Catalyst, preparation method thereof and application thereof

A catalyst and co-catalyst technology, applied in the direction of dehydrohalogenation preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficult regeneration and short service life of catalysts, and achieve extended service life, high selectivity, The effect of high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

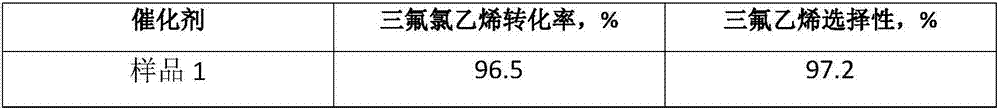

[0031] Embodiment 1 (sample 1)

[0032] Weigh 200g of strip-shaped aluminum fluoride, add 10% nitric acid solution, boil and reflux for 6h, filter and wash with deionized water until pH = 7, dry at 80°C for 12h, and set aside;

[0033] Weigh 1.68g PdCl 2 Dissolve it with concentrated hydrochloric acid, add 100 g of deionized water and stir until the solution is clear to obtain the impregnation solution A. Weigh 1.17g Bi(NO 3 ). 5H 2 Dissolve O in 100 g of deionized water and stir until the solution is clear to obtain impregnation solution B. Mix the impregnating solution A and the impregnating solution B, add the pretreated strip-shaped aluminum fluoride and let it stand for 12 hours. After the impregnated catalyst was filtered, it was dried at 80°C for 24 hours, and then used.

Embodiment 2

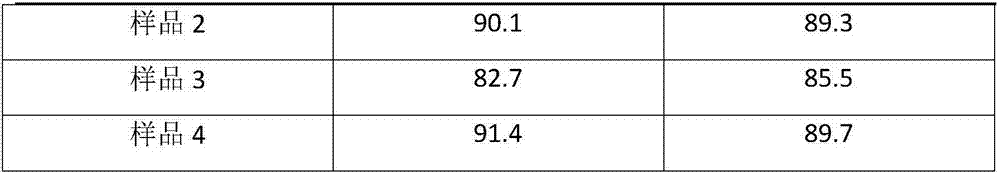

[0034] Embodiment 2 (sample 2)

[0035] Weigh 200g of strip-shaped magnesium fluoride, add 10% nitric acid solution, boil and reflux for 12h, filter, wash with deionized water until pH = 7, dry at 80°C for 12h, and set aside;

[0036] Weigh 3.38g PdCl 2 Dissolve it with concentrated hydrochloric acid, add 100 g of deionized water and stir until the solution is clear to obtain the impregnation solution A. Weigh 5.03g Ni(NO 3 ). 6H 2 Dissolve O in 100 g of deionized water and stir until the solution is clear to obtain impregnation solution B. Mix the impregnating solution A and the impregnating solution B, add the pretreated strip-shaped magnesium fluoride and let stand for immersion for 12 hours. After the impregnated catalyst was filtered, it was dried at 80°C for 24 hours, and then used.

Embodiment 3

[0037] Embodiment 3 (sample 3)

[0038] Weigh 200g of strip-shaped calcium fluoride, add 5% nitric acid solution, boil and reflux for 18h, filter, wash with deionized water until pH=7, dry at 80°C for 24h, and set aside;

[0039] Weigh 10.36g PdCl 2 Dissolve it with concentrated hydrochloric acid, add 100 g of deionized water and stir until the solution is clear to obtain the impregnation solution A. Weigh 3.21g VCl 3Dissolve in 100 g of deionized water, stir until the solution is clear, and obtain impregnation solution B. Mix the impregnating solution A and the impregnating solution B, add the pretreated bar-shaped calcium fluoride and let stand for immersion for 24 hours. After the impregnated catalyst was filtered, it was dried at 80°C for 24 hours, and then used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com