Preparation method of environment-friendly composite polymer film material

A composite polymer and environment-friendly technology, which is applied in the field of preparation of environment-friendly composite polymer membrane materials, can solve the problems affecting the degradability and biocompatibility of biomass polyester, and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In the composite solvent prepared by mixing 41ml dioxane and 41ml chloroform, add 6.4g PHBV and 1.6g tea polyphenols respectively, and mechanically stir for 3 hours under a water bath environment of 55°C. The homogeneous polymer mother liquor is prepared into films of different sizes by the spin coating method, and the solvent is volatilized at room temperature, which is the polymer film prepared by the invention.

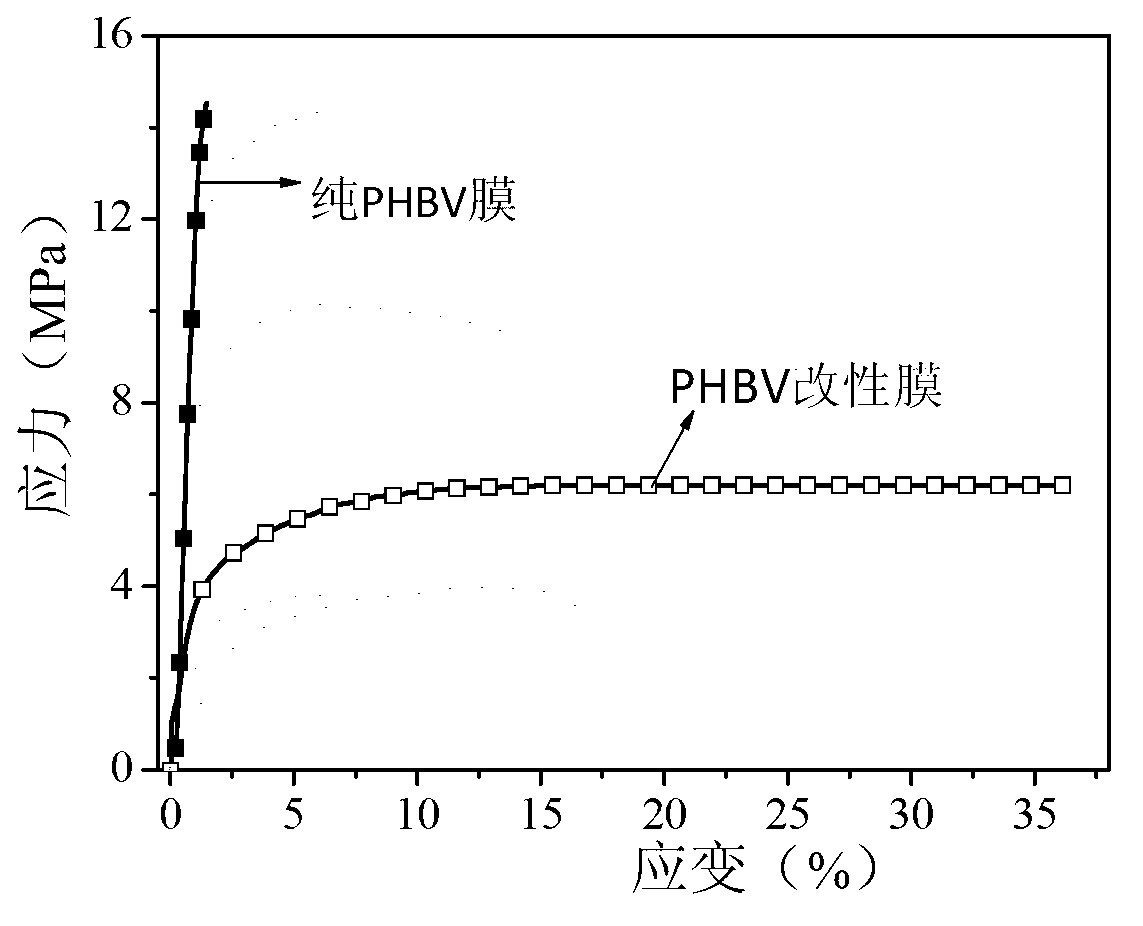

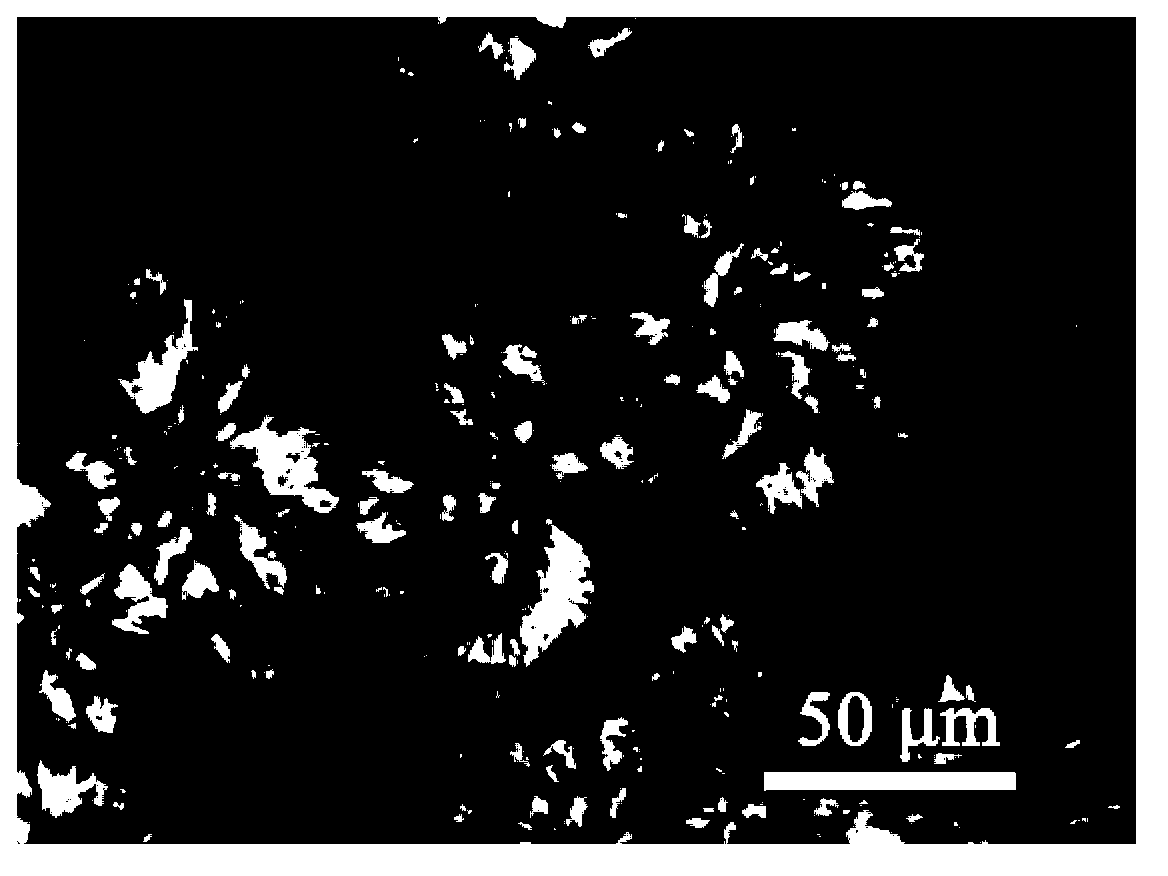

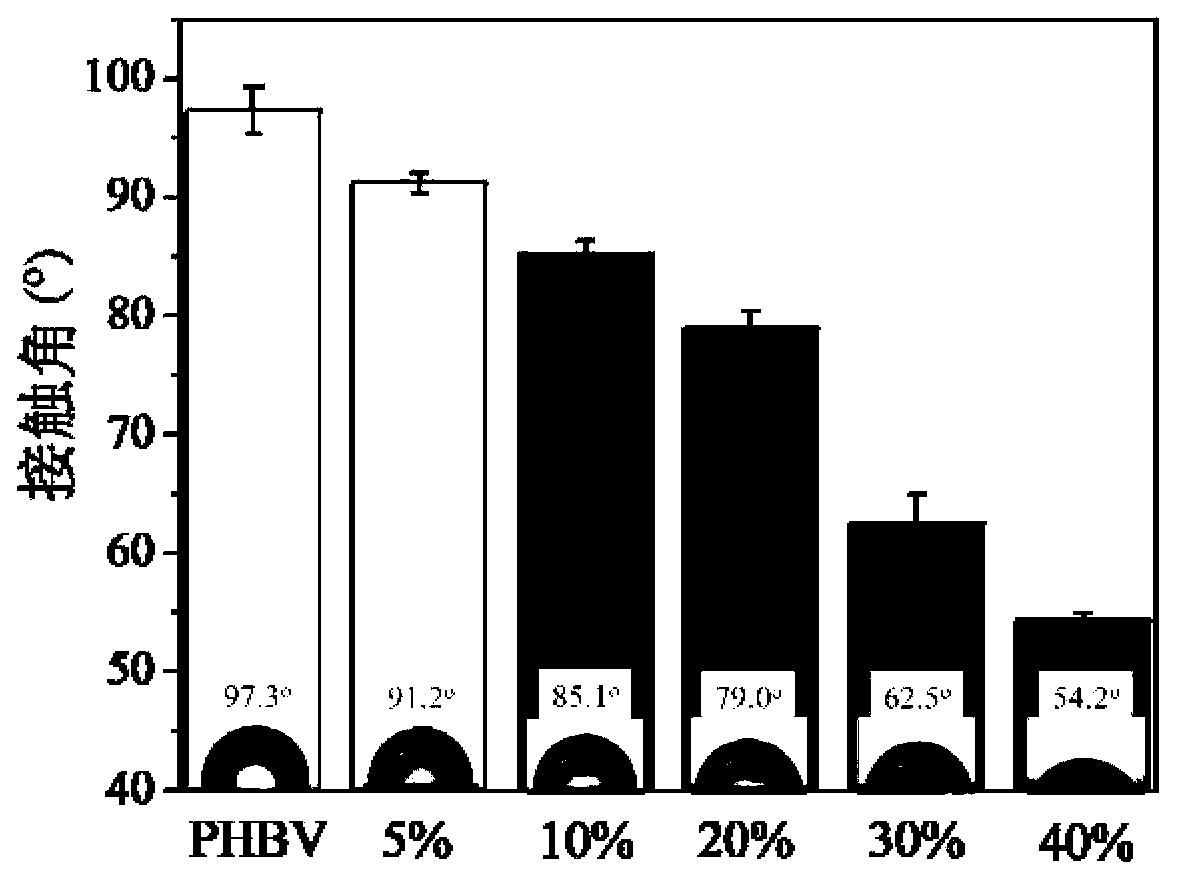

[0026] figure 1 The stress-strain curve of the biomass PHBV film modified by plant polyphenols is shown. It can be seen from the curve that the toughness of the modified PHBV film is nearly 2500% higher than that of the pure PHBV film. The reason why plant polyphenols can significantly improve the toughness of biomass polyesters is that the phenolic hydroxyl groups in plant polyphenols form hydrogen bonds with the carbonyl groups of biomass polyesters, which affects the structural arrangement of pure biomass polyesters. Its crystal structure (such as fig...

Embodiment 2

[0028] In 152ml of dioxane solvent, add 7.92g PHB, 0.08g grape polyphenols respectively, under the water bath environment of 25 ℃, mechanically stir for 4 hours. The homogeneous polymer mother liquor is prepared into films of different sizes by the spin coating method, and the solvent is volatilized at room temperature, which is the polymer film prepared by the invention.

Embodiment 3

[0030] In 45.33ml dioxane solvent, add 4.0g P(3HB-co-4HB), 4.0g apple polyphenol respectively, under the water bath environment of 60 ℃, mechanically stir for 2 hours. The homogeneous polymer mother liquor is prepared into films of different sizes by the spin coating method, and the solvent is volatilized at room temperature, which is the polymer film prepared by the invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com