A sanding process of Tencel cotton home textile fabric

A cotton home textile and sanding technology, applied in the field of textile printing and dyeing, can solve problems such as lack of confidence, large fabric damage, and strong damage, and achieve the effects of reduced damage, uniform fluff, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The optimization of embodiment 1 sanding process step

[0062] In this embodiment, the optimal conditions for the sanding step are determined first.

[0063] In this embodiment, the fabric sample is a blended fabric with a yarn fineness of 7.3tex×7.3tex, a fabric density of 787 strands / 10cm×(362+362) strands / 10cm, and 70% Cotton+30% Lyocell.

[0064] Using L16 (4 3 ) orthogonal table, conduct an orthogonal test on the grinding step, select A, B, C, D as the four factors of the orthogonal test, and mainly investigate the change of the warp breaking strength before grinding and after grinding (decrease strong) to determine the best combination. The level, test results and analysis of the orthogonal test are shown in Table 1, Table 2 and Table 3 respectively.

[0065] The control points of this test process are as follows:

[0066] (1) Use the same batch of 9 stages of semi-finished products that have been boiled and bleached together as the test object. When doing each ...

Embodiment 2

[0086] The sanding process of embodiment 2 Tencel cotton home textile fabric

[0087] In this embodiment, a sanding process of Tencel cotton home textile fabric is provided.

[0088] In this embodiment, the fabric sample is a blended fabric with a yarn fineness of 7.3tex×7.3tex, a fabric density of 787 strands / 10cm×(362+362) strands / 10cm, and 70% Cotton+30% Lyocell.

[0089] The sanding process comprises the following steps: (1) singeing enzyme desizing; (2) scouring and bleaching; (3) pre-drawing and shaping; (4) sanding; (5) printing or dyeing; (6) softening; (7) shrinkage; among them,

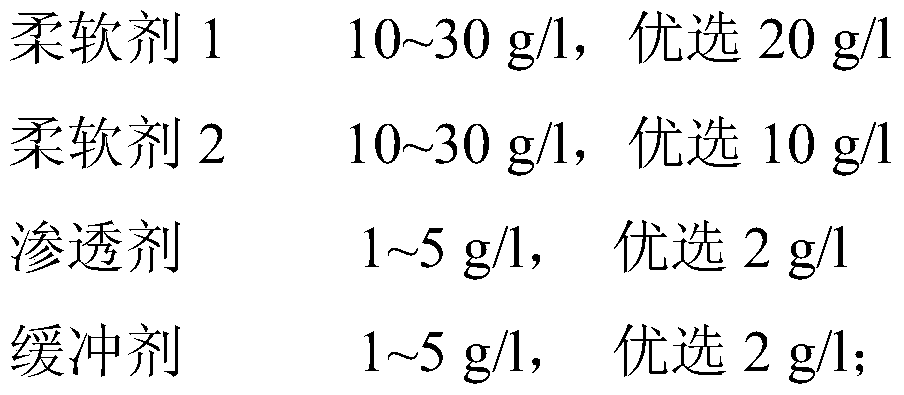

[0090] The scouring and bleaching step includes a scouring step and a bleaching step, wherein; the working liquid components of the scouring step include:

[0091]

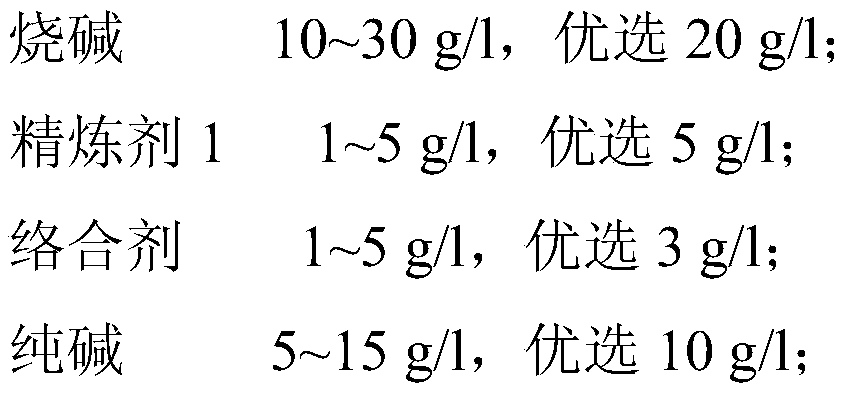

[0092] The working liquid component of described bleaching step comprises:

[0093]

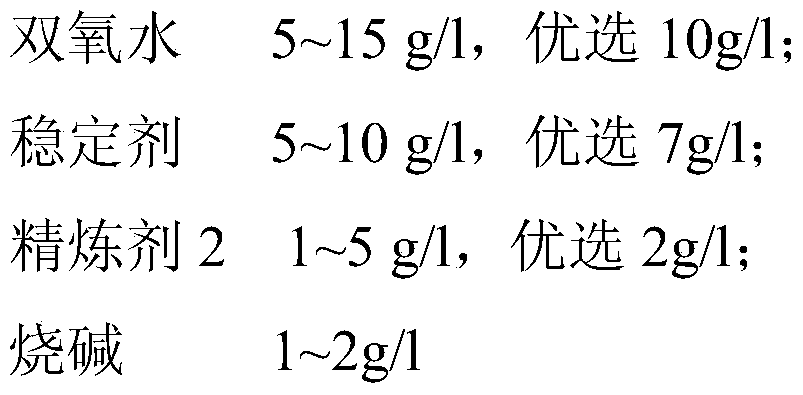

[0094]

[0095] The finishing condition of the bleaching step is 98°C × 6 lanes; wherein,

[0096] The refining agent 1 and refin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com