Patents

Literature

84results about How to "With moisture absorption and breathability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-side leakage degradable polylactic acid sanitary napkin and preparation method thereof

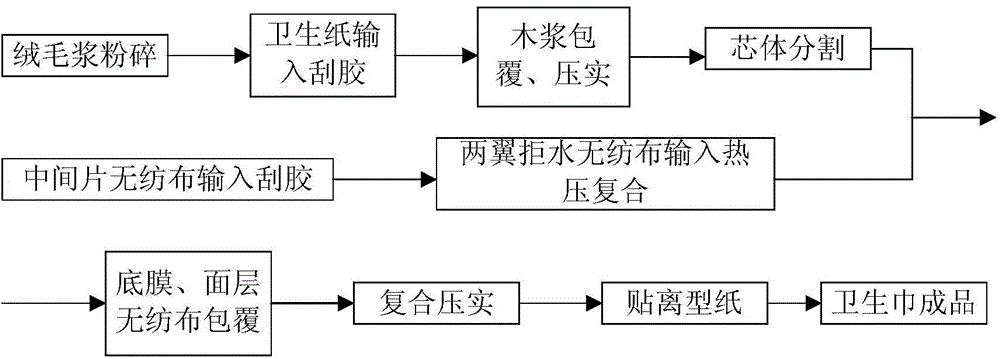

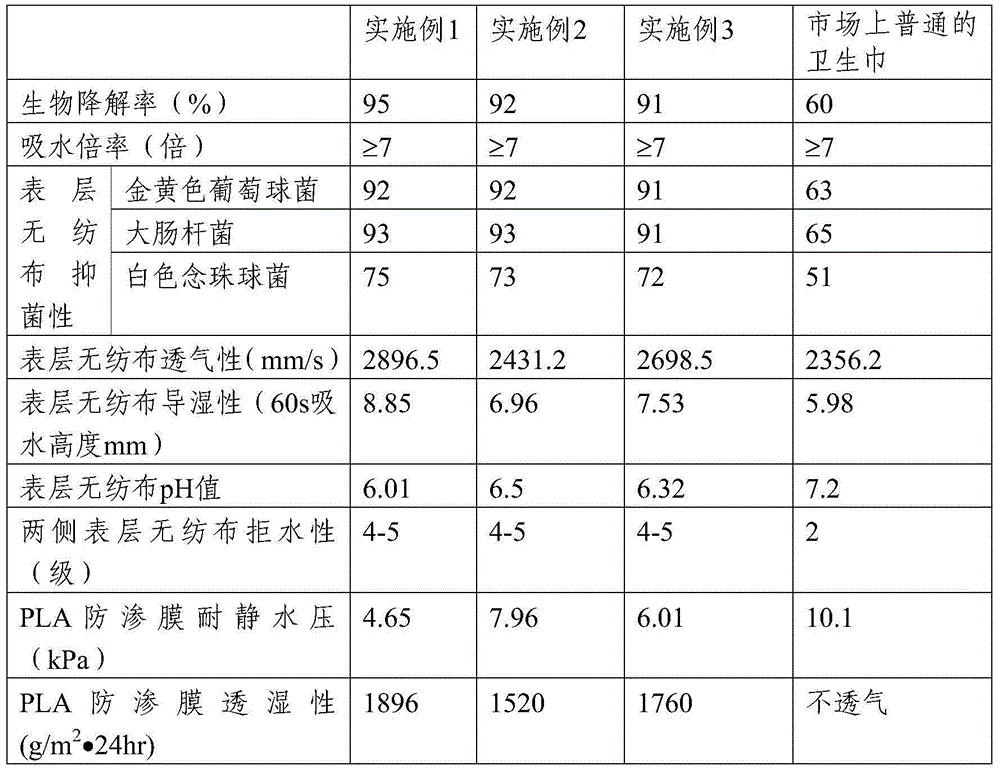

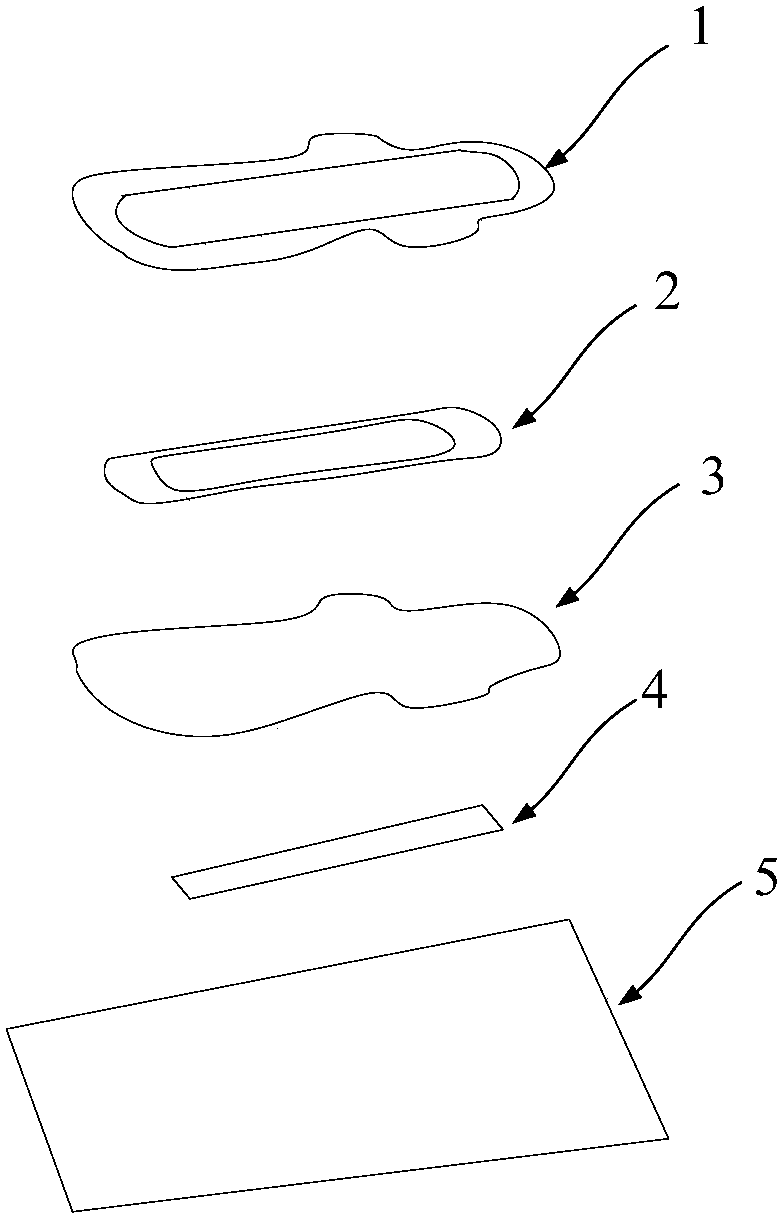

The invention provides an anti-side leakage sanitary napkin, which includes a surface non-woven fabric and a bottom impermeable membrane disposed from the inside out. The surface non-woven fabric has a three-piece structure, the intermediate piece of surface non-woven fabric and the two-wing surface non-woven fabrics are sticked together, and the space between the intermediate piece of surface non-woven fabric and the bottom impermeable membrane is filled with a toilet paper coated wood pulp cellulose absorption core. The surface of the sanitary napkin provided by the invention is composed of 100% polylactic acid fiber or PLA / PBHV fiber hot blast nonwoven fabric. The polylactic acid fiber retains the original characteristics and does not cause any damage. As polylactic acid is formed by polymerization of lactic acid molecules as monomers and spinning, polylactic acid molecules with short molecular chains possibly exist on the fiber surface, so that the pH value of a polylactic acid non-woven fabric surface shows weak acidity and is consistent with that of human body skin. Also an odor removal function is provided. The lateral two pieces of non-woven fabrics have greater gram weight and thickness than the intermediate piece, and side leakage cannot be caused.

Owner:马鞍山同杰良生物材料有限公司

Preparation technology and preparation equipment for high-imitation cotton porous superfine profiled polyester fiber

ActiveCN102877143ASoft lusterSoft touchArtificial thread manufacturing machinesFilament/thread formingChemistryHeat setting

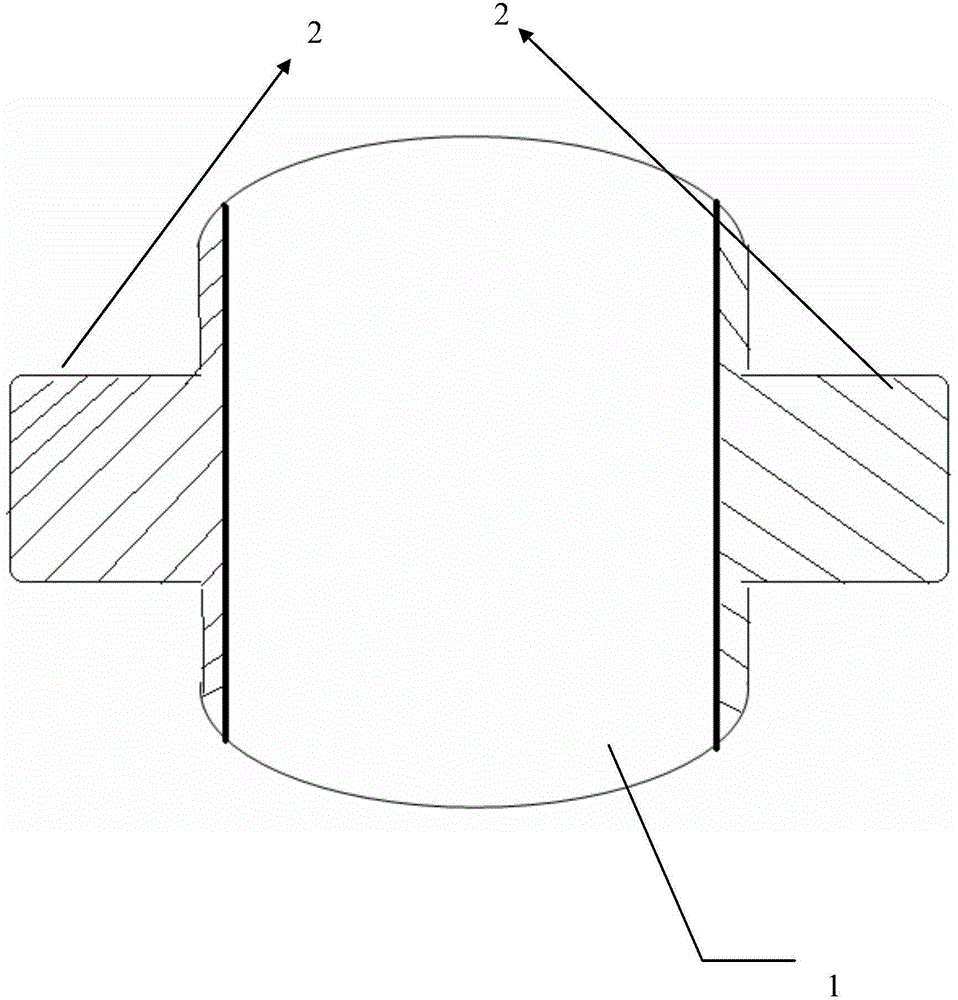

The invention discloses a preparation technology and preparation equipment for high-imitation cotton porous superfine profiled polyester fiber. The technological flow is as follows: polyester chips are dried, the dried polyester chips are placed in an extrusion device, polyhydric alcohol is added in an online manner to carry out blending modification, and then melt is obtained; the melt is filtered and enters a spinning manifold, the filtered melt is subjected to section superfine processing and section profiled processing, the melt is extruded by a profiled spinning plate, and then melt trickle is obtained; circular blowing cooling solidification forming is then carried out, and then filaments are obtained; and then the filaments are wound and formed sequentially through oiling by an oil nozzle, pretangle and heat setting. The preparation equipment comprises a drying device, an extrusion device, a filter device, the spinning manifold, a circular blowing cooling solidifying device and a winding forming device, which are connected in sequence, wherein the extrusion device is connected with an online adding device. The preparation technology and the preparation equipment have the characteristics of moisture absorption, breathability, anti-static electricity, pilling resistance, softness and bulkiness, soft gloss, moisture wicking and discharging, soft touch sense, better surface coverage and bending resilience, and also can realize a high-imitation cotton effect.

Owner:ZHONGRUN SCI & TECH

Black sanitary towel

ActiveCN107898560AWith adsorption and deodorizationAntibacterialBio-packagingSanitary towelsEngineeringMoisture absorption

The invention provides a black sanitary towel. The black sanitary towel comprises a sanitary towel body, and the sanitary towel body comprises a surface non-woven fabric layer, an absorption core anda bottom impermeable membrane from top to bottom in sequence; the surface non-woven fabric layer comprises a middle sheet, retaining walls and side wings; the middle sheet is arranged in the middle ofthe surface non-woven fabric layer and used for cooperating with the bottom impermeable membrane and completely wrapping the absorption core; the side wings are arranged at the two sides of the surface non-woven fabric layer and used for fixing the sanitary towel body; the retaining walls are arranged at the two sides of the middle sheet and used for preventing an absorbed material which is absorbed by the middle sheet or the middle core from leaking from the sides; the side wings are fixedly connected with the middle sheet through partial retaining walls; the surface non-woven layer and thebottom impermeable membrane are both black. The black sanitary towel can meet the basic requirement of sanitary towels and have the advantages of bacterial inhibition, odor removal, moisture absorption and ventilation, soft and comfortable performance and complete degradation.

Owner:上海贝睿斯生物科技有限公司

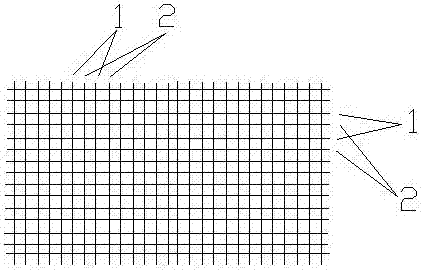

Soft bacteriostatic hygroscopic uvioresistant fabrics and preparation process thereof

InactiveCN101818401AWith moisture absorption and breathabilityAntibacterialWoven fabricsYarnPolyesterCotton fibre

The invention provides soft bacteriostatic hygroscopic uvioresistant fabrics and a preparation process thereof. The fabrics is prepared by interweaving wrap yarn and weft yarn, which is characterized in that the wrap yarn is prepared by twisting and compounding bamboo carbon fiber and cotton fiber; and the weft yarn is prepared by twisting and compounding polyester yarn and cotton fiber. The preparation process comprises the following specific steps: spinning the bamboo carbon fiber and the cotton fiber into yarn proportionally, and then spinning the polyester yarn and the cotton fiber into yarn proportionally; spinning the bamboo carbon fiber and the cotton fiber into yarn proportionally and spinning the polyester yarn and the cotton fiber into yarn proportionally by a knitting machine, and then interweaving the yarn into gray cloth; turning and sewing, refining, dehydrating, scutching, drying, pre-shaping, alkali de-weighting finishing, washing, dying, washing, dehydrating, scutching and then soft-shaping to finally obtain the soft bacteriostatic hygroscopic uvioresistant fabrics. Compared with the prior art, the invention has the advantages of smoothness, softness and warmness, moisture absorption and air permeability, bacteria resistance, uvioresistance and the like.

Owner:山东澳亚纺织有限公司

Production process of modified chinlon yarn

PendingCN112981588AEasy to prepareImproves sun aging propertiesElectroconductive/antistatic filament manufactureSynthetic polymer filament chemical after-treatmentYarnGraphene

The invention discloses a production process of modified chinlon yarn. The production process includes the following steps: 1, mixing 7-8 parts of polyamide slices, 2-4 parts of graphene, 3-6 parts of far infrared ceramic powder, 6-9 parts of an antioxidant, 5-10 parts of a catalyst and 8-12 parts of a dispersing agent, feeding the above materials into a stock bin, mixing and melting to prepare functional master batch; 2, feeding the functional master batch and 70-80 parts of dried chinlon slices into a double-screw extruder to be extruded, then carrying out blended spinning at the temperature of 260-265 DEG C, and finally, carrying out oiling, winding and balanced stretching to obtain chinlon yarn; 3, soaking the chinlon yarn in the step 2 into a graphene solution through a compression roller, guaranteeing that the chinlon yarn makes full contact with graphene, after soaking is completed, feeding the chinlon yarn into a drying device for drying, and finally obtaining the novel modified chinlon yarn. The preparation method is simple, and the prepared modified chinlon yarn is good in use effect, good in antistatic performance, capable of keeping warm, convenient to use, safe and reliable.

Owner:海安海顺化纤有限公司

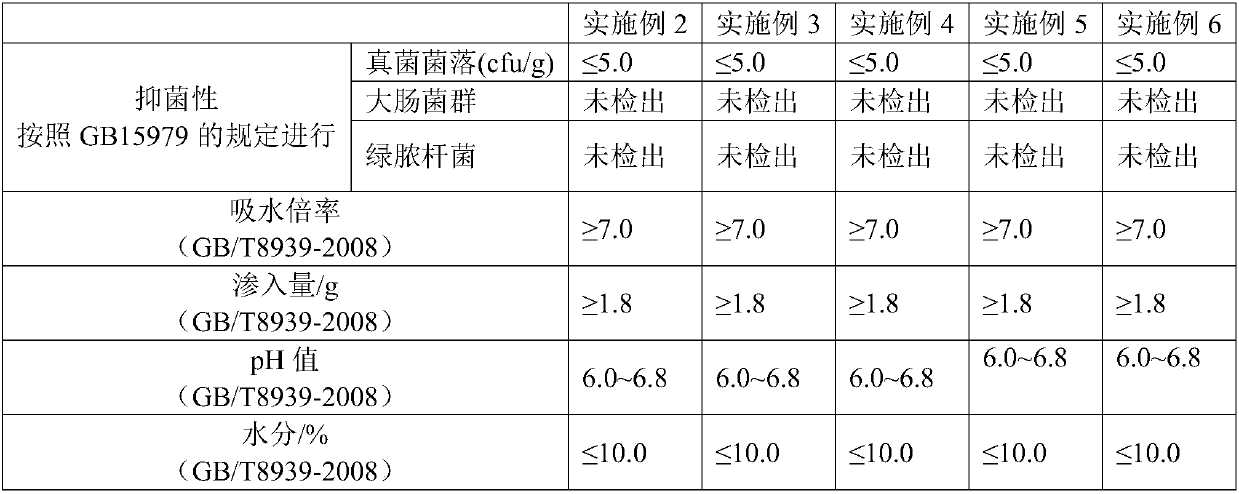

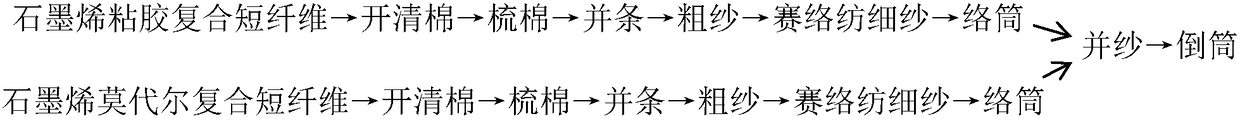

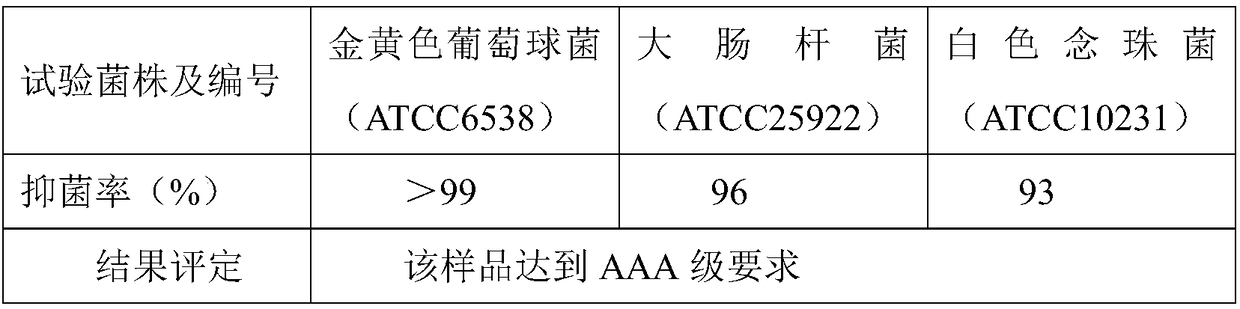

Graphene viscose/graphene modal blended yarn and preparation method and fabric thereof

ActiveCN109487388AImprove conductivityImprove thermal conductivityWeft knittingWarp knittingYarnGraphene

The invention discloses a graphene viscose / graphene modal blended yarn, which is formed by interweaving graphene viscose spun yarn and graphene modal spun yarn, wherein the graphene viscose spun yarnis formed by spinning graphene viscose composite fiber with the graphene content of 0.5-4wt%, and the graphene modal spun yarn is formed by spinning graphene modal composite fiber with the graphene content of 0.5-4wt%. The invention also discloses a preparation method of the blended yarn and a fabric made of the blended yarn. According to the preparation method of the blended yarn, the graphene isintroduced into the viscose fiber or the modal fiber, the functional characteristics of the graphene are reflected on the viscose fiber and the modal fiber, the viscose fiber and the modal which areexcellent in performance are given good electrical conductivity, thermal conductivity, antibacterial property, anti-ultraviolet function, far-infrared function and the like, and the mechanical properties of the viscose fiber and the modal are improved.

Owner:JIANGYIN XIANGFEI APPAREL

Hot melt adhesive net film and preparation process thereof

InactiveCN104805595AEvenly distributedImprove performanceConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsFiberCarbon fibers

The invention discloses a hot melt adhesive net film product including bamboo carbon fibers, so that the hot melt adhesive net film product has the functions of moisture absorption and air permeability, antibiotic inhibition, ultraviolet resistance, deodorization and adsorption, environmental protection and comfort of the product are enhanced, and performances of the hot melt adhesive net film product are expanded. Meanwhile the invention further discloses a process for preparing the hot melt adhesive net film, thereby ensuring that the bamboo carbon fibers are uniformly distributed in the net film product and the reliability of the product is enhanced.

Owner:KUNSHAN TIANYANG HOT MELT ADHESIVE CO LTD +1

Antistatic antibacterial fabric

InactiveCN103637407AImprove antistatic performanceImprove antibacterial propertiesUndergarmentsProtective garmentPolyesterPolymer science

The invention discloses antistatic antibacterial fabric. The antistatic antibacterial fabric is formed by weaving cuprous sulfide conductive polyacrylonitrile fibers, far-infrared polyester fibers, ramie fibers and hemp fibers in a blending manner, wherein the percentages by weight of the fiber components of the antistatic antibacterial fabric are respectively as follows: 12%-16% of the cuprous sulfide conductive polyacrylonitrile fibers, 15%-19% of the far-infrared polyester fibers, 29-33% of the ramie fibers and 32%-44% of the hemp fibers. The fabric is formed by weaving the cuprous sulfide conductive polyacrylonitrile fibers, the far-infrared polyester fibers, the ramie fibers and the hemp fibers in the blending manner, and the woven fabric has excellent antistatic property and antibacterial property, and guarantees human body safety and fabric cleanness; meanwhile, the fabric has the characteristics of being hygroscopic and ventilated, easy to clean and fast to dry, UV-resistant, cool and comfortable.

Owner:SUZHOU IND PARK YOUSHUN CLOTHING FACTORY

Antibacterial shell fabric and production method thereof

The invention discloses antisepsis fabric, relates to composite antisepsis fabric and particularly relates to fabric which can resist bacteria in a long-acting mode, absorb moisture and dry rapidly and has one hydrophilic face and one water-proof face. The fabric which can resist bacteria in the long-acting mode is characterized by being formed by weaving hydrophilic yarn with antisepsis agents and hydrophobic yarn. Thus, the fabric has the inner layer and the outer layer, the inner layer of the fabric is hydrophilic and the outer layer of the fabric is hydrophobic.

Owner:SHANGHAI RUNHE NANO MATERIAL SCI &TECH CO LTD

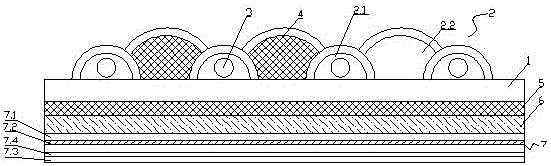

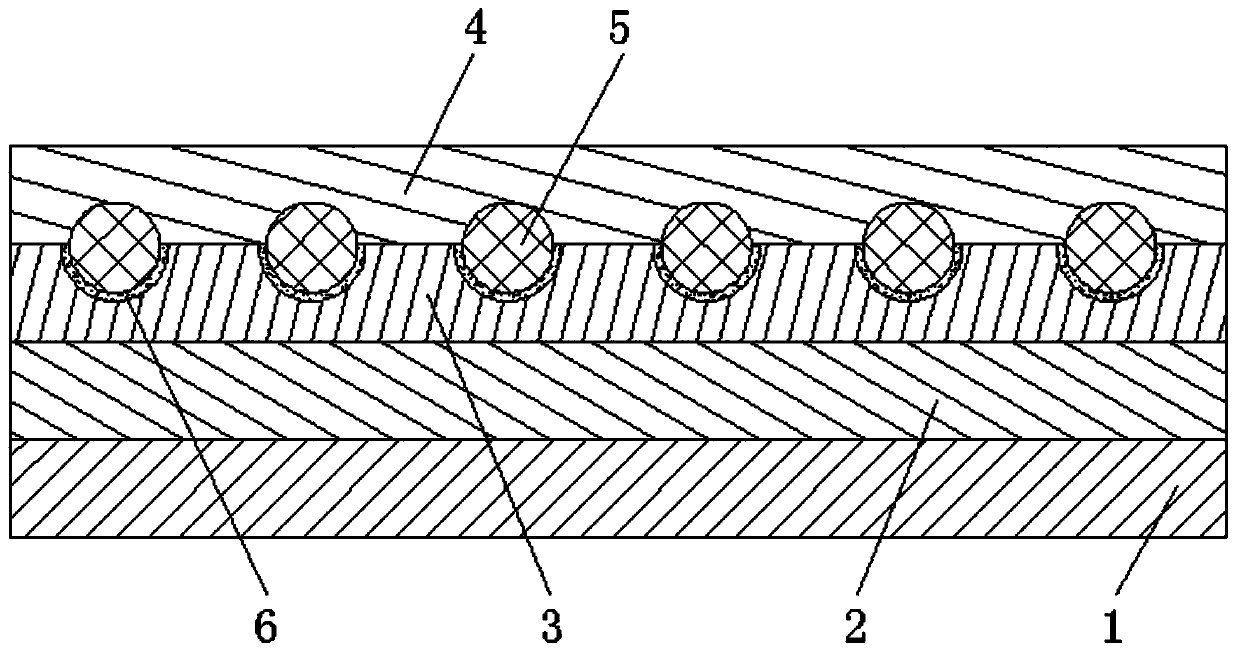

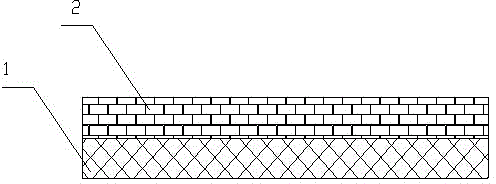

Antibacterial, moisture-absorbing, air-permeable and elastic shell fabric

InactiveCN104228204AAntibacterial hasAchieve antibacterial effectProtective garmentMetal layered productsEngineeringAntibacterial agent

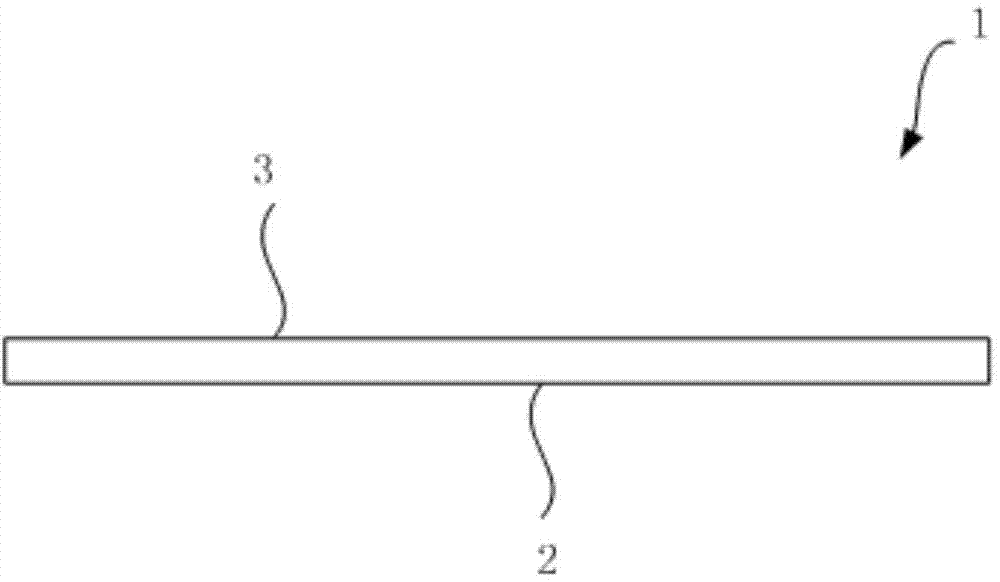

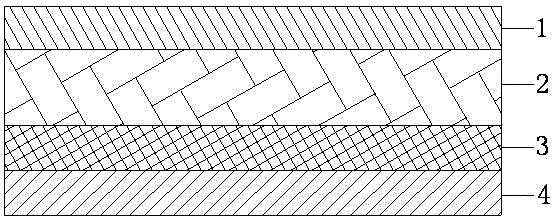

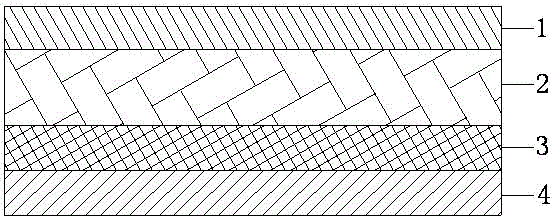

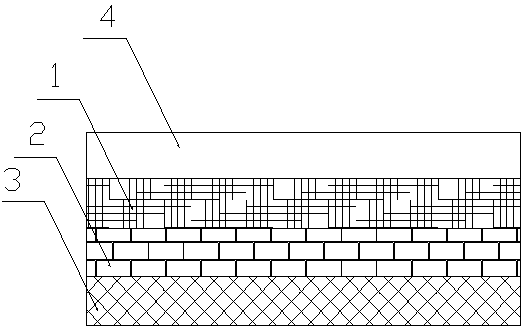

The invention relates to an antibacterial, moisture-absorbing, air-permeable and elastic shell fabric. The shell fabric comprises a base fabric layer (1) and a shell fabric layer (2), wherein an antibacterial layer (3) is arranged between the base fabric layer (1) and the shell fabric layer (2) and is made from a silver ion antibacterial agent, and the silver ion antibacterial agent is bonded between the base fabric layer (1) and the shell fabric layer (2); the base fabric layer is made from three layers, namely velvet, sponge and base fabric which are sequentially arranged from outside to inside, through laminating. The shell fabric has antibacterial and bactericidal functions, thereby achieving an antibacterial effect. The shell fabric is moisture-absorbing, air-permeable and elastic.

Owner:JIANGYIN HULIAN DYEING & FINISHING

Anti-mosquito cloth

InactiveCN103653453AImprove mosquito repellent effectAntibacterial and deodorantProtective garmentSpecial outerwear garmentsPolyesterPolymer science

The invention discloses anti-mosquito cloth. The anti-mosquito cloth is woven by blending four fibers respectively including, by weight, 8%-12% of polyester fibers mixed with deinsectization bacteria, 21%-25% of viscose fibers mixed with citronellal, 18%-22% of tea fibers and 41%-53% of linen fibers. Woven by blending the polyester fibers mixed with the deinsectization bacteria, the viscose fibers mixed with the citronellal, the tea fibers and the linen fibers, the anti-mosquito cloth is good in anti-mosquito effect and has the advantages of antibacterium and deodorization, moisture absorption and breathability, coolness and comfortableness, and breathability.

Owner:SUZHOU BAIBI TEXTILE TECH CO LTD

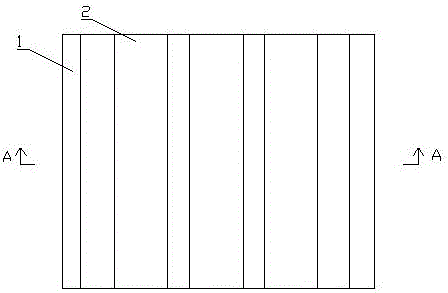

Elegant and non-deformation environmental-protection fabric

InactiveCN106113755AThree-dimensionalAntibacterialSynthetic resin layered productsCellulosic plastic layered productsEngineering

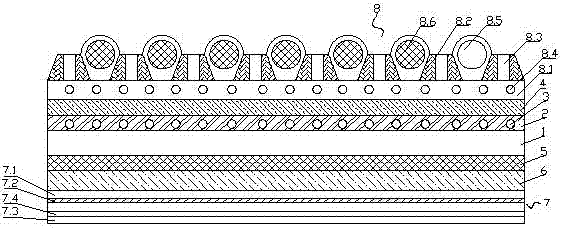

The invention relates to an elegant and non-deformable environmentally friendly fabric, comprising an environmentally friendly fabric body (1), the upper surface of the environmentally friendly fabric body is provided with a vertically arranged hollow jacquard layer (2), and the lower surface of the environmentally friendly fabric body (1) is downward An antistatic layer (5), a fireproof layer (6) and a waterproof layer (7) are arranged in sequence. The lower surface of the waterproof layer is compounded with a lining layer, and the lining layer is composed of a velvet layer, a sponge layer and a base cloth layer sequentially from top to bottom.

Owner:JIANGYIN CHUNZHILAN SPECIAL YARN

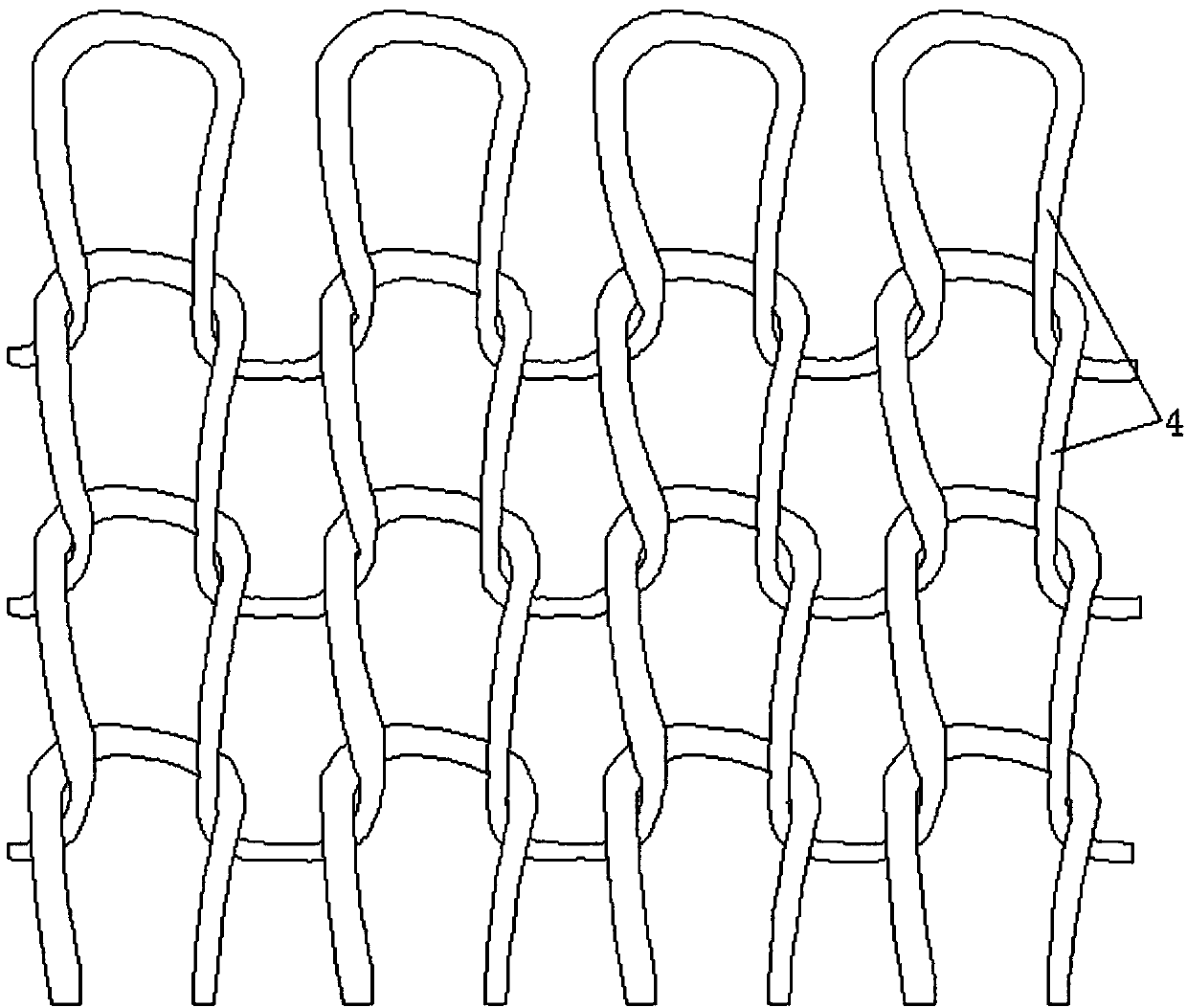

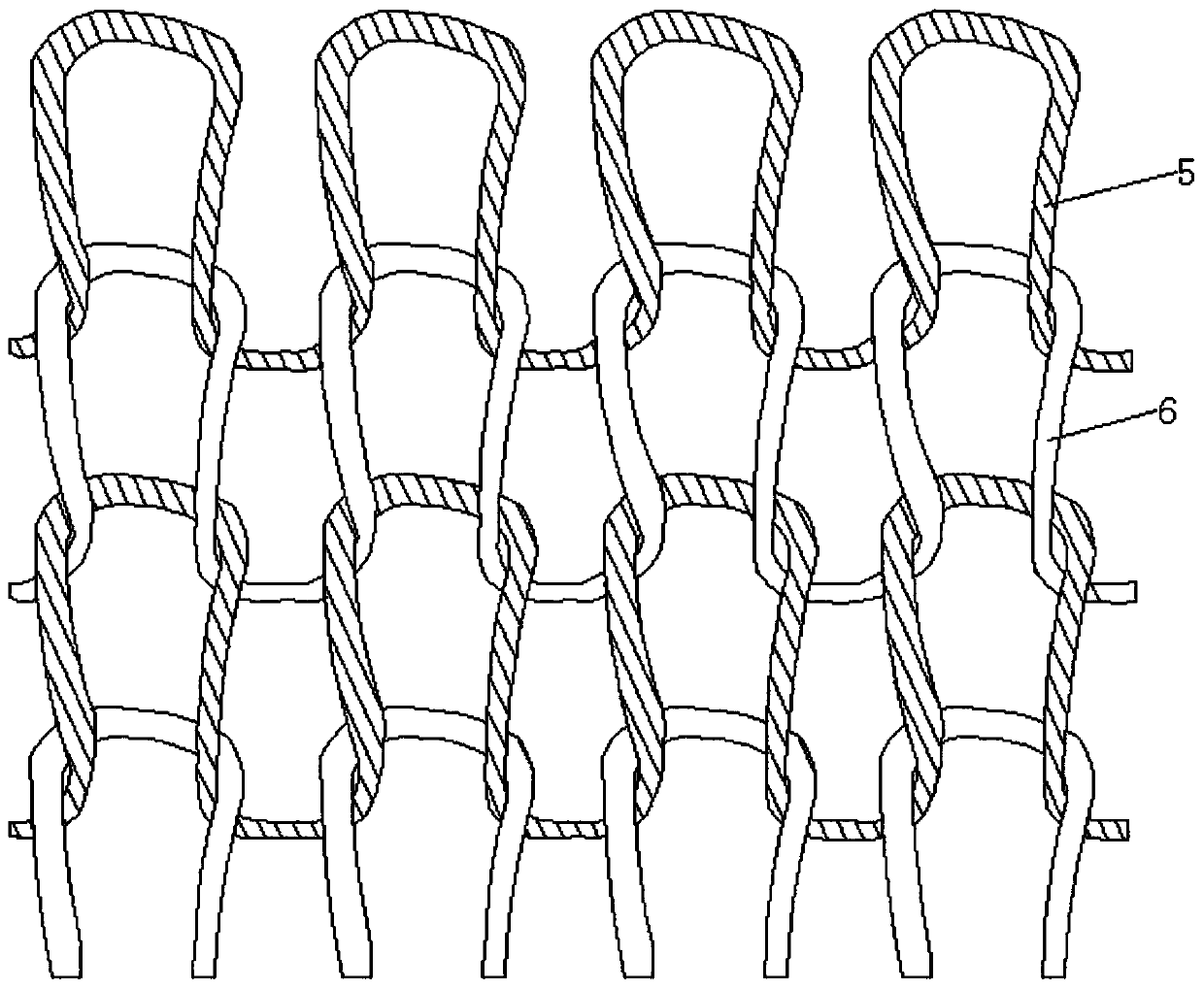

Knitted fabric

InactiveCN109648978AGood elasticityIncreased strength and wear resistanceSynthetic resin layered productsClothingsCoil structureBamboo charcoal

The invention discloses a knitted fabric, which comprises an inner layer, an intermediate layer and an outer layer which are successively arranged from the inside to the outside. The inner layer has atwo-coil structure interwoven by spandex core-spun yarns; the intermediate layer has a two-coil structure interwoven by flame-retardant terylene and conductive fiber; the outer layer has a two-coil structure interwoven by chinlon and bamboo charcoal fiber; and the chinlon is composed of a monofilament which is a cruciform structure having a through-hole at the center. Garment made of the knittedfabric has good elasticity and high wear resistance and strength, is comfortable to wear, and has flame-retardant and antistatic, antibacterial and antibacterial and anti-ultraviolet characteristics.

Owner:绍兴柯桥名瑶纺织品有限公司

Preparation technology and preparation equipment for high-imitation cotton porous superfine profiled polyester fiber

ActiveCN102877143BWith moisture absorption and breathabilityAntistaticArtificial thread manufacturing machinesFilament/thread formingPolyesterAlcohol

The invention discloses a preparation technology and preparation equipment for high-imitation cotton porous superfine profiled polyester fiber. The technological flow is as follows: polyester chips are dried, the dried polyester chips are placed in an extrusion device, polyhydric alcohol is added in an online manner to carry out blending modification, and then melt is obtained; the melt is filtered and enters a spinning manifold, the filtered melt is subjected to section superfine processing and section profiled processing, the melt is extruded by a profiled spinning plate, and then melt trickle is obtained; circular blowing cooling solidification forming is then carried out, and then filaments are obtained; and then the filaments are wound and formed sequentially through oiling by an oil nozzle, pretangle and heat setting. The preparation equipment comprises a drying device, an extrusion device, a filter device, the spinning manifold, a circular blowing cooling solidifying device and a winding forming device, which are connected in sequence, wherein the extrusion device is connected with an online adding device. The preparation technology and the preparation equipment have the characteristics of moisture absorption, breathability, anti-static electricity, pilling resistance, softness and bulkiness, soft gloss, moisture wicking and discharging, soft touch sense, better surface coverage and bending resilience, and also can realize a high-imitation cotton effect.

Owner:ZHONGRUN SCI & TECH

Reflective fabric

InactiveCN109664569AGood reflective effectImprove reflective effectSynthetic resin layered productsClothingsPolyesterYarn

The invention discloses a reflective fabric, which comprises an inner layer, a light storage layer, a glue coating layer and a waterproof moisture-permeable film layer, wherein the inner layer, the light storage layer, the glue coating layer and the waterproof moisture-permeable film layer are sequentially arranged from inside to outside, the inner layer is formed by weaving cotton fiber as warp yarn and polyester yarn having a triangular cross section and used as weft yarn in a crossing manner, the light storage layer is formed by weaving bamboo fiber as warp yarn and noctilucent yarn as weftyarn in a crossing manner, glass micro-beads are embedded on the upper surface of the glue coating layer, and the upper surface of the glue coating layer is provided with the waterproof moisture-permeable film layer covering the glass micro-beads. According to the present invention, the reflective fabric has effects of all-weather warning function, moisture absorption, gas permeability, antibacterial effect and bacterial inhibition.

Owner:绍兴柯桥名瑶纺织品有限公司

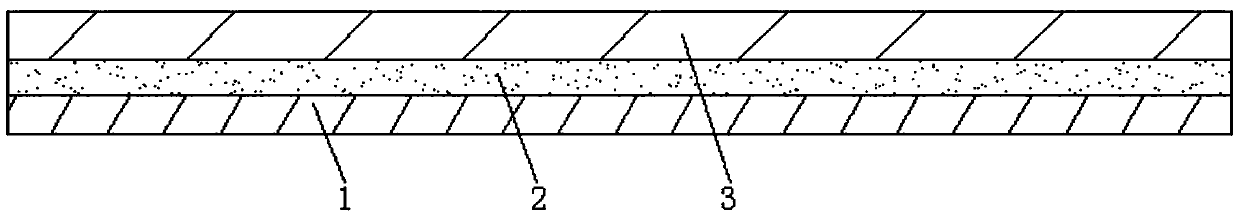

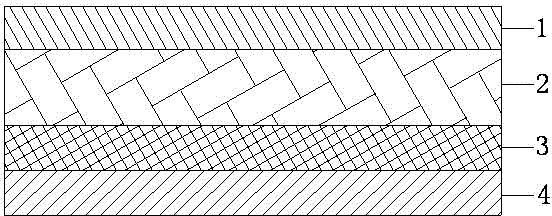

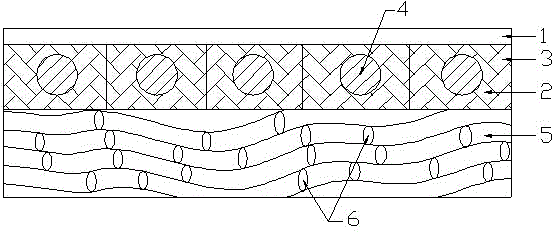

Cold-resistant velvet fabric

InactiveCN104783366ASimple fabric structureAgainst the coldSynthetic resin layered productsProtective garmentCompound (substance)Yarn

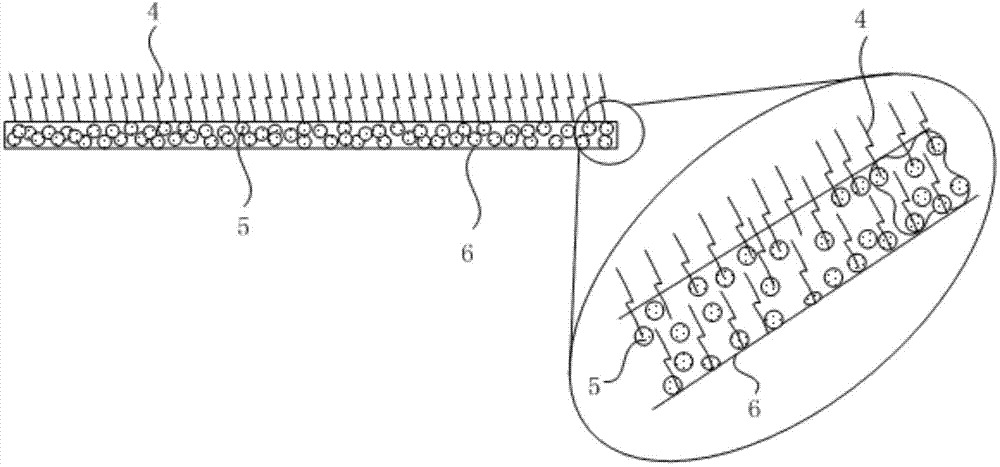

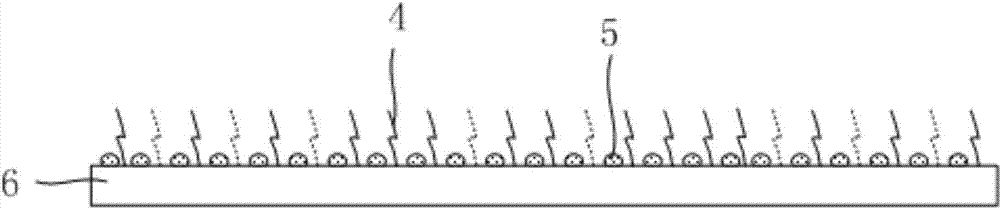

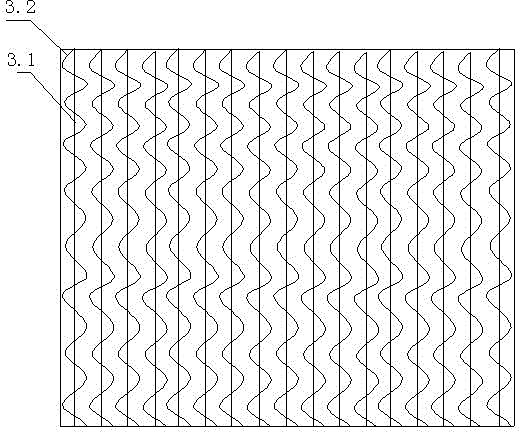

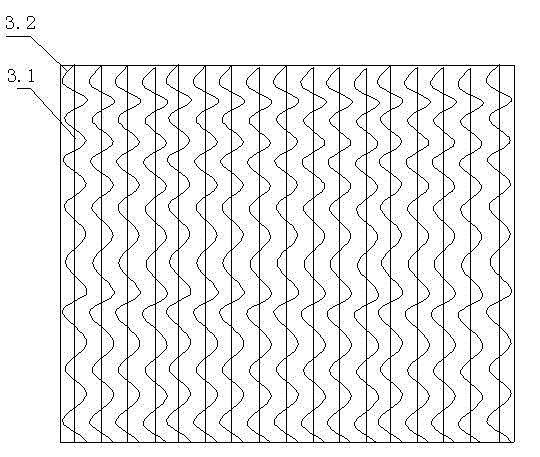

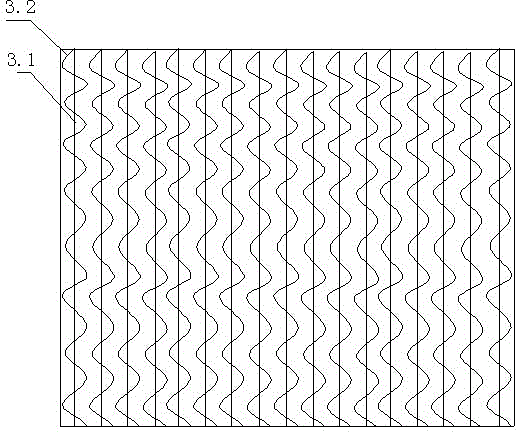

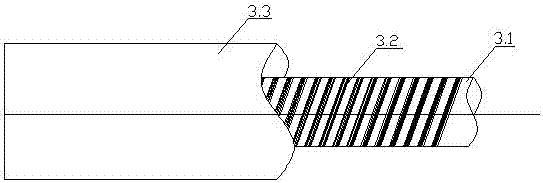

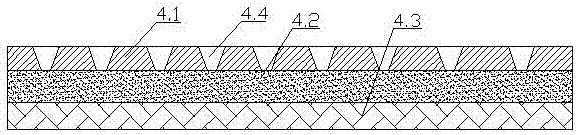

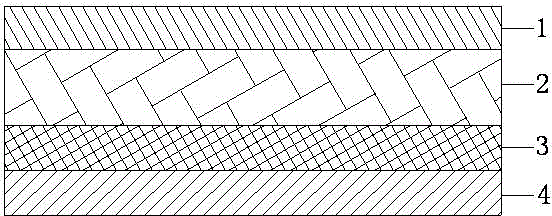

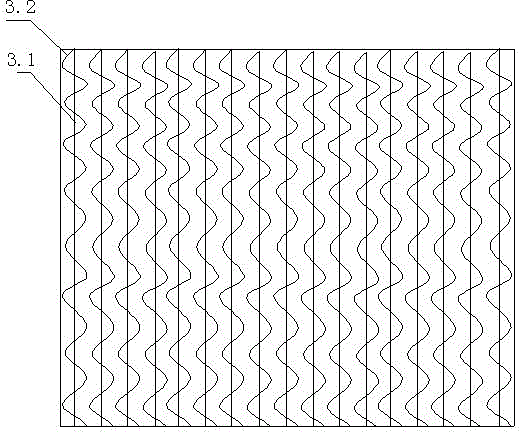

The invention relates to a cold-resistant velvet fabric. The cold-resistant velvet fabric comprises velvet cloth (1). A sponge layer (2) is arranged under the velvet cloth (1). An antistatic layer (3) is arranged under the sponge layer (2) and made of core spun silk fibers. The fibers comprise yarns (3.1) and metal wires (3.2). The metal wires (3.2) are wound around the yarns (3.1). A base layer (4) is arranged under the antistatic layer (3). The base layer (4) is made of a fabric. The fabric is formed by closely combining a fabric layer, a warmth keeping layer, a cavity layer and a surface layer sequentially from inside to outside; the surface layer is formed by interweaving yarns containing conductive fibers and common-fiber yarns, the common fibers are cotton fibers, jute fibers, wool fibers, silk fibers or chemical fibers, and the warmth-keeping layer is made of sponges. The cold-resistant velvet fabric is elegant in color and gloss, gorgeous, sumptuous, strong, resistant to abrasion, not prone to deformation, high in elasticity, capable of absorbing dampness, breathable and resistant to coldness.

Owner:JIANGYIN HANXIN TEXTILE

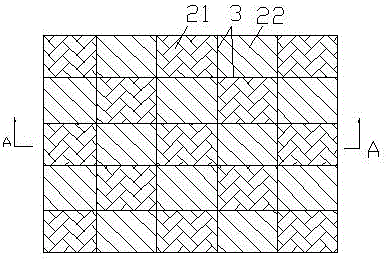

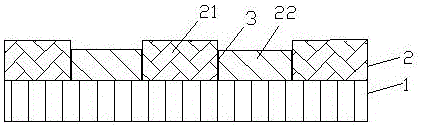

Elegant deformation-free thick grid fabric

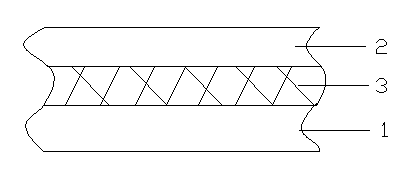

The present invention relates to an elegant, non-deformed coarse check fabric. It includes a fabric body (1), a composite layer (2) of linen strips and leather strips and a braided thread (3) arranged on the front of the fabric body, and the braided thread (3) is arranged between the linen strips (21) and the leather strips (22). The back of the fabric body is provided with a lining layer, and the lining layer is composed of a velvet layer, a sponge layer and a base cloth layer sequentially from top to bottom. The elegant, shapeless and coarse-grained grid fabric of the present invention combines the delicacy of leather strips and the roughness of linen strips, and is full of layering. The present invention is elegant and has no deformation.

Owner:JIANGYIN HANXIN TEXTILE

Velvet fabric with strong ventilation and sweat-permeation capability

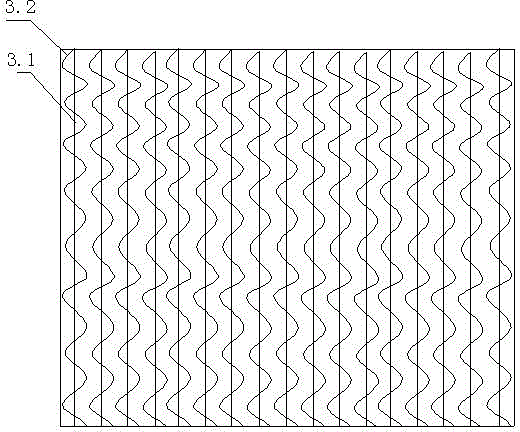

The invention relates to a velvet fabric with strong ventilation and sweat-permeation capability. The velvet fabric comprises velvet cloth (1), wherein a sponge layer (2) is arranged under the velvet cloth (1); an antistatic layer (3) is arranged under the sponge layer (2); the antistatic layer (3) is made of core-spun yarn fibers; the fibers comprise yarns (3.1) and metal wires (3.2); the metal wires (3.2) are wound on the yarns (3.1); and a base layer (4) is arranged under the antistatic layer (3). The base layer is made of a textile and the textile is formed by interweaving warps and wefts; the warps and the wefts are in an up-down plain weave pattern; the wefts comprise first wefts and second wefts; the first wefts and the second wefts are arrayed at the ratio of 1 to 1; the warps are made from PET fibers; the first wefts are made from viscose fibers; and the second wefts are made from moisture-absorption and sweat-permeation fibers. The velvet fabric has elegant color and luster, is gorgeous and is firm and wearable, is not easy to deform, has elasticity and has the moisture-absorption and ventilation functions. The velvet fabric has the strong ventilation and sweat-permeation capability.

Owner:JIANGYIN FANRONG YARN DYE FABRIC

Shrinkproof process for bamboo fiber jean

InactiveCN1304675CReduce shrink spaceShrink Space EliminationShrinkingHeating/cooling textile fabricsYarnDenim

The present invention relates to finishing technique of fabric, and is especially the anti-shrinking process of bamboo fiber jean. The anti-shrinking process of bamboo fiber jean includes the following steps: 1. twisting the bamboo fiber single yarn or multiple ply yarn with bamboo fiber content of 70-100 %; 2. high temperature steam setting after twisting; 3. pre-shrinking treatment after weaving jean; and 4. shrinking treatment, finishing and ironing after tailoring. The process is reasonable, simple, practical and low in cost, and the clothing of bamboo fiber jean is stiff, smooth, firm and comfortable and has the advantages of bamboo fiber.

Owner:李星海

Antifouling breathable velvet fabric

The invention relates to an antifouling breathable velvet fabric. The fabric comprises velvet cloth (1). A sponge layer (2) is arranged below the velvet cloth (1). An antistatic layer (3) is arranged below the sponge layer (2). The antistatic layer (3) is prepared with core-spun fiber. The fiber comprises yarn (3.1) and metal filament (3.2). The metal filament (3.2) is wound on the yarn (3.1). A base layer (4) is arranged below the antistatic layer (3). The base layer is prepared with textile. A fluorine monomer aqueous polyurethane coating layer is coated on the surface of the textile. The fabric provided by the invention has an elegant shade, and is luxuriant, firm, and wear-resistant. The fabric is not prone to deformation. The fabric is rich in elasticity. The fabric can absorb moisture, and is breathable. The fabric is antifouling and breathable.

Owner:李士清

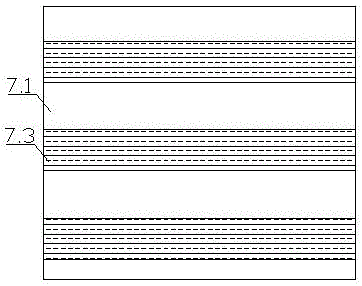

Elegant, non-deformation, wear-resistant and flame-retardant home textile fabric having high color fastness

InactiveCN107538829AHigh color fastness withFlame retardantSynthetic resin layered productsMetal layered productsComposite filmSurface layer

The invention relates to an elegant, non-deformation, wear-resistant and flame-retardant home textile fabric having a high color fastness. The fabric comprises a fabric body (1), the upper surface ofthe fabric body (1) is sequentially provided with a radiation protection layer (2), an antistatic layer (4) and an upper waterproof layer (8), and the lower surface of the fabric body (1) is sequentially provided with an antibacterial layer (5), a flame-retardant layer (6) and a lower waterproof layer (7). The lower surface of the lower waterproof layer is provided with a lining layer, and the lining layer comprises a PU film surface layer, a flax fiber core layer and a ramie fiber bottom layer which are sequentially compounded. The fabric has the characteristics of elegance, non-deformation,good wear resistance, high color fastness, flame retardation, radiation protection, waterproofing and good antistatic property.

Owner:JIANGYIN HAOZHOU TEXTILE CO LTD

Fluorescent and luminous velvet fabric

InactiveCN104802487AEasy to manufactureLight structureSynthetic resin layered productsClothingsYarnFiber

The invention relates to a fluorescent and luminous velvet fabric which includes velvet cloth (1), wherein a sponge layer (2) is arranged under the velvet cloth (1); an antistatic layer (3) is arranged under the sponge layer (2); the antistatic layer (3) is made of core-spun yarn fibers; the fibers include yarns (3.1) and metal wires (3.2); the metal wires (3.2) are wound on the yarns (3.1); a base layer (4) is arranged under the antistatic layer (3) and made of textile fabric; the textile fabric includes a fabric body, as well as an intermediate layer and a luminous body both of which are arranged on the fabric body in sequence; an adhesive layer is arranged on the back face of the luminous body, and a fluorescent surface layer is arranged on the front face of the luminous body. The fluorescent and luminous velvet fabric provided by the invention is gentle in color and light, elegant, firm and anti-wear, not liable to deformation, high in resilience, and good in moisture absorption and air permeability; the velvet fabric is fluorescent and luminous.

Owner:JIANGYIN CHUNLAN TEXTILE

Velvet fabric with good air permeability and comfort

InactiveCN104783375AImproves breathability and comfortIncrease elasticityCellulosic plastic layered productsProtective garmentYarnEngineering

The invention relates to a velvet fabric with good air permeability and comfort. The velvet fabric comprises velvet cloth (1), a sponge layer (2) is arranged below the velvet cloth (1), and an anti-static layer (3) is arranged below the sponge layer (2). The anti-static layer (3) is composed of core-spun yarn fiber which comprises a yarn (3.1) and a metal yarn (3.2), wherein the yarn (3.1) is wound by the metal yarn (3.2). A base layer (4) is arranged below the anti-static layer (3). The base layer is made of a fabric which is formed by tatting viscose filaments and silk in a 1 / 1 tabby mode, wherein the monofilament diameter of the viscose filaments ranges from 0.8 microns to 1.5 microns. The velvet fabric is elegant in colored light, luxuriant, firm, resistant to abrasion, not prone to deformation, elastic, capable of absorbing humidity and breathable. The velvet fabric is good in air permeability and comfort.

Owner:JIANGYIN HONGWEI QINGSHAN SPINNING

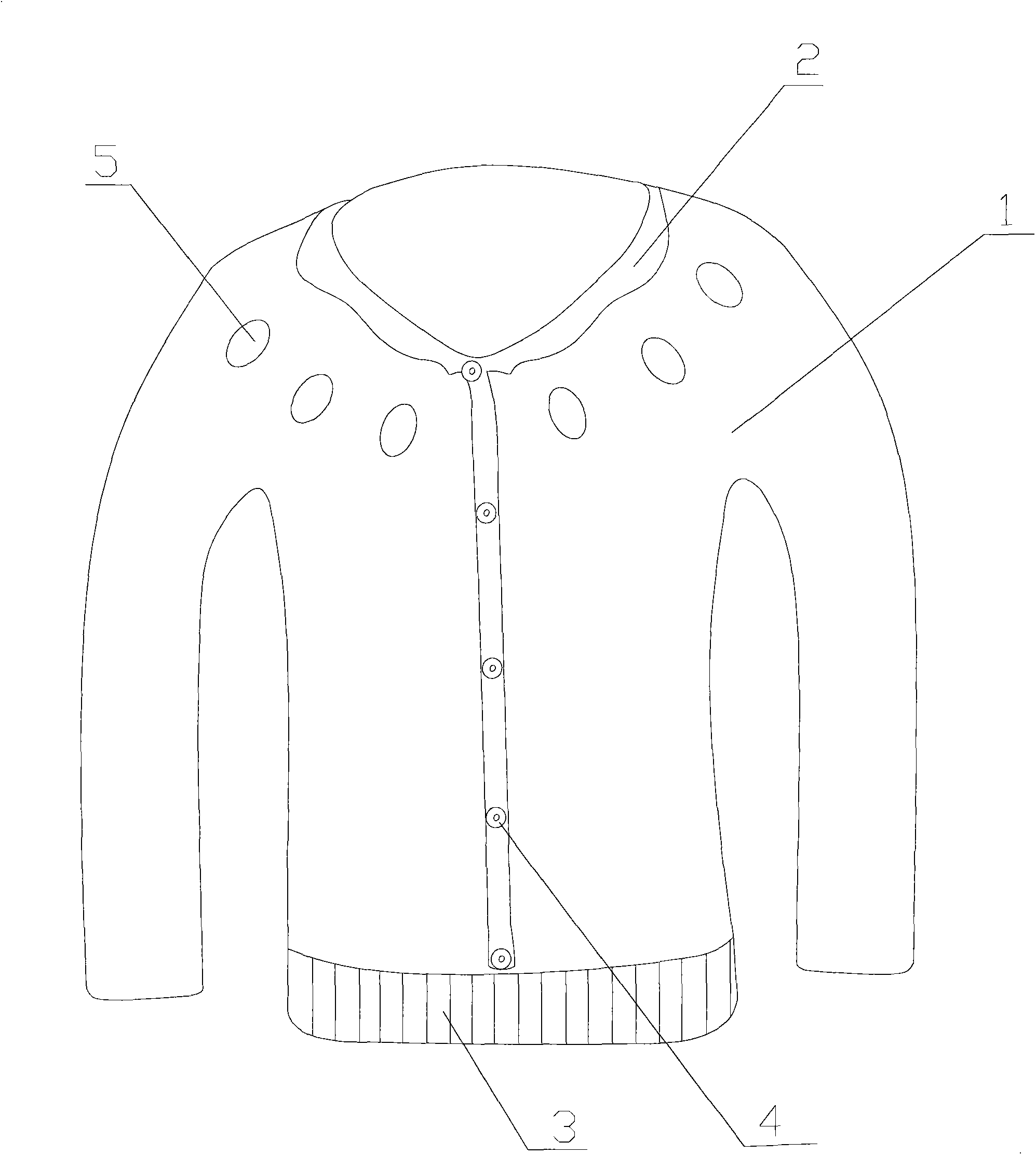

Beautiful, warm-keeping, breathable, moisture-absorption and elastic woman cashmere sweater

InactiveCN104287204AImprove wearing comfortAdd dimensionProtective garmentSpecial outerwear garmentsMoisture absorptionEngineering

The invention relates to a beautiful, warm-keeping, breathable, moisture-absorption and elastic woman cashmere sweater. The woman cashmere sweater comprises a sweater body (1), and a front piece and sleeves of the sweater body (1) are made of cashmere. A cashmere gasket (2) is arranged on the neckline of the sweater body (1). The position, close to the cashmere gasket (2), of the sweater body (1) is provided with a plurality of decorative pieces (5). The decorative pieces (5) are of oval cushion block structures and are made of cashmere. A thickened strip is vertically arranged in the middle of the obverse of the sweater body (1). The thickened strip is provided with decorative fasteners (4). A back piece of the sweater body is made of fabric. The fabric is formed by sequentially compositing velvet, sponges and base cloth from outside to inside. The woman cashmere sweater is beautiful and good in warm-keeping performance. The adopted fabric is capable of absorbing moisture, breathable and elastic.

Owner:钟俊杰

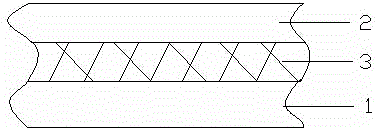

Anti-static moisture absorption and air permeable elastic fabric

The invention relates to an anti-static moisture absorption and air permeable elastic fabric, which includes a base layer (1). An anti-static layer (2) is disposed on the surface of the base layer (1), the anti-static layer (2) is formed by interweaving of warp yarns and weft yarns, the warp yarns are cotton yarns, the weft yarns are conductive fiber, the conductive fiber is stripe type, and the spacing is 5-10mm. The base layer is made of fabric, which is formed by combination of velvet, sponge and base cloth three layers from the outside in sequentially. The anti-static moisture absorption and air permeable elastic fabric provided by the invention has very good antistatic performance, enhances the fabric safety, is hygroscopic, breathable and elastic.

Owner:吴刚

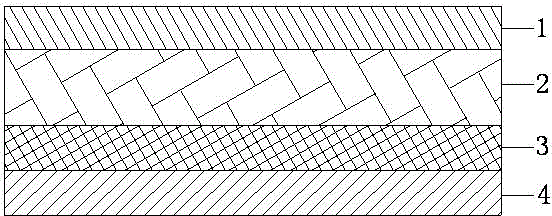

Waterproof, hygroscopic, breathable and elastic warmth retaining fabric

InactiveCN104260522AGood warmth retentionGuaranteed warmthSynthetic resin layered productsProtective garmentInter layerEngineering

The invention relates to a waterproof, hygroscopic, breathable and elastic warmth retaining fabric. The fabric comprises an outer layer (1), an interlayer (2) and an inner layer (3) in sequence, wherein the outer layer (1) and the interlayer (2) are laminated; the outer layer (1) is formed by a windproof and waterproof breathable film; the inner layer (3) is a warmth retention layer and is stuck to the interlayer (2); the interlayer is made from a fabric; the fabric is formed by compositing three layers, namely a layer of velvets, a layer of sponges and a layer of base fabric from outside to inside in sequence. The fabric has waterproof and warmth retention effects and is hygroscopic, breathable and elastic.

Owner:JIANGYIN TIANCHENG TEXTILE

Bamboo fiber gauze kerchief elegant and non-deformation radiation resistant fabric

InactiveCN107541835AStable supportAnti-electromagnetic radiationWoven fabricsYarnRadiation resistantCotton fibre

The invention relates to an elegant and non-deformed anti-radiation fabric of bamboo fiber gauze. The fabric is interwoven with cotton fiber yarn (1) as warp and bamboo fiber yarn (2) as weft. Several core-spun threads (3) are embedded in the cotton fiber yarn (1). The cored wire (3) is formed by silk covering metal ion fibers, and the metal ion fibers are wavy. A lining layer is compounded on the back of the fabric, and the lining layer is composed of a velvet layer, a sponge layer and a base cloth layer sequentially from top to bottom. The invention is elegant, non-deformable and anti-radiation.

Owner:黄磊

Marine-mud-containing multifunctional polyacrylonitrile fiber and preparation method thereof

InactiveCN106012080AImprove bioavailabilityAntibacterial and deodorizingMonocomponent synthetic polymer artificial filamentArtifical filament manufactureEconomic benefitsHealth benefits

The invention discloses a marine-mud-containing multifunctional polyacrylonitrile fiber and a preparation method thereof. The marine-mud-containing multifunctional polyacrylonitrile fiber comprises a polyacrylonitrile solution and a marine mud concentrated solution; in percentage by weight, the marine mud concentrated solution consists of 5 to 35% of marine mud powder, 0.5 to 3% of extract of clinacanthus nutans, 1.2 to 5% of extract of choerospondiasaxillaris bark, 0.3 to 2.5% of extract of ledum palustre, 0.5 to 3% of coupling agent and the balance of deionized water; the polyacrylonitrile solution accounts for 85 to 98% of the total weight of the fiber; the marine mud concentrated solution accounts for 2 to 15% of the total weight of the fiber. The fiber obtained by processing all the raw materials through various approaches not only reserves the original advantages of a polyacrylonitrile fiber, but also has fragrant odor, good skin friendliness, hygroscopicity, spinnability and good dyeing property and high fiber forming strength. Wearability is more excellent; effects of resisting to bacteria and deodorizing, resisting to ultraviolet rays, removing mites and repelling mosquitoes and resisting to static electricity are realized, and nutritional health-care ingredients are released, so that a human body obtains more health benefits; moreover, marine mud resources are sufficiently utilized and have huge social and economic benefits.

Owner:陆建益

Fabric with characteristics of static electricity resistance, moisture absorption, gas permeability, elasticity and slight fragrance

InactiveCN105459556AGuaranteed persistenceEasy to useSynthetic resin layered productsWoven fabricsEngineeringMoisture absorption

The present invention relates to a fabric with characteristics of static electricity resistance, moisture absorption, gas permeability, elasticity and slight fragrance. The fabric sequentially comprises a polyurethane film (1), a fabric substrate and a woven fabric layer (5) from outside to inside, wherein the fabric substrate comprises warp (2) and weft (3), and a base layer is compounded on the back surface of the woven fabric layer, and is formed by sequentially compounding velvet, sponge and a base cloth from outside to outside. The fabric of the present invention has characteristics of slight fragrance, lasting and strong fragrance, good static electricity resistance, moisture absorption, gas permeability, and elasticity.

Owner:陆秋亚

Moisture-absorbing, air-permeable, elastic and light-reflective shell fabric

InactiveCN105459505AEffective reminderEnsure safetyGlass/slag layered productsGlass fiberEngineering

The invention relates to a moisture-absorbing, air-permeable, elastic and light-reflective shell fabric. The shell fabric comprises a base fabric layer (1) and a shell fabric layer (2), wherein the shell fabric layer (2) is transparent, and a light-reflective layer (3) is arranged between the base fabric layer (1) and the shell fabric layer (2) and is made from glass fibers; and the base fabric layer is made from three layers, i.e., velvet, sponge and base fabric which are laminated sequentially from outside to inside. The shell fabric can be used for effectively reminding drivers about human activity, so as to better guarantee safety. The shell fabric is moisture-absorbing, air-permeable and elastic.

Owner:钟俊杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com