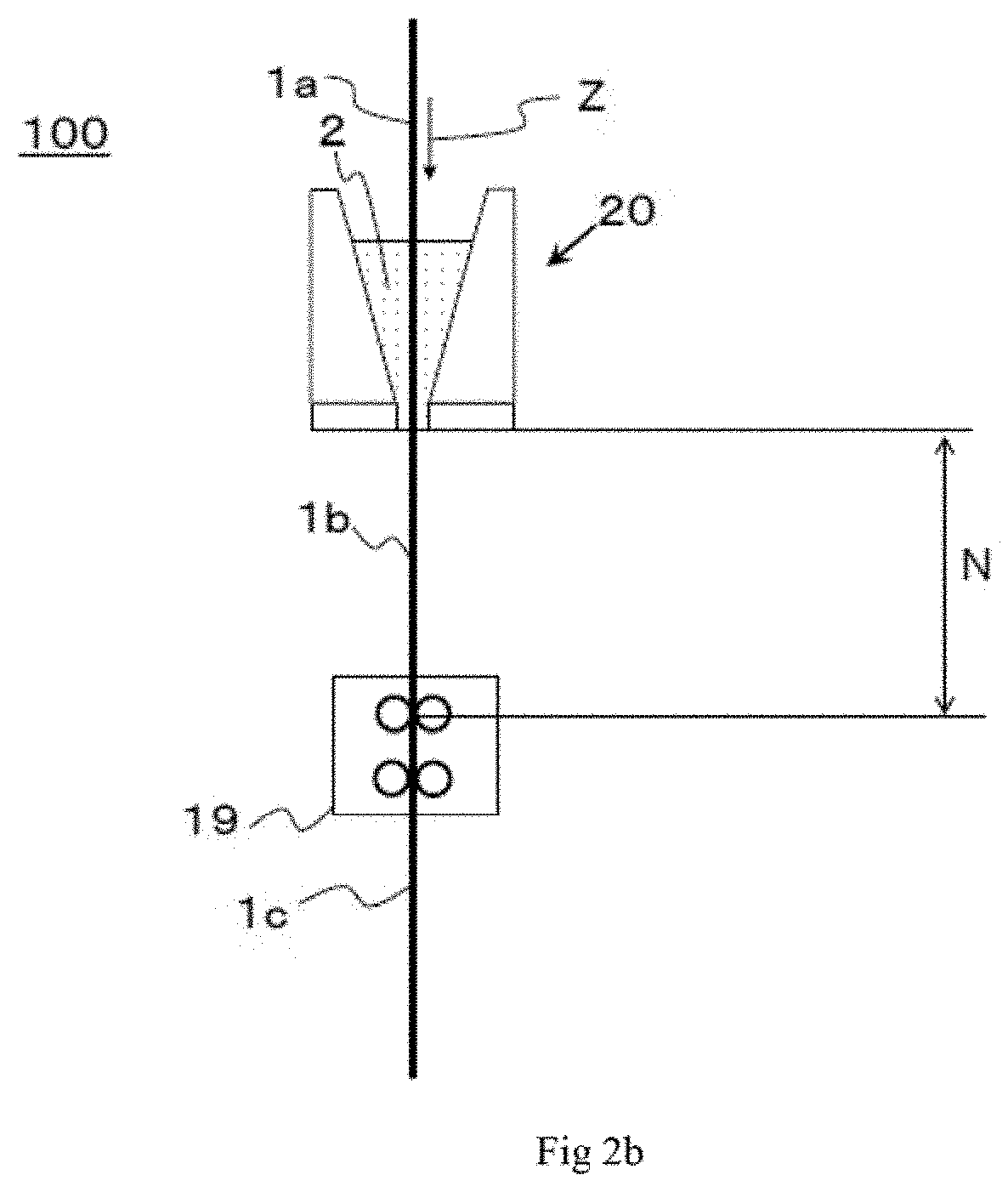

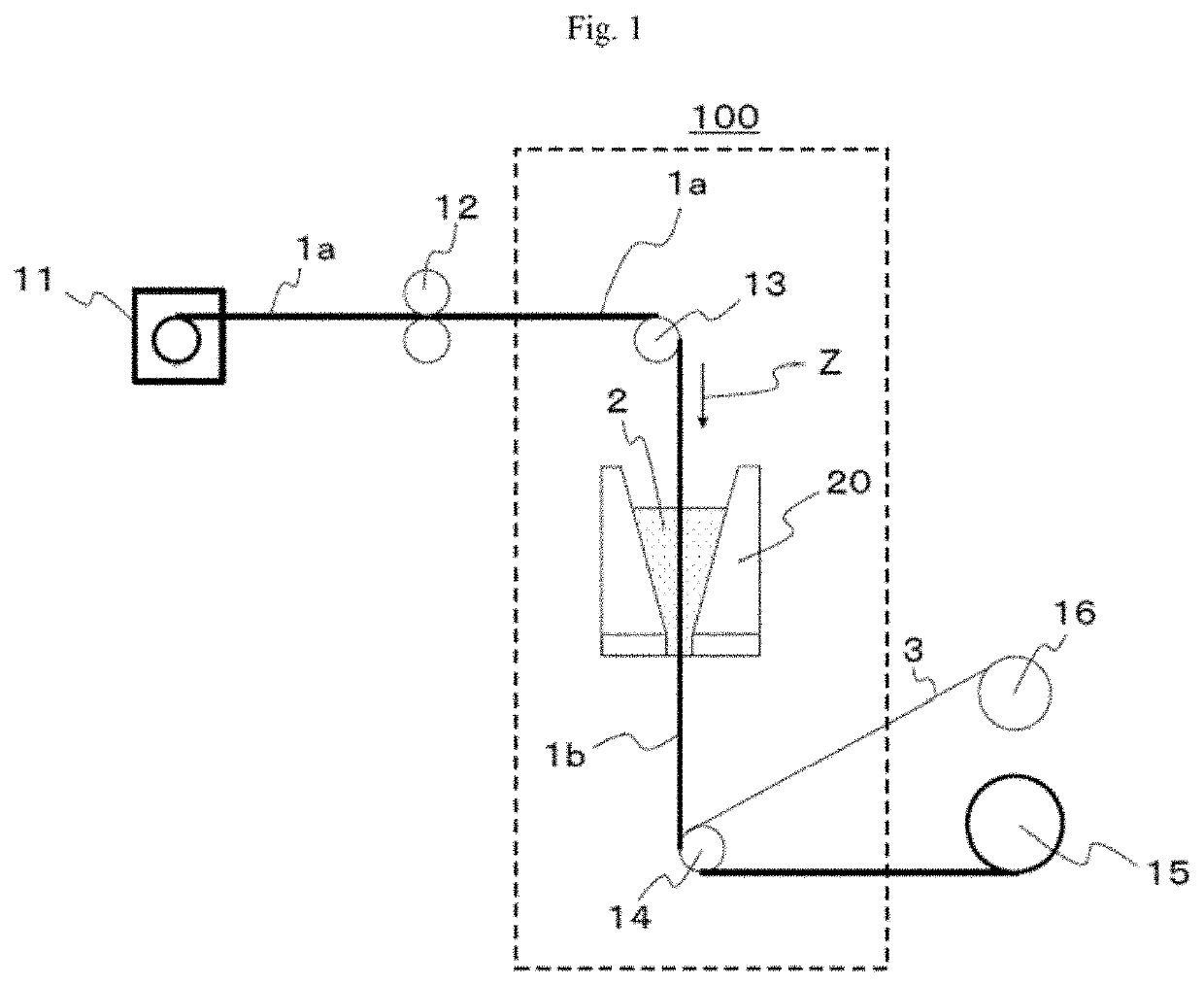

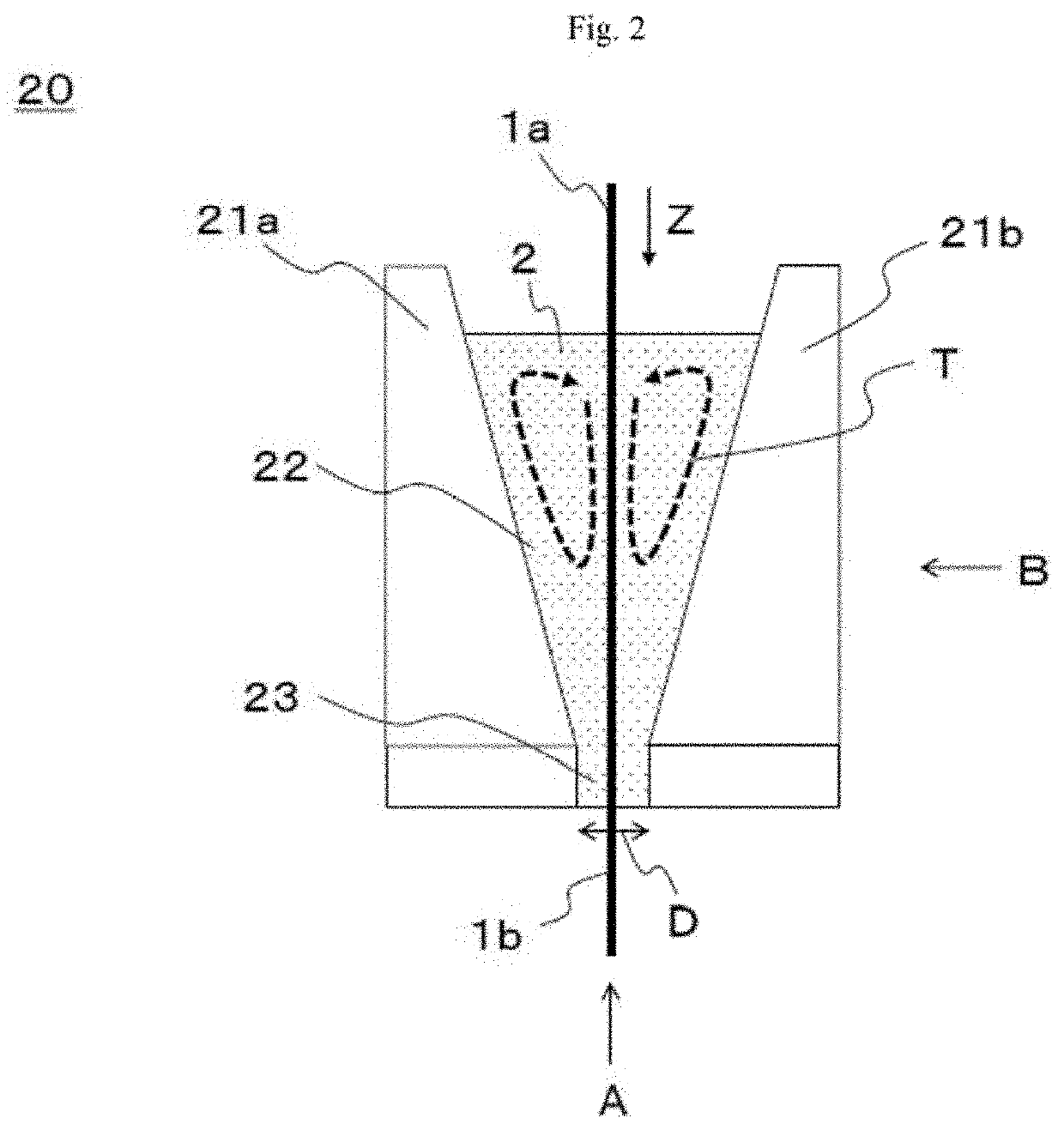

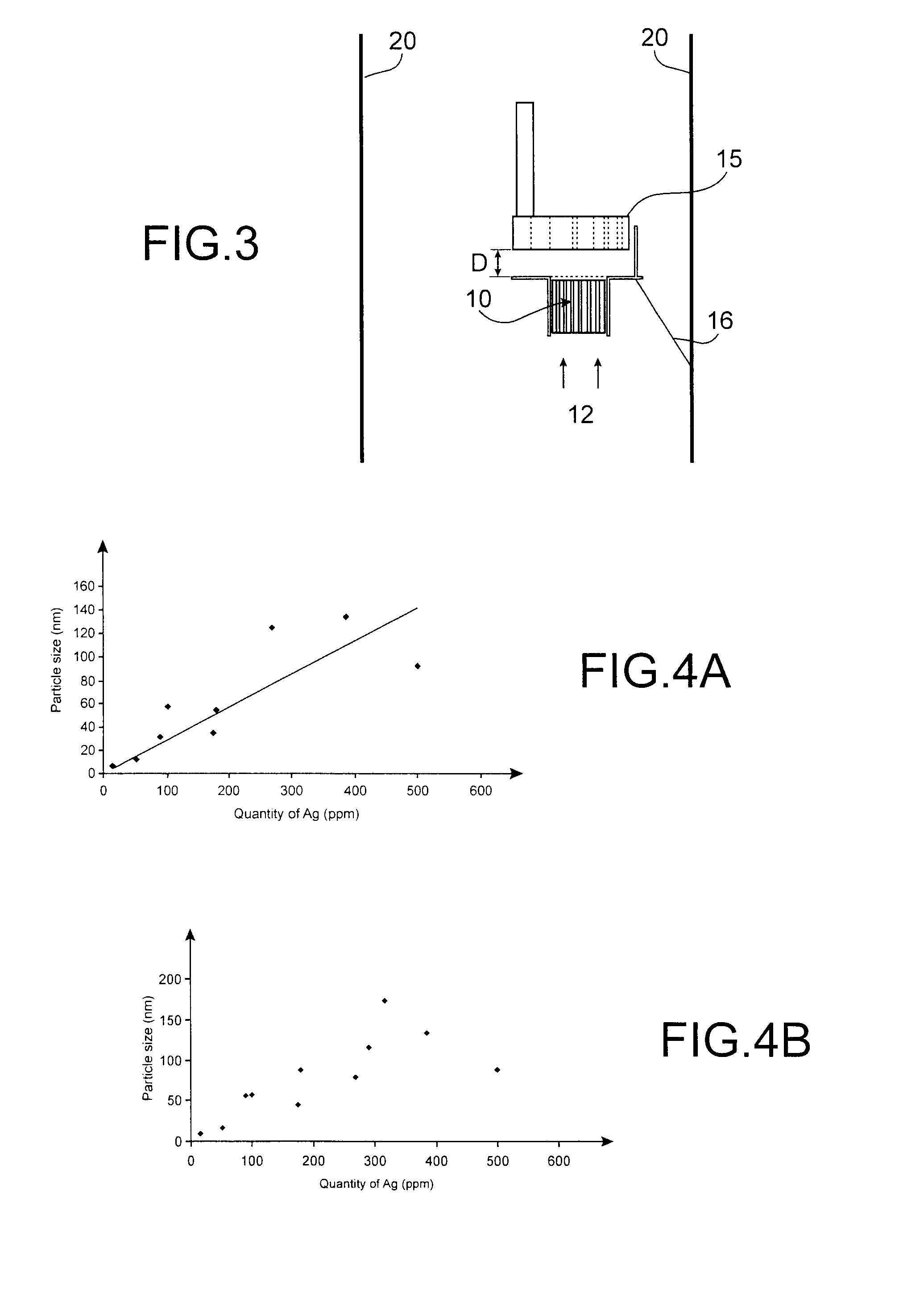

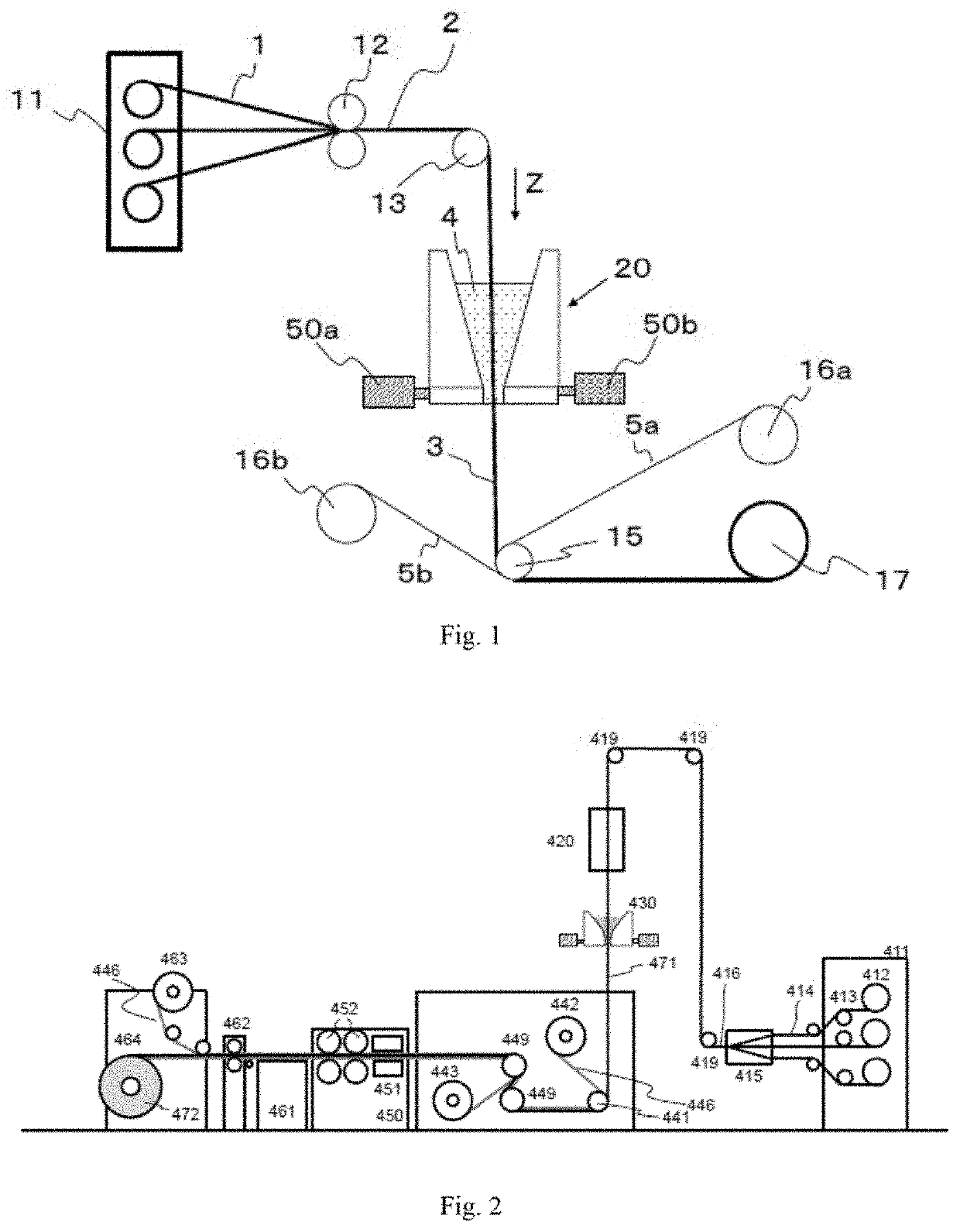

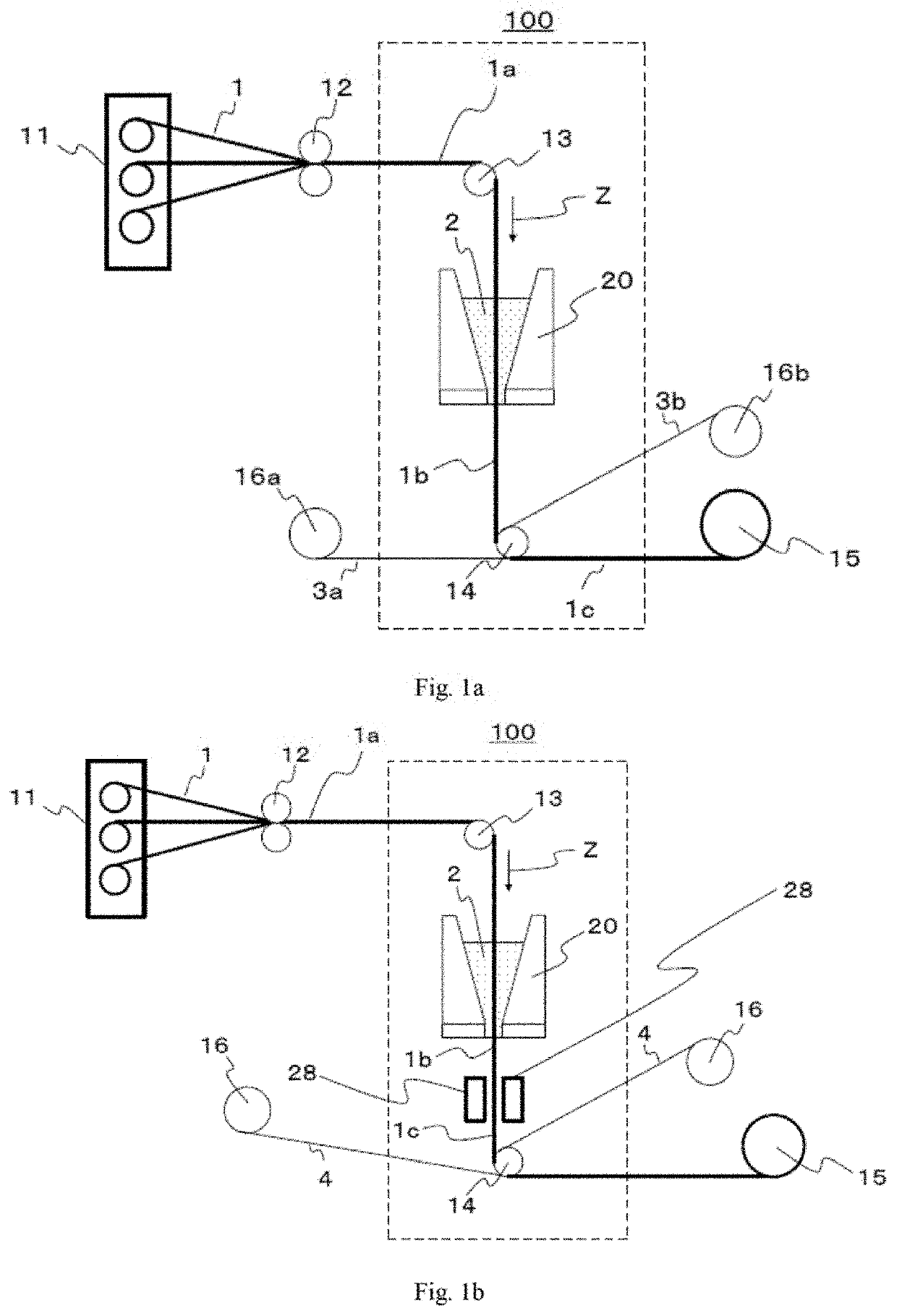

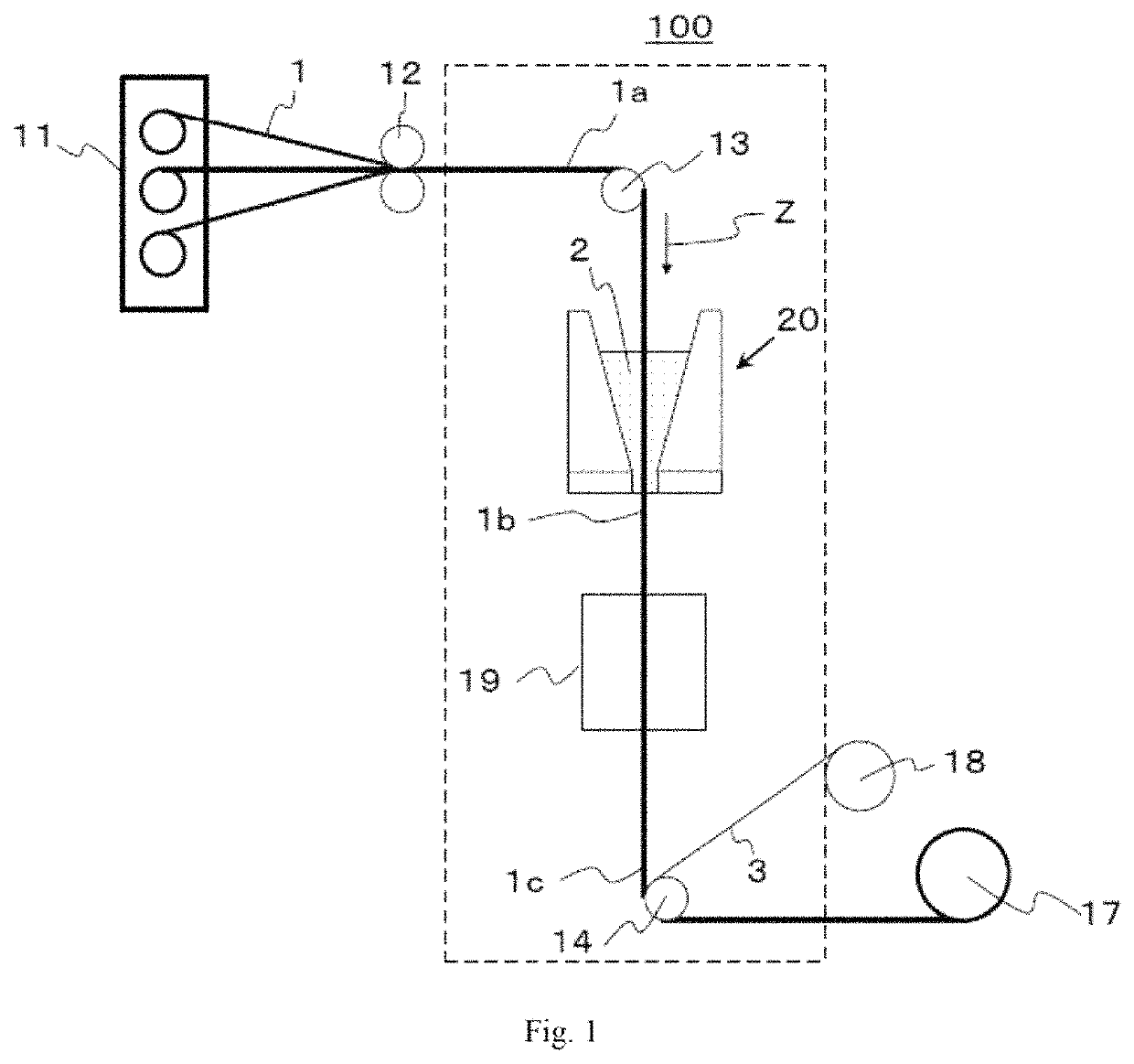

Production method for prepreg, prepreg tape, and fiber reinforced composite material, and prepreg production device

ActiveUS20210291405A1Suppress and prevent cloggingIncrease speedCoatingsFiber-reinforced compositeComposite material

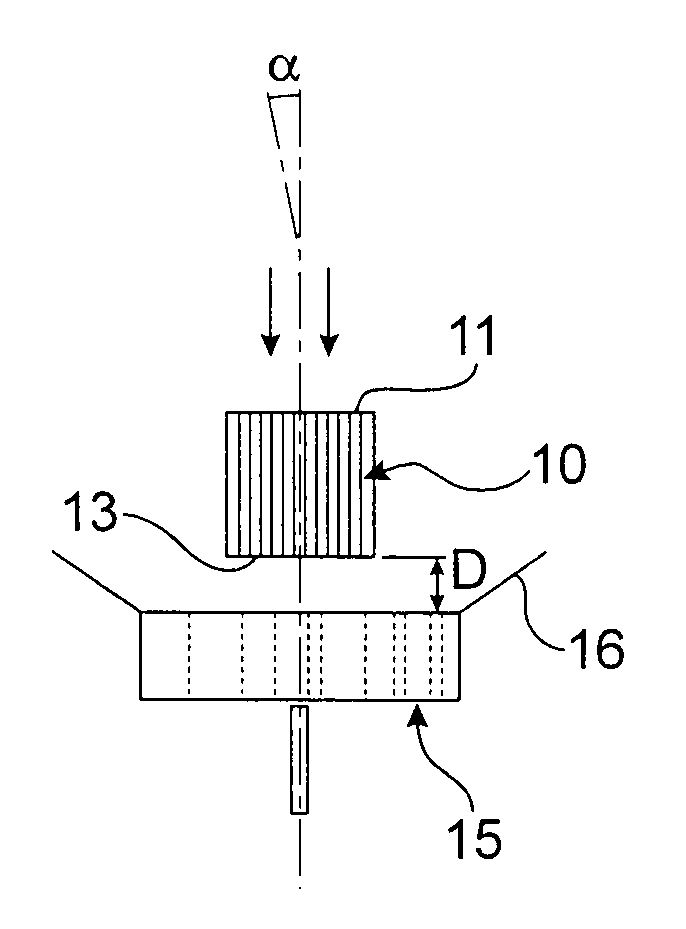

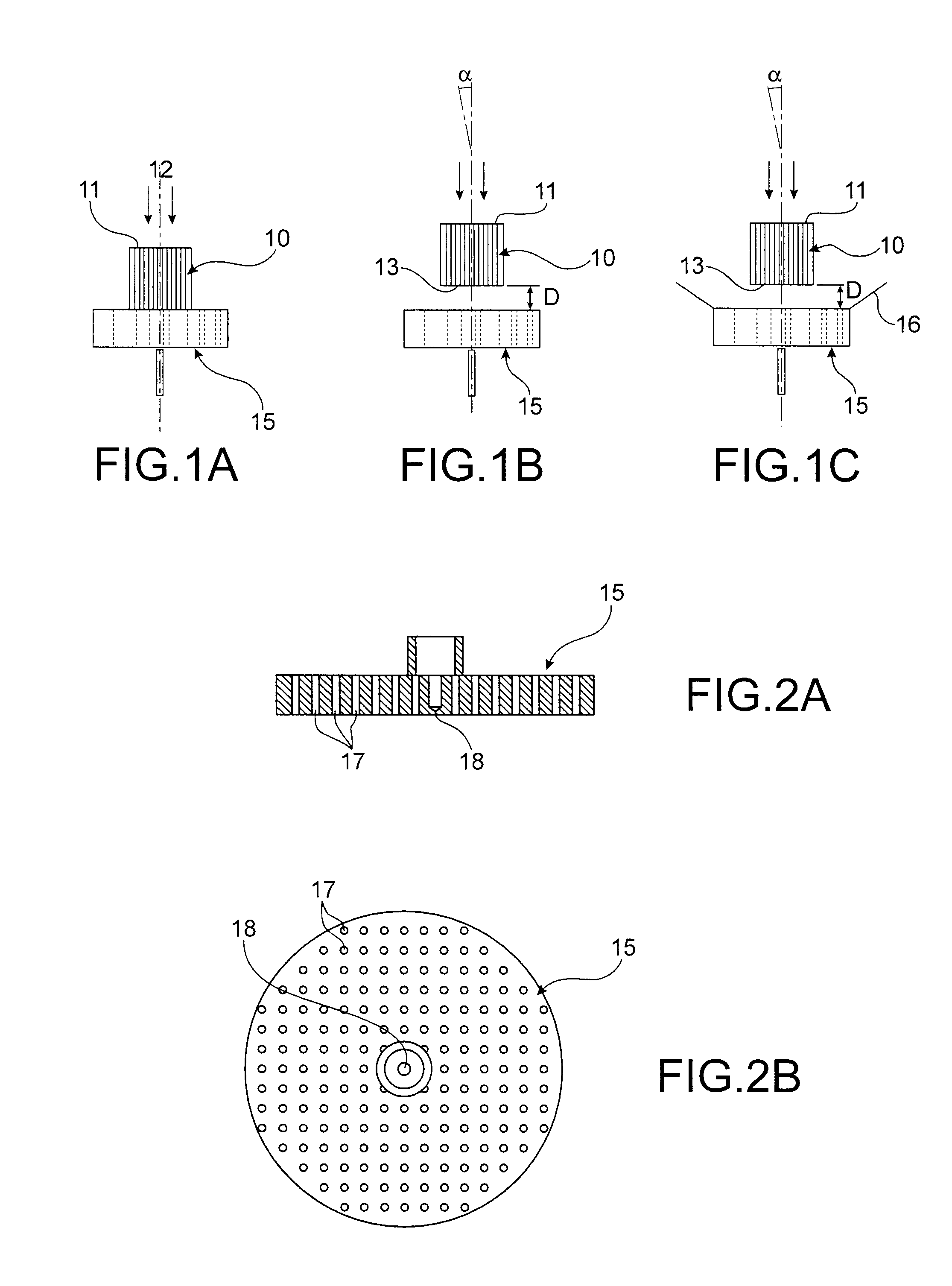

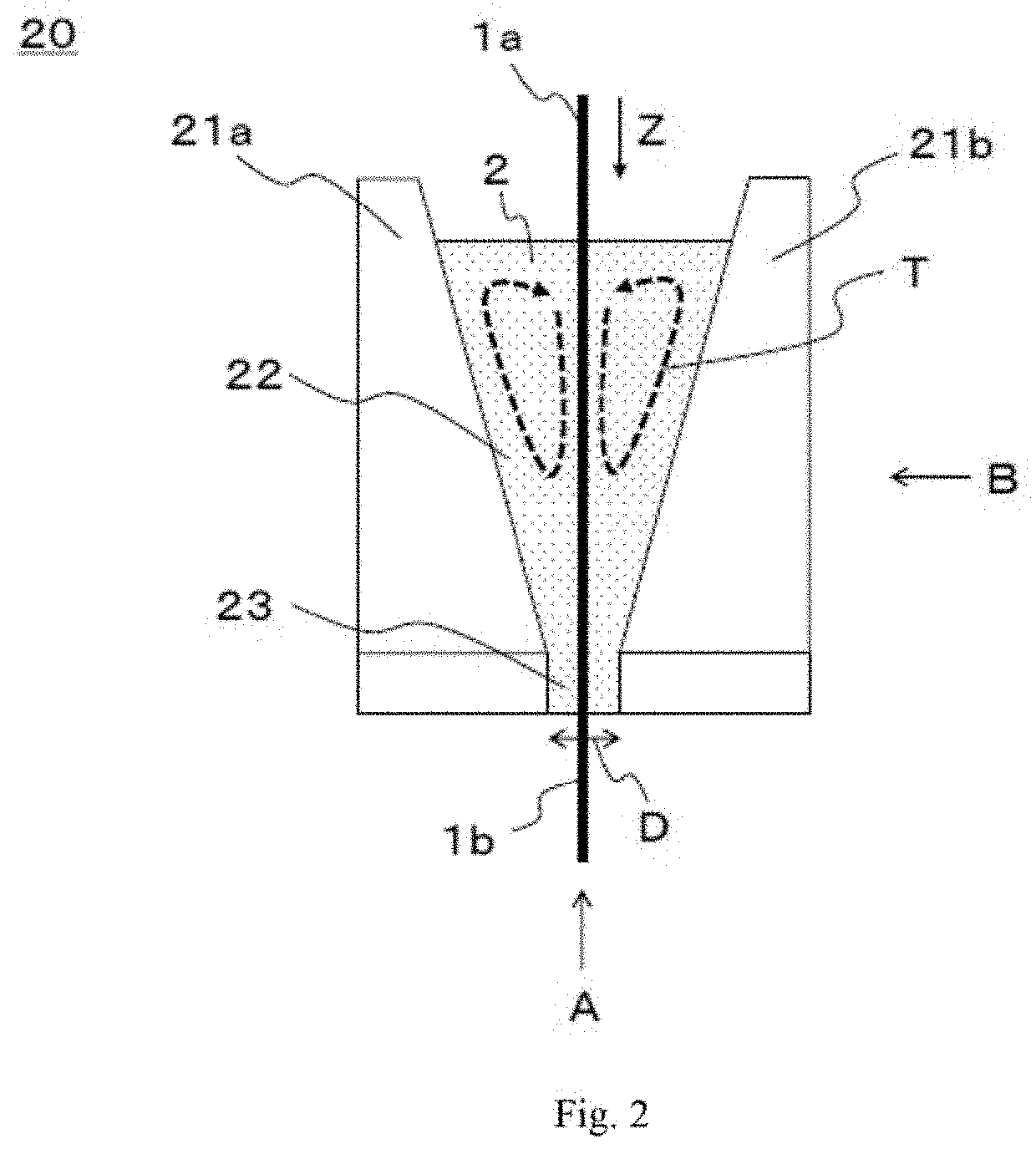

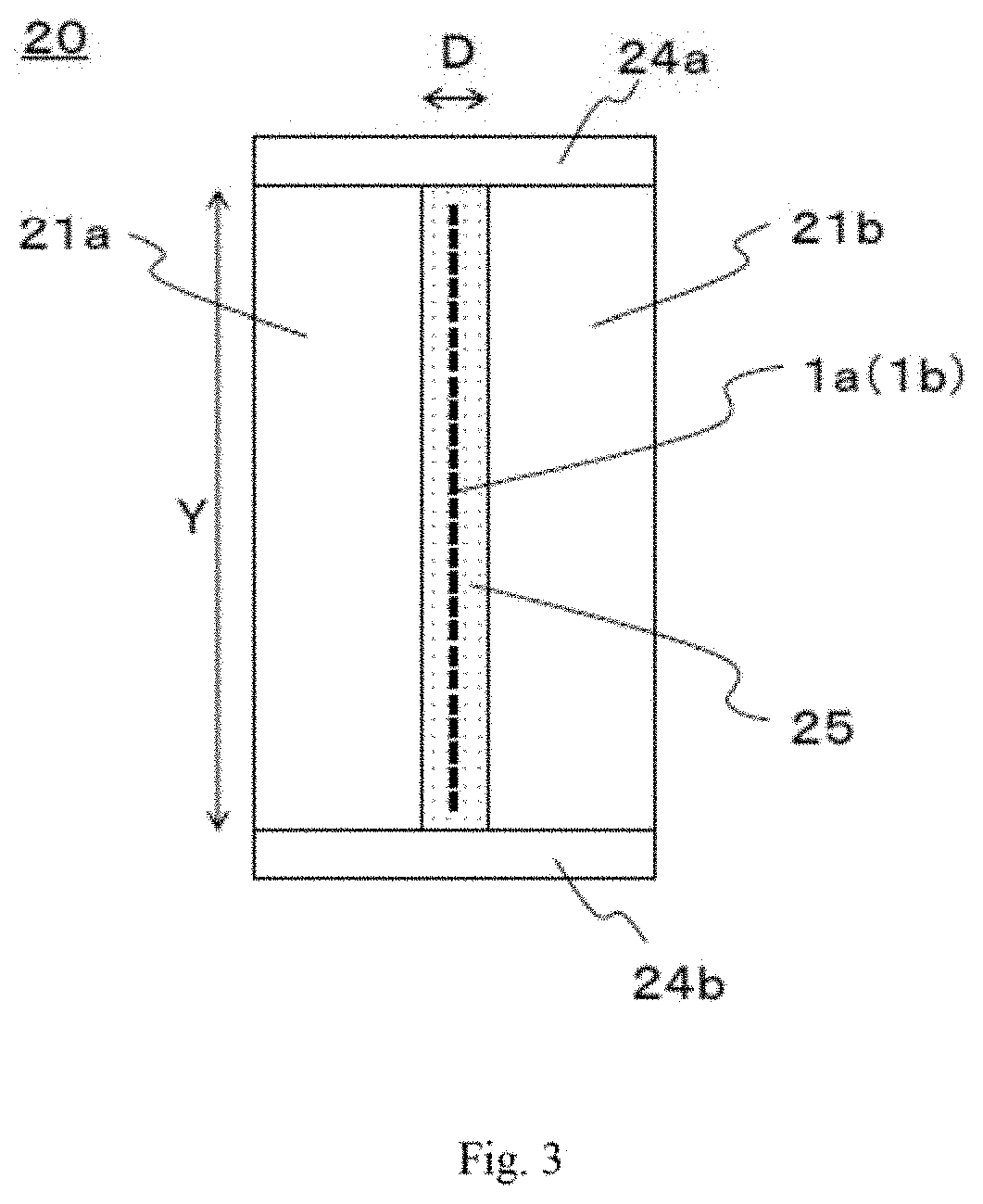

A method is described for producing a prepreg formed by applying a matrix resin to a reinforcing fiber sheet, wherein the method can effect continuous running without clogging due to generated fuzz even at a high running speed and effect efficient impregnation of the reinforcing fiber sheet with a matrix resin. A method of producing a prepreg includes allowing a reinforcing fiber sheet to pass substantially vertically downward through the inside of a coating section storing a matrix resin to obtain a matrix resin-impregnated reinforcing fiber sheet in which the matrix resin is applied to the reinforcing fiber sheet and at least heating the matrix resin-impregnated reinforcing fiber sheet, wherein the coating section includes a liquid pool and a narrowed section which are in communication with each other, wherein the liquid pool has a portion whose cross-sectional area decreases continuously along a running direction of the reinforcing fiber sheet.

Owner:TORAY IND INC

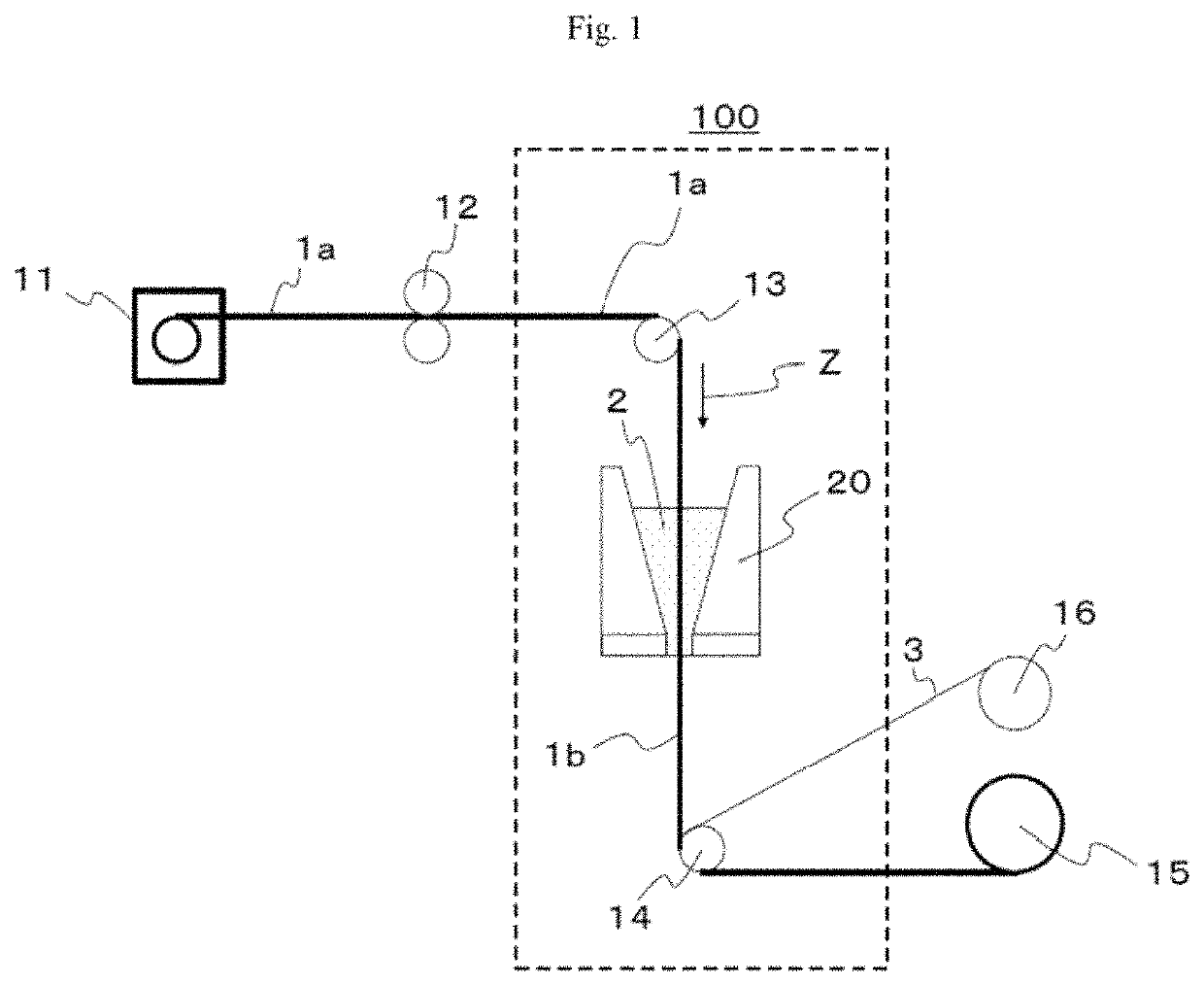

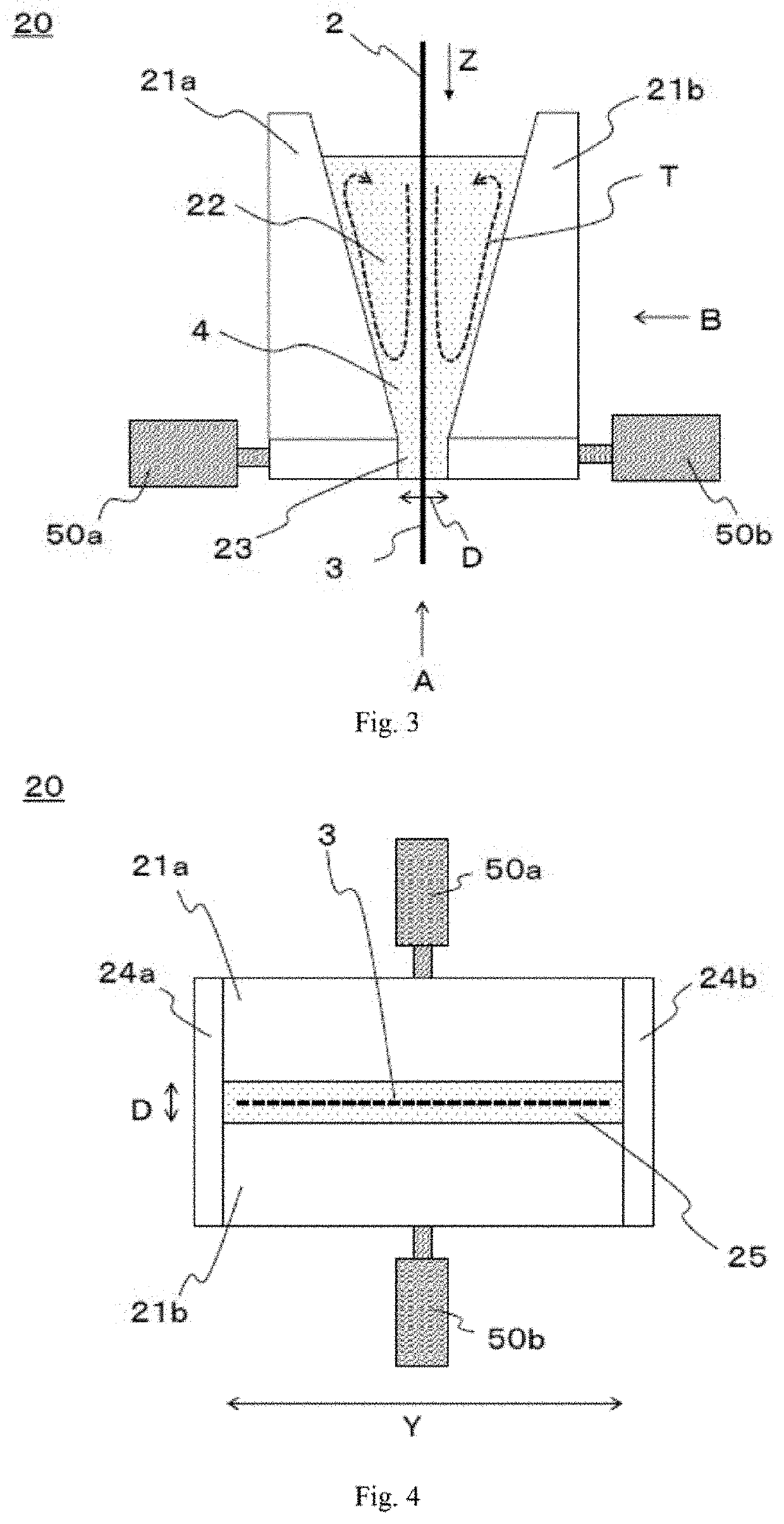

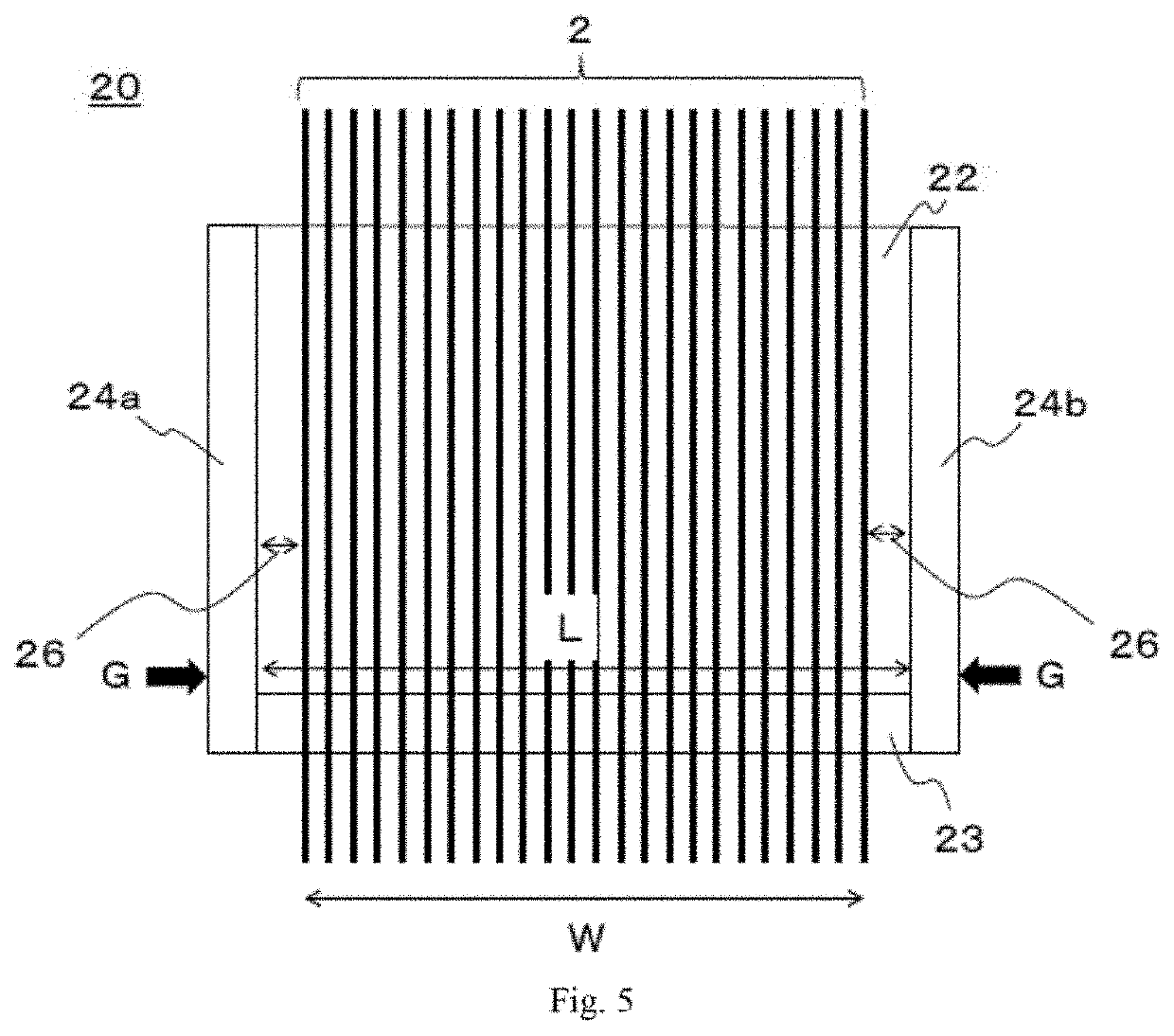

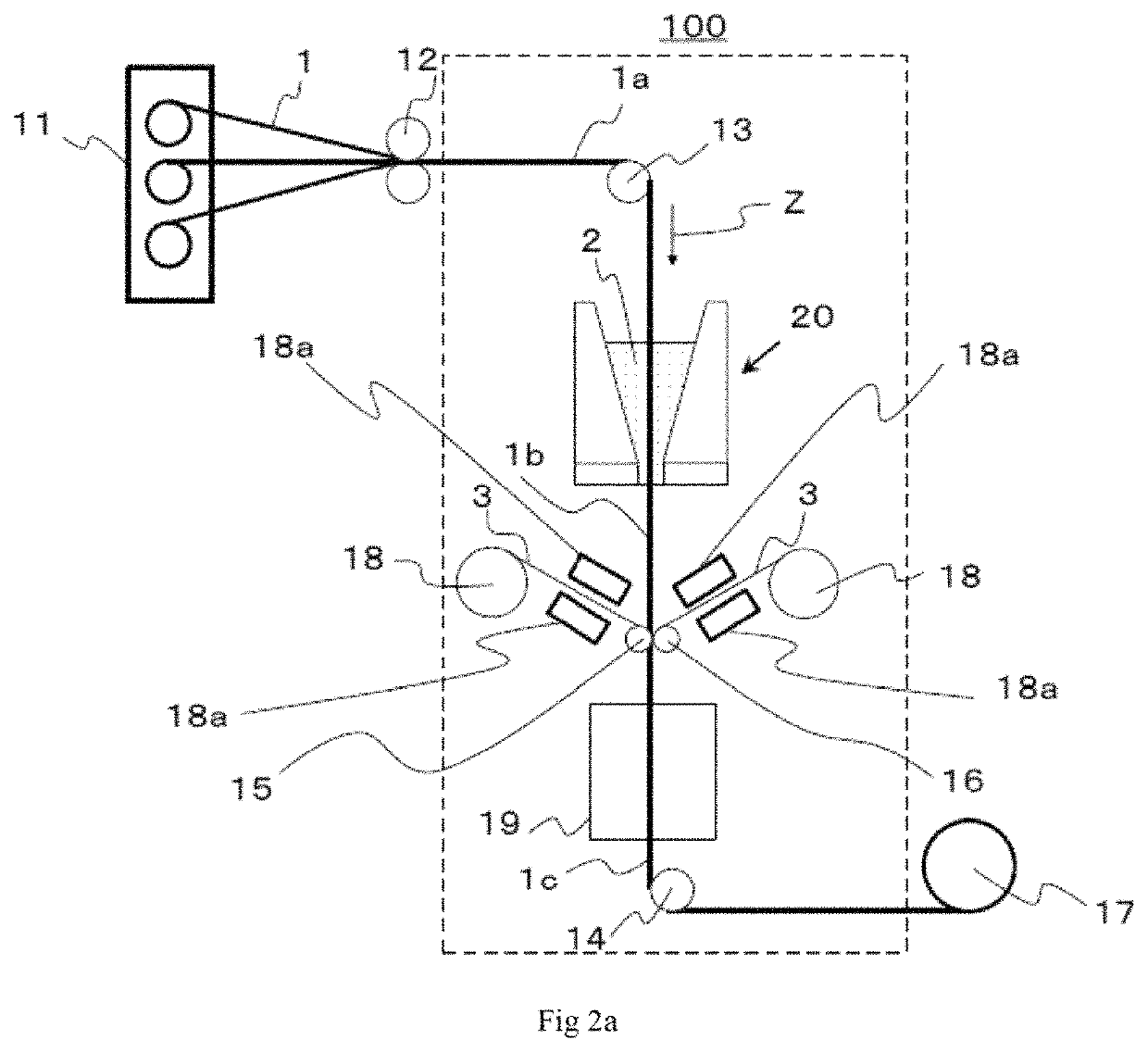

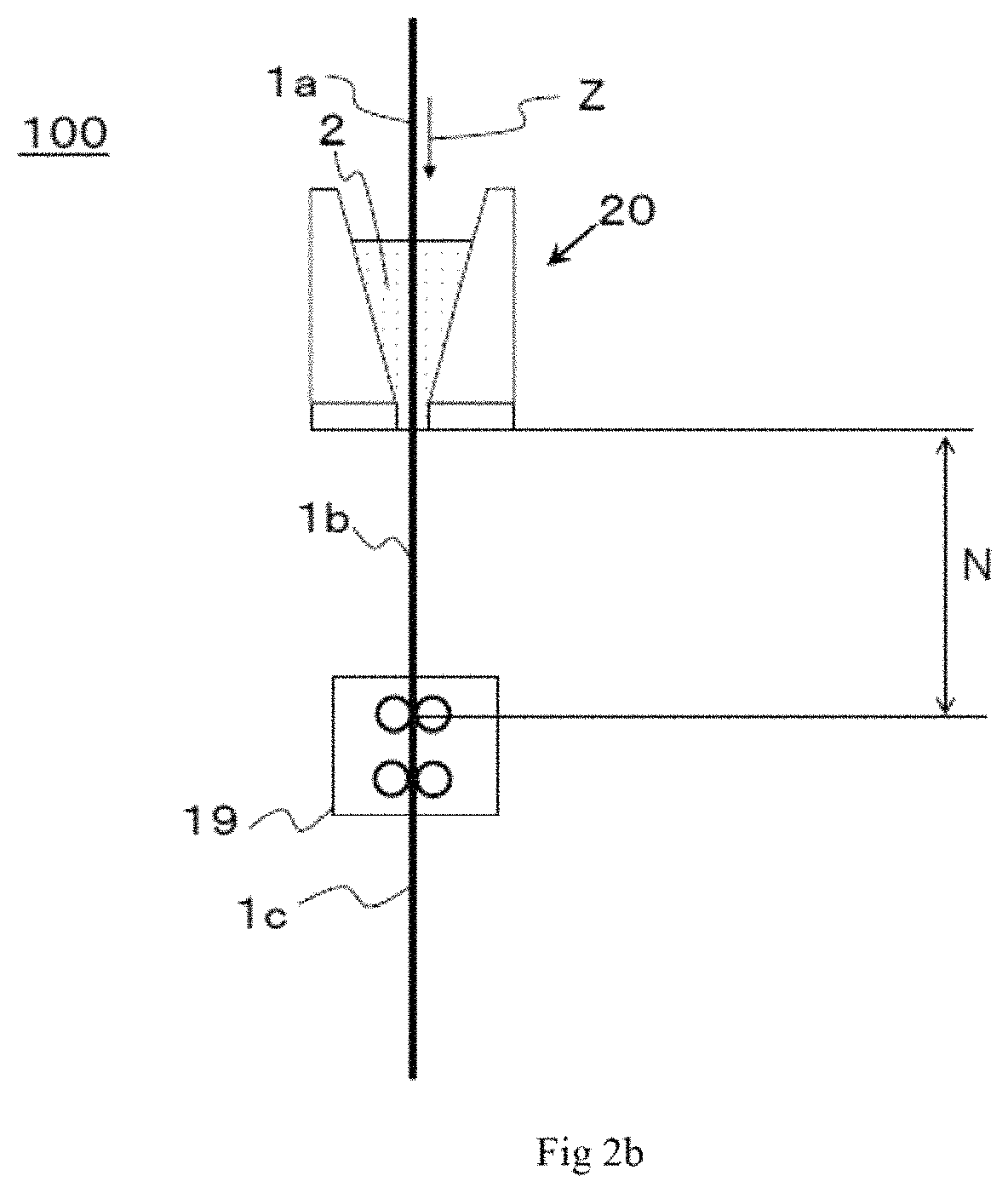

Coating-liquid-impregnated fiber-reinforced fabric, sheet-shaped integrated object, prepreg, prepreg tape, and method for manufacturing fiber-reinforced composite material

ActiveUS20210213649A1Suppress and prevent cloggingImprove productivityLiquid/gas/vapor treatment of indefinite length materialsCoatingsFiber-reinforced compositeMechanical engineering

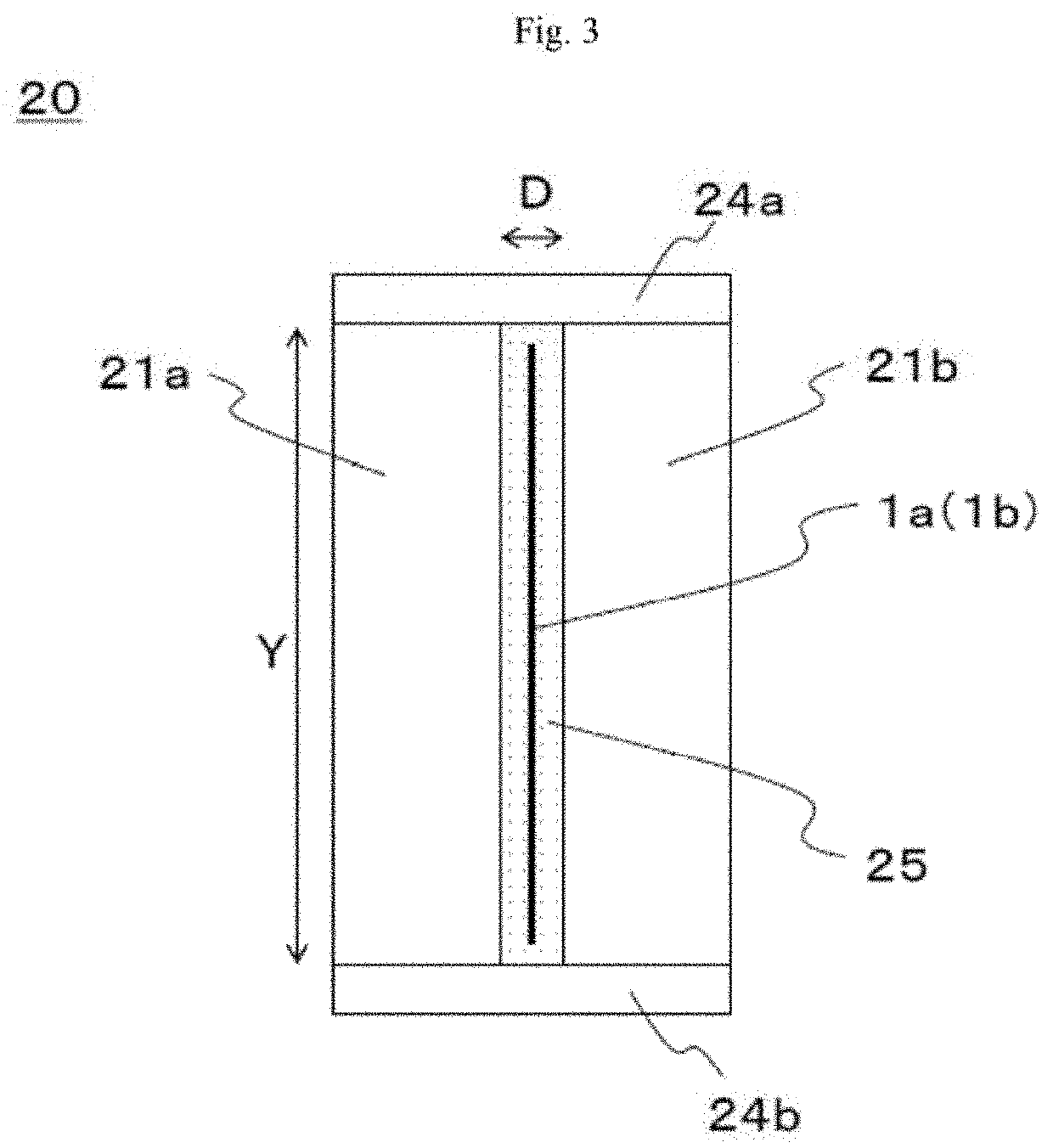

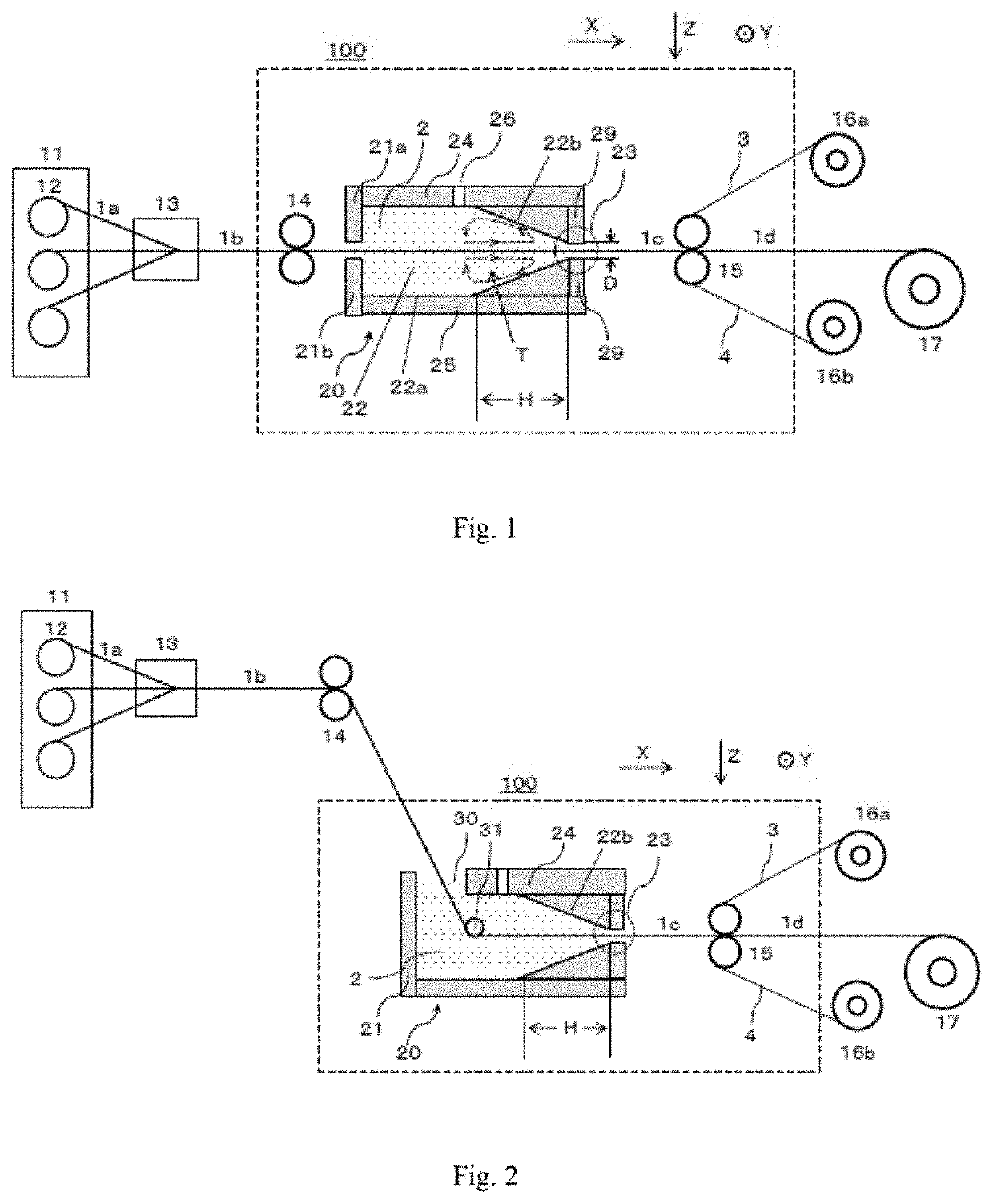

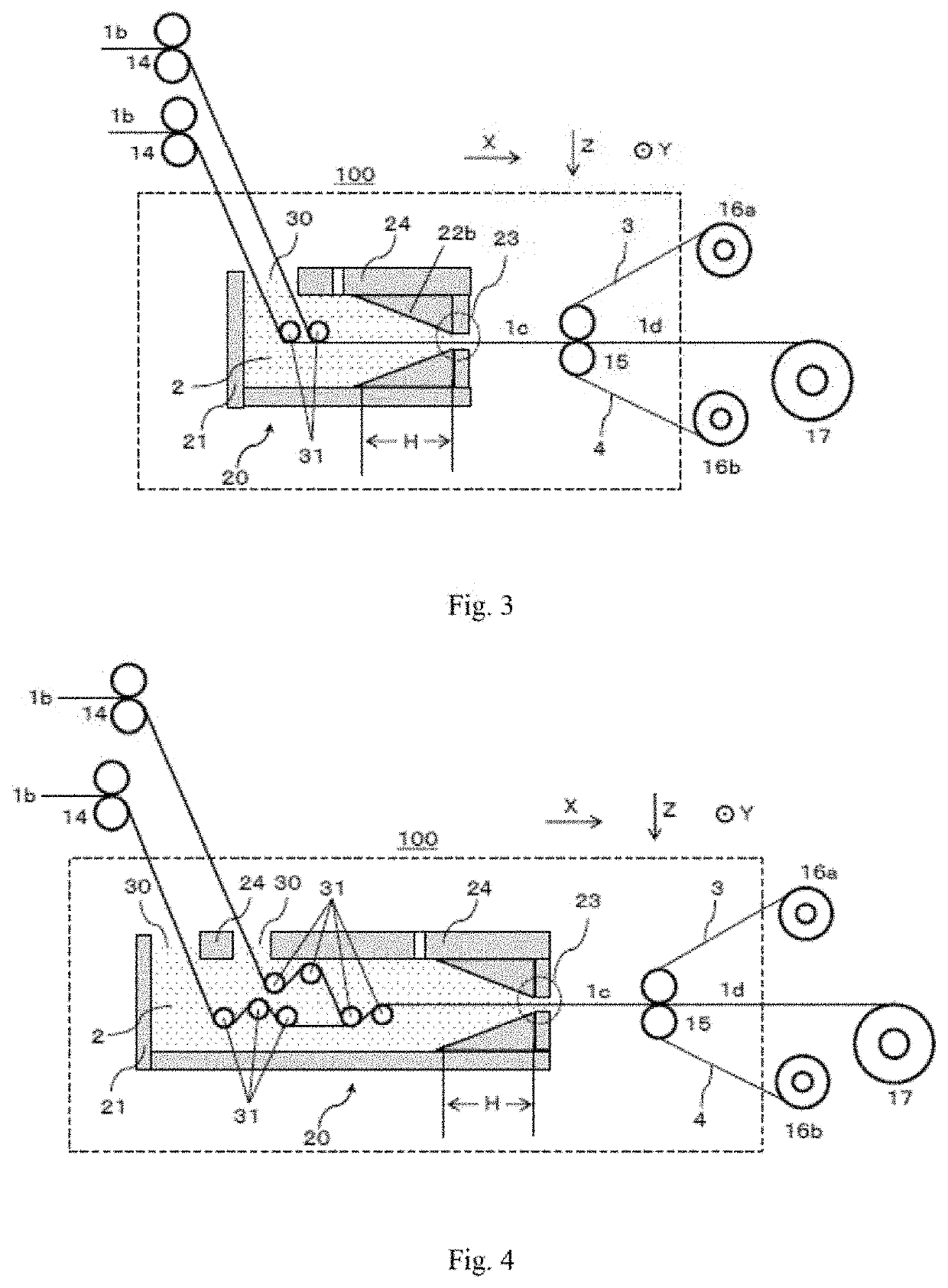

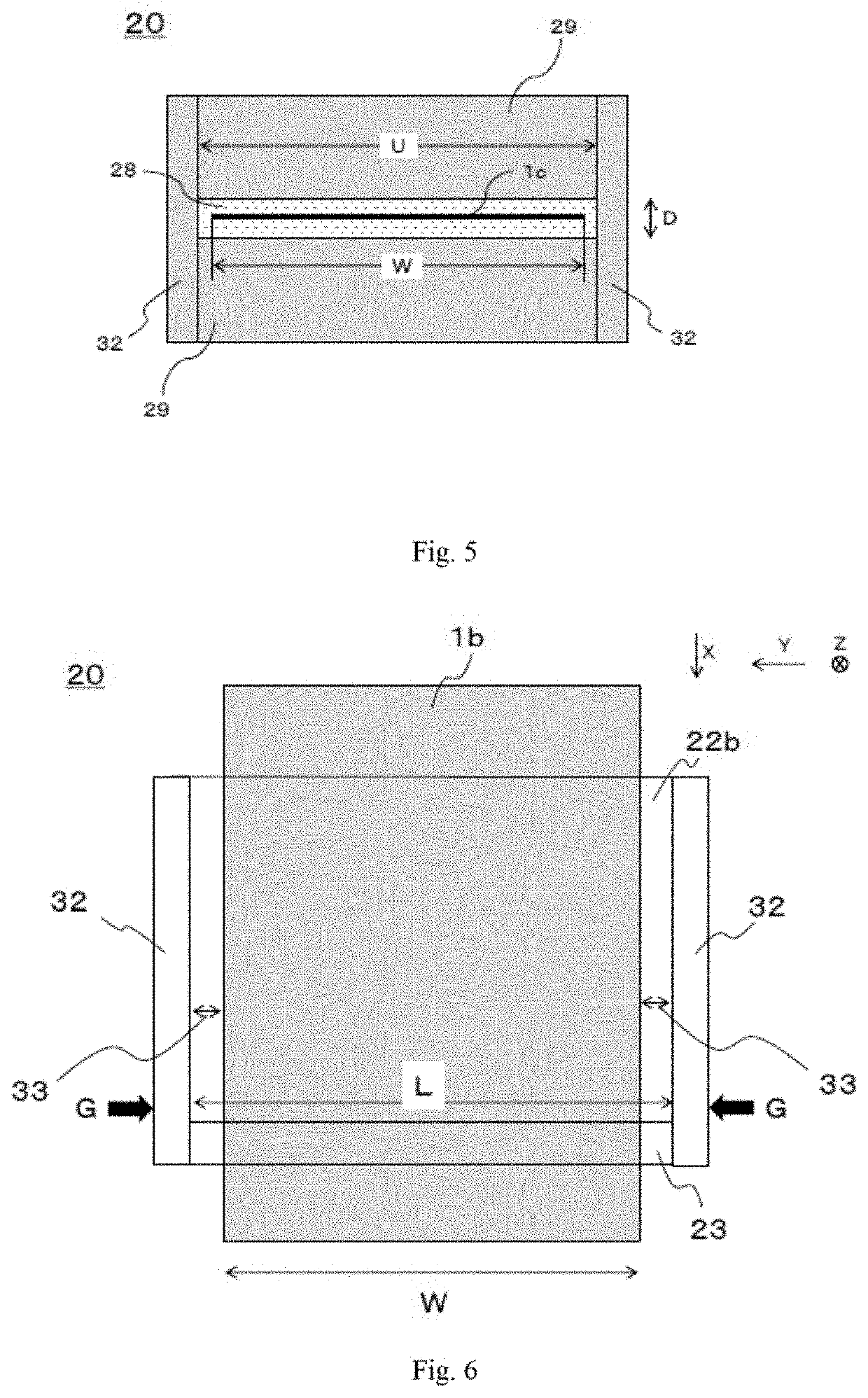

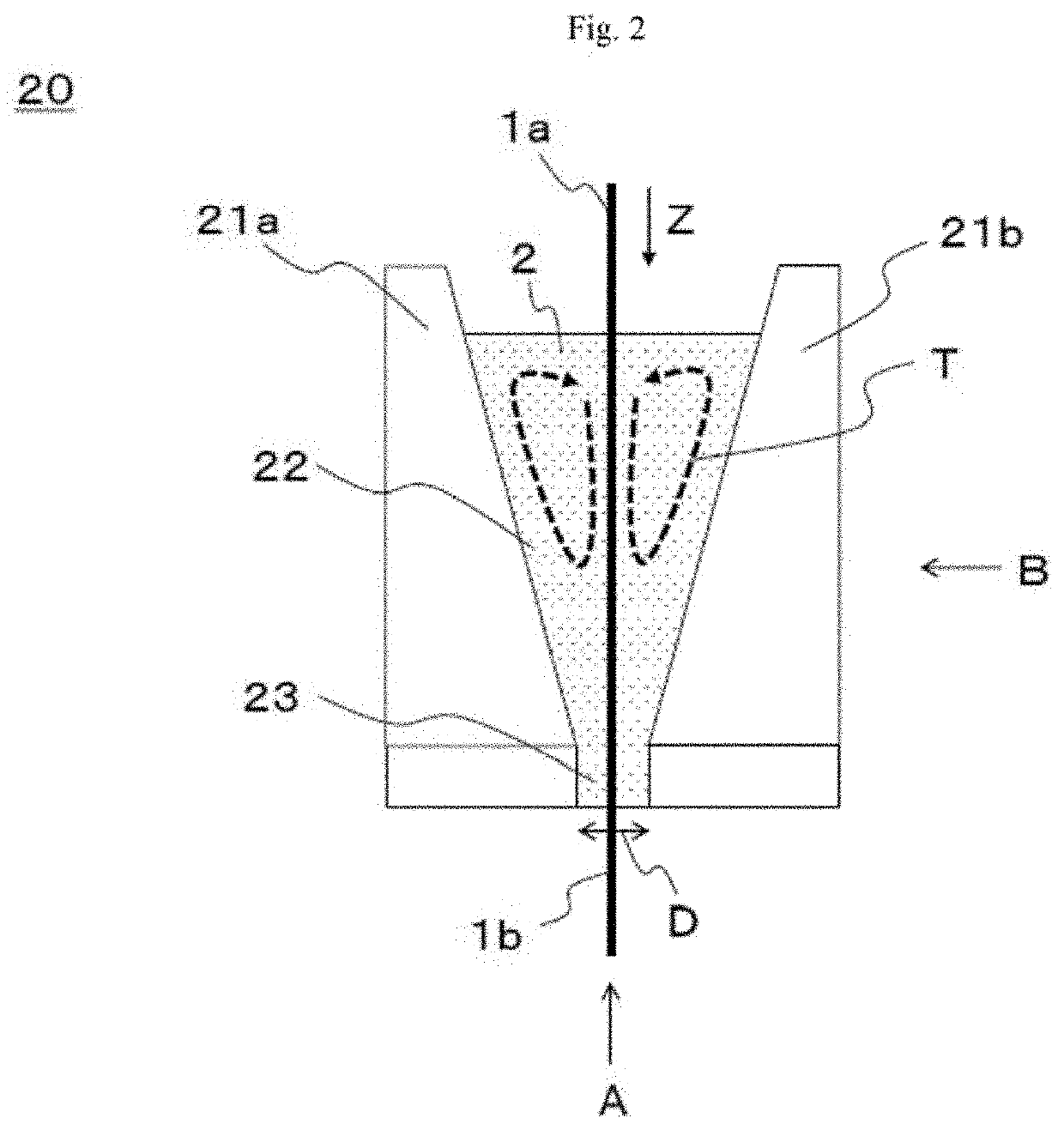

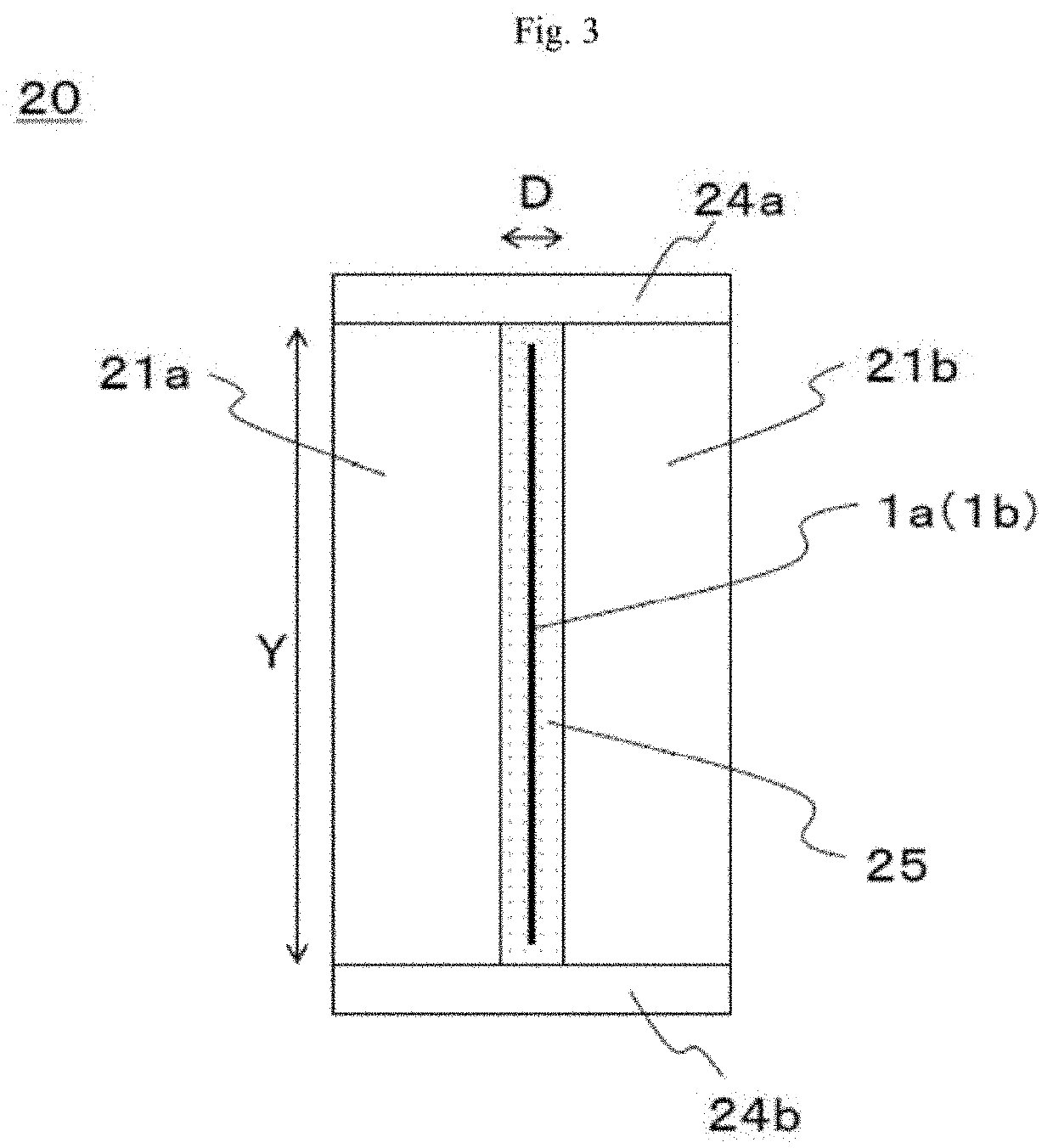

The present invention is a method of producing a coating liquid-impregnated reinforcing fiber fabric 1b, including allowing a reinforcing fiber fabric 1a to pass substantially vertically downward through the inside of a coating section 20 storing a coating liquid 2 to provide the reinforcing fiber fabric 1a with the coating liquid 2; wherein the coating section 20 includes a liquid pool and a narrowed section which are in communication with each other; wherein the liquid pool has a portion whose cross-sectional area decreases continuously along a running direction of the reinforcing fiber fabric 1a, wherein the narrowed section has a slit-like cross-section and has a smaller cross-sectional area than the top side of the liquid pool, and wherein the vertical height of the portion whose cross-sectional area decreases continuously in the liquid pool is 10 mm or more.

Owner:TORAY IND INC

Method for manufacturing prepreg, coating device, and apparatus for manufacturing prepreg

ActiveUS20210301096A1Suppress and prevent cloggingImprove productivityLamination ancillary operationsSynthetic resin layered productsPolymer sciencePolymer chemistry

The present invention relates to a method of producing a prepreg, in which a matrix resin is applied to a reinforcing fiber sheet, where the sheet can continuously run without clogging due to generated fuzz, even at a high running speed, and where the sheet can be efficiently impregnated with the matrix resin. The prepreg is produced by a method which includes a step of allowing a reinforcing fiber sheet to pass horizontally or slantingly through the inside of a coating section storing a matrix resin to apply the matrix resin to the reinforcing fiber sheet, where the coating section includes a liquid pool and a narrowed section which are in communication with each other, where the liquid pool has a portion whose cross-sectional area decreases continuously along a running direction of the reinforcing fiber sheet, and wherein the narrowed section has a slit-like cross-section and has a smaller cross-sectional area than the largest cross-sectional area of the liquid pool.

Owner:TORAY IND INC

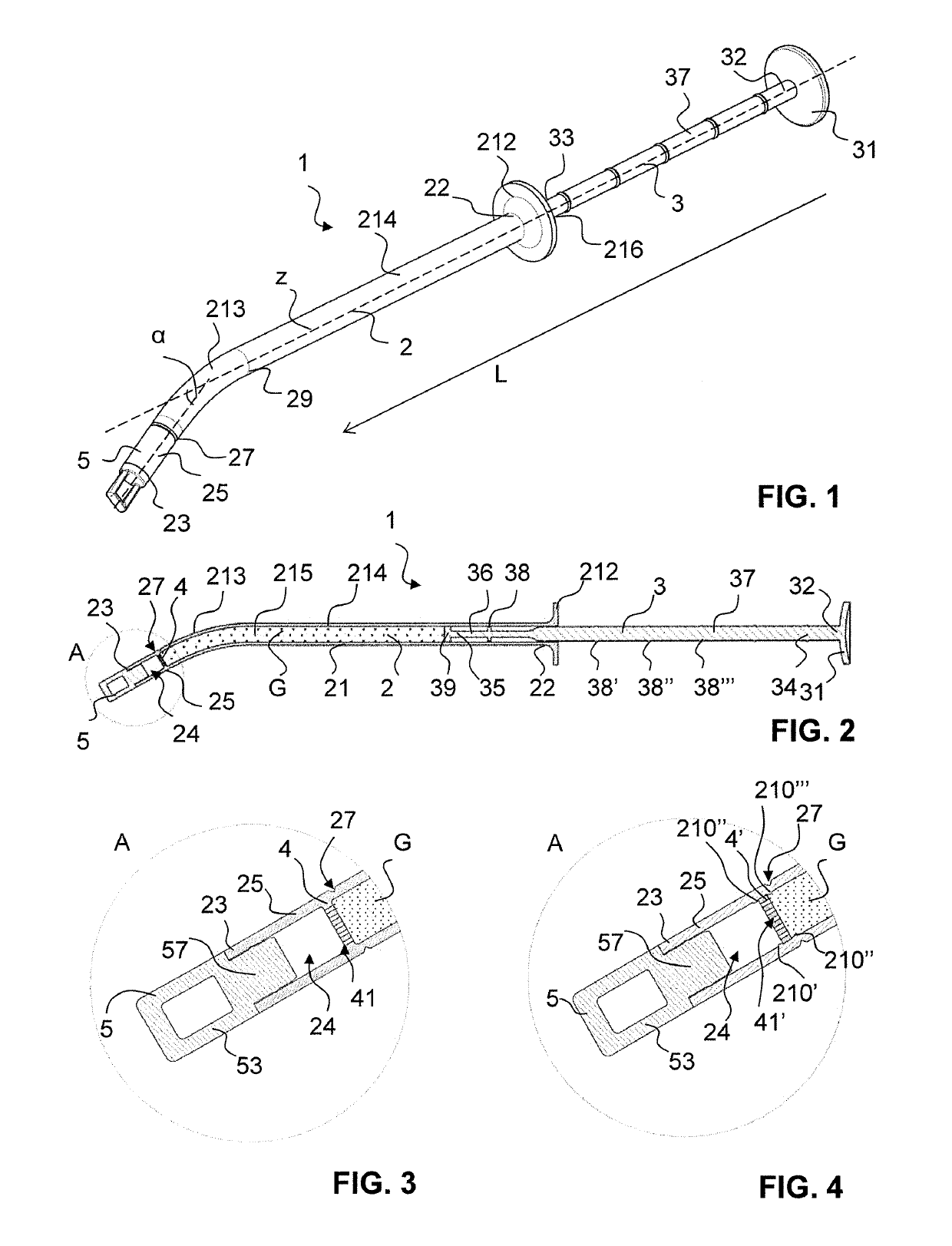

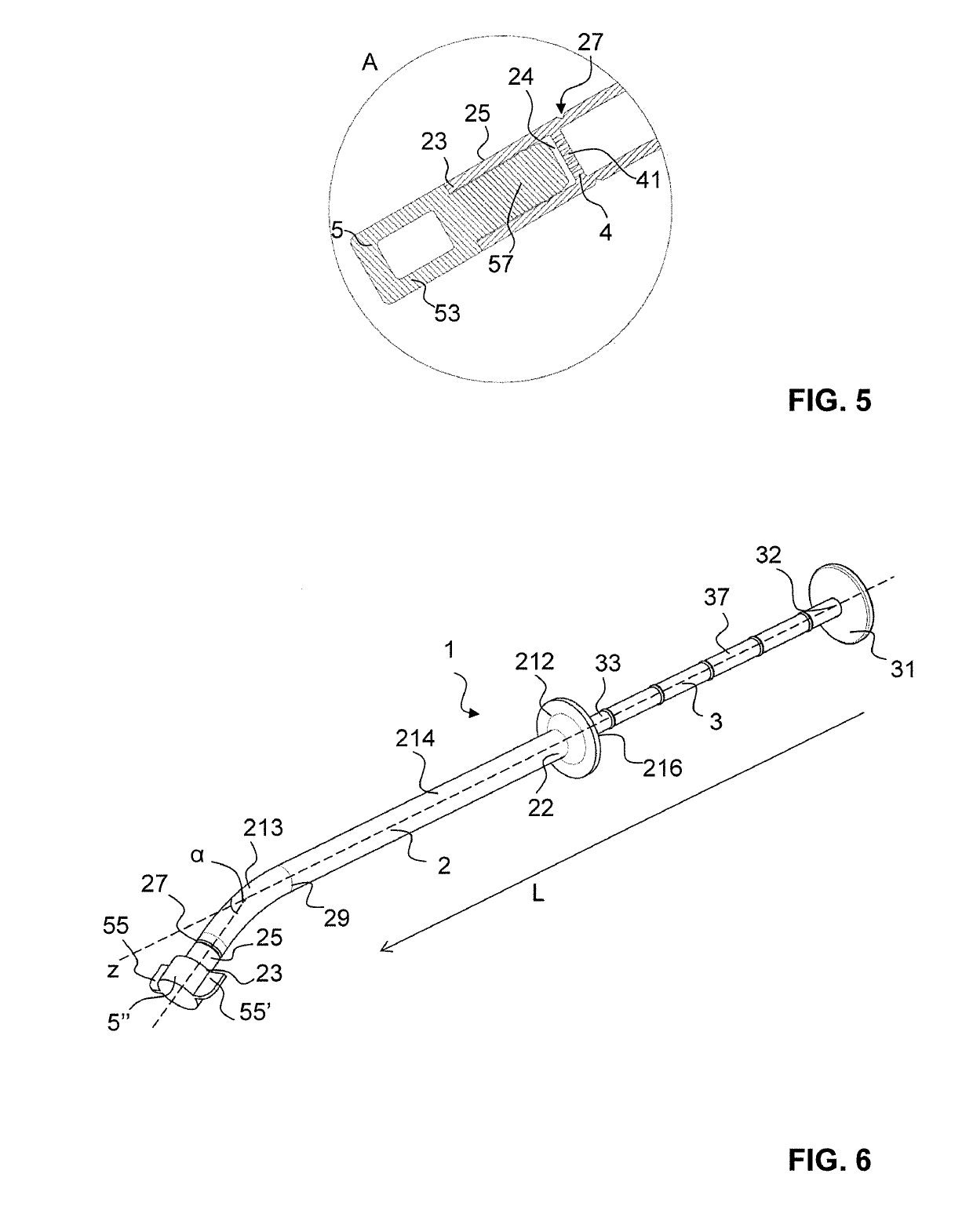

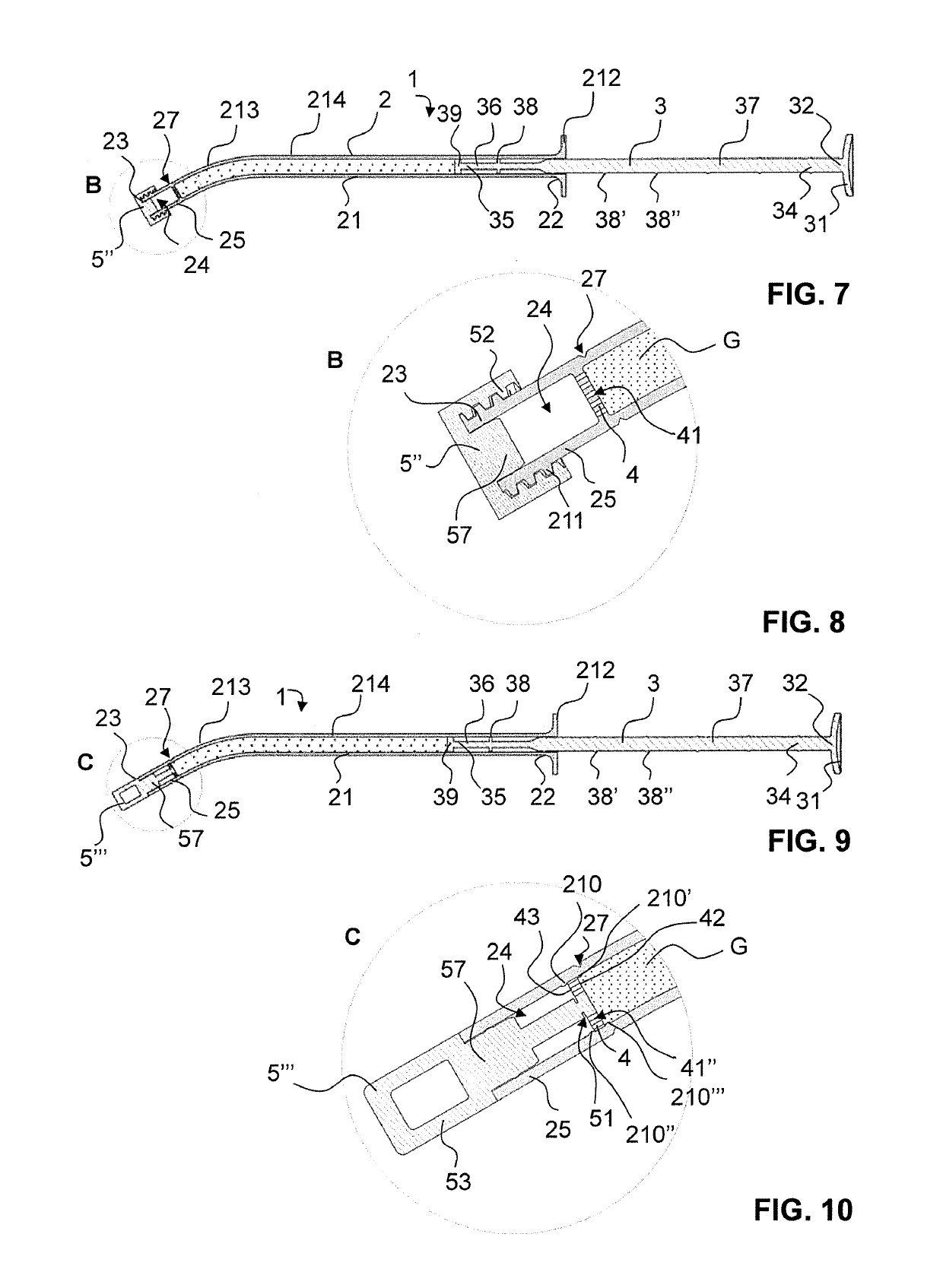

Mixing and discharge system for bone replacement material

InactiveUS20190223931A1Easy to operateSimple and cost-effective manufactureJoint implantsOsteosynthesis devicesBone replacementBreaking point

A mixing and delivery system (1) and a method for impregnating granules (G) with a liquid and for delivering a resulting mixture are specified. The mixing and delivery system (1) has a container (2) for holding the granules. In a distal end region (25) of the container is arranged a separation element (4), which is designed to retain granules but allow liquid to pass through. The container has a predefined breaking point (27) proximal of the separation element (4) so that the distal end region between the predefined breaking point and the distal container end (23) can be broken off from the container together with the separation element (4), thereby creating a delivery opening on the container for delivering the mixture.

Owner:SULZER MIXPAC AG

Coating-liquid-impregnated fiber-reinforced fabric, sheet-shaped integrated object, prepreg, prepreg tape, and method for manufacturing fiber-reinforced composite material

ActiveUS11192280B2Efficient impregnationSuppress generationLiquid/gas/vapor treatment of indefinite length materialsCoatingsFiber-reinforced compositeMechanical engineering

The present invention is a method of producing a coating liquid-impregnated reinforcing fiber fabric 1b, including allowing a reinforcing fiber fabric 1a to pass substantially vertically downward through the inside of a coating section 20 storing a coating liquid 2 to provide the reinforcing fiber fabric 1a with the coating liquid 2; wherein the coating section 20 includes a liquid pool and a narrowed section which are in communication with each other; wherein the liquid pool has a portion whose cross-sectional area decreases continuously along a running direction of the reinforcing fiber fabric 1a, wherein the narrowed section has a slit-like cross-section and has a smaller cross-sectional area than the top side of the liquid pool, and wherein the vertical height of the portion whose cross-sectional area decreases continuously in the liquid pool is 10 mm or more.

Owner:TORAY IND INC

Method and device for the infiltration of a structure of a porous material by chemical vapour deposition

ActiveUS8545939B2Efficient impregnationSpecial surfacesChemical vapor deposition coatingGas phaseCompound (substance)

A method and a device for infiltration of a structure made of a porous material by chemical vapor deposition. According to the method, a first face of the porous material structure is exposed to a gaseous flow, and the second face is maintained at least partially free from any contact.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Prepreg manufacturing method and manufacturing apparatus

The present invention provides an apparatus for producing a prepreg, for applying a coating liquid to a reinforcing fiber sheet, the apparatus including: a coating section including: a liquid pool storing the coating liquid and having a portion whose cross-sectional area decreases continuously and vertically downward, and a narrowed section having a slit-like outlet in communication with the lower end of the liquid pool; a running mechanism for allowing the reinforcing fiber sheet to run vertically downward and be introduced into the coating section; a take-up mechanism for taking up the reinforcing fiber sheet downward from the coating section; wall constituent members opposed to each other in the thickness direction of the reinforcing fiber sheet to form the narrowed section; and an external force application mechanism for applying an external force to the wall constituent members in the thickness direction of the reinforcing fiber sheet.

Owner:TORAY IND INC

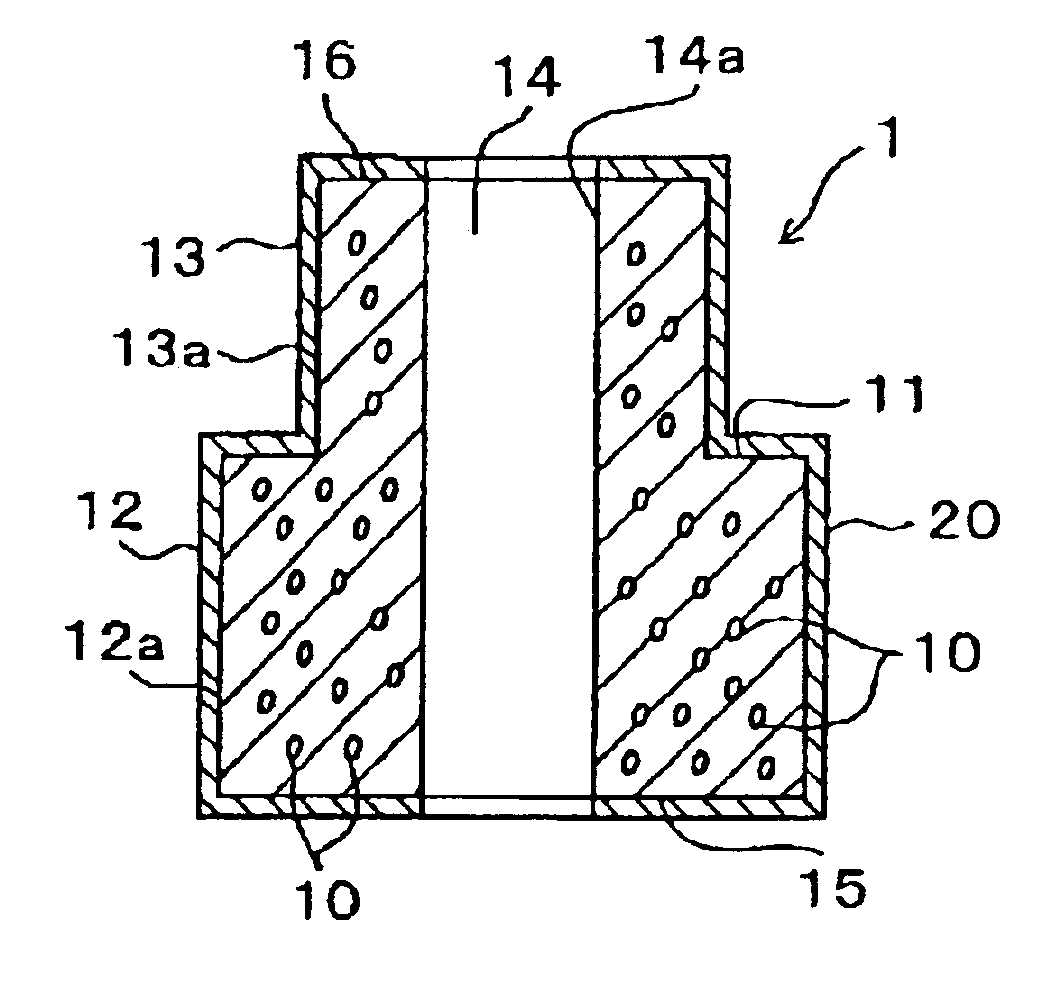

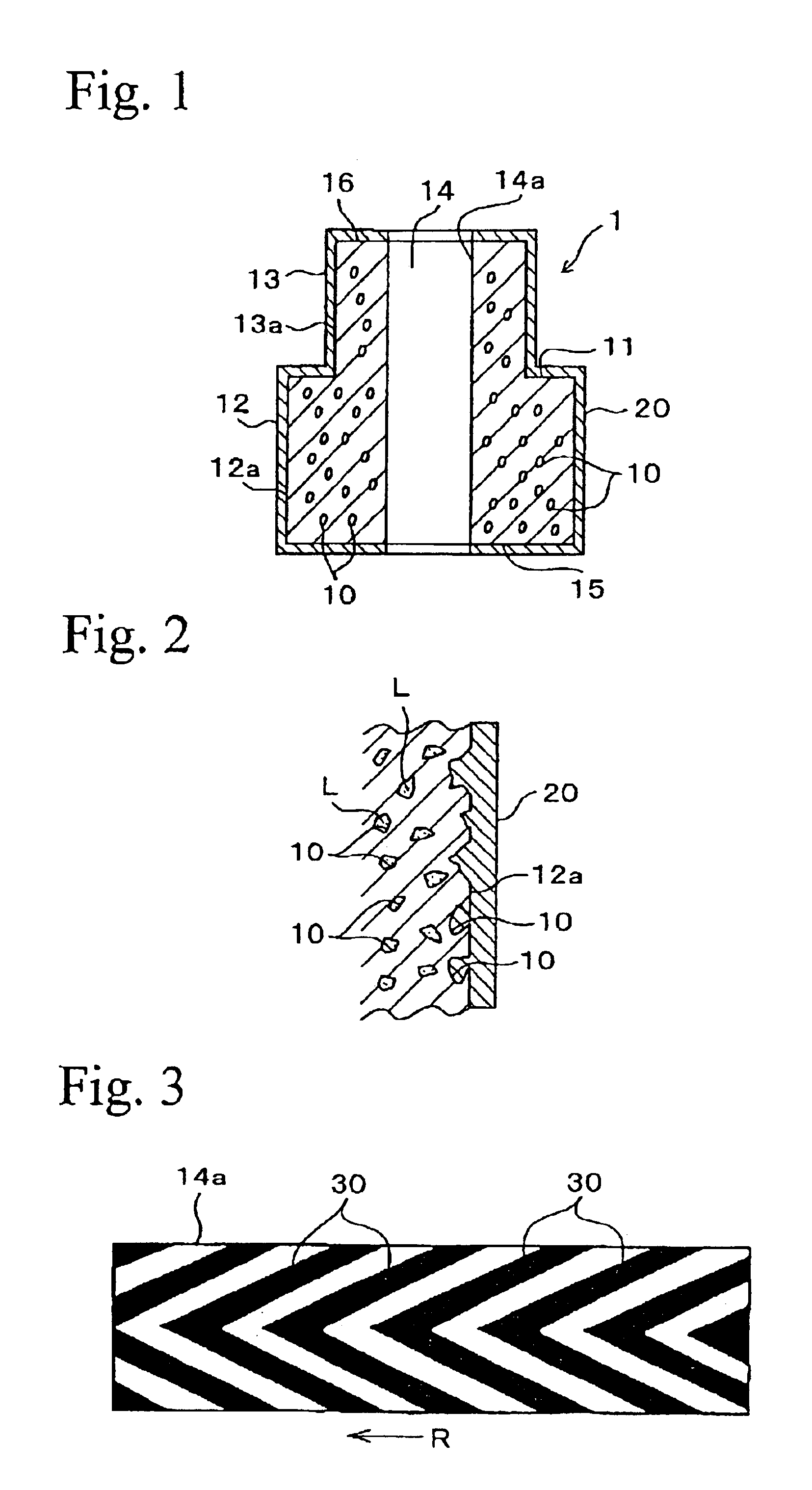

Sintered bearing and production method therefor

InactiveUS6951423B2Improve corrosion resistanceObtaining performanceShaftsMetal-working apparatusResin coatingBearing surface

A sintered bearing is produced by a production method comprising: compacting a metallic raw material powder into a bearing green compact; sintering the green compact into a sintered compact; forming a resin coating 20 over the entire surface of the sintered compact; removing the resin coating 20 on a bearing surface 14a of the sintered compact; and impregnating a lubricating fluid L through the bearing surface 14a from which the resin coating 20 is removed.

Owner:MINEBEA CO LTD +1

Production method for prepreg, prepreg tape, and fiber reinforced composite material, and coating device

ActiveUS20210292496A1Suppress and prevent cloggingImprove productivityCoatingsFiber-reinforced compositeCoating

A method of producing a prepreg is described, in which a matrix resin is applied to a reinforcing fiber sheet in which the sheet can continuously run without clogging due to generated fuzz even at a high running speed and where the reinforcing fiber sheet can be efficiently impregnated with the matrix resin. A method of producing a prepreg includes allowing a reinforcing fiber sheet to pass substantially vertically downward through the inside of a coating section storing a matrix resin to apply the matrix resin to the reinforcing fiber sheet; and then applying a resin film to a primary impregnate prepreg withdrawn from the coating section.

Owner:TORAY IND INC

A kind of fast impregnation equipment of Chinese medicine decoction pieces and automatic impregnation method of Chinese medicine decoction pieces

ActiveCN109157415BShorten the soaking timePrevent corruptionPharmaceutical product form changeMedicinal herbsPhysical chemistry

A Chinese medicine in that form of decoction slice is prepared from 11 Chinese-medicinal material through immersing them in decoction slices, immersing them in water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them withwater, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them, mixing them with water, mixing them, mixingthem with water, mixing them, mixing, mixing, mixing, mixing, mixing, mixing and mixing. The invention can solve the problem that when the prior Chinese medicinal decoction pieces are impregnated, Toolong impregnation time, It usually takes a long time to get there, and soaked for a long time, Chinese herbal slices are prone to decay, Traditional Chinese medicine slices usually float above the water surface when impregnated, impregnation is not complete, traditional Chinese medicine slices usually accumulate together when impregnated, affecting the impregnation effect, complicated operation,slow impregnation, low efficiency and other difficult problems, can realize the function of automatic and high-efficient impregnation of traditional Chinese medicine slices, and has the advantages ofsimple operation, rapid impregnation, high efficiency and so on.

Owner:安徽冯了性中药材饮片有限公司

Liquid Immersion Device

InactiveCN103315369BEfficient impregnationPrevent agglutinationFeeding-stuffPulp and paper industryExhaust pipe

The invention provides a liquid impregnation device, which can make liquids uniformly impregnated in particles without being limited by the types of liquids and particles and adjust the particle oil impregnation rate in a high-precision way. The liquid impregnation device (1) comprises a roller (3) accommodating the particles; a frame (2) supporting the roller (3) to freely rotate; nozzles (11, 11..) spraying oil towards the particles; oil supply pipes (12, 12...) supplying oil to the nozzles (11, 11..); an electric motor (5) driving the roller (3) to rotate; an exhaust pipe (14) reducing pressure inside the roller (3); and a cylinder (21) making the roller (3) swing in high speed. A protruding separation projection (9) protruding towards the inner side of the roller (3) is arranged inside the roller (3). Agglutination prevention walls (10a-10e) are vertically arranged on the upper surface of the separation projection (9). Agglutination prevention walls (10f-10h) are further vertically arranged on the lower surface of the separation projection (9).

Owner:OMC

Fiber substrate stacking method, manufacturing method of roll of fiber substrate group, fiber substrate group, and aircraft

ActiveUS10022918B2Fully impregnatedIncrease flexibilityLaminationEfficient propulsion technologiesFiber bundleOptoelectronics

Owner:MITSUBISHI AIRCRAFT

Wet sheet pillow package

ActiveCN102119109BSpeed up removalImprove stabilityBathroom accessoriesFlat article dispensingEngineeringMechanical engineering

Provided is a wet sheet pillow package wherein a tray that individually arranges and contains individually-folded wet sheets is pillow-packaged, an opening that serves as a wet sheet removal opening is provided in the approximate center of the bottom of the tray, the opening is located on the flat part of the side opposite the butt seam of the pillow package, and a wet sheet removal opening is provided in said flat part. The wet sheet pillow package can adequately impregnate wet sheets economically using the minimum required amount of impregnating solution.

Owner:中村宪司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com