Sanded coffee carbon knitted fabric

A knitted fabric, coffee carbon technology, applied in the field of textile fabrics, can solve the problems of easy pilling, hard hand feel, unsatisfactory thermal performance, etc., and achieves the effect of high performance level, good moisture absorption and heating effect, and good texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below by means of the accompanying drawings and examples.

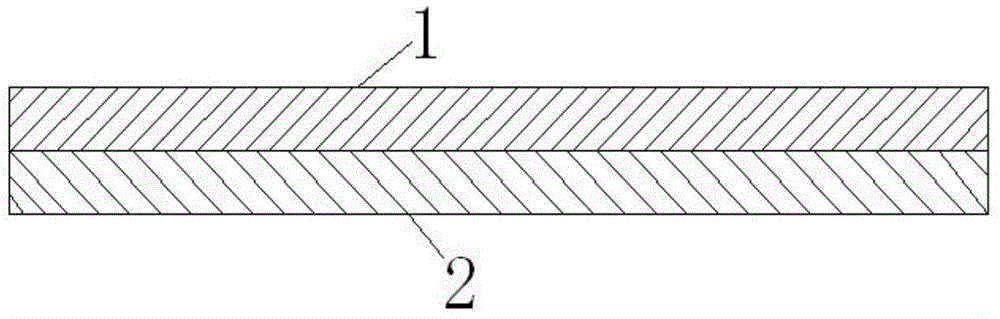

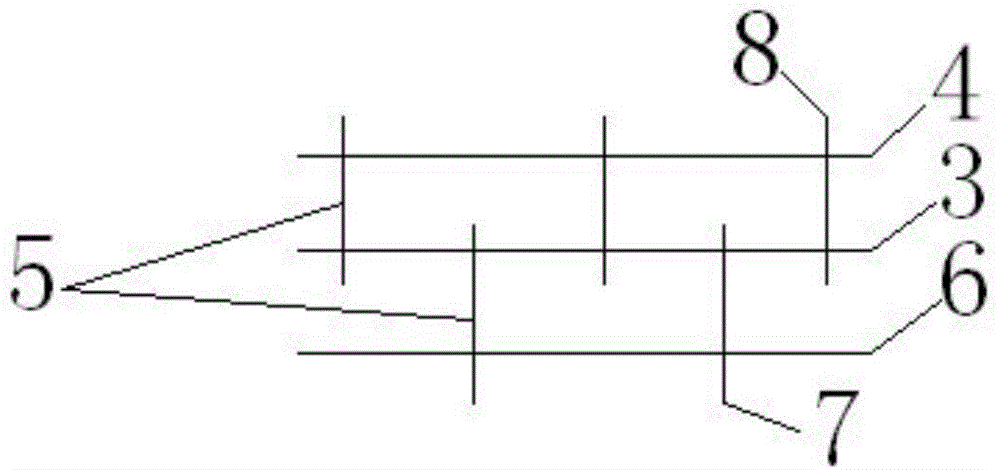

[0015] Such as figure 1 with figure 2 As shown, a ground coffee carbon knitted fabric according to the present invention includes an outer surface layer 1 and a suede layer 2, and the outer surface layer 1 is woven from blended yarn and spandex yarn 3, and the blended The yarn is divided into inner yarn 4, connecting yarn 5 and face yarn 6, the face yarn 6 and inner yarn 4 are interwoven with spandex yarn 3 through connecting yarn 5, and the blended yarn is blended with coffee carbon fine denier acrylic fiber and viscose fiber Forming, the blending ratio of the coffee carbon fine denier acrylic fiber and viscose fiber is 1:4-2:3; the connecting yarn 5 is divided into the first connecting yarn 7 and the second connecting yarn 8; the veil 6 Link to each other with spandex yarn 3 by first connecting yarn 7, described spandex yarn 3 links to each other with inner y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com