Trifluoroethylene recovery method and device thereof

A technology of trifluoroethylene and recovery method, applied in chemical instruments and methods, halogenated hydrocarbon preparation, organic chemistry, etc., can solve the problems of huge investment in catalysts and equipment and high price of trifluoroethylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

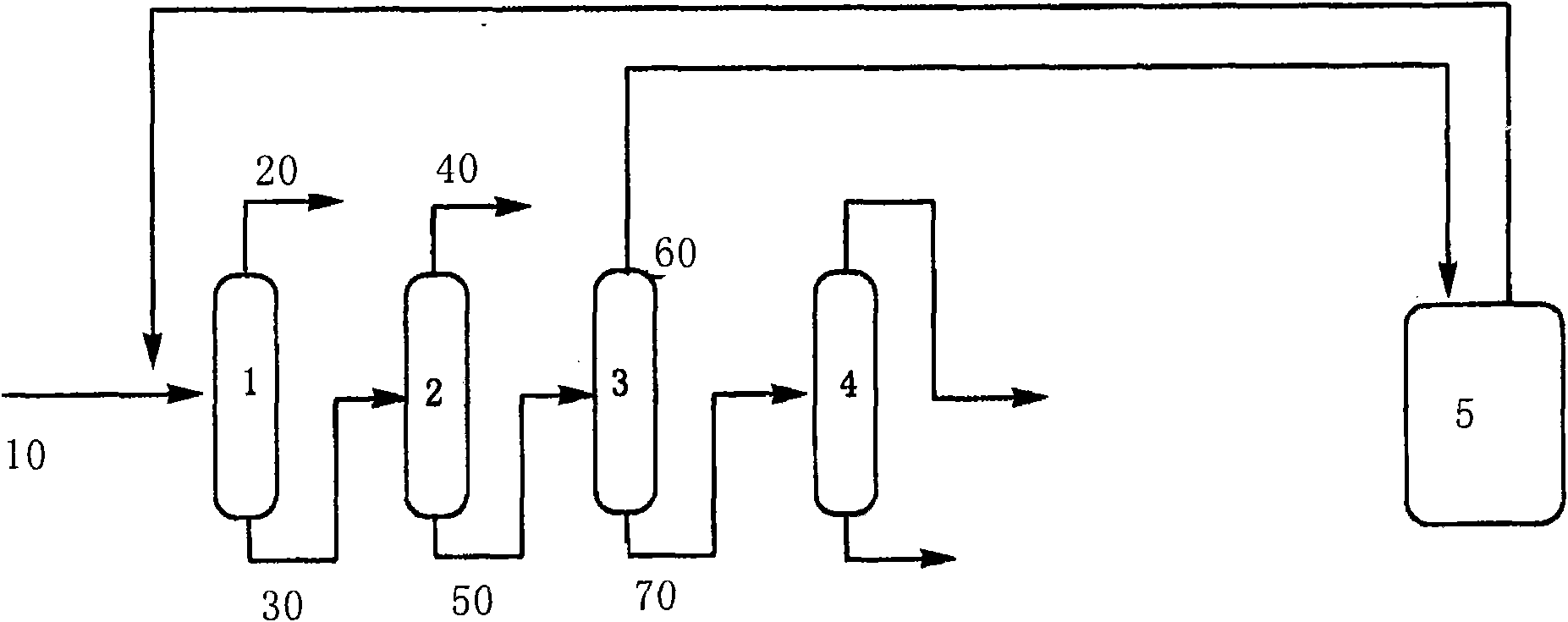

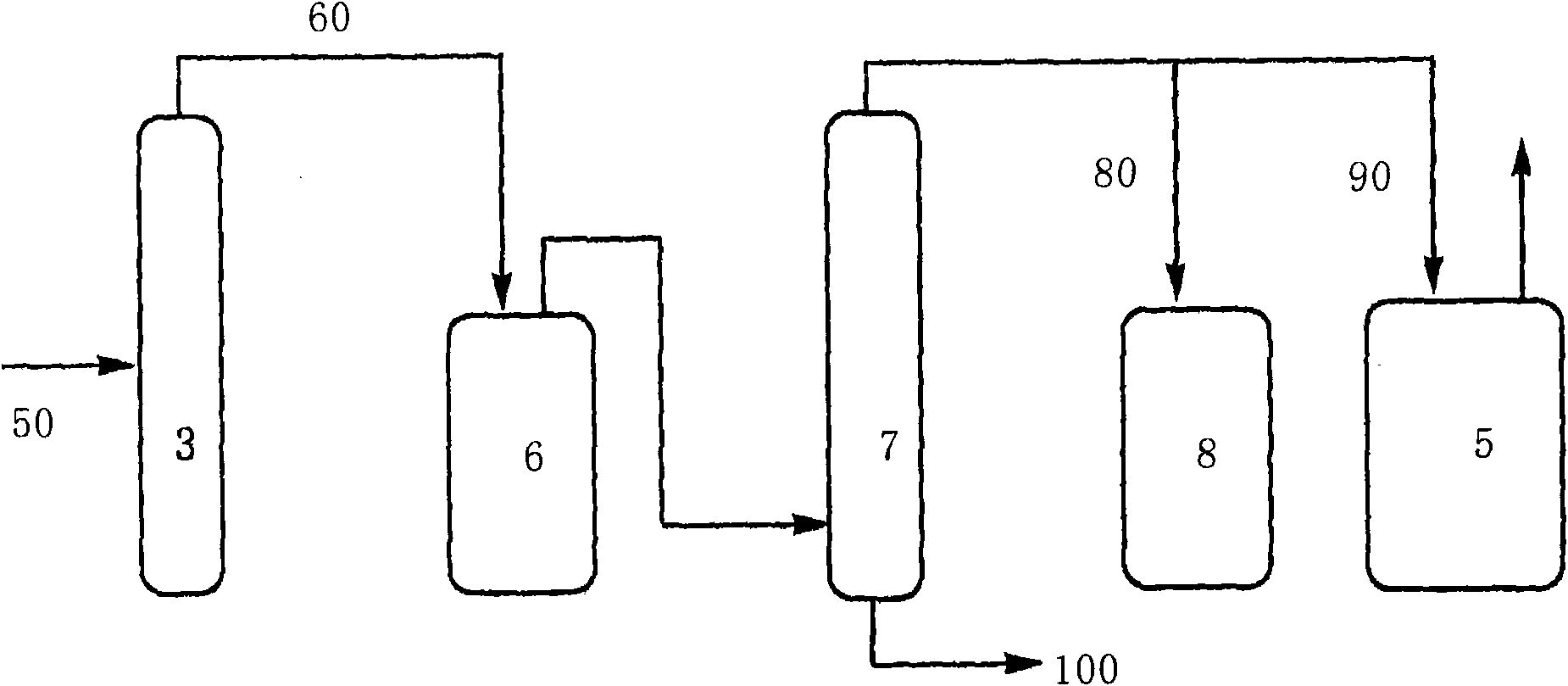

Method used

Image

Examples

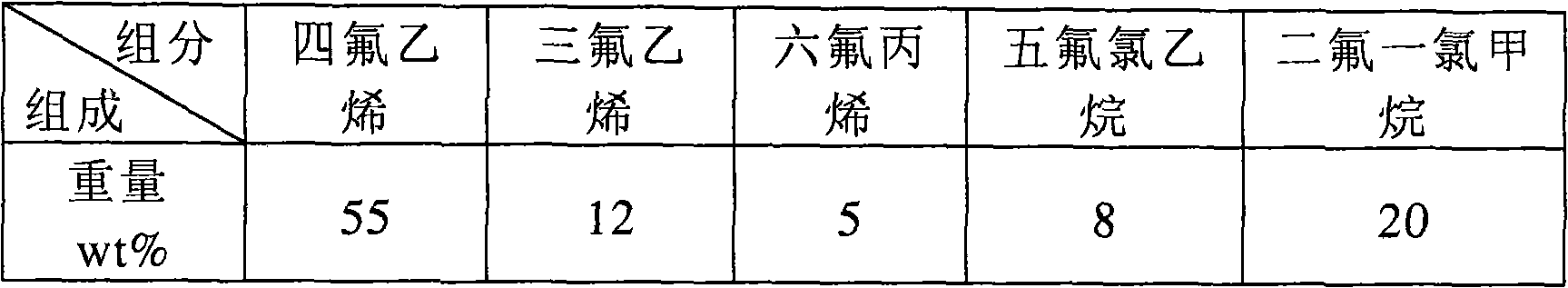

Embodiment 1

[0057] Use a batch type rectification tower to separate tetrafluoroethylene and recover the top material. The composition is shown in Table 2. The inner diameter of the rectification tower is φ53mm, with 3mm×3mm stainless steel calendered ring packing inside, the packing height is 6000mm, and the tower kettle is 60L. Add raw material 45Kg in tower kettle. Control the temperature of the tower kettle at -2~0°C, the temperature at the top of the tower at -24~-26°C, and the operating pressure of the tower at 0.78MPa. When the content of tetrafluoroethylene in the gas phase at the top of the tower is 100 wt%, the reflux ratio is controlled to be 10-12:1, and the gas phase at the top of the tower is used to recover the tetrafluoroethylene to the low-pressure system. Analyze the composition of the gas phase at the top of the tower every 0.5h. After 16h, the content of trifluoroethylene in the top of the tower is greater than 1wt%. The rectification enters the transition section, and...

Embodiment 2

[0059] The tower equipment used in this embodiment is the same as that in Embodiment 1, and the raw material composition is shown in Table 2. Add raw material 45Kg in tower kettle. Control the temperature of the tower kettle at -2~0°C, the temperature of the tower top at -24~-26°C, and the operating pressure of the tower at 0.75MPa. When the content of tetrafluoroethylene in the gas phase at the top of the tower is 100 wt%, the reflux ratio is controlled to be 10-12:1, and the gas phase at the top of the tower is used to recover the tetrafluoroethylene to the low-pressure system. The composition of the gas phase at the top of the tower is analyzed every 0.5 hours. After 9 hours, the content of trifluoroethylene at the top of the tower is greater than 1wt%. The rectification enters the transition section, and the alternate operation of total reflux and partial reflux is adopted, that is, after 1 hour of total reflux, the extraction is 0.5h Frequency operation, control reflux r...

Embodiment 3

[0061]The tower equipment used in this embodiment is the same as that in Embodiment 1, and the raw material composition is shown in Table 2. Add raw material 50Kg in tower kettle. Control the temperature of the tower kettle at -2~0°C, the temperature of the tower top at -24~-26°C, and the operating pressure of the tower at 0.76MPa. When the content of tetrafluoroethylene in the gas phase at the top of the tower is 100 wt%, the reflux ratio is controlled to be 10-12:1, and the gas phase at the top of the tower is used to recover the tetrafluoroethylene to the low-pressure system. The composition of the gas phase at the top of the tower is analyzed every 0.5 hours. After 14 hours, the content of trifluoroethylene in the top of the tower is greater than 1wt%. The rectification enters the transition section, and the alternate operation of total reflux and partial reflux is adopted, that is, after 1 hour of total reflux, the extraction is 0.5h Frequency operation, control the refl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com