Antibacterial shell fabric and production method thereof

A technology for antibacterial fabrics and fabrics, applied in the direction of fabrics, textiles, textiles and paper making, etc., can solve the problems of easy oxidative discoloration, discomfort, application limitations, etc., and achieve the effect of improving the antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: This embodiment provides a kind of antibacterial fabric, and its production method comprises the following steps:

[0043] (1) Chemically modify the polyester filament to make it hydrophilic, and add 6g / L silver-containing antibacterial treatment agent to the hydrophilic polyester filament in the dye bath process, heat up to 60°C, and keep it warm for 20min , taken out, shaped and dried to obtain a hydrophilic polyester filament with antibacterial function.

[0044] (2) Add 10g / L fluorocarbon water repellent to ordinary polyester filaments in the dye bath process, heat up to 50°C, keep warm for 30min, take them out, and dry them to obtain polyester filaments with hydrophobic function.

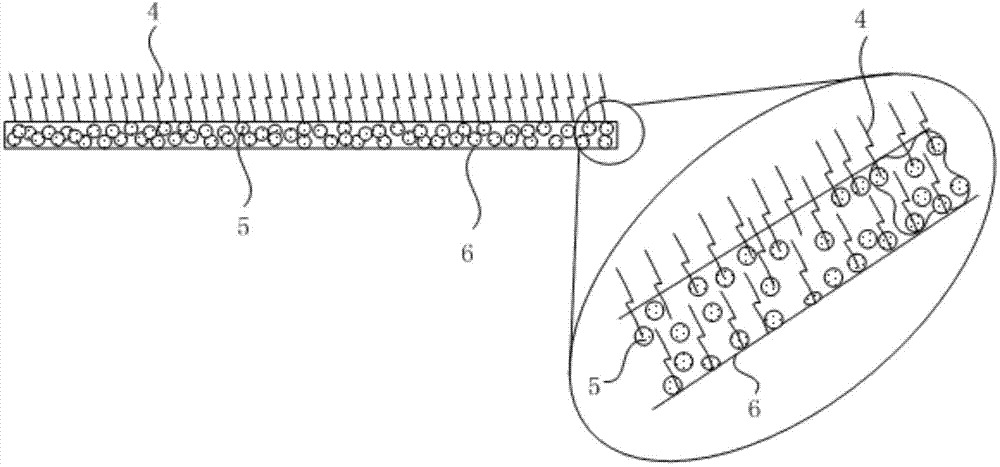

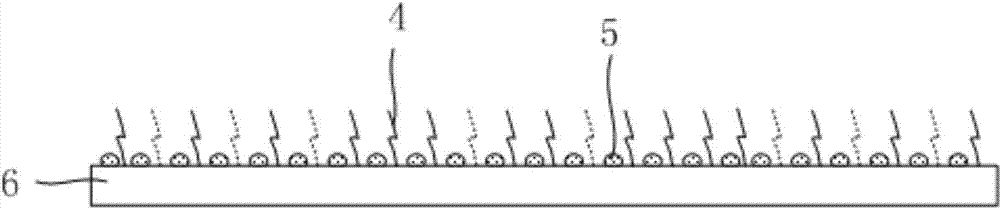

[0045] (3) The hydrophilic polyester filament with antibacterial function and the polyester filament with hydrophobicity are woven into a fabric. The fabric has an inner layer and an outer layer, wherein the inner layer is hydrophilic and the outer layer is hydrophobic. Se...

Embodiment 2

[0048] Embodiment 2: the present embodiment provides a kind of antibacterial fabric, and its production method comprises the following steps:

[0049] (1) After slicing and drying polyester A and silver-containing antibacterial polyester masterbatch B raw materials, input the screw to blend and melt, extrude and draw to obtain polyester filaments with built-in antibacterial function, in which silver-containing antibacterial polyester masterbatch B The silver ion content fraction is 1.5%.

[0050] (2) Add 8g / L of moisture-absorbing and sweat-wicking treatment agent to the polyester filament with built-in antibacterial function in the dye bath process, heat up to 60°C, keep it warm for 20 minutes, take it out, and dry it to obtain a hydrophilic polyester filament with built-in antibacterial function. permanent polyester filament.

[0051] (3) Add 10 g / L fluorocarbon water repellent to ordinary polyester filaments in the dye bath process, heat up to 50°C, keep warm for 30 minute...

Embodiment 3

[0055] Embodiment 3: This embodiment provides a kind of antibacterial fabric, and its production method comprises the following steps:

[0056] (1) After adding 6g / L silver-based antibacterial treatment agent and 8g / L moisture-absorbing and sweat-wicking treatment agent to the polyester filament in the dye bath process, the temperature is raised to 60°C, kept for 20min, taken out, and dried to obtain Hydrophilic polyester filament with antibacterial function.

[0057] (2) Add 10g / L fluorocarbon water repellent to ordinary polyester filaments in the dye bath process, heat up to 50°C, keep warm for 30min, take them out, and dry them to obtain polyester filaments with hydrophobic function.

[0058] (3) The hydrophilic polyester filament with antibacterial function and the polyester filament with hydrophobicity are woven into a fabric. The fabric has an inner layer and an outer layer, wherein the inner layer is hydrophilic and the outer layer is hydrophobic. property, wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com