Patents

Literature

33results about How to "Antibacterial and deodorizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

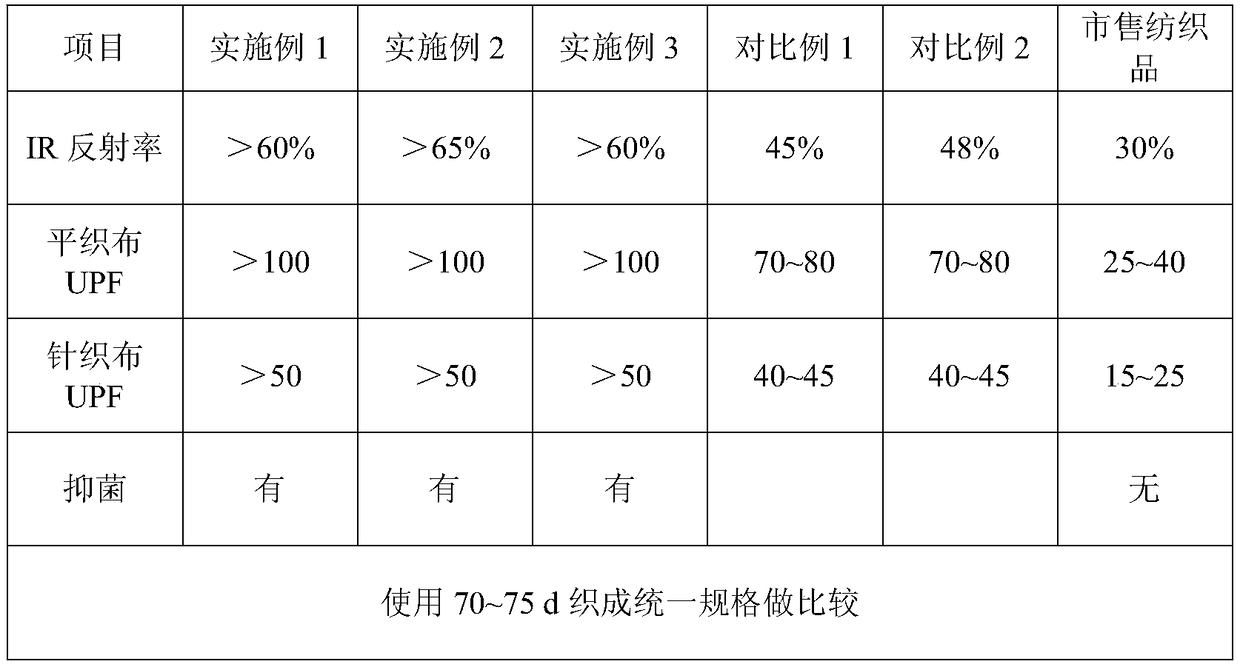

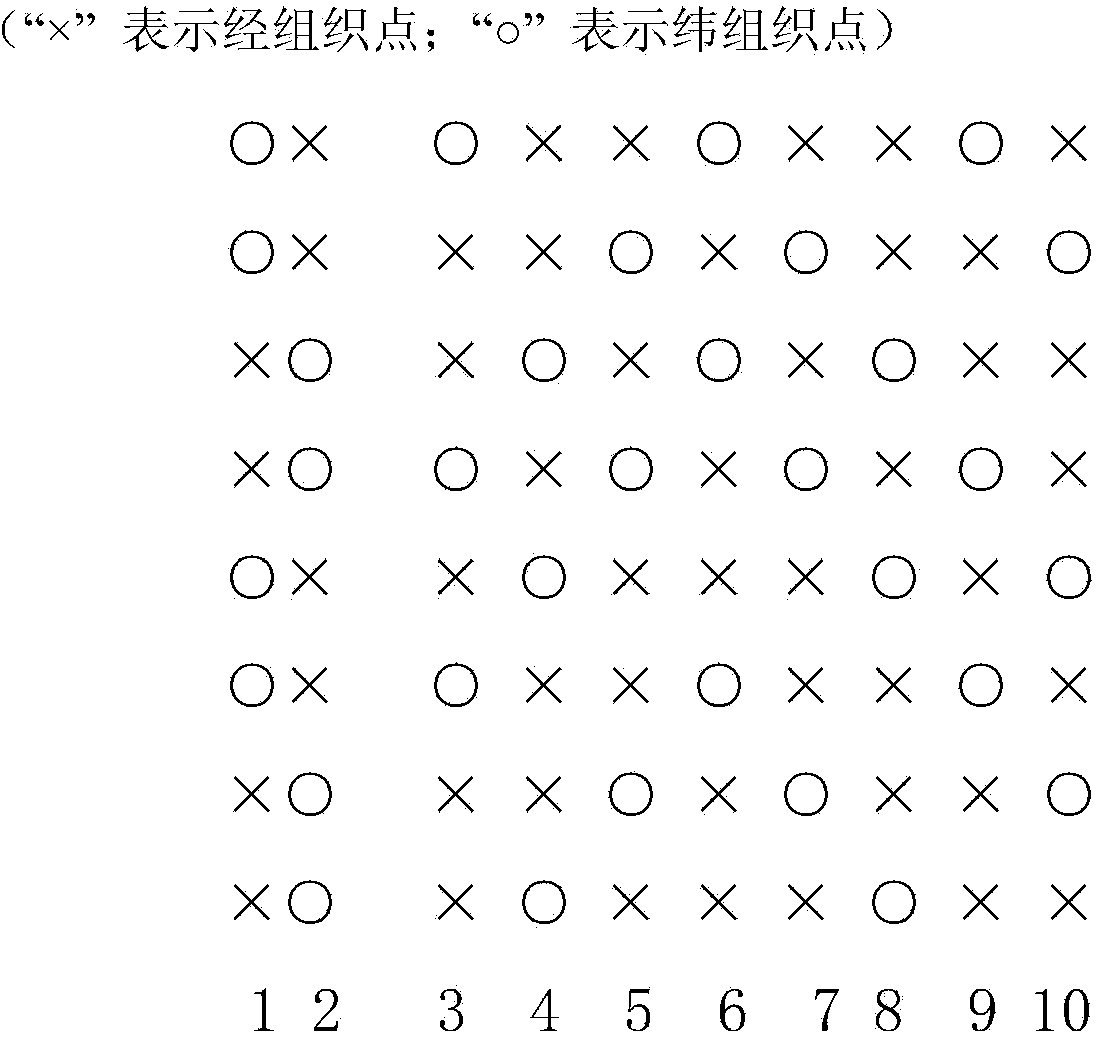

Coffee carbon multi-component fiber weaving fabric and preparation method thereof

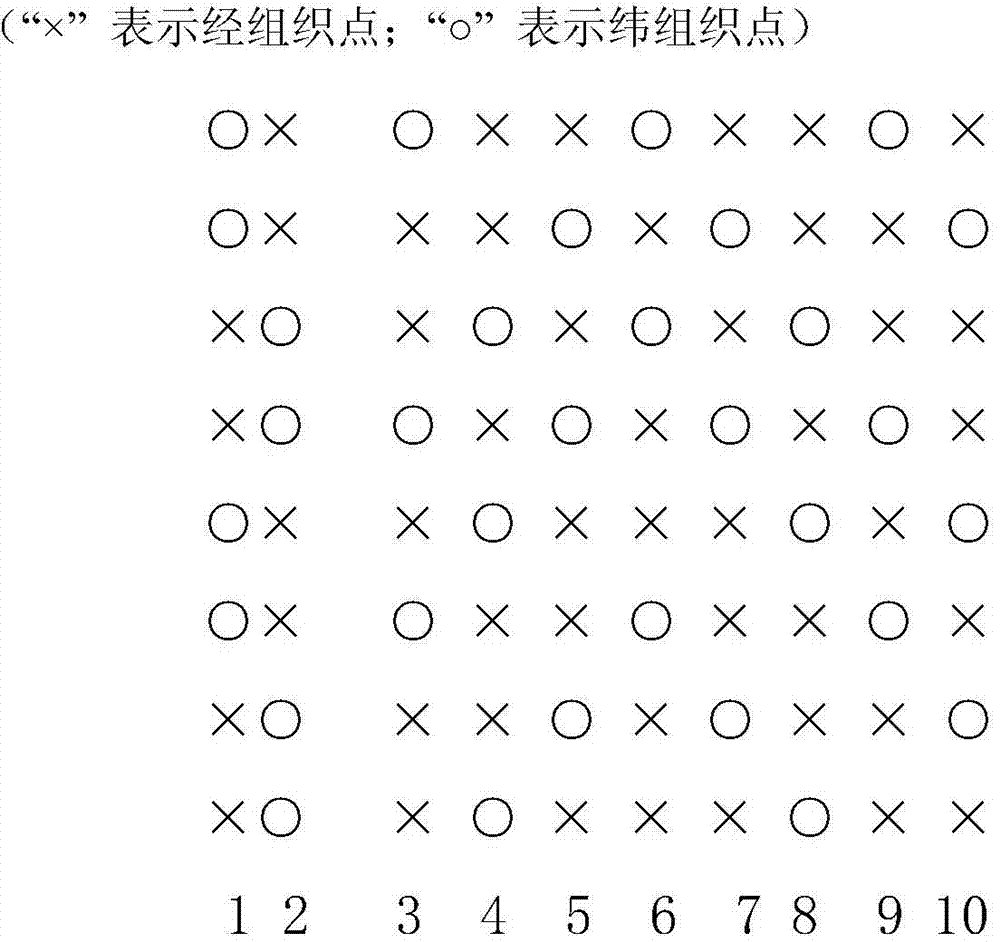

The invention belongs to the field of spinning, dyeing and finishing, and particularly relates to coffee carbon multi-component fiber weaving fabric and a preparation method of the coffee carbon multi-component fiber weaving fabric. The coffee carbon multi-component fiber weaving fabric is made of the following raw materials of warp direction yarns and weft direction filaments, wherein the warp direction yarns are formed by blending the following raw materials, by weight, 25-45% of coffee carbon fibers, 25-40% of bamboo fibers, 20-30% of cationic modified polyester fibers and 0.5-0.8% of conductive fibers, and the weft direction filaments are formed by alternately ranking 150D-160D coffee carbon fiber filaments and 100D-120D PTP fiber filaments at the ratio of 1 to 1. The coffee carbon multi-component fiber weaving fabric has the advantages that different characteristics of the coffee carbon fibers and the other fibers are exerted, comfort of the apparel fabric and the uvioresistant function and other protection functions are integrated, physicochemical indexes are good, dyefastness is high, and cost performance of the fabric is high. The preparation method is provided, the process is reasonable, and a new path is opened up for improving high performance and comfort of the coffee carbon multi-component fiber weaving fabric.

Owner:SHANDONG WOYUAN NEWFASHIONED FABRIC

Production process of fiber velvet Raschel blanket

ActiveCN105310378AFeel smoothGood moisture absorption and air permeabilityBlanketFibre typesFiberYarn

The invention relates to a production process of a fiber velvet Raschel blanket. The production process comprises the following steps: 1) selecting yarns; 2) weaving; 3) pre-finishing; 4) dyeing; and 5) post-finishing. The entire production process of the invention is optimized and improved, and the fluffiness of the blanket is improved by improving luster finishing temperature on a front surface; the production process, which makes use of environmental-friendly dyeing auxiliaries during dyeing, is absolutely green and environmental-friendly; a finished product complies with the green, environmental-friendly and ecological development trend of international textile industry and is capable of achieving effects of being natural, environmental-friendly and comfortable; and the project, with implementation, is good in economic and social benefits.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

Automobile sealing strip rubber material with effects of restraining bacteria and removing abnormal smells and preparation method thereof

The invention discloses an automobile sealing strip rubber material with the effects of restraining bacteria and removing abnormal smells. The automobile sealing strip rubber material is prepared from, by weight, 100-120 parts of ethylene propylene diene monomer, 30-50 parts of white carbon black, 10-15 parts of shell powder, 2-4 parts of blumea oil, 2-4 parts of zinc oxide, 1.5-2.5 parts of sulphur S80, 1.5-2.5 parts of antiager MB, 0.3-0.5 part of accelerant TMTD, 0.03-0.05 part of tetradecyl dimethyl benzyl ammonium, 0.1-0.15 part of glycerol monolaurate, 3-5 parts of methyltrimethoxysilane, 0.5-1 part of tetrabutyl titanate, 0.15-0.25 part of titanate coupling agent NDZ-401, 6-8 parts of nano-graphite powder and 20-30 parts of castor oil. The rubber material is good in anti-abrasion effect and durable in anti-friction performance, has the effects of restraining bacteria and removing abnormal smells, and has the advantages of being long in service life, good in sealing performance and good in sanitation when used as an automobile sealing strip material.

Owner:闻承岳

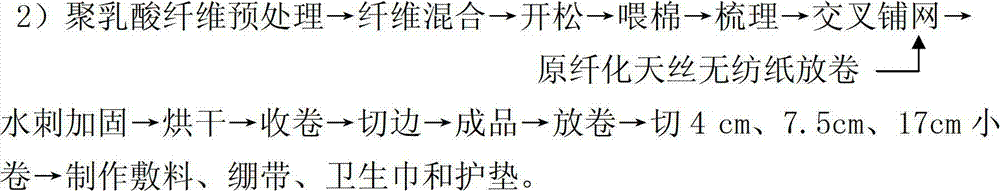

Non-allergenic fully-degradable medical and hygienic non-woven material capable of adjusting moisture

ActiveCN102733096AStrong and goodGood skin affinityPulp beating methodsNon-woven fabricsPolymer chemistryPolylactic acid

The invention discloses a non-allergenic fully-degradable medical and hygienic non-woven material capable of adjusting moisture, and aims to solve the problem that the conventional degradable medical and hygienic materials are mainly made by a spunbonding method, and certain production processes are complex. The non-allergenic fully-degradable medical and hygienic non-woven material consists of the following raw materials of 60 to 80 mass percent of polylactic acid fibers and 20 to 40 mass percent of Tencel fibers and is prepared by the following steps of: preparing Tencel fiber non-woven paper by a wet laying method, wherein part of the Tencel fiber non-woven paper is fibrillated; pre-treating the polylactic acid fibers and preparing a polylactic acid fiber web; unreeling the non-woven paper on the polylactic acid fiber web once again, interweaving the fibrillated Tencel fibers with the polylactic acid fiber web by a high-pressure spraying method, and fibrillating the Tencel fibers further; and drying at proper temperature to bind the fibrillated Tencel fibers to the periphery of the polylactic acid fibers firmly. The non-allergenic fully-degradable medical and hygienic non-woven material has the characteristics of non-allergenic property and capacity of adjusting the moisture, and can be degraded fully after being discarded.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

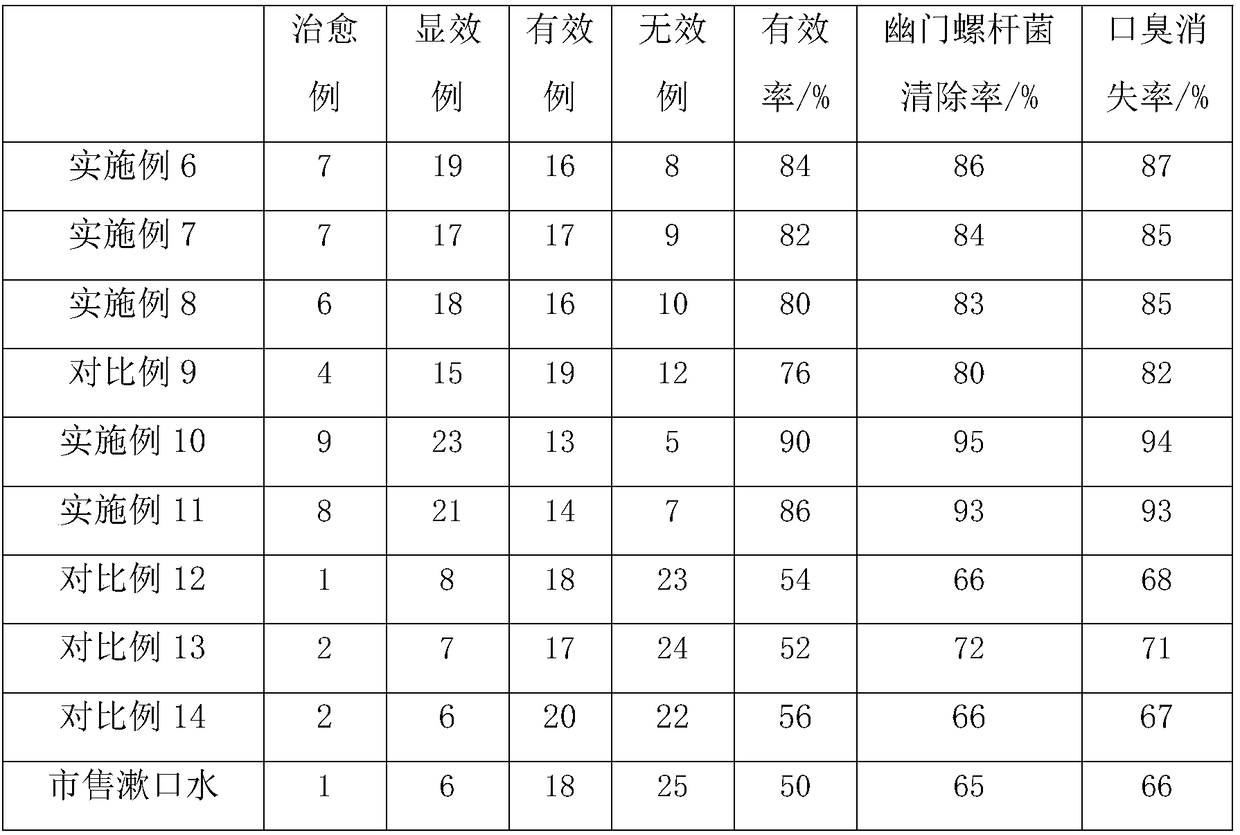

Oral care composition and application thereof

InactiveCN108652993APlaque removalPrevent dental cariesCosmetic preparationsToilet preparationsOral mucosaZinc

The invention discloses oral care composition. The oral care composition is prepared from components in parts by weight as follows: 0.6-5 parts of zinc salt, 0.2-1.8 parts of fluoride, 0.1-1 part of strontium salt, 1-5 parts of potassium salt and 0.5-1 part of alkaline sodium salt. Compared with the prior art, the oral care composition has the beneficial effects that bacteriostasis, deodorization,desensitization, tooth strengthening and dental plaque removal can be realized, gums can be nourished, and oral mucosa can be protected.

Owner:丽睿客信息科技(北京)有限公司 +1

Sanded coffee carbon knitted fabric

InactiveCN105297270AMeet the requirementsHigh level of anti-pilling propertiesWeft knittingYarnYarnSurface layer

The invention relates to sanded coffee carbon knitted fabric formed by knitting of a double-sided woven weft-knitted structure. The sanded coffee carbon knitted fabric comprises an outer surface layer and a suede layer. The outer surface layer is formed by knitting of blended yarns and polyurethane filaments. The blended yarns comprise lining yarns, connecting yarns and surface yarns. The surface yarns and the lining yarns are interwoven with polyurethane filaments via the connecting yarns. The blended yarns are formed by blending of coffee carbon fine-denier acrylic fibers and viscose. The blending ratio of coffee carbon fine-denier acrylic fibers and viscose ranges from 1:4 to 2:3. The sanded coffee carbon knitted fabric is high in degree of pilling-performance, good in quality and multiple additional functions.

Owner:JIANGSU NEW XUEZHU INT FASHION

Complex with self heat accumulation function, its preparation and use thereof

InactiveCN1635045AHigh strengthControllable heat production efficiencyHeat-exchange elementsPhysical chemistryPolymer chemistry

The invention relates to a composite material with heat accumulation function, which comprises (by weight ratio) tourmaline ultramicro powder 25-50%, caloric powder 40-65%, adhesive 2-5%, embedding agent 1-5%. The process for preparation comprises raw material preparation, mixing, and press forming, wherein the pressure for press forming is 12-30 MPa.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Humidifying liquid medicine for mask filter element and preparation method of humidifying liquid medicine

InactiveCN107050195AAntibacterial and deodorizingClears the throat and moisturizes the lungsHydroxy compound active ingredientsRespiratory disorderSide effectMedicine

The invention relates to humidifying liquid medicine for a mask filter element and a preparation method of the humidifying liquid medicine. The humidifying liquid medicine which is a traditional Chinese medicine composition comprises, by weight, 3-5 parts of chrysanthemum, 4-8 parts of radix sileris, 4-8 parts of radix angelicae dahuricae, 6-9 parts of pericarpium citri reticulatae, 1-3 parts of radix glycyrrhizae, 3-5 parts of folium artemisiae argyi, 3-5 parts of Agastache rugosus, 0.1-0.3 part of mentha haplocalyx, 0.1-0.3 part of honeysuckle, 3-5 parts of eucalyptus, 0.1-0.3 part of borneol and 3-5 parts of tea leaf. The filter element is completely soaked into the mixed liquid medicine and taken out when the filter element does not absorb the mixed liquid medicine any more, and then the filter element is baked under the temperature of 55-65 DEG C and the vacuum degree of 780mmHg for 1-1.5 hours. The filter element is placed into a haze-preventing mask during use, and one treatment course lasts one month. The filter element placed into the haze-preventing mask during use is capable of preventing haze and treating nasosinusitis and sphagitis. The humidifying liquid medicine is convenient to use, low in cost, good in effect and small in toxic and side effects.

Owner:石家庄市中医院 +1

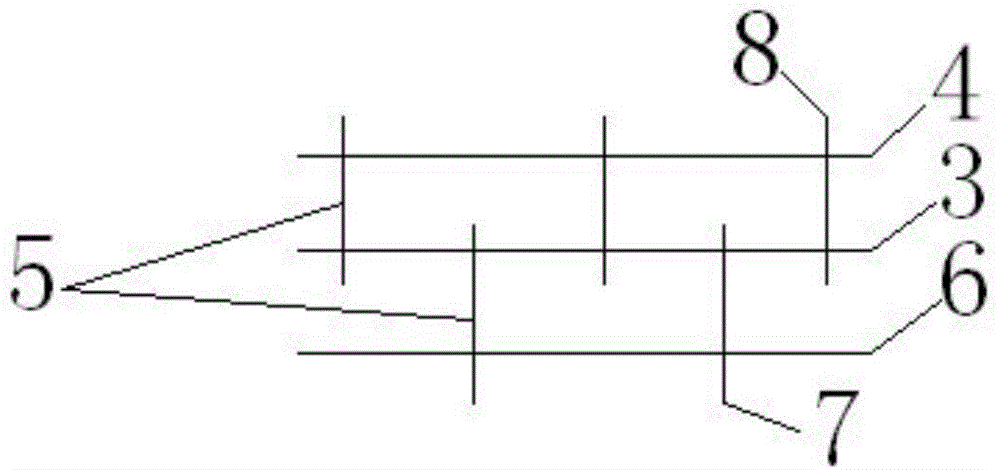

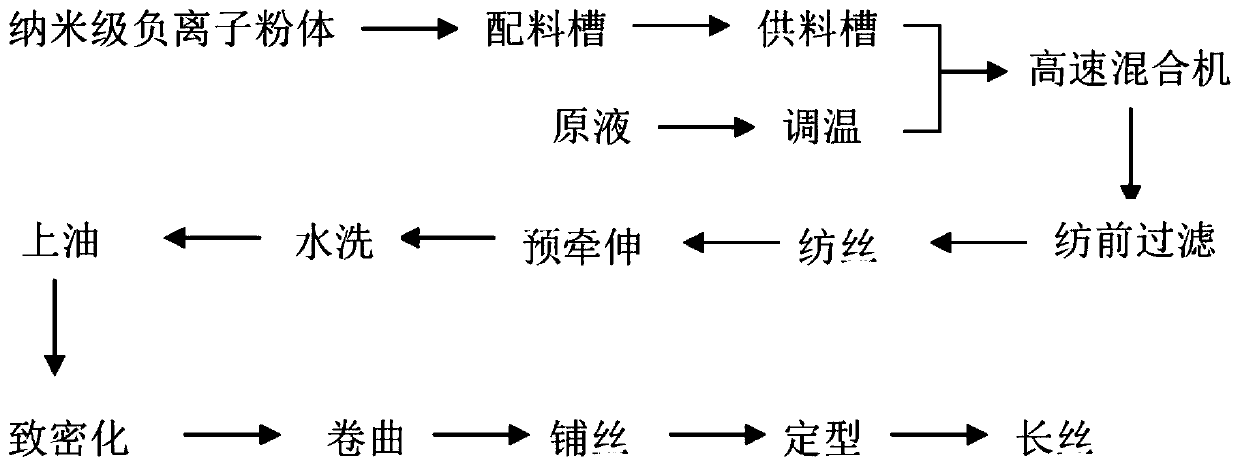

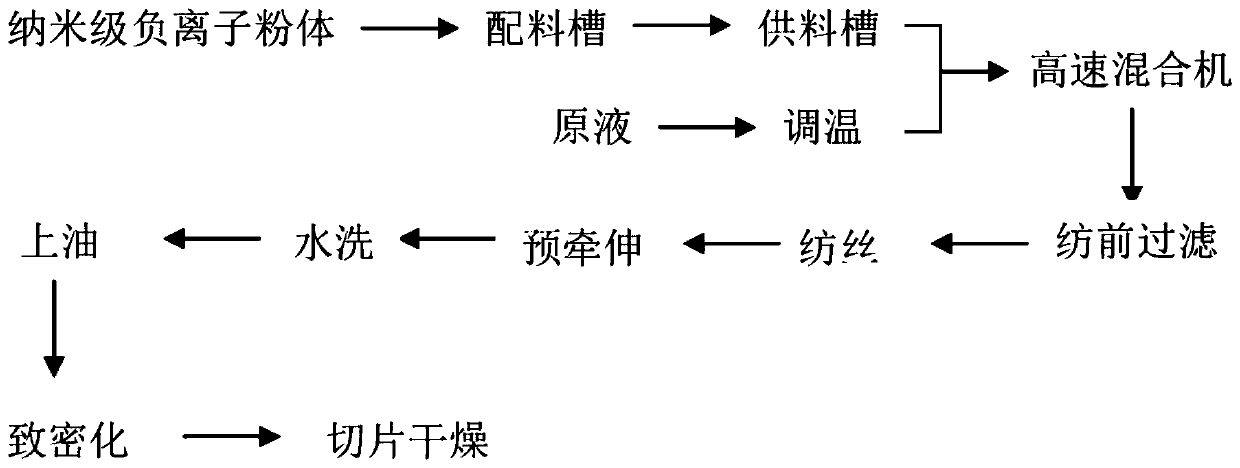

Weaving method and product of polyester and acrylic fiber anion fiber woven home textile fabric

InactiveCN110106621ACompatibility is reasonableLow costWarp knittingMonocomponent synthetic polymer artificial filamentPolyesterStock solution

The invention provides a weaving method and product of a polyester and acrylic fiber anion fiber woven home textile fabric. The method includes the steps of adding a acrylic fiber spinning stock solution to nanoscale anion powder with permanent spontaneous polarization to be evenly dispersed to prepare an anion acrylic fiber spinning stock solution, and weaving the acrylic fiber anion fiber home textile fabric from acrylic fiber anion fiber and polyester through spinning. The polyester is reasonable in ratio, high in spinnability and moderate in price and meets the market requirements; the advantages of being bright in color and luster, good in heat retention property and soft in handfeel of the acrylic fiber anion fiber can be given into full play; the fabric has the functions of emittingfar infrared rays and capable of realizing dehumidifying and drying; the fabric releases anions and is beneficial for body health; the fabric is high in mineral quality content and has a special healthcare function.

Owner:JIANGYIN XIANGFEI APPAREL +1

Multifunctional woollen sweater finishing agent containing marine mud

InactiveCN106087385AExcellent water and oil repellencyGood skin affinityBiochemical fibre treatmentLight resistant fibresWrinkle skinBetaine

The invention discloses a multifunctional woollen sweater finishing agent containing marine mud. The multifunctional woollen sweater finishing agent is prepared from the following raw materials in percentage by weight: 6-20% of a marine mud solution, 0.5-3% of a cinnamomum camphora leaf extract, 0.3-1.5% of a Xingan rhizoma cimicifugae root extract, 1.5-3% of a banyan gum liquid, 0.01-1.2% of tea saponin, 5-15% of a softening agent, 5-10% of propylene glycol block polyether, 1.5-3% of dodecyl dimethyl betaine and the balance of deionized water. Therefore, a woollen sweater treated by using the multifunctional woollen sweater finishing agent has the effects of preventing bacterium and eliminating odor, preventing ultraviolet light, killing mints and insects, preventing static electricity and emitting fragrance, meanwhile is capable of releasing nutrient healthcare components and promoting human body health, has a remarkable property of wrinkle and shrinkage prevention, and is long in service life and relatively good in effect, and the wollen sweater can be excellent in brightness, softness, smoothness, slipperiness, fullness, brightening and the like, and the system can be kept stable for a long time. An advantageous direction is provided for recycling use of marine mud, and relatively great predicable economic and social benefits can be made.

Owner:陆建益

Bacteria-resisting and odor-removing straw treatment fluid and preparation method thereof

InactiveCN106182279AImprove the protective effectGood for healthWood treatment detailsReed/straw treatmentPolyvinyl chlorideGluconic acid

The invention discloses a bacteria-resisting and odor-removing straw treatment fluid which is prepared from the following raw materials in part by weight: 2-4 parts of nano jade powder, 2-4 parts of nano maifan stone powder, 3-5 parts of polyethylene wax, 0.4-0.6 part of fatty alcohol polyoxyethylene ether O-10, 0.3-0.5 part of glycerol monolaurate, 0.3-0.5 part of caprylic capric triglyceride, 10-15 parts of modified polyvinyl chloride latex, 1-2 parts of sodium gluconate, 0.2-0.4 part of carboxymethyl chitosan, and 40-50 parts of water. A transparent and uniform coating is formed on the surface of straw, is high in water resistance and moisture permeability, has a good protection effect on the straw material, and is not prone to damp and mould. Moreover, the bacteria-resisting and odor-removing straw treatment fluid has bacteria-resisting and odor-removing effects, is beneficial for environmental sanitation and human health, and is high in practicability.

Owner:FUNAN YONGXING ARTS & CRAFTS

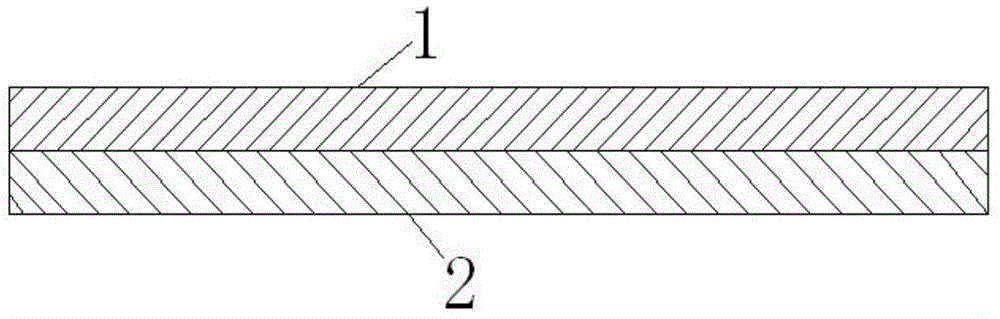

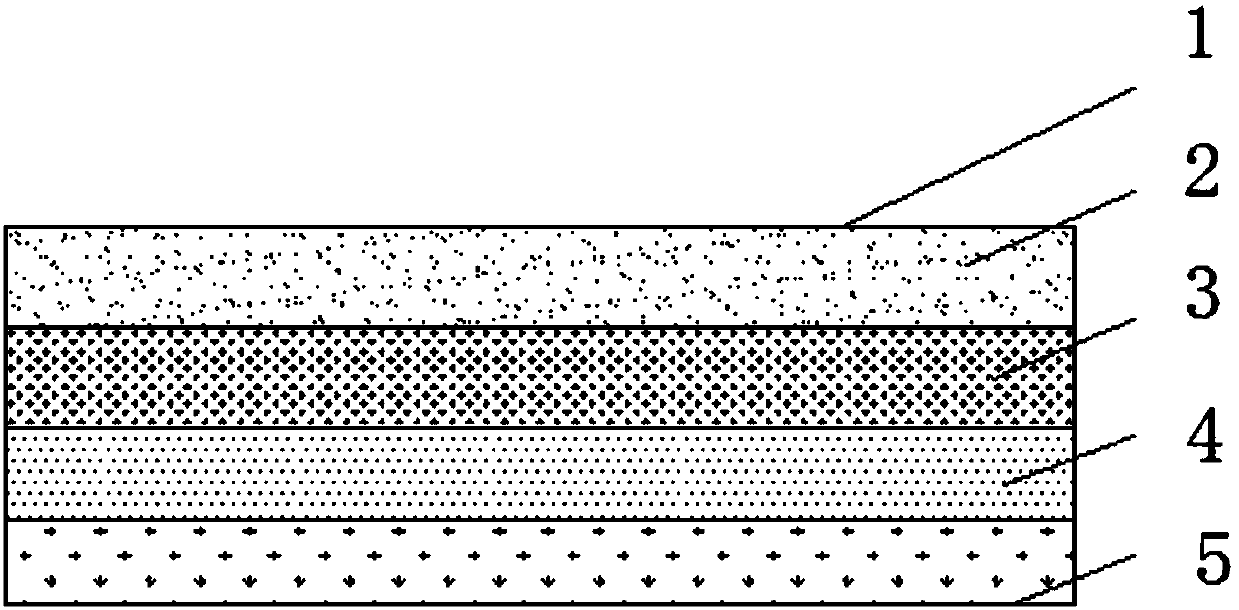

Crease-resistant microfiber synthetic leather

InactiveCN109795167APlay the role of waterproof and breathableImprove insulation effectSynthetic resin layered productsTextiles and paperMicrofiberChemistry

The invention discloses crease-resistant microfiber synthetic leather. The crease-resistant microfiber synthetic leather comprises a synthetic leather body, wherein the synthetic leather body is composed of a shape memory fiber layer, a waterproof and breathable polyurethane layer, a base cloth layer and a chitosan fiber layer, the upper surface of the base cloth layer is covered with the waterproof and breathable polyurethane layer, the upper surface of the waterproof and breathable polyurethane layer is covered with the shape memory fiber layer, and the lower surface of the base cloth layeris covered with the chitosan fiber layer. The crease-resistant microfiber synthetic leather has the advantages that the air permeability and waterproofness are good, the surface of the synthetic leather does not crease easily, and clothing materials or leather shoes made from the microfiber synthetic leather have effects of keeping warm and inhibiting bacteria.

Owner:JIANGXI HOPU HIGH TECH COATED FABRIC CO LTD

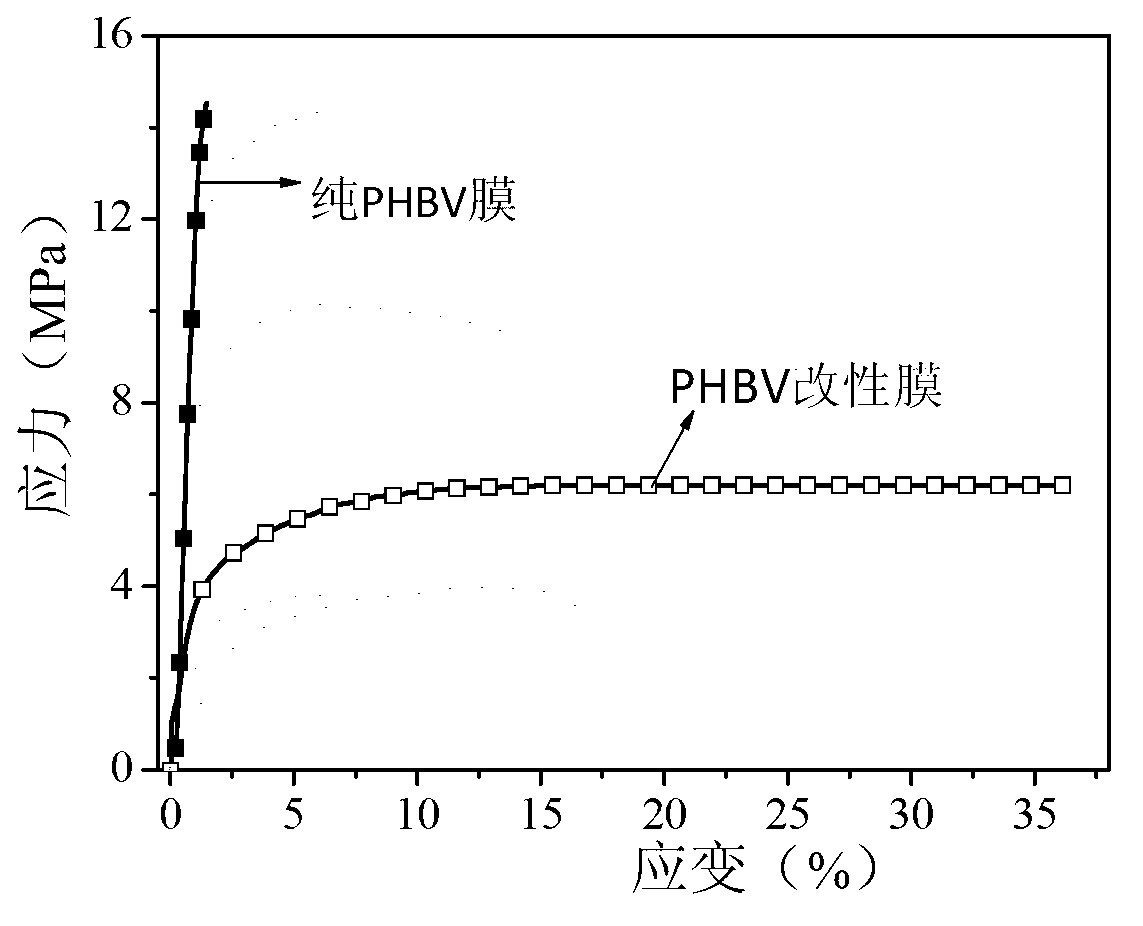

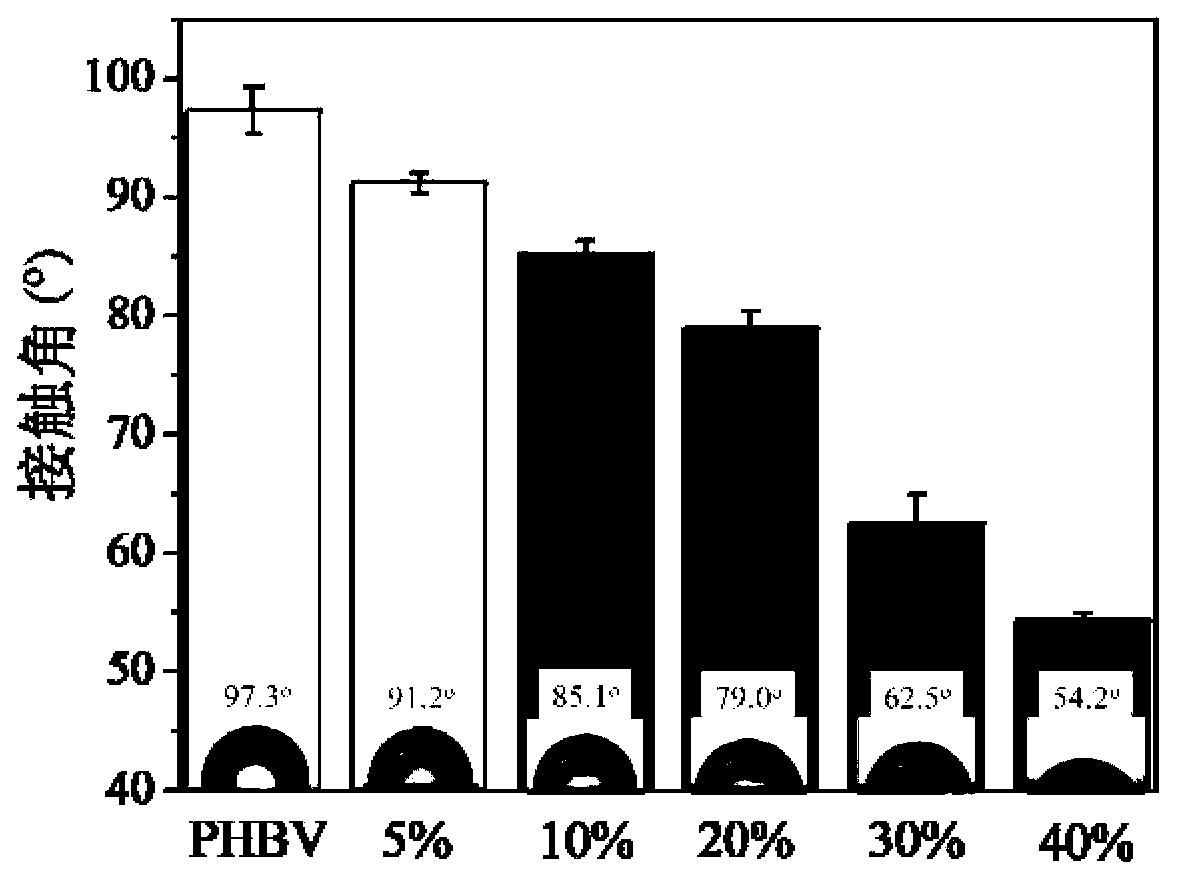

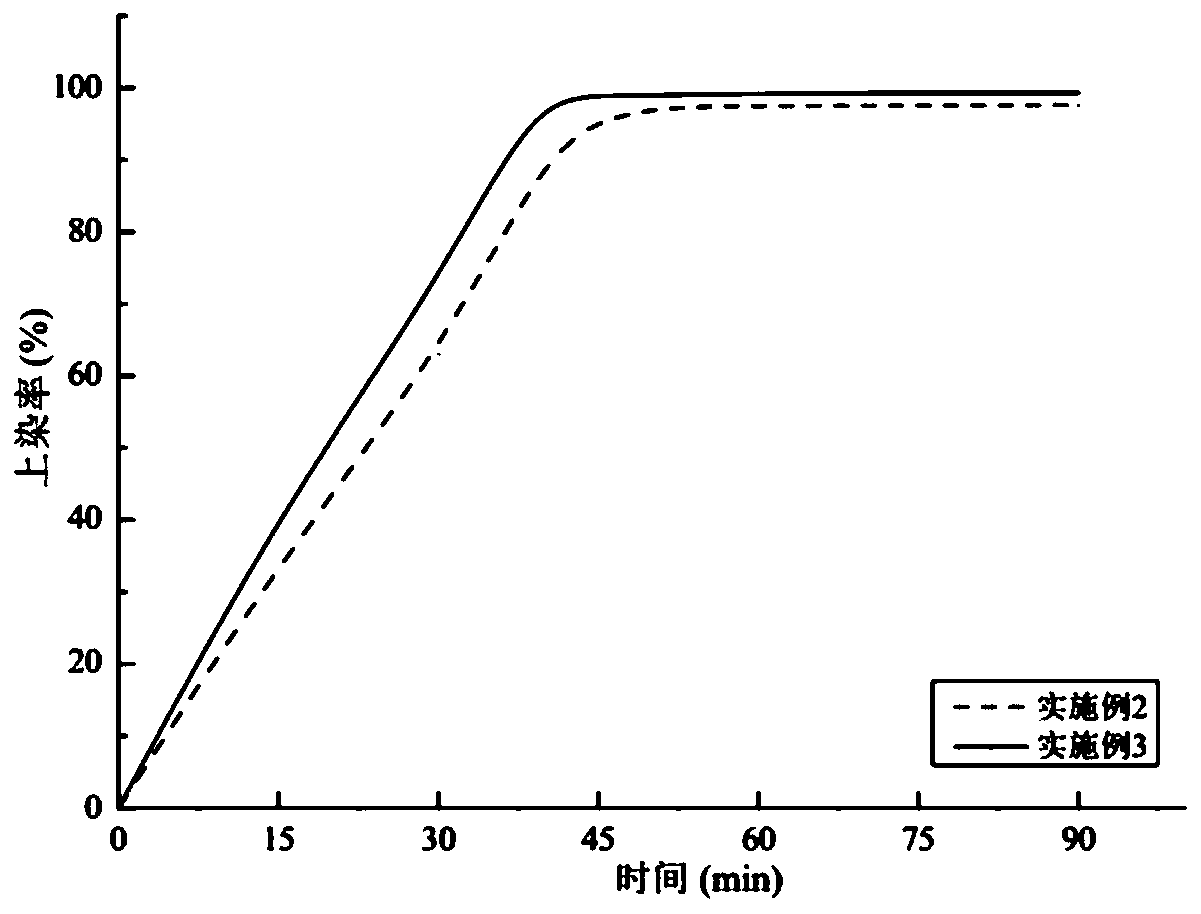

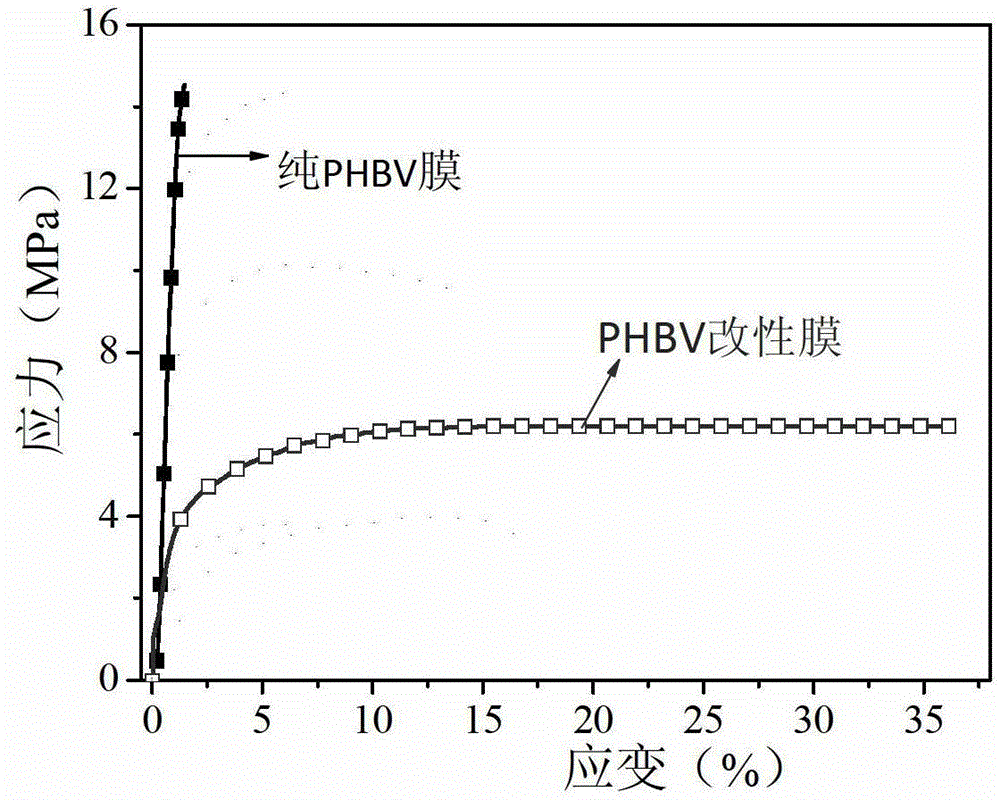

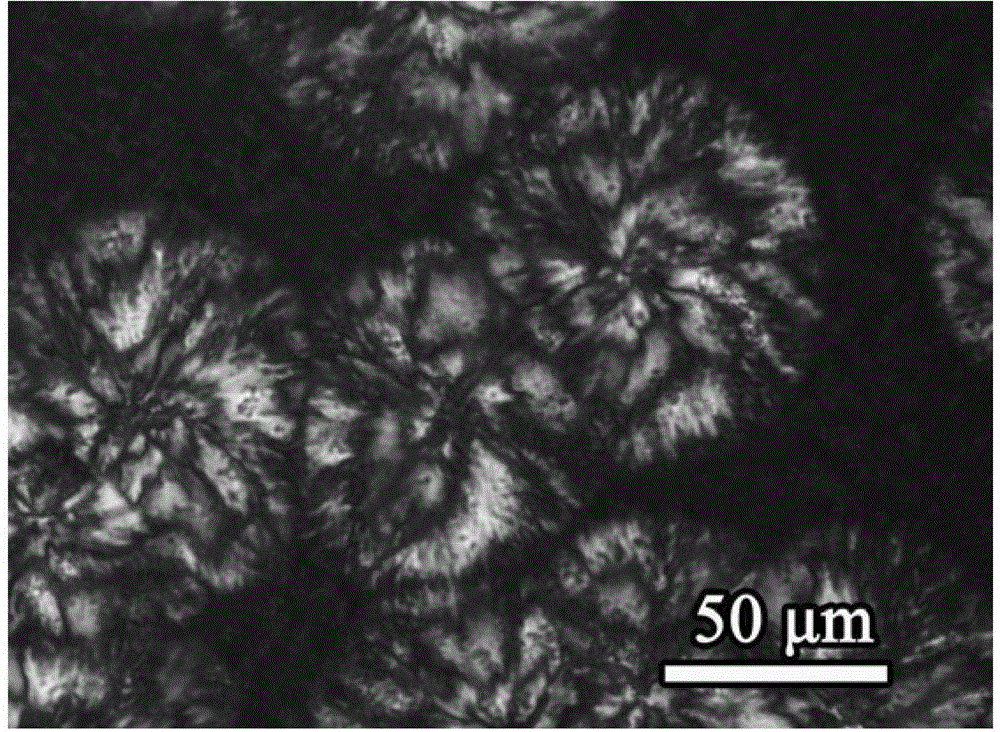

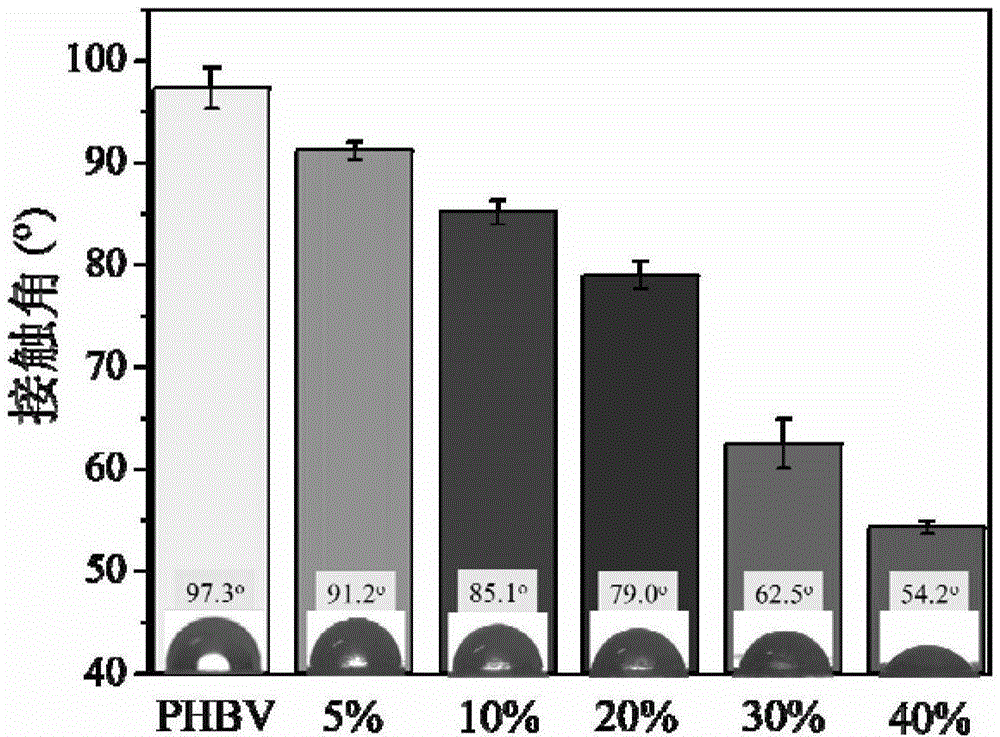

Preparation method of environment-friendly composite polymer film material

The invention relates to a preparation method of an environment-friendly composite polymer film material, which comprises the following steps: adding biomass polyester and modifier into solvent, and stirring to dissolve at 25-60 DEG C for 2-4 hours, thus obtaining a polymer mother solution; and then, preparing the polymer mother solution into a film through a film coating method, and volatilizing the solvent at room temperature to obtain the composite polymer film material. The biomass polyester and the modifier thereof used in the invention have the characteristics of favorable biodegradability and biocompatibility; and the composite polymer film prepared by the invention has the characteristics of environment friendliness and wide application range, and is hopefully popularized and used in the fields of biomedical materials and ecological environment protection.

Owner:DONGHUA UNIV

Sponge rubber for cervical pillow

The invention relates to the technical field of rubber compositions, in particular to sponge rubber for a cervical pillow. The sponge rubber is prepared from, by weight, 80-120 parts of ethylene propylene diene monomer, 50-80 parts of natural rubber, 4-12 parts of foaming agents, 1.5-3.5 parts of dialkyl dithio-phosphoro-amidate, 2-6 parts of accelerators DM, 10-20 parts of elastic fibers, 3-9 parts of activated zinc oxide, 1-2 parts of far infrared ceramic powder, 10-30 parts of lavender and 5-10 parts of multi-element composite antibacterial materials. The sponge rubber is high in elasticityand has the functions of maintaining and protecting health, resisting bacterium and removing odor, the cervical pillow prepared from the sponge rubber is conveniently maintained and cleaned, sleep quality can be effectively improved, cervical pain is relieved, and the cervical pillow has a wide application prospect in the field of bedding.

Owner:德清舒华泡沫座椅有限公司

Insect-killing and sterilizing colorful interior wall-simulating environment-friendly coating and preparation method thereof

InactiveCN107779026AImprove the decorative effectPromote environmental protectionAntifouling/underwater paintsPaints with biocidesEnvironmental resistanceTalc

The invention provides a kind of insecticidal and sterilized colorful imitation interior wall environmental protection paint, and its raw materials include the following components by weight: 60-90 parts of organic silicon modified acrylate emulsion, 15-30 parts of negative ion powder, 3-9 parts of titanium dioxide 2-6 parts of lithopone, 2-6 parts of light calcium carbonate, 1-3 parts of talcum powder, 0.5-0.8 parts of hydroxyethylcellulose, 3-5 parts of iridescent pearlescent pigment, 0.3-0 parts of insecticide 0.6 parts, 0.1-0.3 parts of fungicides, 0.1-0.3 parts of defoamers, 2-5 parts of coalescents, 0.2-0.5 parts of thickeners, 0.2-0.5 parts of wetting agents, 0.2-0.5 parts of dispersants, 60‑100 parts of deionized water. The invention also provides a preparation method thereof. The insecticidal and sterilizing colorful imitation interior wall environmental protection paint has good decoration, environmental protection, water resistance, alkali resistance, temperature change resistance and weather resistance, is non-toxic, tasteless, and environmentally friendly. , Good safety, contain negative ions, can inhibit bacteria and deodorize, kill insects and sterilize.

Owner:清远市思彤新材料科技有限公司

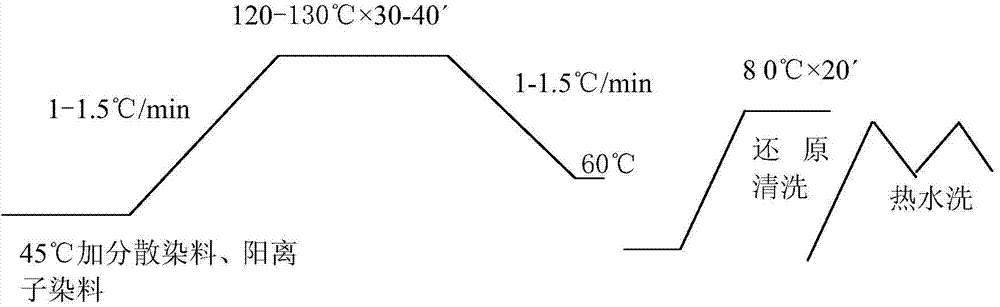

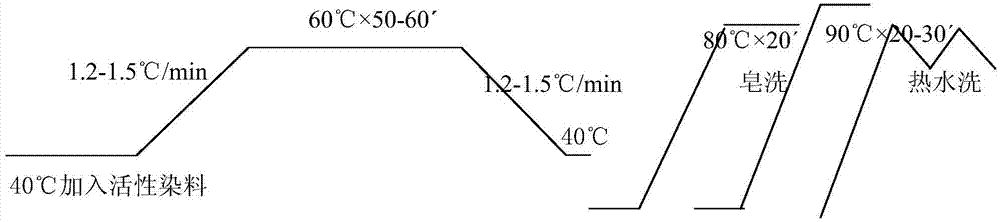

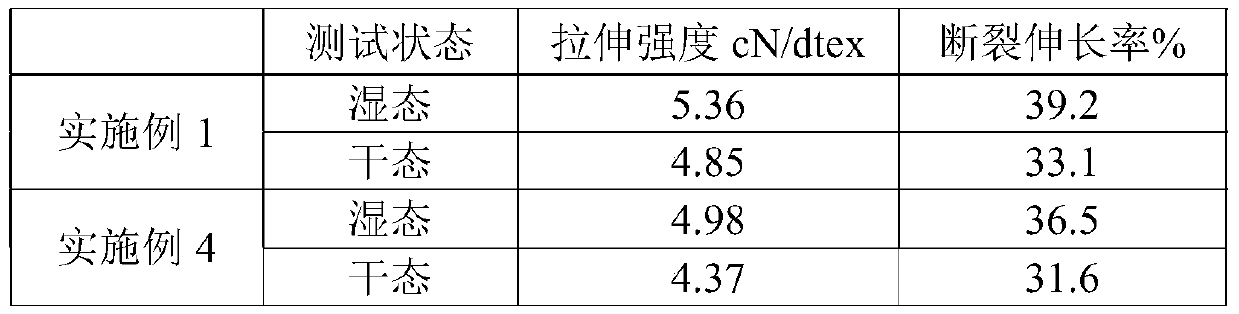

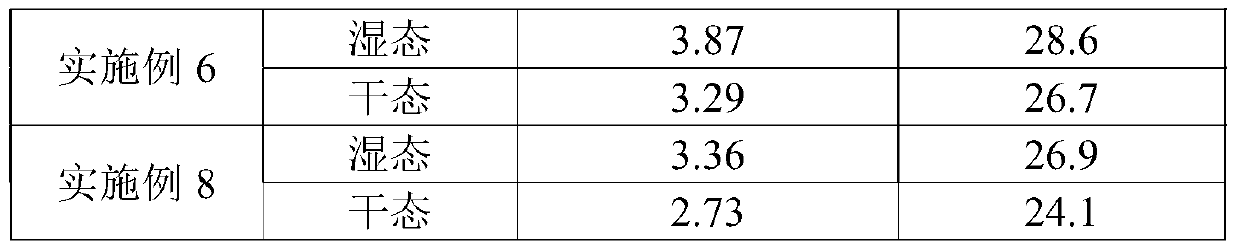

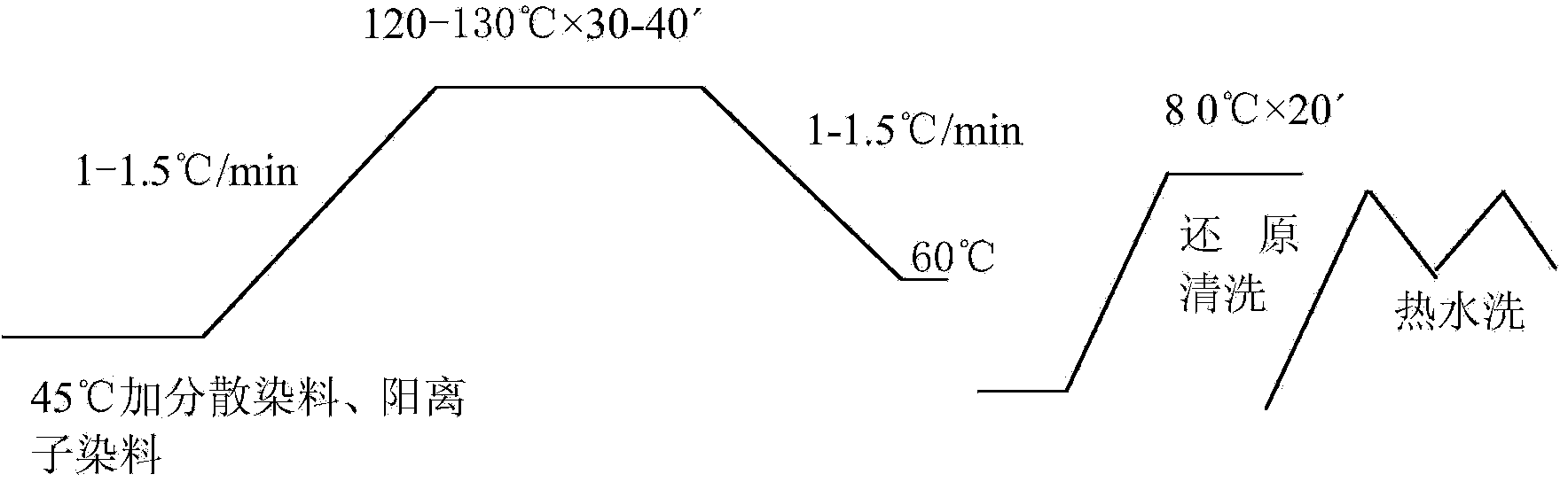

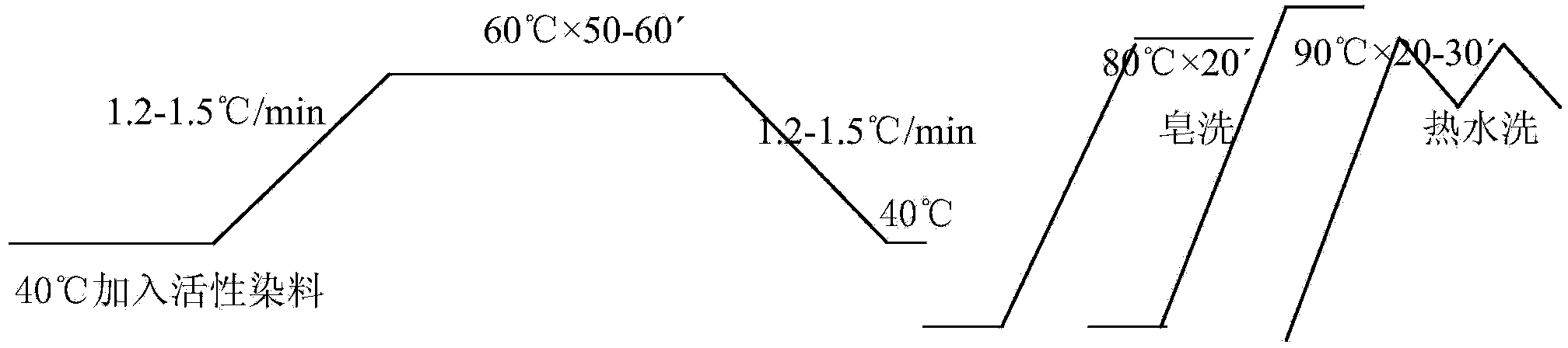

Manufacturing method of coffee-carbon-containing PLA fiber fabric

ActiveCN110820081AHeat preservationAntibacterial and deodorizingDyeing processConjugated synthetic polymer artificial filamentsTextile technologyColour fastness

The invention provides a manufacturing method of a coffee carbon containing PLA fiber fabric and belongs to the technical field of textile, including the steps of spinning, pre-treating, dyeing, weaving, finishing and sizing. Raw fibers for spinning are prepared by the steps of providing polylactic acid chips comprising poly-L-lactic acid and poly-D-lactic acid and coffee carbon polylactic acid master batch comprising flexibilizers and antioxidants, melting and spinning the master batch and the polylactic acid chips, performing hot drafting and hot setting to obtain the coffee-carbon-containing PLA fiber fabric. According to the manufacturing method, heat resistance and high temperature resistance of the fibers can be improved, tensile strength and elongation at break can be enhanced, andresilience and crease resistance performance of fibers and fabric can be improved by increasing crease recovery angle, further, dye-uptake and dyeing rate of the fibers can be increased, color fastness to dyeing and washing is improved, color persistence and shape preservation of the fibers and fabric are also can be promoted, time for dyeing can be shortened, production cost and energy consumption can be reduced greatly.

Owner:咖法科技(上海)有限公司

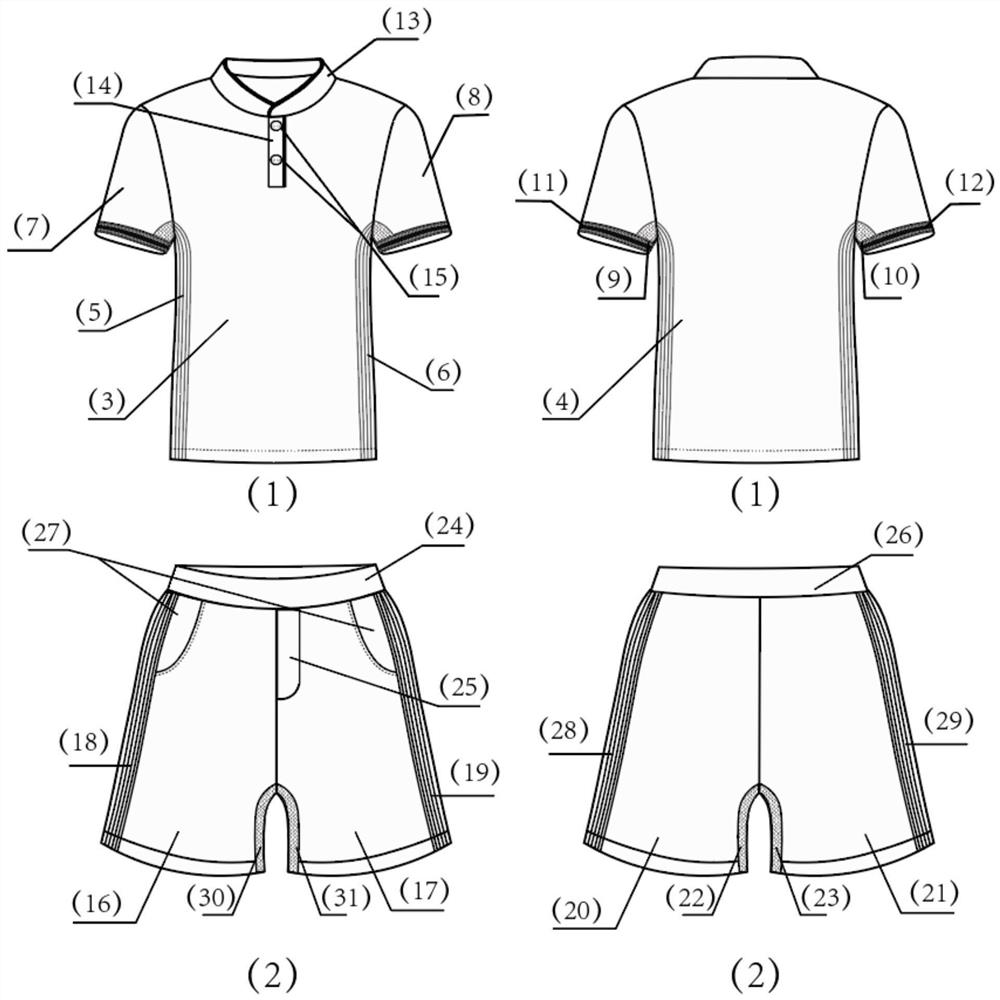

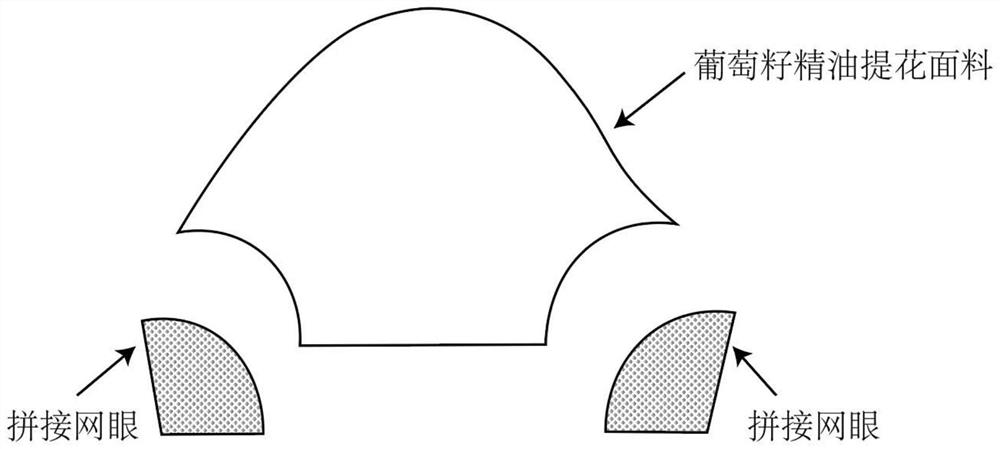

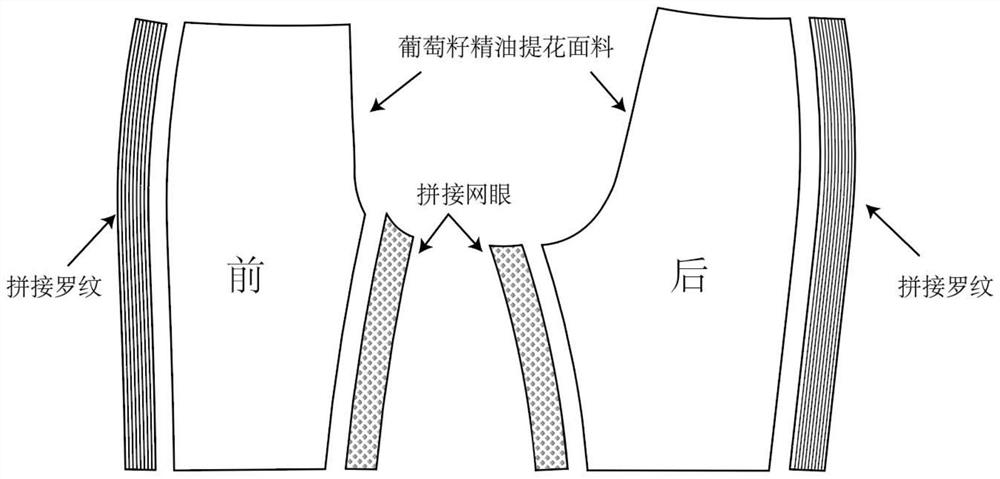

Grape seed essential oil homewear and manufacturing method thereof

PendingCN113439893AIncrease the adjustable range of fat and thinFree and flexible activitiesTrousersPyjamasBiotechnologyGrape seed

The invention provides grape seed essential oil homewear and a manufacturing method thereof. Grape seed essential oil jacquard fabrics are arranged on a front piece, a rear piece, a left sleeve piece, a right sleeve piece, a front piece left side, a front piece right side, a rear piece left side and a rear piece right side; the left sleeve splicing mesh, the right sleeve splicing mesh, the crotch left rear side splicing mesh, the crotch right rear side splicing mesh, the crotch left front side splicing mesh and the crotch right front side splicing mesh are made of Binchotan antibacterial deodorant mesh fabric; the left side splicing rib, the left front side splicing rib, the left rear side splicing rib, the right side splicing rib, the right front side splicing rib and the right rear side splicing rib are high-elastic grape seed essential oil rib fabric. The spliced short-sleeve upper garment and the spliced short pants are formed by splicing and sewing the fabrics of different textures, the fabrics are designed according to special requirements of different parts, the effects of moisturizing, skin friendliness, bacteriostasis, deodorization, stain resistance and easy cleaning can be achieved, the used grape seed essential oil viscose can fully play the skin care effect of grape seed essential oil, and the homewear is suitable for long-term wearing.

Owner:QINGDAO XUEDA GRP

Multifunctional fabric and processing technique and application thereof

InactiveCN109440451AEliminate odorImprove immunityStain/soil resistant fibresBiochemical fibre treatmentEngineeringMultiple function

The invention provides multifunctional fabric and a processing technique and application thereof. The processing technique of the multifunctional fabric includes the steps of straightening gray fabric, spreading the gray fabric in a composite finishing agent, soaking for 5-15 min, and drying to obtain the multifunctional fabric. The multifunctional fabric provided herein meets the demand of wearers for enhanced functionality when wearing clothes with different demanded functions, and meets the demand of people for health preservation.

Owner:GUANGZHOU SHENGMEIYIZHONG SCI & TECH CO LTD

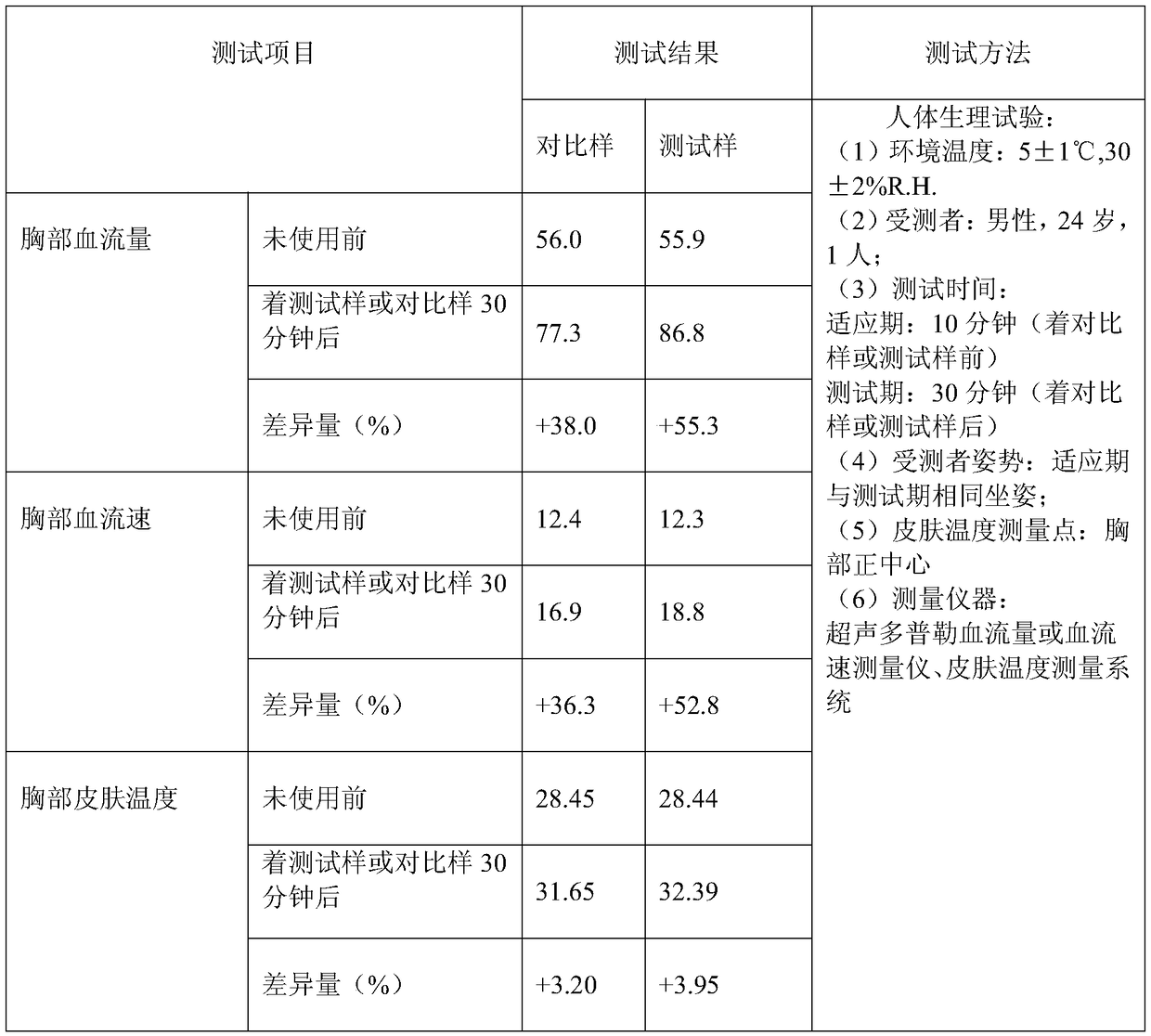

Anti-static fabric for pregnant women and preparation method thereof

InactiveCN111376556ASoft and comfortableGood hygroscopicityCarbon fibresBiochemical fibre treatmentPolyesterPolymer science

The invention relates to the technical field of fabrics, and provides an anti-static fabric for pregnant women and a preparation method thereof. The problems that in the prior art, fabric is poor in antistatic property, and static electricity is easy to accumulate to cause harm can be solved. The anti-static fabric comprises a base fabric layer, wherein a surface layer is arranged on the base fabric layer; wherein an anti-radiation layer is arranged between the base fabric layer and the surface layer; wherein the base fabric layer is formed by interweaving first warp yarns and first weft yarns; the surface layer is formed by interweaving second warp yarns and second weft yarns; the first warp yarns are copper ammonia / cotton blended yarns; the first weft yarns are polylactic acid / cotton blended yarns; wherein the first warp yarns are chitin / polyester blended yarns, the second weft yarns are modal / bamboo charcoal fibers, the anti-radiation layer raw materials are uniformly mixed and thencoated on the base fabric layer, then the surface layer is bonded on the anti-radiation layer through an adhesive, and finally the fabric is soaked in an anti-static finishing liquid and dried to obtain the anti-static fabric for pregnant women.

Owner:诸暨市孕创互联服饰有限公司

Liuhuan stone additive and use thereof in fabric finishing process

The invention relates to application of a six-ring stone additive in the textile finishing technique, which is characterized in that: the six-ring stone additive is prepared by the addition of dispersants (sodium laurylsulfate), bonding agents (acrylate) and water according to a creation proportion into 0.3 to 0.5 micrometers of six-ring stone superfine powder to prepare a suspension solution. The six-ring stone additive utilizes natural six-ring stones to emit far infrared rays and release anions, has the functions of bacteriostasis, deodorization and so on, particularly has superior stability and dispersity during the process of processing the superfine powder, and is applied to the textile finishing field.

Owner:SHANGHAI HONGKANG SCI TECH +1

Complex with self heat accumulation function, its preparation and use thereof

InactiveCN1315974CHigh negative ion countNo side effectsHeat-exchange elementsThermal treatmentMaterials science

The invention relates to a composite material with heat accumulation function, which comprises (by weight ratio) tourmaline ultramicro powder 25-50%, caloric powder 40-65%, adhesive 2-5%, embedding agent 1-5%. The process for preparation comprises raw material preparation, mixing, and press forming, wherein the pressure for press forming is 12-30 MPa.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Hexacyclic ring stone additive agent for cosmetics and preparation method thereof

InactiveCN101327170AReduce or eliminate useThe effect is obviousCosmetic preparationsHair cosmeticsAnti bacteriaMaterials science

The present invention relates to a Liuhuan stone additive used in cosmetic and a preparation method thereof, in particular to a superfine powder used in the cosmetic field and a preparation method thereof. The superfine powder is characterized in that the superfine powder is the superfine Liuhuan stone powder with the average granularity of 0.3 to 0.5 microns and is prepared by selecting material, crashing, smashing, grinding, vacuum filtering and dehydrating, drying and smashing. The functions of emitting far infrared, releasing anions, anti-bacteria, removing peculiar smell, and the like of natural Liuhuan stone are used, and the Liuhuan stone additive particularly has excellent stability and dispersibility during the course of processing the superfine powder and is applied in the cosmetic field.

Owner:SHANGHAI HONGKANG SCI TECH +1

A kind of production technology of velvet raschel blanket

ActiveCN105310378BFeel smoothGood moisture absorption and air permeabilityBlanketFibre typesEnvironmental resistanceYarn

The invention relates to a production process of a fiber velvet Raschel blanket. The production process comprises the following steps: 1) selecting yarns; 2) weaving; 3) pre-finishing; 4) dyeing; and 5) post-finishing. The entire production process of the invention is optimized and improved, and the fluffiness of the blanket is improved by improving luster finishing temperature on a front surface; the production process, which makes use of environmental-friendly dyeing auxiliaries during dyeing, is absolutely green and environmental-friendly; a finished product complies with the green, environmental-friendly and ecological development trend of international textile industry and is capable of achieving effects of being natural, environmental-friendly and comfortable; and the project, with implementation, is good in economic and social benefits.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

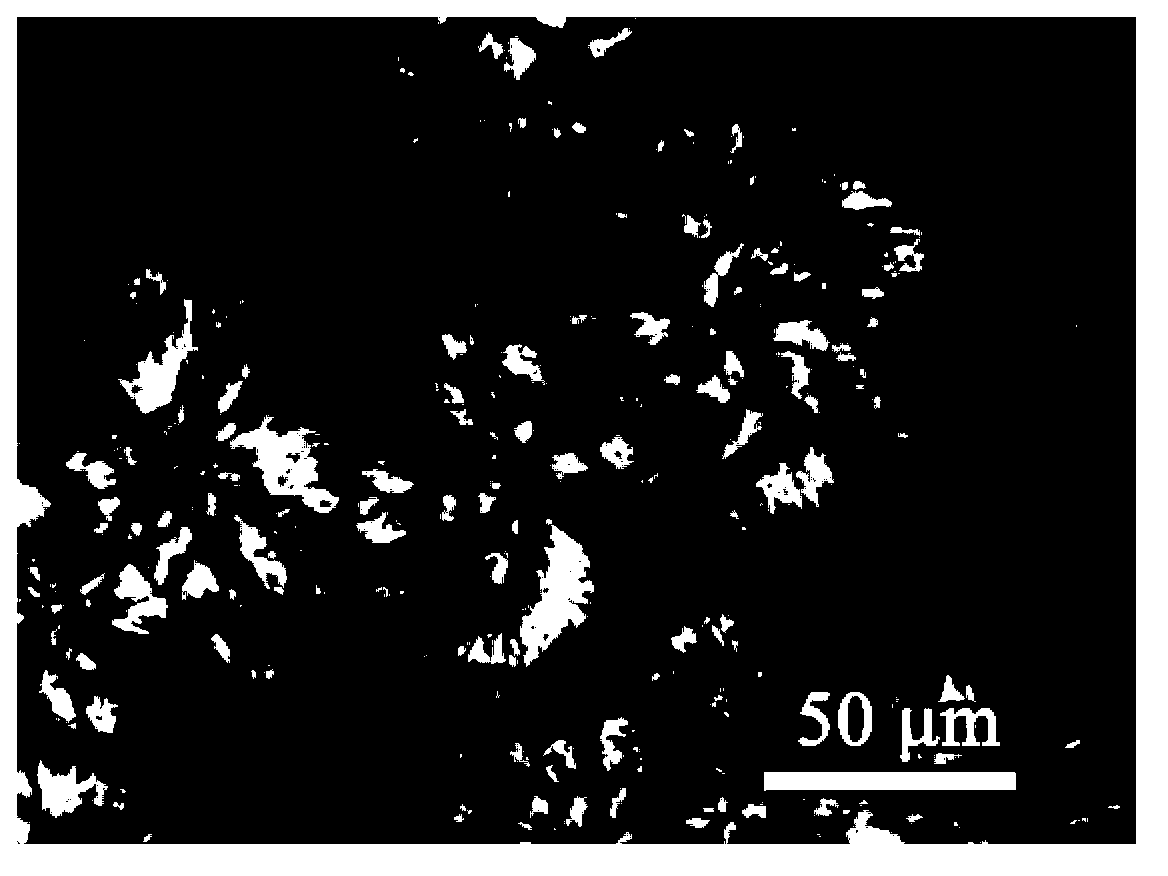

Marine-mud-containing multifunctional polyacrylonitrile fiber and preparation method thereof

InactiveCN106012080AImprove bioavailabilityAntibacterial and deodorizingMonocomponent synthetic polymer artificial filamentArtifical filament manufactureEconomic benefitsHealth benefits

The invention discloses a marine-mud-containing multifunctional polyacrylonitrile fiber and a preparation method thereof. The marine-mud-containing multifunctional polyacrylonitrile fiber comprises a polyacrylonitrile solution and a marine mud concentrated solution; in percentage by weight, the marine mud concentrated solution consists of 5 to 35% of marine mud powder, 0.5 to 3% of extract of clinacanthus nutans, 1.2 to 5% of extract of choerospondiasaxillaris bark, 0.3 to 2.5% of extract of ledum palustre, 0.5 to 3% of coupling agent and the balance of deionized water; the polyacrylonitrile solution accounts for 85 to 98% of the total weight of the fiber; the marine mud concentrated solution accounts for 2 to 15% of the total weight of the fiber. The fiber obtained by processing all the raw materials through various approaches not only reserves the original advantages of a polyacrylonitrile fiber, but also has fragrant odor, good skin friendliness, hygroscopicity, spinnability and good dyeing property and high fiber forming strength. Wearability is more excellent; effects of resisting to bacteria and deodorizing, resisting to ultraviolet rays, removing mites and repelling mosquitoes and resisting to static electricity are realized, and nutritional health-care ingredients are released, so that a human body obtains more health benefits; moreover, marine mud resources are sufficiently utilized and have huge social and economic benefits.

Owner:陆建益

Preparing method of hemp forming insole

The invention discloses a preparing method of a hemp forming insole. The preparing method comprises the following steps of a, cutting a hemp material into an insole shape according to the shape of a shoe tree, and punching a heel end surface of the material to an insole opening by a punching knife; b, punching a hole on one front side of the material according to the size of an ABS (acrylonitrile butadiene styrene) injection opening, for injecting the ABS; c, putting the cut insole in a die, wherein the temperature of the die is 55 to 75 DEG C, and ABS resin is injected into the reserved hole by the ABS injection opening aligning with the reserved hole; and d, closing the die and pressurizing, wherein the pressure is 30kgf / cm<2>, and the pressurizing time is 5 to 6 minutes; and opening the die, and cleaning. The preparing method has the advantages that the insole is injected and molded by one-time forming, the inner structure of the insole material deforms at high temperature and high pressure through the heat treatment effect during processing, and then the insole material is subjected to secondary forming, so the insole completely meets the requirements of the shoe tree, and is more closer to the structure of a foot; a finished shoe made by the hemp insole prepared by the method is more comfortable in wearing, the elasticity and the original shape can be maintained after the finished shoe is worn for a long time, the iron cores are not needed, the weight is reduced by 30% in comparison with the traditional mid-sole, and the comfortable degree is higher.

Owner:JIHUA 3515 LEATHER & SHOES

Preparation method of environment-friendly composite polymer film material

The invention relates to a preparation method of an environment-friendly composite polymer film material, which comprises the following steps: adding biomass polyester and modifier into solvent, and stirring to dissolve at 25-60 DEG C for 2-4 hours, thus obtaining a polymer mother solution; and then, preparing the polymer mother solution into a film through a film coating method, and volatilizing the solvent at room temperature to obtain the composite polymer film material. The biomass polyester and the modifier thereof used in the invention have the characteristics of favorable biodegradability and biocompatibility; and the composite polymer film prepared by the invention has the characteristics of environment friendliness and wide application range, and is hopefully popularized and used in the fields of biomedical materials and ecological environment protection.

Owner:DONGHUA UNIV

Volcanic ash fiber blended fabric for home textiles

InactiveCN110295441AGood hygroscopicityGood moisture absorption and vapor permeabilityFibre treatmentProtective fabricsFiberPolymer science

The invention discloses a volcanic ash fiber blended fabric for home textiles. A fabric dyeing and finishing manufacturing process includes the step of breaking microcapsules on volcanic ash fibers and is characterized by further including the steps: blending the volcanic ash fibers and modal fibers to prepare blended yarns; blending and weaving the blended yarns and combed cotton to form the fabric; dyeing and finishing the fabric. In the preparation process of the blended yarns, the volcanic ash fibers and the modal fibers are separately prepared into strips, blending is implemented in the drawing manner, the blended yarns and the combed cotton are blended and woven to form the fabric by a twill weave method, and weft yarns are the combed cotton. The fabric dyeing and finishing process includes the steps: capsule breaking; cooling and soup discharging; water washing; bleaching and dyeing; light dehydration; drying; finally, setting to obtain the volcanic ash fiber blended fabric forthe home textiles.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Coffee carbon multi-component fiber weaving fabric and preparation method thereof

ActiveCN103614842BUniform comfortExcellent physical and chemical indicatorsWoven fabricsYarnPolyesterYarn

The invention belongs to the field of textile dyeing and finishing, and in particular relates to a coffee carbon multi-component fiber woven fabric and a preparation method thereof. Made of the following raw materials: the warp yarn is blended with the following raw materials by weight: coffee carbon fiber 25-45%, bamboo fiber 25-40%, cationic modified polyester 20-30%, conductive fiber 0.5-0.8%; The filaments are two kinds of filaments arranged alternately at 1:1: coffee carbon fiber filaments 150D-160D, PTT fiber filaments 100D-120D. The present invention utilizes the different characteristics of coffee carbon fiber and other fibers, realizes the unification of comfort and anti-ultraviolet protective functions of clothing fabrics, excellent physical and chemical indicators, high dyeing fastness, and high cost performance of fabrics; the present invention also provides its preparation The method and the process are reasonable, and open up a new way for the high performance and comfort of the coffee carbon multi-component fiber woven fabric.

Owner:SHANDONG WOYUAN NEWFASHIONED FABRIC

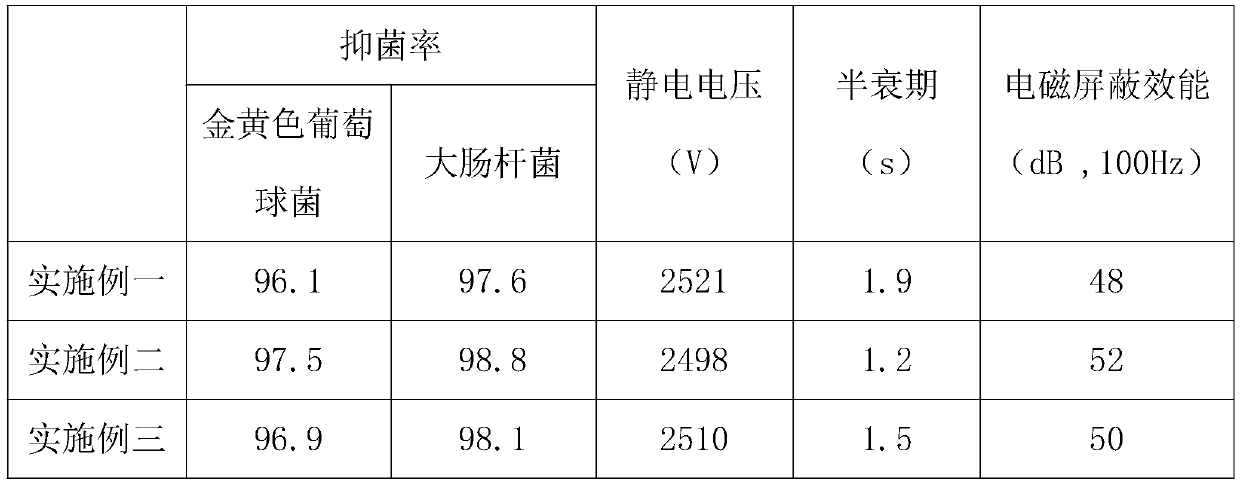

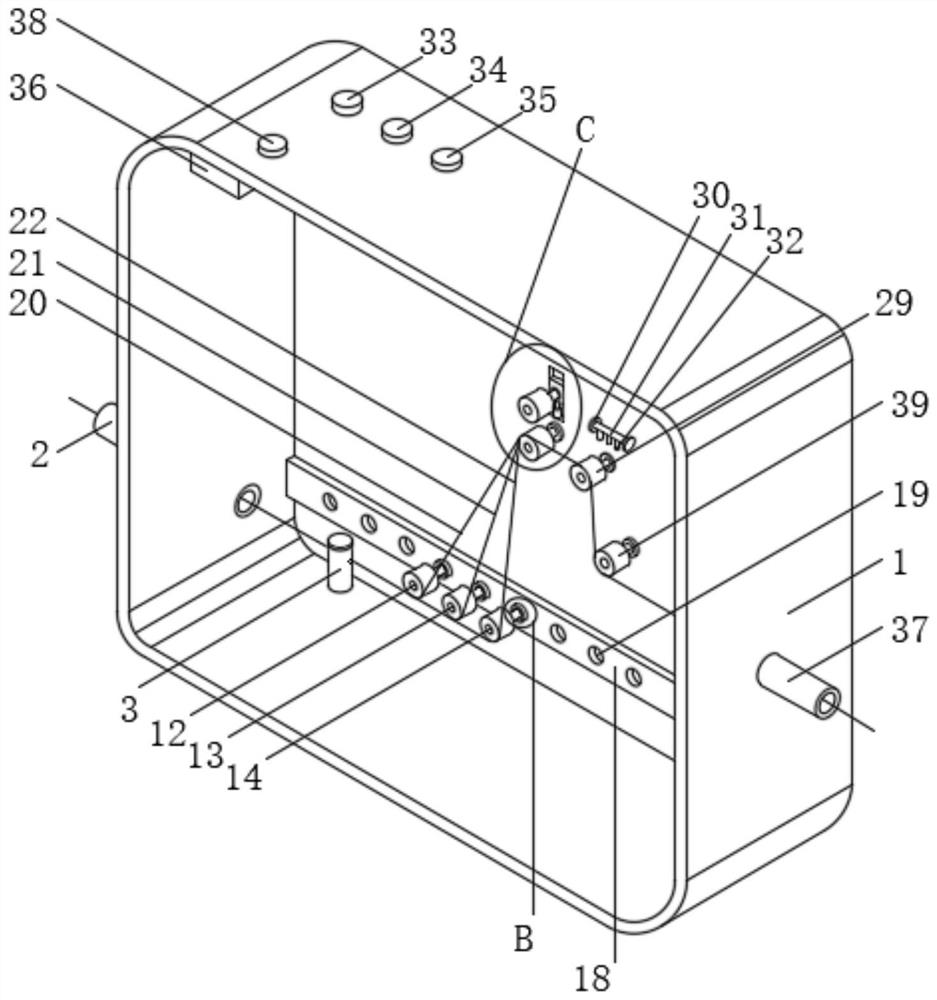

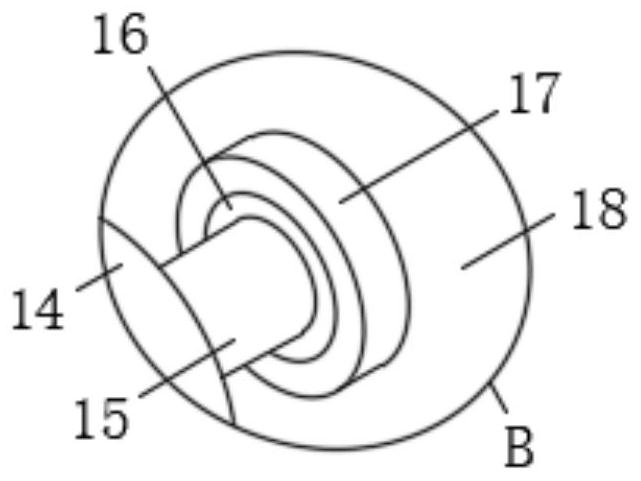

Composite fiber wrapped yarn and preparation method thereof

InactiveCN111663215AImprove efficacyImprove the effect of stackingBiochemical fibre treatmentUltrasonic/sonic fibre treatmentYarnFiber

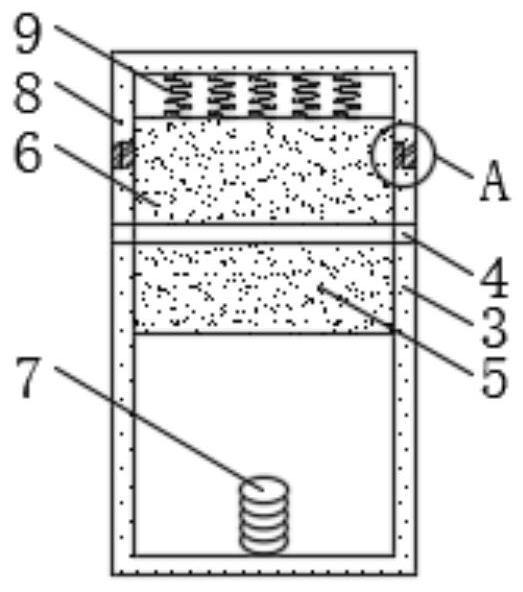

The invention discloses composite fiber wrapped yarn and a preparation method thereof, and belongs to the technical field of composite fiber wrapped yarn processing. The method comprises a rack; a softening tank is fixedly connected with the bottom on the inner side of the rack; a penetrating hole is formed in the side surface of the softening tank; a first softening foam plate is arranged on theside surface of the softening tank at the position corresponding to the penetrating hole; and an electric heater is arranged at the bottom of the inner side of the softening tank at the position corresponding to the first softening foam plate. According to the method, through an output roller wheel, a hydraulic cylinder, a hot ironing device, an electret plate installation rack, an electret plate,and a high-pressure static generating needle which are matched with each other; when fibril flows through a first guiding roller wheel, the first guiding roller wheel is grounded via conducting wire,the high-pressure static generating needle can realize constant-temperature dual-pole corona electret on the fibril after fibril overlapping in the working process, so the fibril has restricting andsterilizing effects on common bacteria, the effect of single fibril can be effectively increased; and the method is applicable to filtering materials and the performance is more excellent.

Owner:HANGZHOU HUACHUANG IND

Cowhide collagen multifunctional health socks and its preparation method and application

ActiveCN108236133BMoisturizing and anti-crackingWarm and breathableWeft knittingHandkerchiefsBiotechnologyAnti bacterial

The invention provides a cattlehide collagen multifunctional health maintenance sock as well as a preparation method and application thereof and relates to the technical field of weaving of socks. Thehealth maintenance sock takes cattlehide collagen fibers as a functional component and has multiple effects of resisting to bacteria and removing odor, moisturizing and controlling crack, keeping warm and ventilating as well as nourishing skin. The preparation method of the cattlehide collagen multifunctional health maintenance sock comprises the step of weaving cattlehide collagen fiber blendedyarns to obtain the health maintenance sock. The preparation method takes the cattlehide collagen fibers as a raw material and the functional component, so that the health maintenance function of theobtained health maintenance sock is durable. The cattlehide collagen multifunctional health maintenance sock has durability when being applied to remission of dermatophytosis, antisepsis and deodorization as well as podoschisis prevention and can not lose effect after being washed for multiple times. The invention solves the technical problem that a natural multifunctional durable health maintenance sock and a preparation method do not exist in the prior art.

Owner:嘉兴奥克兰特种牛皮科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com