Weaving method and product of polyester and acrylic fiber anion fiber woven home textile fabric

A technology of negative ion fiber and polyester fiber, which is applied in rayon manufacturing, fiber chemical characteristics, textiles and paper making, etc. It can solve the problems of undurable health care effect and poor hand feeling, achieve high production efficiency, good spinnability, and promote subcutaneous The effect of microvascular dilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: making acrylic anion fiber blanket fabric

[0035] (1) Preparation of acrylic anion fiber

[0036] Nanoscale anion powder is prepared by wet ultrafine processing method, using 200-mesh anion tourmaline particles in a centrifugal classifier at a speed of 10000r / min to process it into a 50nm anion powder.

[0037] The acrylic fiber spinning stock solution is prepared as follows: Sodium sulfhydric acid NaSCN, vinyl acetate VAC, acrylonitrile AN, and sodium methacrylic sulfonate MAS are rapidly dissolved at 60°C in a mass ratio of 2:3:3::2. Made by suspension polymerization.

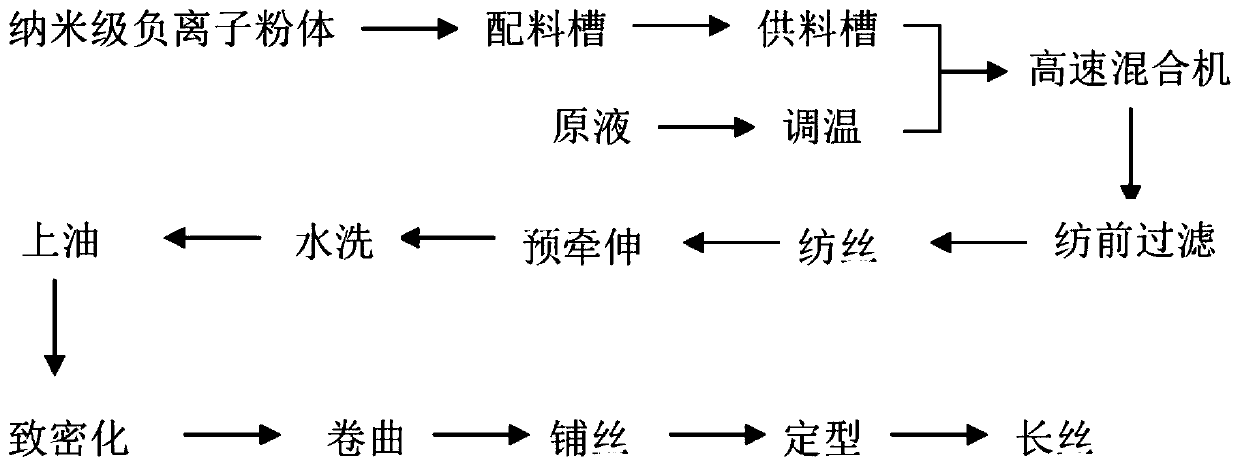

[0038] Put the nano-scale negative ion powder into the batching tank, and then transport it to the feeding tank through the equipment pipeline. At the same time, adjust the temperature of the acrylic fiber spinning stock solution at 50°C for 0.5h, and then disperse the nano-anion powder and the acrylic fiber spinning stock solution in a high-speed mixer at a speed of 1000r / min to prepare...

Embodiment 2

[0048] Embodiment 2: making acrylic fiber negative ion fiber sofa release

[0049] (1) Preparation of acrylic anion fiber

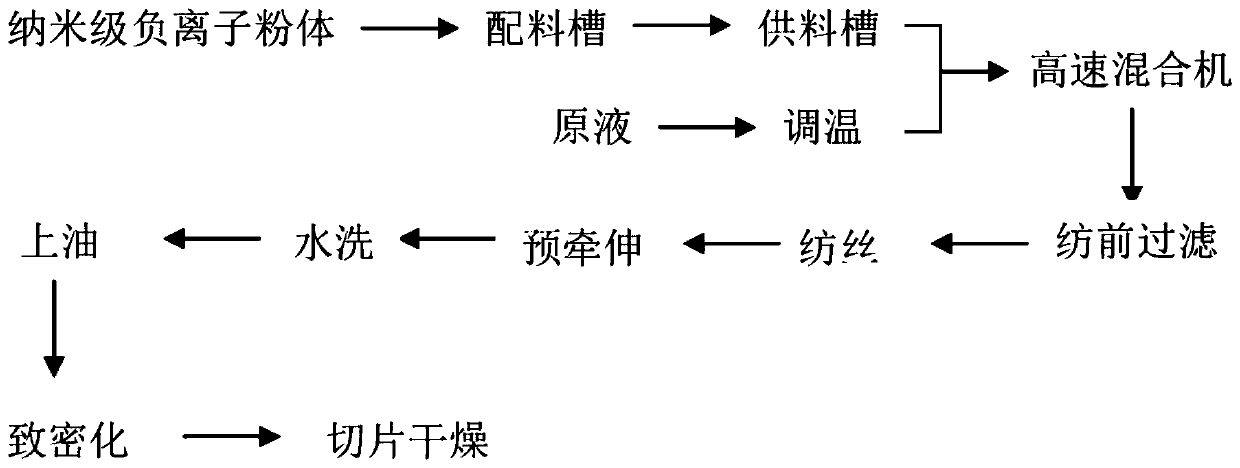

[0050] Nanoscale anion powder is prepared by wet ultrafine processing method, using 400-mesh anion tourmaline particles to be processed into 5nm anion powder in a centrifugal classifier at a speed of 20000r / min. Put the nano-scale negative ion powder into the batching tank, and then transport it to the feeding tank through the equipment pipeline. At the same time, the acrylic fiber spinning stock solution (same as Example 1) was adjusted at 30° C. for 1 hour. Nano-anion powder and acrylic fiber spinning stock solution are uniformly dispersed in a high-speed mixer at a speed of 1100r / min to prepare anion acrylic fiber spinning stock solution, and the weight of negative ion powder accounts for 4% of the negative ion acrylic fiber spinning stock solution. The prepared negative ion acrylic fiber spinning stock solution is surface-filtered through the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com