Continuous glass fiber stitchbonded felt production device and production method

A technology of glass fiber and production equipment, which is applied in warp knitting, flat warp knitting machines, textiles and papermaking, etc. It can solve the problems of short-slit stitched mats that cannot meet the requirements, low strength of glass fiber reinforced plastic products, and high price of continuous glass fiber mats. problem, to achieve the effect of considerable product profit, low production cost and high production stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

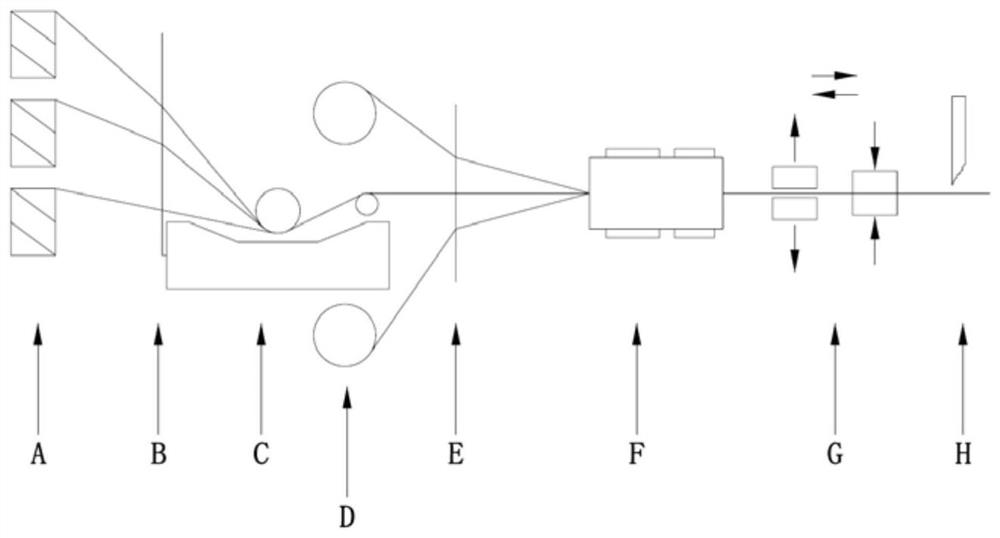

[0073] Such as Figure 4 As shown, the continuous glass fiber stitched mat production device includes a creel 1, a creel 1, a yarn dividing device 2 and a spinning head 3 connected in sequence, and a conveyor belt 4 is arranged under the spinning head 3, and one end of the conveyor belt 4 Yarn pressing device 5 is arranged above, conveying belt 4, transition plate 6, sewing head 7, pulling roller 8 are connected with coiler 9 in sequence, and sewing head 7 is connected with sewing thread pan head 10.

[0074] The number of creels 1 is four.

[0075] Two creels 1 form a creel group, and the two creel groups are respectively arranged on both sides of the conveying belt 4 .

[0076] The number of yarn splitting devices 2 is four.

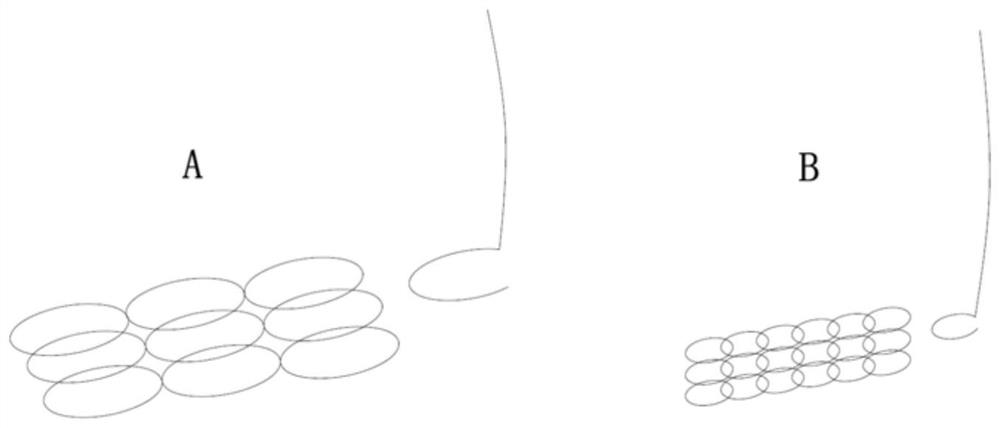

[0077] Such as Figure 5 As shown, the yarn splitting device 2 is composed of a yarn guide plate 12, a lateral moving device 13 and a power device 14, and the yarn guide plate 12, the lateral moving device 13 and the power device 14 are connected in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com