Circular cockled steamed stuffed bun processing machine

A wrinkled bun and round technology, applied in the field of food machinery, can solve the problems of low production efficiency, uneven size, poor hygiene indicators, etc., and achieve the effects of high production efficiency, uniform weight and beautiful shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

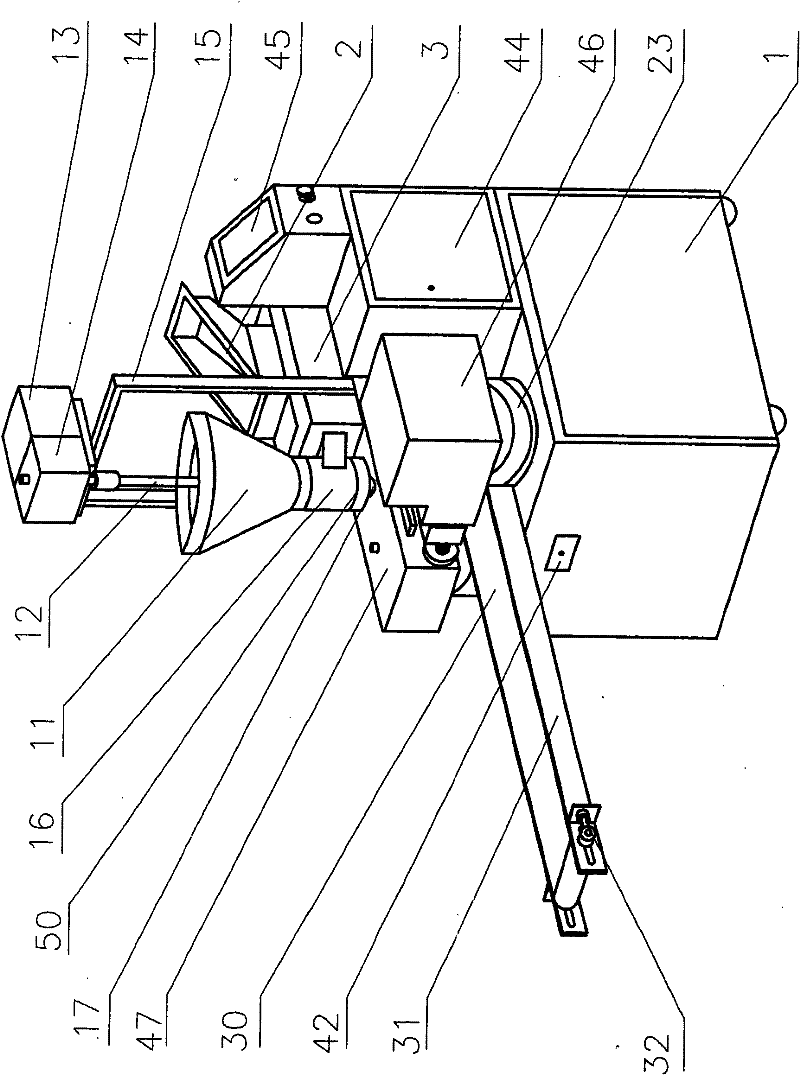

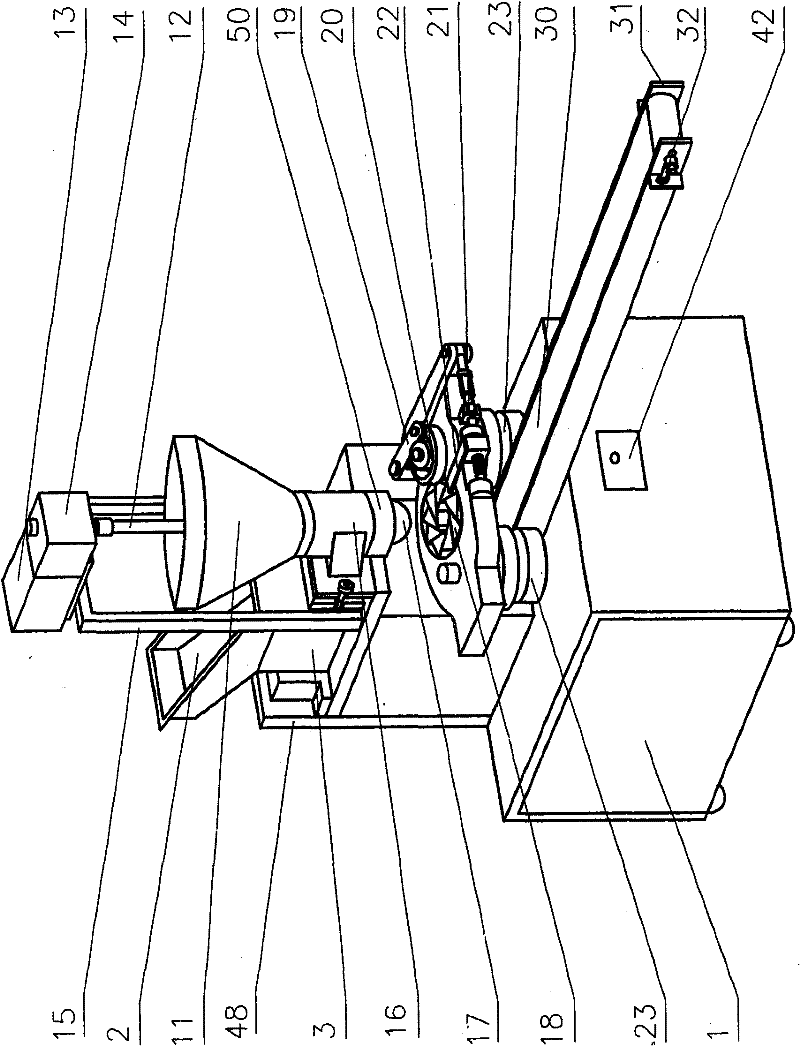

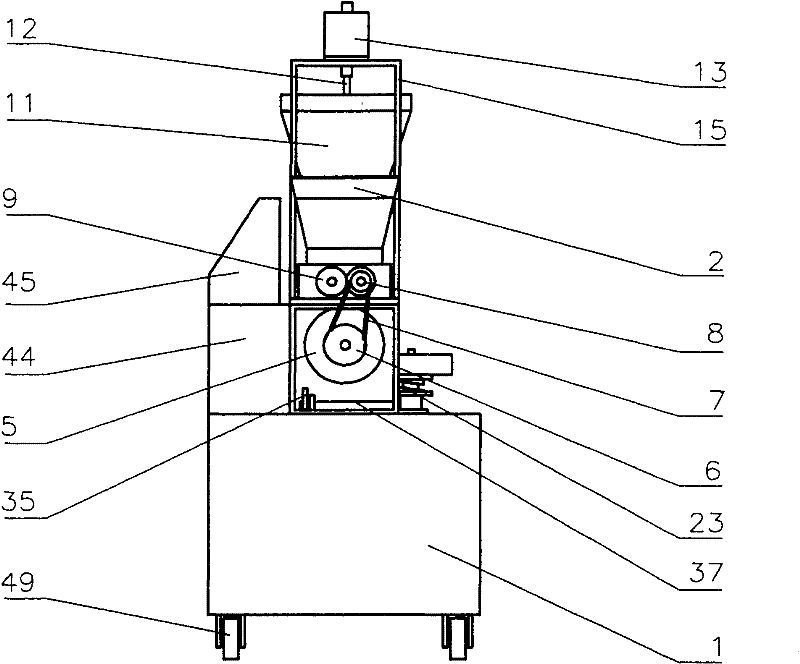

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 Shown, 1 among the figure is a frame, is fixed with extruding face square box 3 above frame 1, is fixed machine head 16 at the side of extruding face square box 3, is provided with empty hole in the center of machine head 16, and this hole One side of one side communicates with the square box 3 for extruding noodles, and the lower end of the hole communicates with the filling mouth 17; a support flower plate 4 is fixed in the square box 3 for extruding noodles, and the extruding screw 10 is installed on the supporting flower plate 4, and the extruding screw 10 is installed on the supporting flower plate 4. 10 is a pair of symmetrical spirals, gear 9 is fixed on the face extruding screw 10 in the face extruding square box 3; sprocket wheel 8 is fixed on the outer end of extruding face screw 10; Be fixed with motor 5 between square box 3, be fixed with sprocket wheel 6 on the rotating shaft o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com