Manufacturing method of coffee-carbon-containing PLA fiber fabric

A production method, coffee carbon technology, applied in fiber chemical characteristics, dyeing method, rayon manufacturing, etc., can solve problems such as poor color fastness, low dye uptake, scratches and fluffing, and reduce production costs and energy consumption , Increased dyeing rate, increased wrinkle recovery angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031]In one embodiment of the present invention, the viscosity-average molecular weight of poly-L-lactic acid is 45-350kDa, wherein the molar content of L optical isomer is 97.5-99.9%; the viscosity-average molecular weight of poly-D-lactic acid is 15-80kDa, wherein D The molar content of optical isomers is 97.5-99.9%. Preferably, the viscosity-average molecular weight of PLLA is 80-230 kDa, and the viscosity-average molecular weight of PDLA is 45-65 kDa. More preferably, the viscosity-average molecular weight of PLLA is 100-180 kDa, and the viscosity-average molecular weight of PDLA is 50-60 kDa. The addition of poly-D-lactic acid can make the left-handed and right-handed structures complementary, make the molecular chains tightly packed, strengthen the intermolecular force, improve the heat resistance and high-temperature stability of poly-lactic acid, and avoid high-temperature drying or spinning. The hydrolysis reaction and degradation reaction of polylactic acid further...

Embodiment 1

[0051] A kind of preparation method of the PLA fiber containing coffee carbon, comprises the following steps:

[0052] (1) According to the weight ratio of 1:0.1, poly-L-lactic acid and poly-D-lactic acid are mixed to form polylactic acid raw material slices, and then dried at 95°C for 8 hours, and the final water content can be controlled at ≤50ppm. The viscosity average of the above-mentioned PLLA The molecular weight is 130kDa, wherein the molar content of L optical isomer is 98.9%, the viscosity average molecular weight of PDLA is 55kDa, wherein the molar content of D optical isomer is 99.1%;

[0053] (2) Add 0.15 parts by weight of plasticizer to 68 parts by weight of polylactic acid slices, stir evenly and pulverize into powder, then add 18 parts by weight of coffee carbon nano powder and 0.5 parts by weight of antioxidant 1010 After mixing evenly, melt and granulate at 170-250°C to obtain coffee carbon polylactic acid masterbatch. The above-mentioned toughening agent is...

Embodiment 2

[0056] A method for making a PLA fiber fabric containing coffee carbon, the concrete steps are as follows:

[0057] (1) Spinning: get the fiber spinning made in Example 1, the yarn is the twisted silk of PLA fiber containing coffee carbon, and its specification is 100D / 45F-180D / 75F;

[0058] (2) Pre-treatment: Put the yarn in the dyeing tank, enter water, first add the penetrant sodium alkyl succinate sulfonate in an amount of 0.15g / L, react for 30min, and then use 5g / L and 6.5g respectively Add soda ash and sodium silicate in an amount of / L, then raise the temperature to 75°C, add hydrogen peroxide in an amount of 5g / L and keep it warm for 10 minutes, then raise the temperature to 90°C, keep it warm for 35 minutes, cool down, and wash with water;

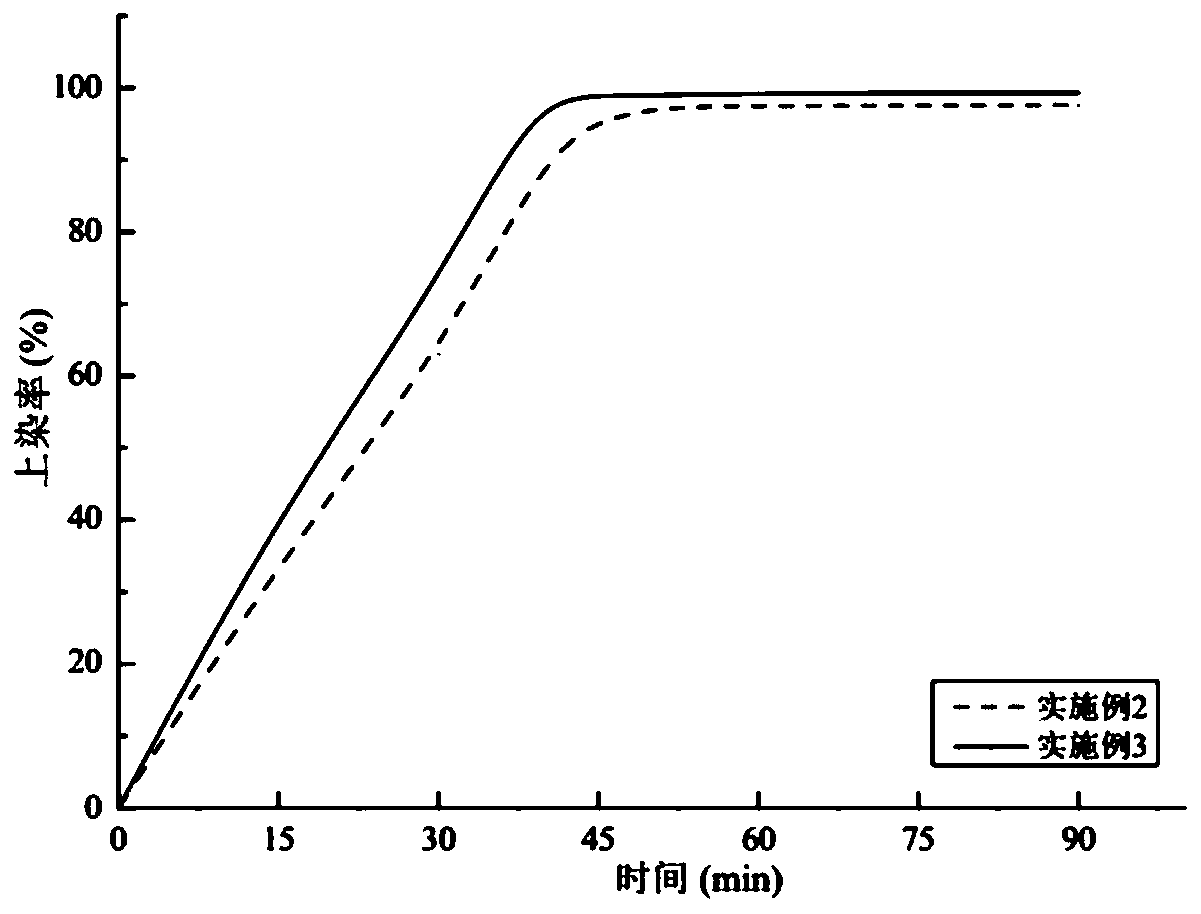

[0059] (3) Dyeing: enter water according to the bath ratio of 1:33, then add leveling agent triethanolamine, dyes and salt at 40°C, raise the temperature to 105°C at a heating rate of 1.5°C / min, keep it warm for 45min, add soda as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity average molecular weight | aaaaa | aaaaa |

| viscosity average molecular weight | aaaaa | aaaaa |

| viscosity average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com