Dental cord using nanofiber conjugate yarn, and manufacturing method therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

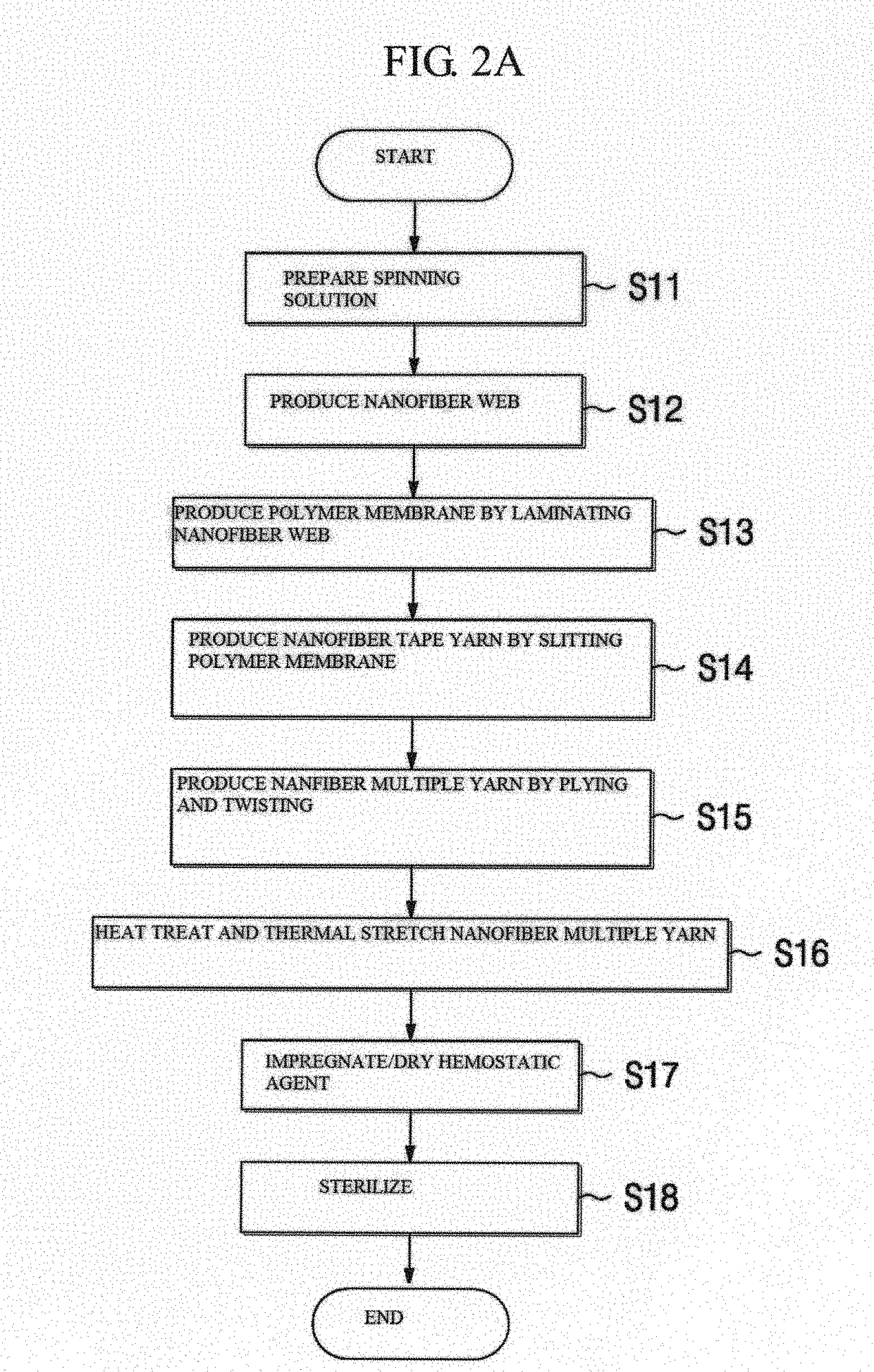

Method used

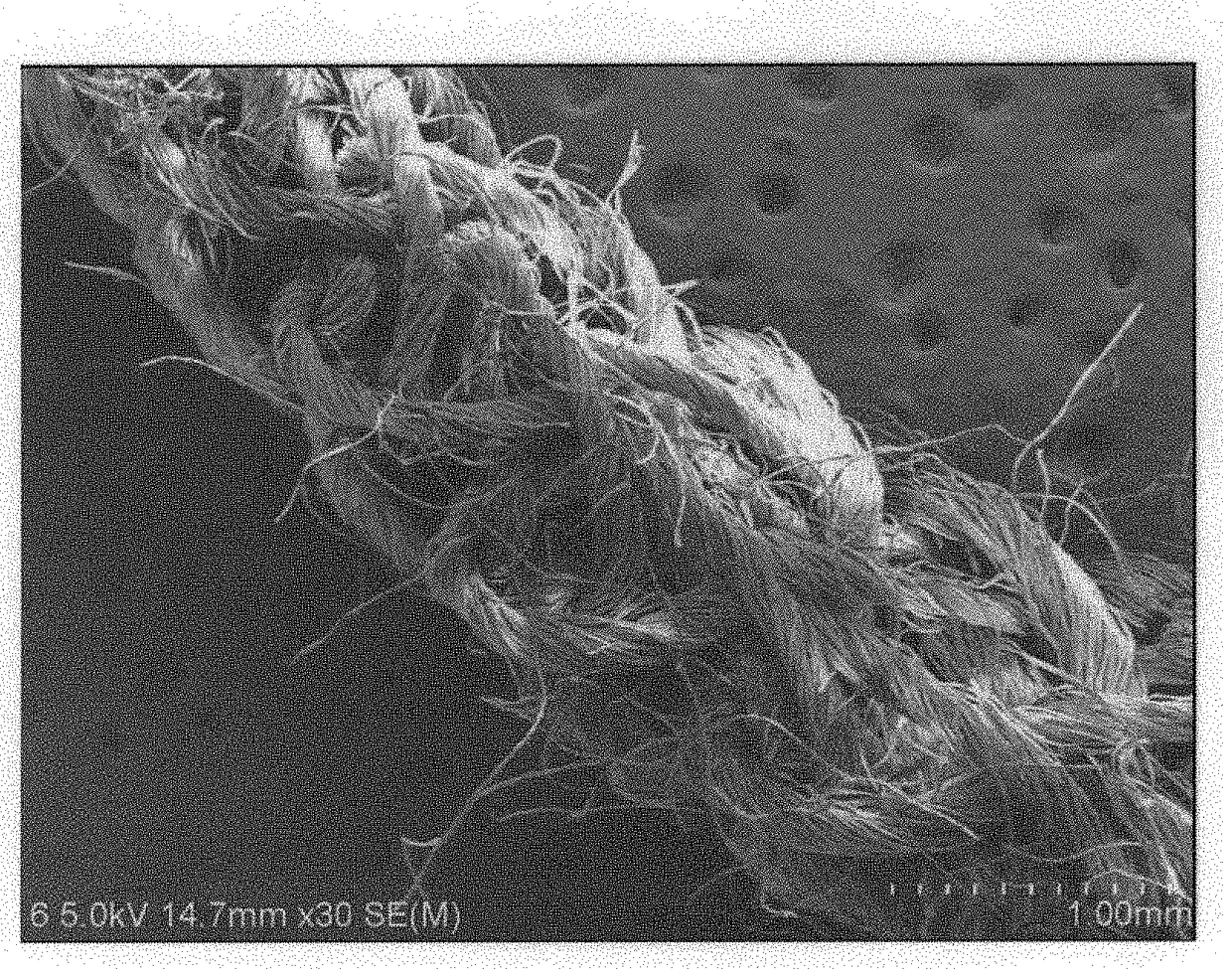

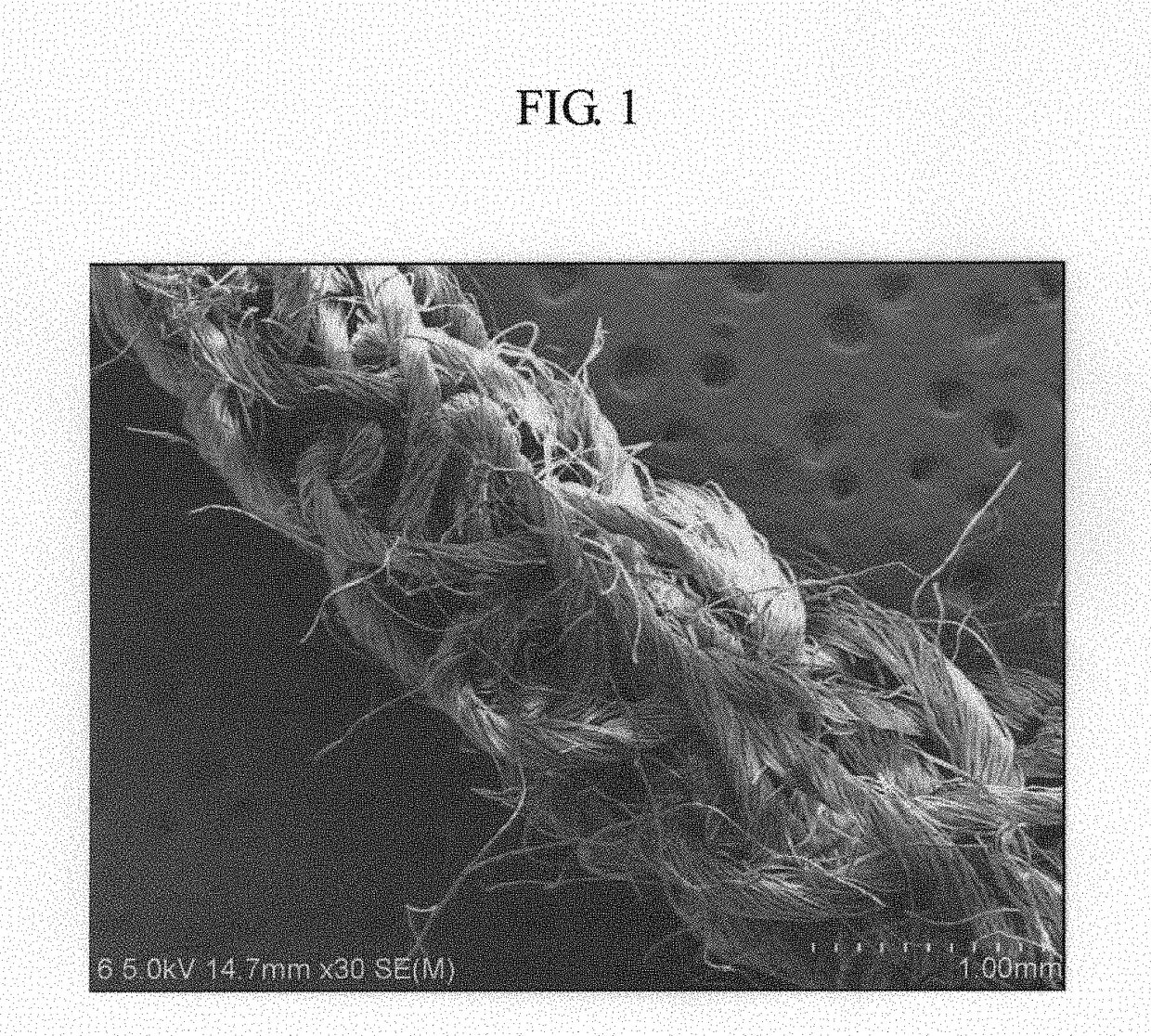

Image

Examples

Embodiment Construction

. Production of PAN Nanofiber Tape Yarn

[0078]PAN (polyacrylonitrile) having a molecular weight of 200,000 of Mitsui Chemical Co. Ltd., was dissolved in the solvent DMAc in an amount of 20 wt % to prepare a spinning solution.

[0079]This spinning solution was transferred to a spinning nozzle by using a metering pump, and was spun under the conditions of an applied voltage of 25 kV, a distance between a spinneret and a collector of 20 cm, a discharging amount of 0.05 cc / g.hole per minute, a spinning temperature of 30° C., and a relative humidity of 60%, to produce a nanofiber web.

[0080]FIG. 3 is a scanning electron microscope (SEM) image of the PAN nanofiber web obtained according to the present embodiment. It can be seen that the nanofiber web is composed of uniform nanofibers having an average diameter of about 500 nm.

[0081]The basis weight of the nanofiber web was about 5 gsm. The nanofiber web was laminated at a pressure of 100 g / cm2 by using a roller heated to 100° C. to prepare a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com