Multifunctional fabric and processing technique and application thereof

A processing technology and multi-functional technology, applied in the fields of biochemical fiber processing, fiber types, textiles and papermaking, etc., can solve the problems of not meeting the needs of health and health preservation, and improve dry and wet rubbing fastness, enhance energy, and eliminate odors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

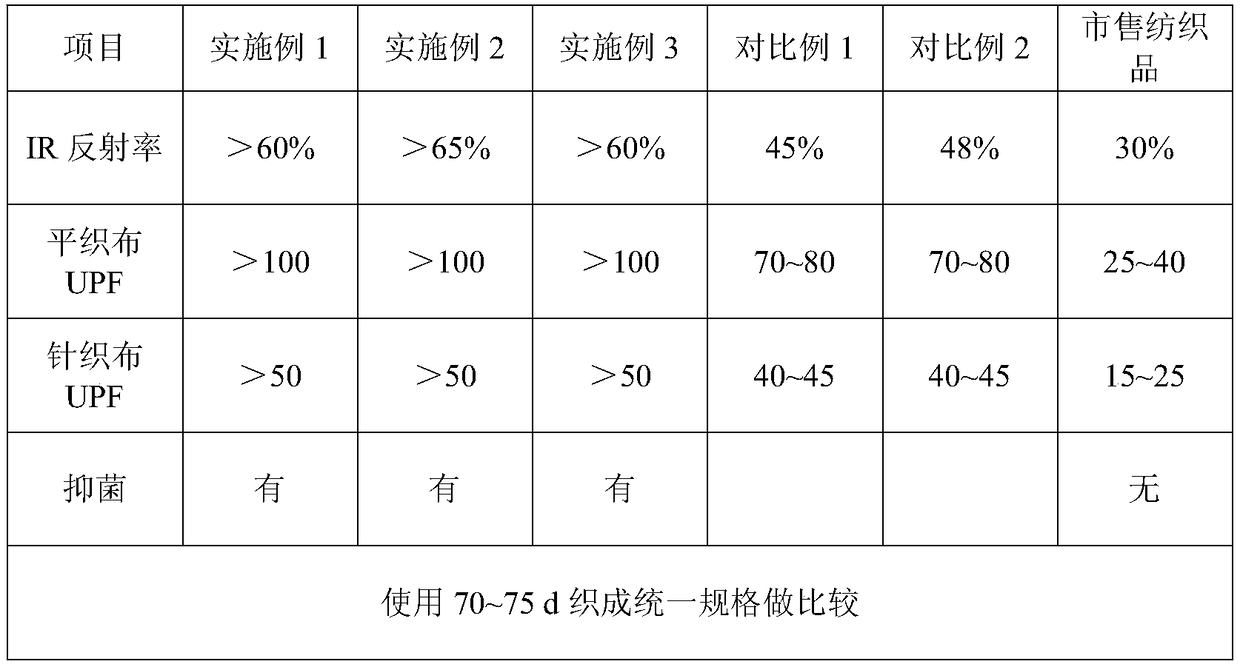

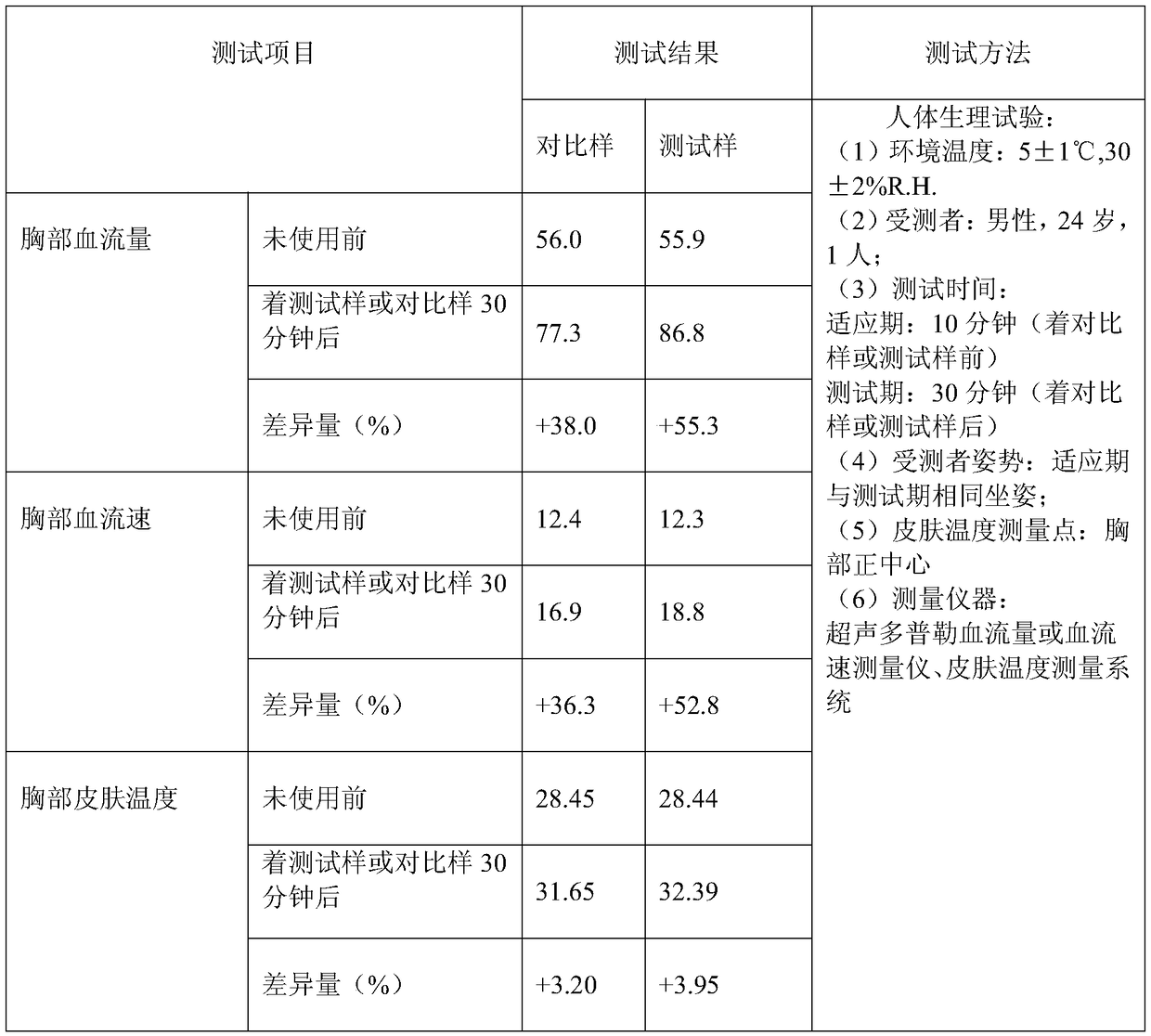

Embodiment 1

[0025] A processing technology for a multifunctional fabric, specifically comprising the following steps: put the finished gray fabric straight and flat into a liquid pool of a composite finishing agent, soak for 15 minutes at 25°C, and then dry at 120°C to obtain the multifunctional fabric. Gray cloth is woven from cotton warp.

[0026] The composite finishing agent is composed of the following components in mass percentage, 6% of atomic carbon, 5% of fastness accelerator, 4% of negative ion finishing agent, and 85% of water.

[0027] Atomic carbon is prepared through the following steps: in a nitrogen atmosphere, heat raw wood at 300°C for 70 minutes, then raise the temperature to 450°C to discharge nitrogen, and introduce low-temperature nitrogen to lower the temperature of the system to 50°C. That is, atomic carbon is obtained.

Embodiment 2

[0029] A processing technology for a multifunctional fabric, specifically comprising the following steps: put the finished gray fabric straight and flat into a liquid pool of a composite finishing agent, soak for 10 minutes at 28°C, and then dry at 100°C to obtain the multifunctional fabric. The gray cloth is woven from polyester cotton.

[0030] The composite finishing agent is composed of the following components in mass percentage, 8% of atomic carbon, 4% of fastness accelerator, 5% of negative ion finishing agent, and 83% of water.

[0031] Atomic carbon is prepared through the following steps: in a nitrogen atmosphere, heat raw bamboo at 400°C for 80 minutes, then raise the temperature to 450°C to discharge nitrogen, and introduce low-temperature nitrogen to lower the temperature of the system to 80°C. That is, atomic carbon is obtained.

[0032] Depend on figure 1 As shown, the surface structure of the unprocessed gray fabric is compact, and the air bag formed in the m...

Embodiment 3

[0034] A processing technology for a multifunctional fabric, specifically comprising the following steps: put the finished gray fabric straight and flat into a liquid pool of a composite finishing agent, soak for 5 minutes at 30°C, and then dry at 80°C to obtain the multifunctional fabric. Gray cloth is woven from cotton warp.

[0035] The composite finishing agent is composed of the following components in mass percentage, 9% of atomic carbon, 2% of fastness accelerator, 7% of negative ion finishing agent, and 82% of water.

[0036] Atomic carbon is prepared by the following steps: in a nitrogen atmosphere, heat raw wood at 500°C for 90 minutes, then raise the temperature to 450°C to discharge nitrogen, and introduce low-temperature nitrogen to lower the temperature of the system to 100°C. That is, atomic carbon is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com