Velvet fabric with strong ventilation and sweat-permeation capability

A velvet and velvet cloth technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problems of difficult processing, easy to be stretched, uneven tension in the warp and weft directions, and achieve uniform ductility, strong ventilation and perspiration, Even tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

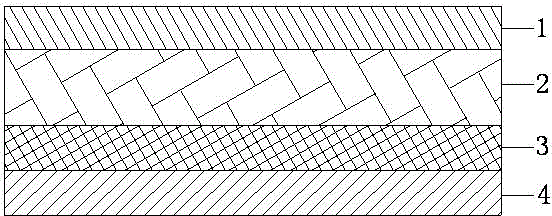

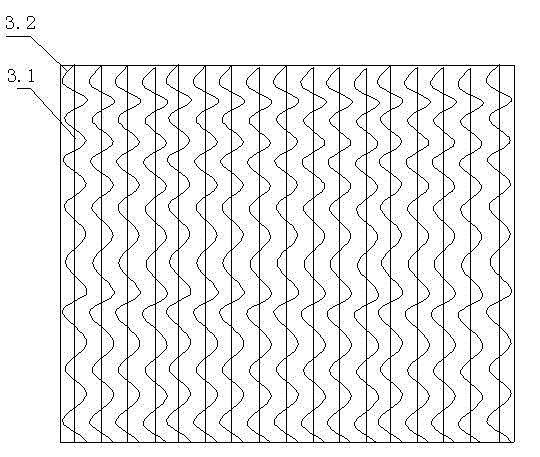

[0017] see figure 1 and figure 2 , the present invention relates to a breathable and sweat-wicking strong velvet fabric, which comprises a velvet cloth 1, a sponge layer 2 is arranged under the velvet cloth 1, an antistatic layer 3 is arranged under the sponge layer 2, and the antistatic layer 3 is wrapped by a Made of core fiber, the fiber includes yarn 3.1 and metal wire 3.2, the metal wire 3.2 is wound on the yarn 3.1, and the yarn 3.1 and metal wire 3.2 make the fabric have special rigidity and bending Variable, shining metallic luster, delicate hand feeling, anti-static and anti-radiation effects, a base layer 4 is provided under the anti-static layer 3, and the adjacent two layers of the velvet cloth 1, the sponge layer 2 and the base layer 4 are evenly spaced. Bonded by glue.

[0018] Because the uppermost layer is velvet cloth, its surface color is elegant, rich and luxurious, firm and wear-resistant. At the same time, because the middle layer and the lowermost laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com