Coffee carbon multi-component fiber weaving fabric and preparation method thereof

A multi-component fiber, coffee carbon fiber technology, applied in the direction of fabrics, textiles, textiles and papermaking, etc., to achieve the effect of water-washing dimensional stability, permanent antistatic properties, and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 1. It is made of the following raw materials: warp yarn, blended with the following raw materials in weight percentage:

[0057]

[0058]The weft filaments are two kinds of filaments arranged alternately at 1:1:

[0059] Coffee Carbon Filament 160D,

[0060] PTT filament 100D.

[0061] Two, preparation method comprises the steps:

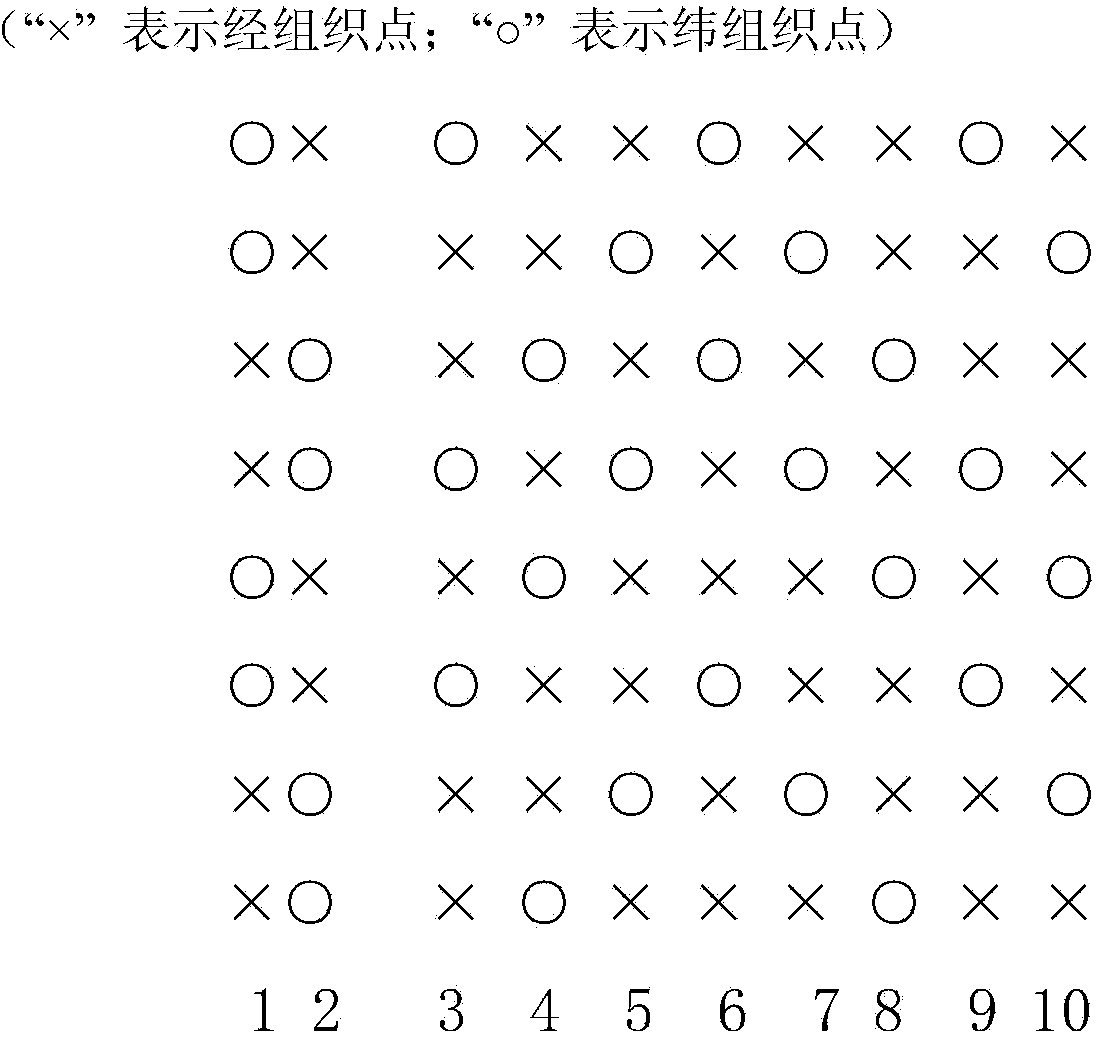

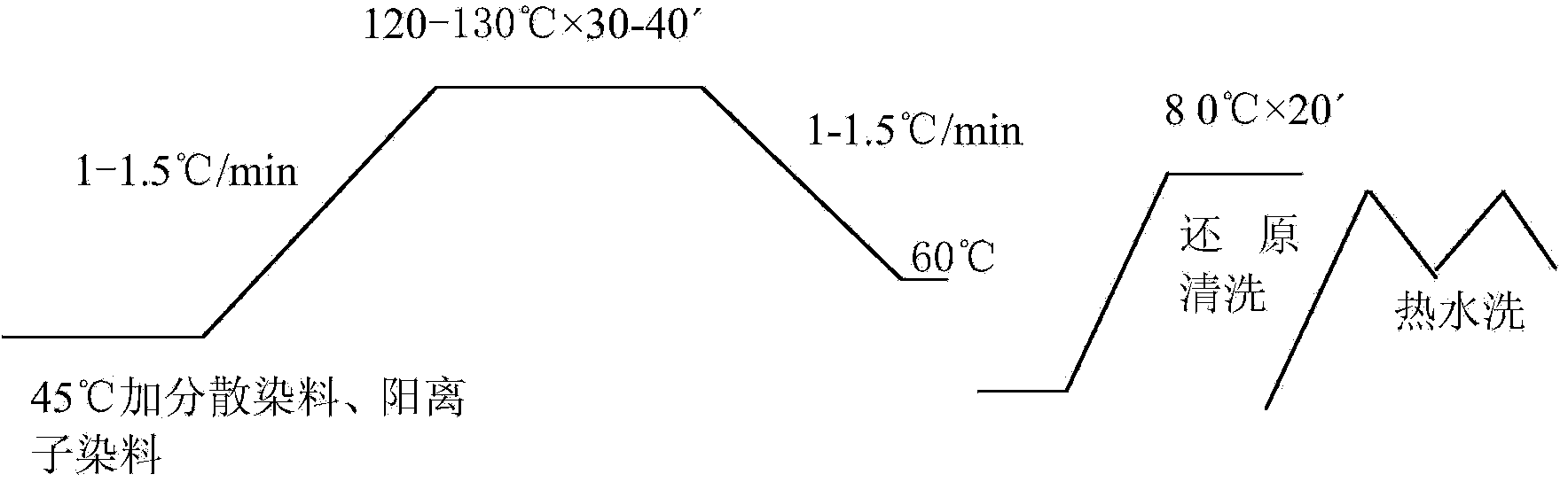

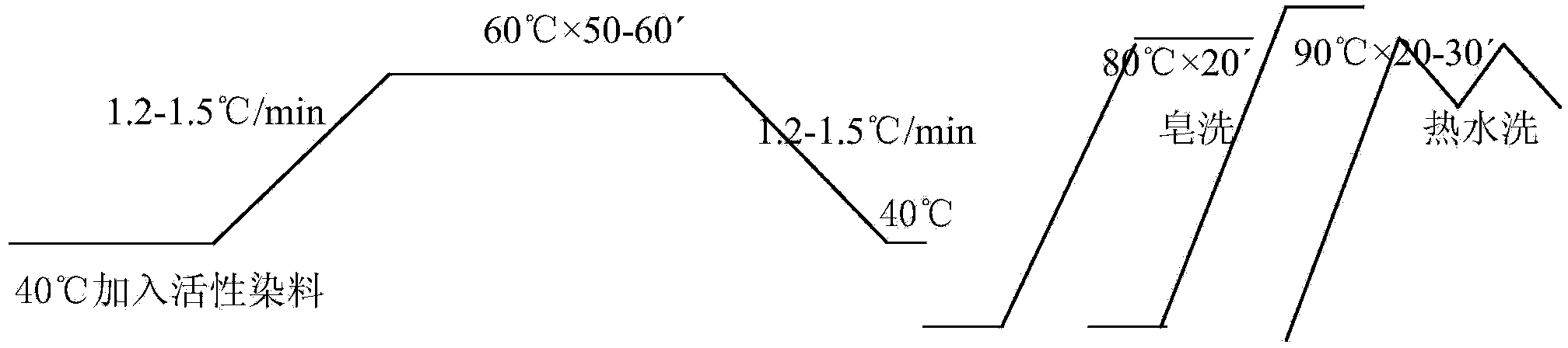

[0062] Preparation before weaving of warp yarns and weft filaments → weaving → gray fabric inspection → scouring and pre-shrinking treatment → pre-singing → pre-singeing → high temperature and high pressure overflow dyeing → dehydration → opening width → tenter drying → post-singing → Soft finishing→calendering→pot steaming→cloth inspection→rolling;

[0063] 1. Preparation process before weaving of warp yarn and weft filament:

[0064] ①Doubling and double twisting:

[0065] Warp yarn: use a twist doubling machine to parallel two Z-twist 65S / 1 single yarns with the above-mentioned fiber ratio to form a plied yarn 65S / 2; twist with a t...

Embodiment 2

[0117] 1. Made of the following raw materials:

[0118] Radial yarn, blended from the following raw materials in weight percentages:

[0119]

[0120] The weft filaments are two kinds of filaments arranged alternately at 1:1:

[0121] Coffee Carbon Filament 150D,

[0122] PTT filament 120D.

[0123] Two, preparation method comprises the steps:

[0124] Preparation before weaving of radial yarns and weft filaments → weaving → gray fabric inspection → scouring and pre-shrinking treatment → pre-singing → pre-singeing → high temperature and high pressure overflow dyeing → dehydration → opening width → tenter drying → post-singing → Soft finishing→calendering→pot steaming→cloth inspection→rolling;

[0125] 1. Preparation process before weaving:

[0126] ①Doubling and double twisting:

[0127] Radial yarn: two 55S / 1 single yarns are paralleled with a twisted doubling machine to form a 55S / 2 ply yarn; twisted with a two-for-one twister, the twist is 1400T / m, S twist, and the...

Embodiment 3

[0147] 1. Made of the following raw materials:

[0148] Radial yarn, blended from the following raw materials in weight percentages:

[0149]

[0150] The weft filaments are two kinds of filaments arranged alternately at 1:1:

[0151] Coffee Carbon Filament 155D,

[0152] PTT filament 105D.

[0153] Two, preparation method comprises the steps:

[0154] Preparation before weaving of radial yarns and weft filaments → weaving → gray fabric inspection → scouring and pre-shrinking treatment → pre-singing → pre-singeing → high temperature and high pressure overflow dyeing → dehydration → opening width → tenter drying → post-singing → Soft finishing→calendering→pot steaming→cloth inspection→rolling;

[0155] 1. Preparation process of radial yarn and weft filament before weaving:

[0156] ①Doubling and double twisting:

[0157] Radial yarn: two 60S / 1 single yarns are paralleled with a twisted doubling machine to form a plied yarn of 60S / 2; twisted with a two-for-one twister, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com