Warp-knitted corrugated stripe fabric and preparation method and application thereof

A technology of warp knitting and vertical strips, which is applied in the field of fabric textiles, can solve problems such as complex processing technology, and achieve the effect of comfortable wearing, strong three-dimensional effect and good comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment provides a warp-knitted wrinkled vertical strip fabric, which is prepared by the following preparation method:

[0053] (1) Warping: GB1&GB2 warping adopts negative yarn feeding, GB3 warping adopts positive yarn feeding, the warping machine is imported from KarlMayer Germany, the warping temperature is 25℃, and the warping humidity is 65%. Set process parameters;

[0054] (2) Select knitting equipment: single-needle bed Raschel warp knitting machine, the machine size is 28 needles / 25.4mm, the machine width is 130", the number of bars is 3bars, and the machine speed is 1600r / min;

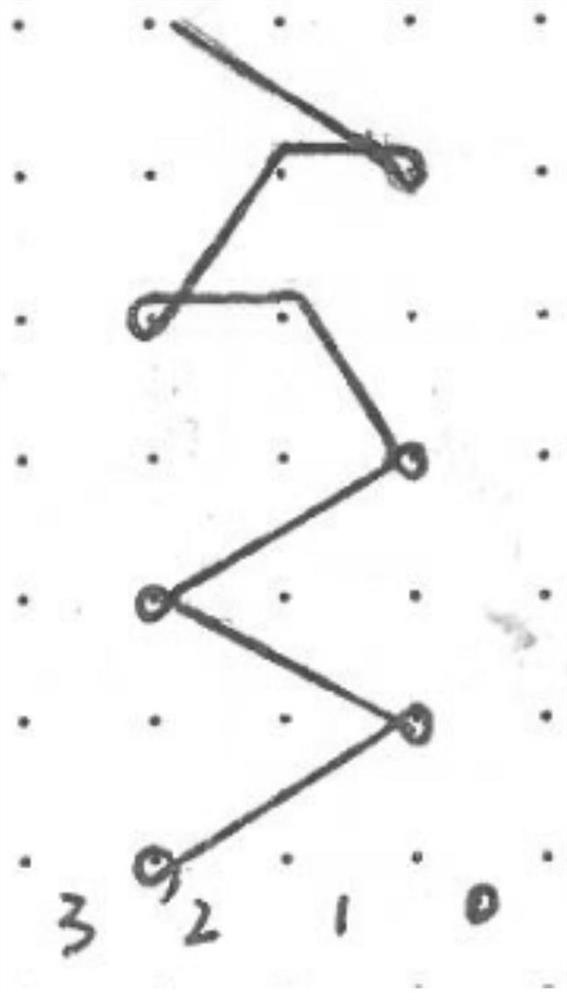

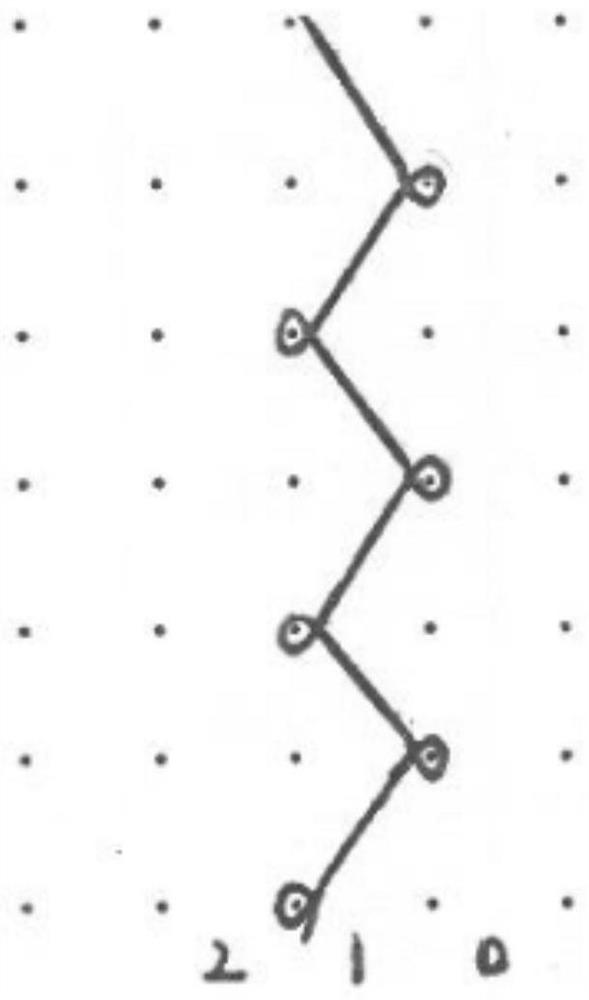

[0055] (3) Select yarn and weave: the yarn of GB1 is 40D / 34F Nylon6 matte straight yarn, and the lapping number is 23 / 10 / 23 / 10 / 13 / 20 / 13 / 20 / / , each disc The number of threaded yarns at the head is 187, the threading method is 2 threads and 4 empty, and the number of pan heads is 6; the yarn of GB2 is 20D / 6F Nylon6 semi-gloss straight yarn, and the lapping number is 12 / 10 / / , t...

Embodiment 2

[0061] This embodiment provides a warp-knitted wrinkled vertical strip fabric, which is prepared by the following preparation method:

[0062] (1) Warping: GB1&GB2 warping adopts negative yarn feeding, GB3 warping adopts positive yarn feeding;

[0063] The warping machine is imported from Germany by Karl Mayer. The warping temperature is 25°C and the warping humidity is 65%. The process parameters are set under this temperature and humidity condition;

[0064] (2) Select knitting equipment: single-needle bed Raschel warp knitting machine, the machine size is 28 needles / 25.4mm, the machine width is 130", the number of bars is 3bars, and the machine speed is 1600r / min;

[0065] (3) Select yarn and weave: the yarn of GB1 is 40D / 34F Nylon6 matte straight yarn, and the lapping number is 23 / 10 / 23 / 10 / 13 / 20 / 13 / 20 / / , each disc The number of threaded yarns at the head is 280, the threading method is 4 threads and 4 empty, and the number of pan heads is 6; the yarn of GB2 is 20D / 6F Nylo...

Embodiment 3

[0071] This embodiment provides a warp-knitted wrinkled vertical strip fabric, which is prepared by the following preparation method:

[0072] (1) Warping: GB1&GB2 warping adopts negative yarn feeding, GB3 warping adopts positive yarn feeding; the warping machine is imported from KarlMayer Germany, the warping temperature is 25°C, and the warping humidity is 65%. Set process parameters;

[0073] (2) Select knitting equipment: single-needle bed Raschel warp knitting machine, the machine size is 28 needles / 25.4mm, the machine width is 130", the number of bars is 3bars, and the machine speed is 1600r / min;

[0074] (3) Select yarn and weave: the yarn of GB1 is 40D / 48F PET semi-gloss straight yarn, and the number of lap yarn is 23 / 10 / 23 / 10 / 13 / 20 / 13 / 20 / / , each disc The number of threaded yarns at the head is 280, the yarn threading method is 4 threads and 4 empty, and the number of pan heads is 6; the yarn of GB2 is 30D / 12F PET semi-gloss straight yarn, and the lapping number is 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com