Application of polythene polyamide polythene composite membrane in carpet

A polyethylene polyamide and polyethylene technology, which is applied in the field of carpet manufacturing, can solve the problems of heavy product weight, smelly environment, and high carpet price, and achieve the effect of weight reduction, economy and comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with example the present invention will be further described:

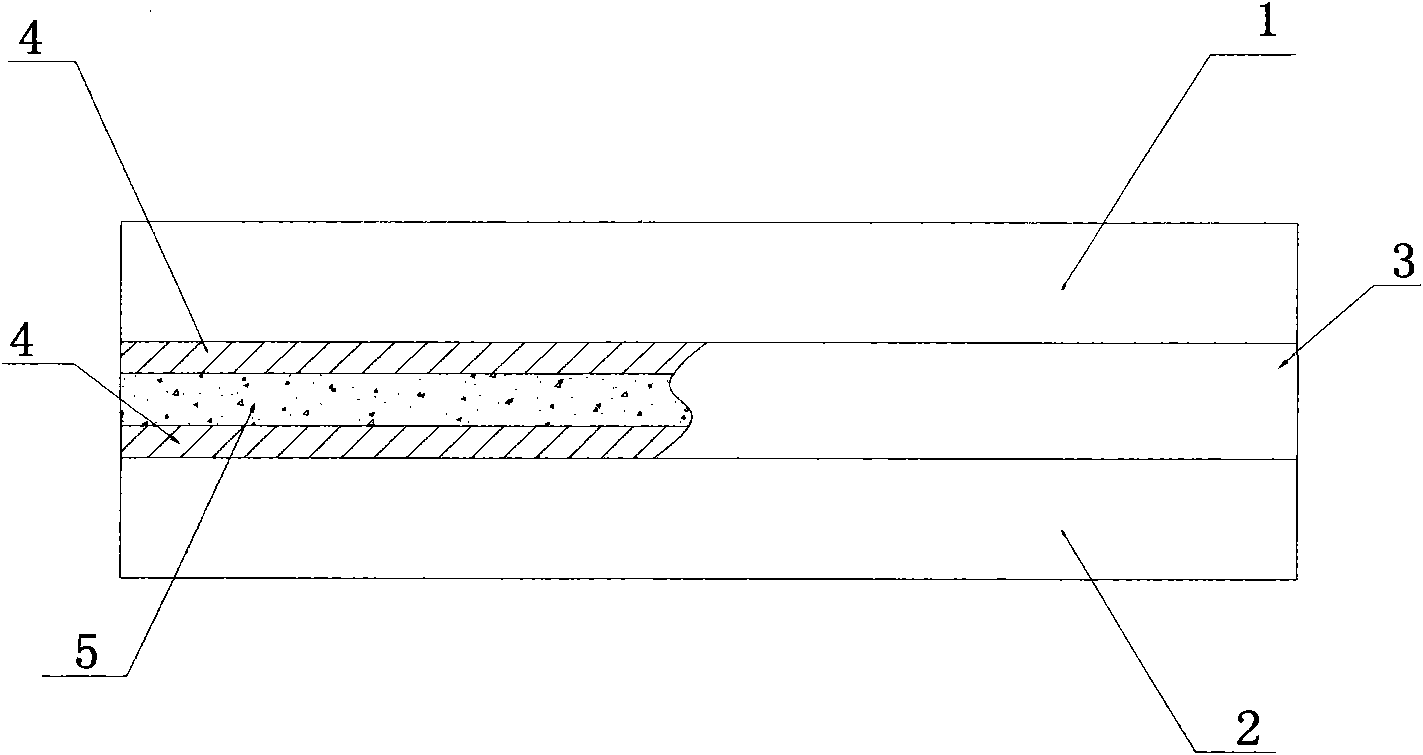

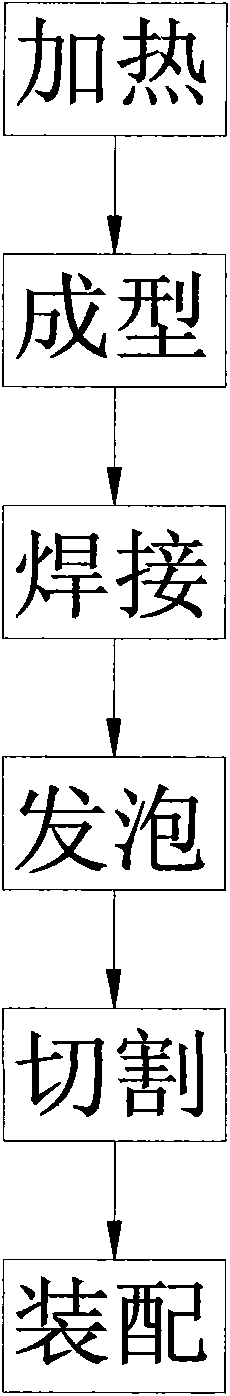

[0016] like figure 1 The carpet of the present invention shown is formed by adding a polyethylene polyamide polyethylene composite film 3 between the needle punched carpet surface 1 and the forming felt 2, and takes the following manufacturing process:

[0017] a) Heating: Add polyethylene polyamide polyethylene composite film between the needle-punched carpet surface of the carpet and the forming felt, and heat together, using a press-type heating table, the heating temperature is 180 ° C ~ 205 ° C, and the time is 55S ~65S; the pressure is 8Mpa~15Mpa during heating; during the heating process, the melting point of polyethylene in the polyethylene polyamide polyethylene composite film between the needled felt surface and the forming felt is 100℃~140℃ and starts to melt, and passes through The pressurization of the press on the press-type heating table makes the polyethylene part in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com