A deodorizing and deodorizing functional fabric and yarn preparation process based on coffee carbon fiber

A coffee carbon fiber and odor-removing technology, which is applied in fiber type, fiber treatment, biochemical fiber treatment, etc., can solve problems such as long drying time, odor caused by bacterial reproduction, uncomfortable wearing, etc., to achieve fast drying and shape retention Wrinkle-free and comfortable to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

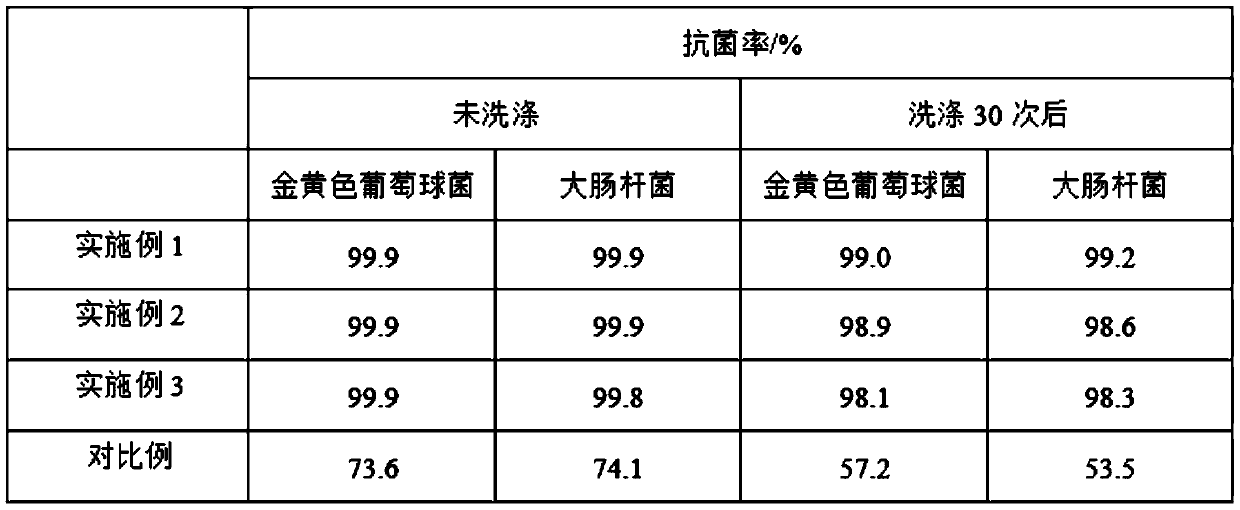

Examples

Embodiment 1

[0047] A deodorizing and deodorizing functional fabric based on coffee carbon fiber. The fabric is made of warp yarns and weft yarns interlaced. made;

[0048] The deodorizing and deodorizing functional blended yarn is calculated in parts by weight, including: 45 parts of coffee carbon functional fiber, 55 parts of cotton fiber and 12 parts of spandex;

[0049] The preparation process of described coffee carbon functional fiber is as follows:

[0050] Step 1, prepare coffee carbon fiber:

[0051] S1: Melt 1kg of recovered plastic bottles and add 10g of epoxy chain extender to blend to obtain the first co-melt; wherein a twin-screw extruder is used for melt blending, and the first to fourth zones of the twin-screw extruder ( The melting temperature of melting zone) is 280°C, 290°C, 290°C, 300°C;

[0052] S2: Metering and extruding the first co-melt in the extruder, and cooling it, wherein the extruder is a metering pump, the cooling method is water cooling, and the water tem...

Embodiment 2

[0072] A deodorizing and deodorizing functional fabric based on coffee carbon fiber. The fabric is made of warp yarns and weft yarns interlaced. made;

[0073] The deodorizing and deodorizing functional blended yarn is calculated in parts by weight, including: 25 parts of coffee carbon functional fiber, 35 parts of cotton fiber and 10 parts of spandex;

[0074] The preparation process of described coffee carbon functional fiber is as follows:

[0075] Step 1, prepare coffee carbon fiber:

[0076] S1: Melt 2kg of recovered plastic bottles and add 20g of diisocyanate chain extender to blend to obtain the first co-melt; twin-screw extruders are used for melt blending, twin-screw extruders one to four The melting temperature of the zone (melting zone) is 280°C, 290°C, 290°C, 300°C;

[0077] S2: Metering and extruding the first co-melt in the extruder, and cooling it, wherein the extruder is a metering pump, the cooling method is water cooling, and the water temperature is 45°C,...

Embodiment 3

[0097] A deodorizing and deodorizing functional fabric based on coffee carbon fiber. The fabric is made of interwoven warp yarns and weft yarns. The warp yarns are blended yarns with deodorizing and deodorizing functions. made;

[0098] The deodorizing and deodorizing functional blended yarn is calculated in parts by weight, including: 55 parts of coffee carbon functional fiber, 65 parts of cotton fiber and 12 parts of spandex;

[0099] The preparation process of described coffee carbon functional fiber is as follows:

[0100] Step 1, prepare coffee carbon fiber:

[0101] S1: Melt 1000g of recovered plastic bottles and add 5g of diisocyanate chain extender to blend to obtain the first co-melt; twin-screw extruders are used for melt blending, twin-screw extruders one to four The melting temperature of the zone (melting zone) is 280°C, 290°C, 290°C, 300°C;

[0102] S2: Metering and extruding the first co-melt in the extruder, and cooling it, wherein the extruder is a metering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com