Liquid Immersion Device

A liquid impregnation and liquid technology, applied in the direction of feed, food science, application, etc., can solve the problems of particle crushing and pulverization, impregnation of oil and other liquids, difficulty in oil ratio, etc., to prevent uneven impregnation, inhibit agglutination, and high The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

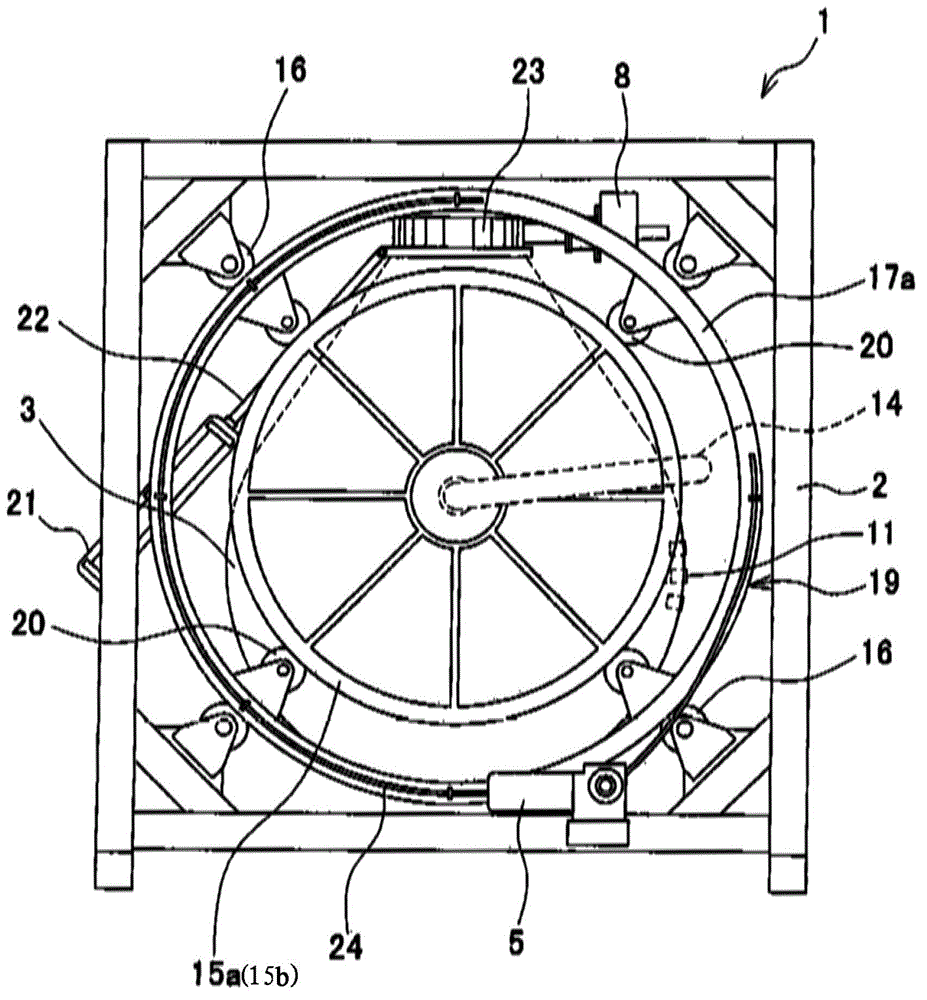

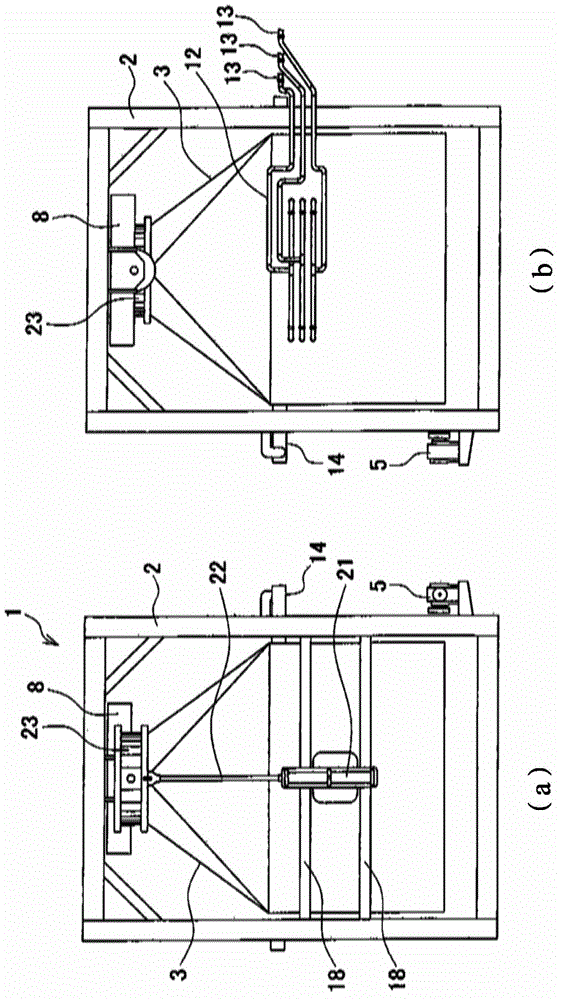

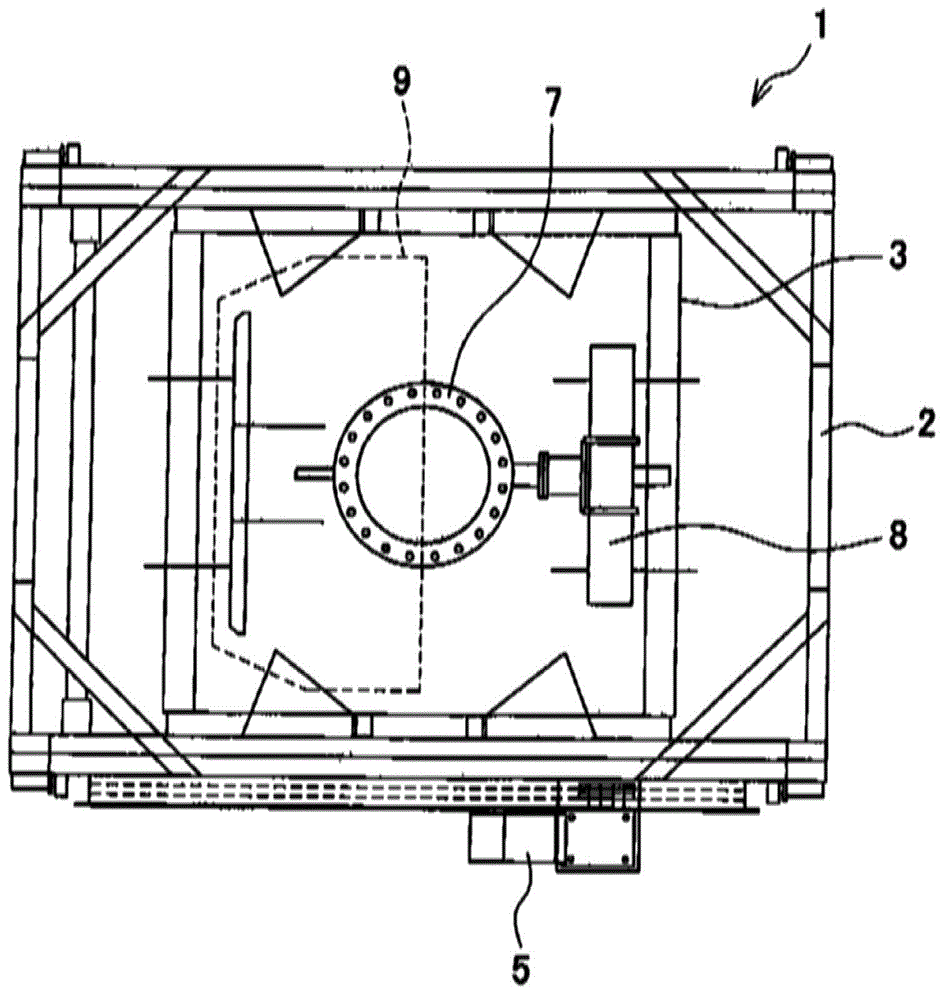

[0032] (Structure of liquid immersion device)

[0033] Hereinafter, an embodiment in which the liquid impregnation device of the present invention is used as an apparatus for impregnating fats and oils (liquid) into feed pellets will be described in detail based on the drawings. Figure 1 ~ Figure 3 A liquid immersion device is shown. The liquid immersion device 1 includes: a drum 3 for accommodating particles; a frame 2, which supports the drum 3 in a way that the drum 3 can rotate around a horizontal axis; nozzles 11, 11... , Used to spray grease to the particles contained in the drum 3; as a liquid supply device, the oil supply pipes 12, 12... are used to supply grease to the nozzles 11, 11...; as a driving device, the motor 5 is used to drive the drum 3 Rotation; The exhaust pipe 14 as a decompression device is used to decompress the drum 3; and the air cylinder 21 is used to make the drum 3 swing at a high speed.

[0034] By welding the metal plate, the drum 3 is formed in a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com