Preparation method of lead-based halogen perovskite film for high-energy ray detection

A high-energy ray and lead-based halogen technology, which is applied in sputtering coating, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem that the perovskite thick film has not achieved good success, crystals cannot grow in a large area, Perovskite thick film phase impurity and other problems, to achieve the effect of promoting purification and optimization of crystallinity, good uniformity, and large grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the inorganic perovskite thick film that is applicable to X-ray detection among the present invention, generally speaking its steps are as follows:

[0043] (1) using a method for preparing perovskite powder to prepare a large amount of pure-phase perovskite powder raw material;

[0044] (2) Take a certain mass of pure-phase perovskite powder, add a certain mass ratio of a certain component raw material powder therein, fully mix it uniformly, and use it as a gas phase source;

[0045] (3) pretreating the conductive substrate;

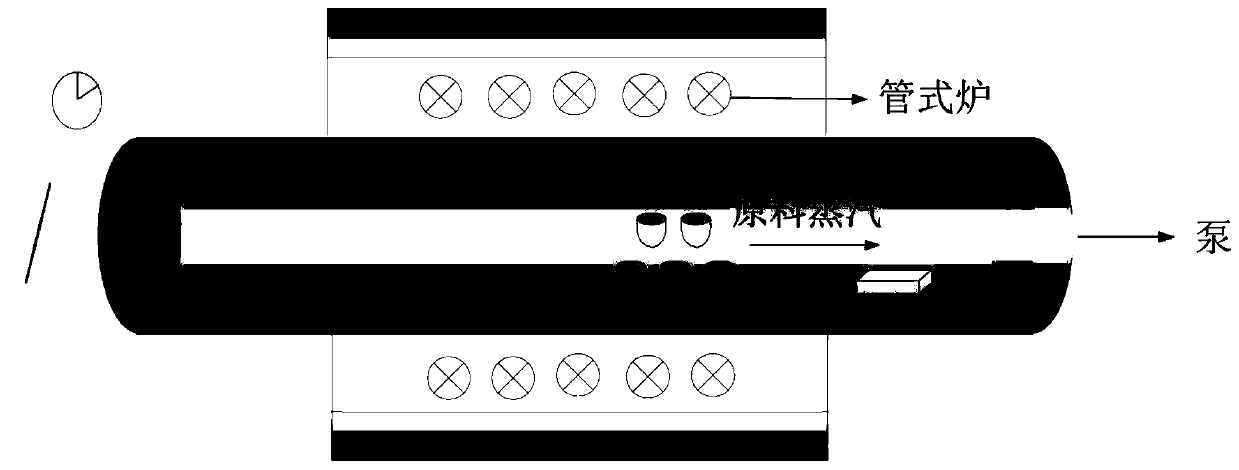

[0046] (4) Evenly distribute the uniformly mixed gas-phase source powder into several identical high-temperature-resistant quartz crucibles, place them in the high-temperature zone of the high-temperature-resistant quartz tube, and perform thermal evaporation; place the pretreated conductive substrate in the quartz tube The low temperature zone of the low temperature zone is used as the substrate for deposition, and the...

Embodiment example 1

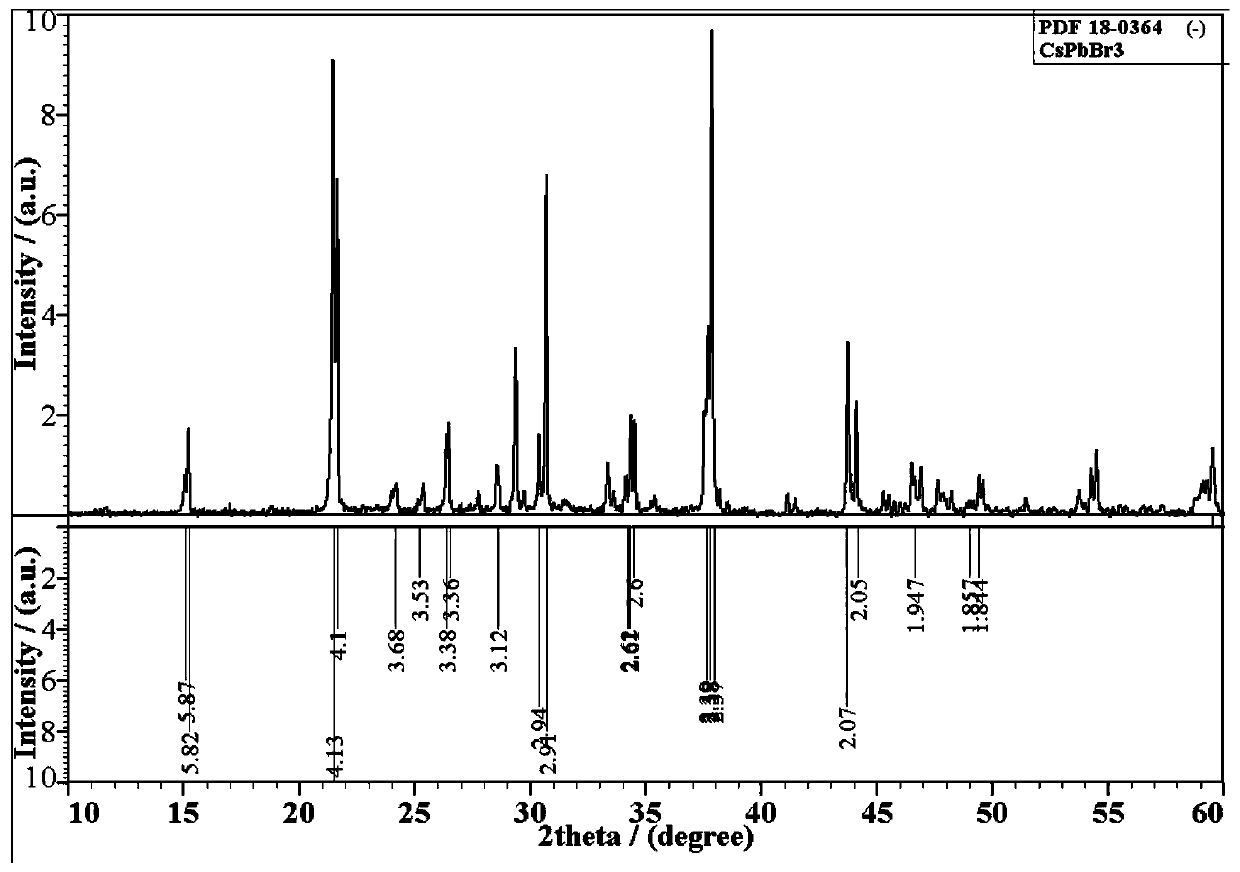

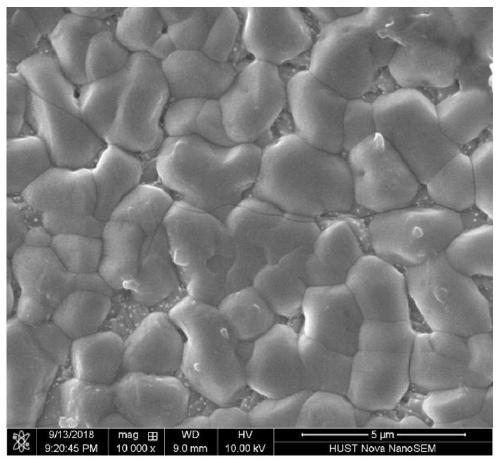

[0051] In this example, CsPbBr 3 As a raw material, under optimal conditions, CsPbBr with a thickness of 10 μm was prepared by the following steps 3 Perovskite film:

[0052] (1) Prepare a large amount of CsPbBr 3 powder;

[0053] According to CsPbBr 3 The chemical composition, identified as CsPbBr 3 The component raw material is 1:1 PbBr 2 and CsBr. First weigh out PbBr with a molar ratio of 1:1 2 and CsBr powder, put them in the same mortar, mix and grind them; then pour the mixed powder into a high-temperature resistant quartz crucible, add a quartz cover (to prevent the component raw materials from being vaporized and escaped at high temperature), and place them into a small muffle In the furnace, seal it; raise the temperature of the muffle furnace to 350 ° C, and perform high-temperature sintering reaction on the powder; after 30 minutes, take out the crucible, pour the agglomerates in the crucible into the mortar, and after grinding again, pour the powder back in...

Embodiment example 2

[0063] This embodiment prepares CsPbBr with a thickness of 50 μm by the same method as in Example 1. 3 Thick film, the difference is:

[0064] Weigh out the pure phase CsPbBr of 10g in step (3) 3 powder and 0.5g of PbBr 2 Powder (mass ratio is 5%), it is mixed evenly.

[0065] In step (4), uniformly mixed raw material powders are evenly placed in 5 small quartz crucibles. After the constant temperature reaction time is extended to 40 minutes, the heating of the tube furnace is turned off, and after natural cooling, a CsPbBr with a thickness of about 50 μm is obtained. 3 thick film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com