Long glass fiber reinforced polypropylene material adopting foaming technique and preparation method thereof

A technology of long glass fiber and polypropylene materials, applied in the field of materials, can solve the problems of reducing the service life of equipment, high frictional resistance, and endangering human health, and achieve the effect of reducing contact probability, reducing traction resistance, and facilitating impregnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

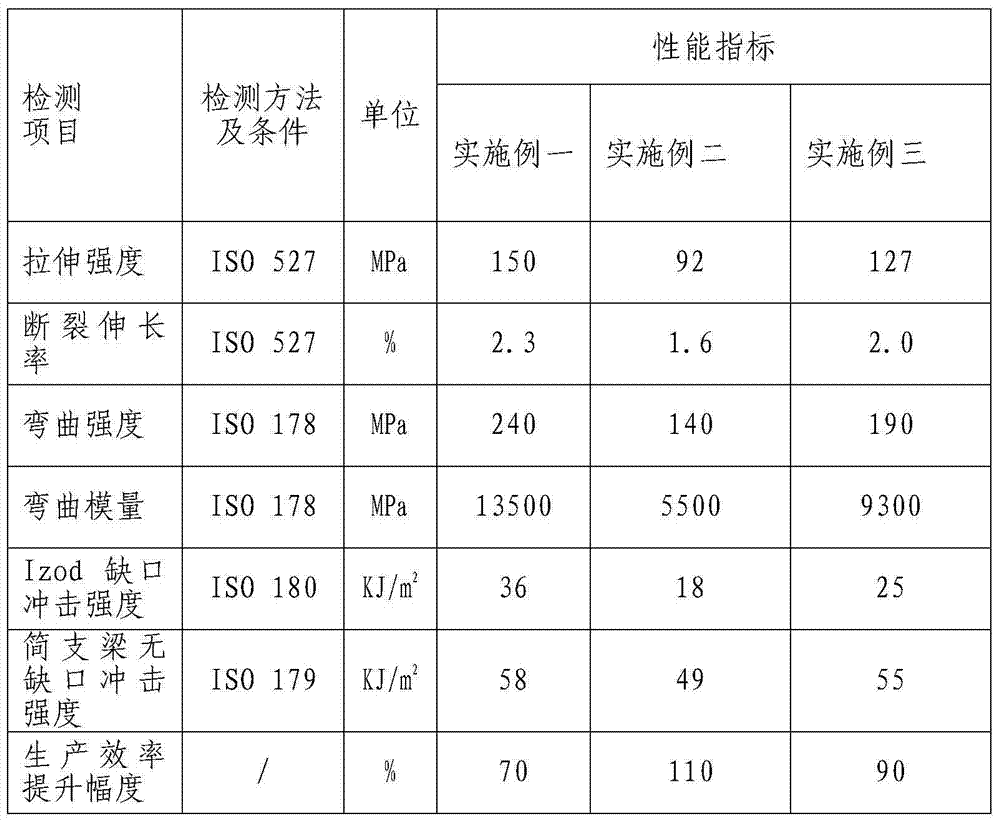

Embodiment 1

[0018] In this example, the proportioning is carried out according to the following mass percentage composition: commercially available high-fluidity polypropylene (melt index 30g / 10min) is 35wt%, and commercially available environmentally friendly compatibilizer (low-odor maleic anhydride grafted PP) is 4wt% , commercially available chemical blowing agent azodicarbonamide 1wt%.

[0019] The above-mentioned raw material components are prepared in the following way,

[0020] Step 1. First, add the above-mentioned materials into a high-speed mixer and stir evenly;

[0021] Step 2. Add the mixture obtained in the first step into the twin-screw extruder. The temperature of the twin-screw extruder has 8 sections. The extrusion temperature of the first section and the second section is 160-200°C. The outlet temperature is 200-220°C; the pressure is 12MPa, melted and mixed by an extruder, metered stably by a metering pump, and continuously sent to the dipping mold with a temperature...

Embodiment 2

[0024] In this example, the proportioning is carried out according to the following mass percentage composition: commercially available high-fluidity polypropylene (melt index 50g / 10min) is 70wt%, and commercially available environmentally friendly compatibilizer (low-odor maleic anhydride grafted PP) is 2wt% , commercially available chemical blowing agent azodicarbonamide 3wt%.

[0025] The above-mentioned raw material components are prepared in the following way,

[0026] Step 1. First, add the above-mentioned materials into a high-speed mixer and stir evenly;

[0027] Step 2. Add the mixture obtained in the first step into the twin-screw extruder. The temperature of the twin-screw extruder has 8 sections. The extrusion temperature of the first section and the second section is 160-200°C. The outlet temperature is 200-220°C; the pressure is 18MPa, melted and mixed through the extruder, metered stably by the metering pump, and continuously sent to the dipping mold with the t...

Embodiment 3

[0030] In this example, the proportioning is carried out according to the following mass percentage composition: commercially available high-fluidity polypropylene (melt index 100g / 10min) is 53wt%, and commercially available environmentally friendly compatibilizer (low-odor maleic anhydride grafted PP) is 5wt% , commercially available chemical blowing agent azodicarbonamide 2wt%.

[0031] The above-mentioned raw material components are prepared in the following way,

[0032] Step 1. First, add the above-mentioned materials into a high-speed mixer and stir evenly;

[0033] Step 2. Add the mixture obtained in the first step into the twin-screw extruder. The temperature of the twin-screw extruder has 8 sections. The extrusion temperature of the first section and the second section is 160-200°C. The outlet temperature is 200-220°C; the pressure is 16MPa, melted and mixed by the extruder, metered stably by the metering pump, and continuously sent to the dipping mold with the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com